Hello Simon7000 and All,

This is what I came up with to minimize environmental noise, I am sure that there are improvements that can be made.

XLR cable cut in half with Muller mini alligator clips soldered on the bare wire ends of each half a cable.

Soldered the test leads to the test bridge, this is slower than the mini alligator clips and only a tiny improvement over the clips.

Shorten the resistor lead lengths.

Both generator output and analyzer input are balanced.

This one I just stumbled on.

My test setup is on the carpeted concrete floor in the center of the room. The test leads lay flat on the carpeted concrete floor. The test bridge sits on a couple of bamboo chop sticks cut to about 3 inches long. Then a Hubble SC080804 junction box (shield ) is placed open side down over the test bridge. There is no ground attached to the junction box. This provides effective isolation from the noisy mains in the wall, lights and other stuff. Turning on the overhead LED lights on a dimmer does not seem to make a difference.

Thanks DT

This is what I came up with to minimize environmental noise, I am sure that there are improvements that can be made.

XLR cable cut in half with Muller mini alligator clips soldered on the bare wire ends of each half a cable.

Soldered the test leads to the test bridge, this is slower than the mini alligator clips and only a tiny improvement over the clips.

Shorten the resistor lead lengths.

Both generator output and analyzer input are balanced.

This one I just stumbled on.

My test setup is on the carpeted concrete floor in the center of the room. The test leads lay flat on the carpeted concrete floor. The test bridge sits on a couple of bamboo chop sticks cut to about 3 inches long. Then a Hubble SC080804 junction box (shield ) is placed open side down over the test bridge. There is no ground attached to the junction box. This provides effective isolation from the noisy mains in the wall, lights and other stuff. Turning on the overhead LED lights on a dimmer does not seem to make a difference.

Thanks DT

Marcel, your ignore list is your friend ;-)

Jan

I didn't even know that was an option. Jan, you are a scholar and a gentleman.

frequency response of the resistor

One nonlinear effect of any resistor is caused by the skin effect of any conductor. Resistors are made of conductor with a certain resistance. At high frequency, current tends to flow on the surface of the conductor, which reduces the effective cross section area of the conductor, hence increases the effective resistance of the resistor. In this sense, the resistance of any resistor is frequency dependent. I assume the instantaneous signal you mentioned include a high frequency component, at which the resistance should be higher than the DC resistance value shown in the resistor datasheet.

I know that resistors exhibit resistance variations with temperature (temperature coefficient), and with voltage across them (voltage coefficient). These change with signal levels, causing the resistor to change value with instantaneous signal level, giving rise to signal distortion. All well documented and quantified.

But are these the only sources of resistor non-linearity? (I consider noise as a separate phenomenon so exclude it here).

Jan

One nonlinear effect of any resistor is caused by the skin effect of any conductor. Resistors are made of conductor with a certain resistance. At high frequency, current tends to flow on the surface of the conductor, which reduces the effective cross section area of the conductor, hence increases the effective resistance of the resistor. In this sense, the resistance of any resistor is frequency dependent. I assume the instantaneous signal you mentioned include a high frequency component, at which the resistance should be higher than the DC resistance value shown in the resistor datasheet.

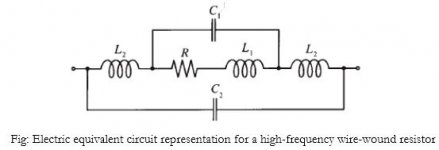

I did measurements of frequency dependance of impedance of various resistors. Because of stray capacitance, impedance usually decreases above 20kHz. This is valid even for MF resistors dedicated for high frequency applications (I mean here russian S2-10 resistors).

Attachments

One nonlinear effect of any resistor is caused by the skin effect of any conductor.

Aren't you mixing up frequency dependent and nonlinear?

