Roederstein 'BAKELITE' series EK capacitors - "Living Legend" OR "Looney Legacy" ...?

Hi cap cruncher's !

Just wondered if anyone has ANYTHING at all, to say about these ?

I searched around a bit on the wonderfull WWW...

...but turned up...not much.

I believe they were used in Quad 22's for example...

...and I think Naim Audio used them for sensitive de-coupling duties.

Very old Bakelite has somewhat of a reputation for simply disintegrating & falling apart.

At best not much long term ( we are talking DECADES here ! ) dimensional stability.

However, I believe later, perhaps slightly post WWII Bakelite, was a bit improved.

It seems that the Roederstein EK series, was produced long AFTER other plastics & materials as alternatives, were available.

Also, why not just bung the cap in a 'tin can' like everybody else ?

It's seems to be an early version of the now common 'audio electrolytic'...

...obviously sonic issues addressed in the design ?

Is it 'low impedance' ? ( haven't got a clue ).

Does it 'sound good' ? ( dunno mate ).

Did you pull 'em out of your Naim gear, & reach Nirvana ?

Did you pull 'em out of your Quad gear, & wish you never had ?

Anyone using 'em for phono-pre's ?

Anyone think they're only fit for the dustbin...

...or have their stash in a bank vault ?

Love to know any members loves, hates, anecdotes etc...

..." Tales Of The Legendary ROE Cap"

Cheers.

Si.

PS...if you tap 'em with something, they seem VERY non resonant, compared to say, Nichicon MUSE...

...pretty scientific, huh ?

Hi cap cruncher's !

Just wondered if anyone has ANYTHING at all, to say about these ?

I searched around a bit on the wonderfull WWW...

...but turned up...not much.

I believe they were used in Quad 22's for example...

...and I think Naim Audio used them for sensitive de-coupling duties.

Very old Bakelite has somewhat of a reputation for simply disintegrating & falling apart.

At best not much long term ( we are talking DECADES here ! ) dimensional stability.

However, I believe later, perhaps slightly post WWII Bakelite, was a bit improved.

It seems that the Roederstein EK series, was produced long AFTER other plastics & materials as alternatives, were available.

Also, why not just bung the cap in a 'tin can' like everybody else ?

It's seems to be an early version of the now common 'audio electrolytic'...

...obviously sonic issues addressed in the design ?

Is it 'low impedance' ? ( haven't got a clue ).

Does it 'sound good' ? ( dunno mate ).

Did you pull 'em out of your Naim gear, & reach Nirvana ?

Did you pull 'em out of your Quad gear, & wish you never had ?

Anyone using 'em for phono-pre's ?

Anyone think they're only fit for the dustbin...

...or have their stash in a bank vault ?

Love to know any members loves, hates, anecdotes etc...

..." Tales Of The Legendary ROE Cap"

Cheers.

Si.

PS...if you tap 'em with something, they seem VERY non resonant, compared to say, Nichicon MUSE...

...pretty scientific, huh ?

Attachments

I have tested them, along with many other types, old and young.

I am unable to find the thread, I don't even know if I posted the results on DIYaudio.

Anyway, I remember they were excellent, capable of competing with more modern types on all aspects, except the size/capacitance ratio.

Other than that, they are of exceptional quality, and also remarkably durable since the samples I had were at the very least 25 years old, some much older than that.

Siemens also made very comparable caps, both in construction and quality.

They also had an identical form factor (probably resulting from some old DIN standard).

The only difference was the color: bright orange instead of dull brick. But the quality was very comparable. It was the GSF series.

I'll try to make some fresh measurements on both types and post the results.

I am unable to find the thread, I don't even know if I posted the results on DIYaudio.

Anyway, I remember they were excellent, capable of competing with more modern types on all aspects, except the size/capacitance ratio.

Other than that, they are of exceptional quality, and also remarkably durable since the samples I had were at the very least 25 years old, some much older than that.

Siemens also made very comparable caps, both in construction and quality.

They also had an identical form factor (probably resulting from some old DIN standard).

The only difference was the color: bright orange instead of dull brick. But the quality was very comparable. It was the GSF series.

I'll try to make some fresh measurements on both types and post the results.

Those are the ones that I used to replace in almost every defective Grundig TV set that I had in the workshop. They all ran out of capacity and dried out, some of them even cracked up. Maybe that was only due to lots of heat in narrow power supply sections, but since then I don't like them very much  .

.

Hi Elvee

Yes...Interesting...I have seen ( but not used ) the Siemens GSF orange ones as well.

Hi Preamp

Yes indeed...I heard they did not fare too good in hot environments...Quad 22's were an example.

Haven't seen bad reports from 'cooler' Naim Audio preamp environments though.

Perhaps they prefer, say 20v duties for a 40v cap ( bit underated ? ).

So...not sure there was any great 'audio advantage' in a Grundig TV set...

...I wonder why they used the EK's as opposed to regular 'metal cans' ?

Had wondered if it was a 'can insulation' issue...

...but I've not seen an EK series cap that is over 40v rated.

Did they come in much higher voltage ratings ?

Anyone know ?

I think Quad may have used them near HOT cathode resistors...

...not sure though.

Cheers.

Si.

Yes...Interesting...I have seen ( but not used ) the Siemens GSF orange ones as well.

Hi Preamp

Yes indeed...I heard they did not fare too good in hot environments...Quad 22's were an example.

Haven't seen bad reports from 'cooler' Naim Audio preamp environments though.

Perhaps they prefer, say 20v duties for a 40v cap ( bit underated ? ).

So...not sure there was any great 'audio advantage' in a Grundig TV set...

...I wonder why they used the EK's as opposed to regular 'metal cans' ?