Unless I'm missing something, with or without skin effect, when you increase the current by a factor of two, the current density in each part of the resistor increases by a factor of two, and when you apply the sum of two signal currents to the resistor, the current density in each part of the resistor is just the sum of the current densities caused by each signal current. That is, superposition applies in a resistor with skin effect, so it is linear.

But skin-effect is not a non-linear function.One nonlinear effect of any resistor is caused by the skin effect of any conductor.

Skin effect is not completely ignorable at audio frequencies, in fact, as its ~0.5mm for copper at 20kHz, which will impact high current wiring to loudspeakers especially for long runs where the wires have to be thicker - but usually you can ignore it.

The other area where skin-effect does matter for audio is that it controls the screening performance of metal enclosures - at mains frequencies the skin depth of copper or aluminium is large (~1cm) meaning mains-derived magnetic fields will penetrate these materials significantly, compared to magnetic metals like steel (more like 0.3mm skin depth).

Thus 2mm of steel should perform better than 1cm of copper for screening a transformer.

The other area where skin-effect does matter for audio is that it controls the screening performance of metal enclosures - at mains frequencies the skin depth of copper or aluminium is large (~1cm) meaning mains-derived magnetic fields will penetrate these materials significantly, compared to magnetic metals like steel (more like 0.3mm skin depth).

Thus 2mm of steel should perform better than 1cm of copper for screening a transformer.

Fascinating thread, many thanks for posting for the community!

Has anyone tested the large TKD CM2 2W Metal films? While 100ppm Id assume their very large body and thick lead may assist with heat and linearity.

This post has picture of relative sizes; https://www.lencoheaven.net/forum/index.php?topic=20984.1365

They are much bigger than Vishay CMF 3W, or RN65 or 70 and thicker leads at 1.0mm

Has anyone tested the large TKD CM2 2W Metal films? While 100ppm Id assume their very large body and thick lead may assist with heat and linearity.

This post has picture of relative sizes; https://www.lencoheaven.net/forum/index.php?topic=20984.1365

They are much bigger than Vishay CMF 3W, or RN65 or 70 and thicker leads at 1.0mm

That's not non-linear. Its just a frequency response curve. Non linear means the output doesn't scale linearly with the input level for a given input signal, not that the frequency response is flat.One nonlinear effect of any resistor is caused by the skin effect of any conductor. Resistors are made of conductor with a certain resistance. At high frequency, current tends to flow on the surface of the conductor, which reduces the effective cross section area of the conductor, hence increases the effective resistance of the resistor.

Being 100ppm makes them much less linear than the others you quoted. The RN65's can be had with 5ppm tempco.Fascinating thread, many thanks for posting for the community!

Has anyone tested the large TKD CM2 2W Metal films? While 100ppm Id assume their very large body and thick lead may assist with heat and linearity.

This post has picture of relative sizes; https://www.lencoheaven.net/forum/index.php?topic=20984.1365

They are much bigger than Vishay CMF 3W, or RN65 or 70 and thicker leads at 1.0mm

Jan

Sort of, but skin effect does actually start to show in the audio range, but only for fat wires. Skin effect limits mains busbars to an inch or so across, as the skin depth in copper at 50/60Hz is about 8mm, at 10kHz its about 1mm, so audio signal wires are not really affected, but speaker wires often are, but not grossly - you can choose litz wire for biamped tweeters if you really worry about this, but its not really warranted.Skin-effect is a VHF and higher kind of thing.

Once up at VHF (100MHz for example), skin effect is huge, depth only 10µm for copper for instance, so current only travels on the surface layer of any practical wiring, which is why waveguides are often used for high power (much more surface area, much lower losses).

Yes. I have sag in the power line from the street to my house. Lights dim when the pump starts. I can see the line is "long", but is it right? I started calculating. Simple resistance (about 0.33r per side) accounts for most of it. Inductance at 60Hz gets me within 10% of observation (so nothing is actually wrong, it's just a long line). Figuring skin effect gets me within 5% of observed drop. Uncertainty in actual length, pole-transformer sag (these are standardized but not with precision) suggests the wire is working as expected, no phantom loss or grossly bad contact. But I did have to allow for skin-effect to feel satisfied there was no unaccounted loss.skin effect does actually start to show in the audio range, but only for fat wires. Skin effect limits mains busbars to an inch or so across

The conductors are almost 1/4" diameter, smaller but in-sight-of your benchmarks.

Being 100ppm makes them much less linear than the others you quoted. The RN65's can be had with 5ppm tempco.

Jan

Hello All,

Sometimes you need to look a little bit deeper into the model to find what you are looking for.

See the link to the Vishay data sheet for RN and or CMF metal film resistors.

You will see that these resistors have a voltage coefficient of (5 ppm/V) and that the nominal thermal coefficient can be as low as 25ppm/degree C.

Take a look at the data sheet, the nominal thermal coefficient varies depending on the CHARACTERISTIC (D 100 ppm, C 50 ppm or E 25ppm ).

A Vishay RN60D resistor has a thermal coefficient of between -100 ppm and +100 ppm. It is not a fixed or constant coefficient. There is a temperature range where thermal coefficient is near zero.

So yes a larger RN65D resistor will have less thermally caused distortion than a RN55D for an equal applied signal. This is for two reasons; there is a smaller temperature swing (delta T times ppm := distortion) and also because of the smaller delta T, the thermal coefficient ppm will be less than the nominal + -100ppm at the maximum thermal rating of the resistor.

https://www.mouser.com/datasheet/2/427/cmfmil-1762972.pdf

Thanks DT

Are you sure about that? The tempco is likely non-linear, but in which way? Concave, convex, parabolic, higher order?and also because of the smaller delta T, the thermal coefficient ppm will be less than the nominal + -100ppm at the maximum thermal rating of the resistor.

Are you sure about that? The tempco is likely non-linear, but in which way? Concave, convex, parabolic, higher order?

Elvee,

If I were to call the temco cure a name I would call it a soup spoon shape.

https://eepower.com/resistor-guide/resistor-fundamentals/temperature-coefficient-of-resistance/# Take a look see.

Thanks DT

Many thanks for the replies!

I would have thought the CM2 with approximately 2.14x the surface area, 3.74x the volume, and larger diameter leads than the RN65, would have closed the gap even to the 25ppm TCR RN65, through less delta T. Am I thinking correctly?

Shame the 100ppm version of the CM2 appears the commonly stocked one at sites I've checked, not the 50ppm version.

I would have thought the CM2 with approximately 2.14x the surface area, 3.74x the volume, and larger diameter leads than the RN65, would have closed the gap even to the 25ppm TCR RN65, through less delta T. Am I thinking correctly?

Shame the 100ppm version of the CM2 appears the commonly stocked one at sites I've checked, not the 50ppm version.

Many thanks for the replies!

I would have thought the CM2 with approximately 2.14x the surface area, 3.74x the volume, and larger diameter leads than the RN65, would have closed the gap even to the 25ppm TCR RN65, through less delta T. Am I thinking correctly?

Shame the 100ppm version of the CM2 appears the commonly stocked one at sites I've checked, not the 50ppm version.

Hello,

Your thinking is right on target.

If you dig a little deeper into the details you will find that specification MIL-STD-202 Method 304 is used to measure and calculate the TCR printed on the resistor data sheets. Method 304 uses DC procedures which complicates things when we measure and discuss distortion in AC audio frequencies.

An example:

Using DC test methods Z Foil resistors have very low TCR yet when it comes to AC distortion Z Foil resistors test only marginally better than carbon compound resistors. Z Foil resistors have low mass and have wide temperature swings with an applied AC signal.

Resistor distortion is frequency dependent, the higher the frequency the lower the distortion.

Thanks DT

- Home

- Design & Build

- Parts

- What causes resistor distortion?