Had wondered if it was a 'can insulation' issue...

...but I've not seen an EK series cap that is over 40v rated.

Did they come in much higher voltage ratings ?

Anyone know ?

I think Quad may have used them near HOT cathode resistors...

...not sure though.

Cheers.

Si.

I don't think they were used for any audio advantage, simply they were low esr, suitable for power operation at 15625Hz, and the fact their case is thermoset is probably an inheritance of manufacturing traditions.So...not sure there was any great 'audio advantage' in a Grundig TV set...

...I wonder why they used the EK's as opposed to regular 'metal cans' ?

The epoxy sealing is also more durable and gas-tight than rubber, particularly in the hot environment of a TV set

63V was the maximumHad wondered if it was a 'can insulation' issue...

...but I've not seen an EK series cap that is over 40v rated.

Did they come in much higher voltage ratings ?

Anyone know ?

Here is a thread where they were discussed:

http://www.diyaudio.com/forums/parts/211422-help-id-capacitors-my-preamp.html

I just measured the esr (@1KHz) of some used ones:

100µ/16V: 295mΩ

47µ/40V: 249mΩ

220µ/16V: 130mΩ

I have other samples in my stock, but I may need some time to locate them

Hi Elvee

Thanks VERY much for that.

I thought last night...Yep...not audio, in the TV set's...but high-frequency.

BINGO !

And yes...

...manufacturing techniques !

Roederstein produced superb plastic film/foil caps...I have used loads.

All end-potted in resin.

Never seen a Roederstein product in a 'tin can'.

Thanks for the ESR figures.

A quick 'vauge check' suggests that the ESR figures are AT LEAST as good as Panasonic FC's...

...and in one of your examples; actualy better.

Not exact uF-V comparison, as values differ...

...but def. in 'the ball-park'.

I believe ESR can go up a bit, particularly with high-voltage/ripple etc. & time...

...so I guess it's possible, the one's you tested ( depending on use ) could have had ever lower ESR, straight from the factory.

And yes...also...no vent...totaly-sealed...

...as per Roederstein's plastic-caps...

...no air out...

...= no air in, either...

...I wonder if that prevents any internal oxidising ?

Still...the intrigueing use of 'Bakelite'...

...well past the end of the 'Bakelite-age'.

The Russians having said that, seemed to be still making terminal-strips & group panels out of Bakelite, untill relatively recently.

Perhaps again, a Roederstein 'legacy production technique'...

...or is there some other reason for the Bakelite construction...

...Resonance ?

Mmmm...?

Cheers.

Si.

Thanks VERY much for that.

I thought last night...Yep...not audio, in the TV set's...but high-frequency.

BINGO !

And yes...

...manufacturing techniques !

Roederstein produced superb plastic film/foil caps...I have used loads.

All end-potted in resin.

Never seen a Roederstein product in a 'tin can'.

Thanks for the ESR figures.

A quick 'vauge check' suggests that the ESR figures are AT LEAST as good as Panasonic FC's...

...and in one of your examples; actualy better.

Not exact uF-V comparison, as values differ...

...but def. in 'the ball-park'.

I believe ESR can go up a bit, particularly with high-voltage/ripple etc. & time...

...so I guess it's possible, the one's you tested ( depending on use ) could have had ever lower ESR, straight from the factory.

And yes...also...no vent...totaly-sealed...

...as per Roederstein's plastic-caps...

...no air out...

...= no air in, either...

...I wonder if that prevents any internal oxidising ?

Still...the intrigueing use of 'Bakelite'...

...well past the end of the 'Bakelite-age'.

The Russians having said that, seemed to be still making terminal-strips & group panels out of Bakelite, untill relatively recently.

Perhaps again, a Roederstein 'legacy production technique'...

...or is there some other reason for the Bakelite construction...

...Resonance ?

Mmmm...?

Cheers.

Si.

I am no material expert, but I don't think they are actually Bakelite, even if the material bears some superficial resemblance. At the time they were designed, many high perf thermoset materials already existed.

Original Bakelite included porous load materials like saw-dust, making it very poor regarding water absorption, strong bases or acids resistance, permeability, etc.

The guys at Roe and Siemens were real experts, and knew perfectly well what to use to achieve durability. The resin was probably urea/methanal or phenolic, or some proprietary mix with suitable inert loads to achieve (very, very) long term stability.

I don't think oxidization is a problem: on the contrary, it is necessary to maintain the oxide layer.

But the important thing is to prevent the loss of contents. Maintaining the oxide layer requires a small amount of electrolysis, of which the resulting gases are normally recombined thanks to additives, but ordinary caps with a rubber seal always lose some of their hydrogen in the process, and in the end when the supply is exhausted (~water content), the capacitor dries up.

A completely tight seal prevents any loss, but also demands an extreme purity and stability of the materials inside, otherwise the pressure would build up and make the capacitor explode (I have seen such capacitors explode when subjected to reverse bias).

This demands very high standards of manufacturing, because you have no right to error.

This is typical of the german industry at the time, they were also the first to be able to produce plastic film caps of a consistently high quality, and this was no mean achievement (I have some Hunts samples of that time which by contrast were complete failures due to poor quality control at every stage)

Original Bakelite included porous load materials like saw-dust, making it very poor regarding water absorption, strong bases or acids resistance, permeability, etc.

The guys at Roe and Siemens were real experts, and knew perfectly well what to use to achieve durability. The resin was probably urea/methanal or phenolic, or some proprietary mix with suitable inert loads to achieve (very, very) long term stability.

I don't think oxidization is a problem: on the contrary, it is necessary to maintain the oxide layer.

But the important thing is to prevent the loss of contents. Maintaining the oxide layer requires a small amount of electrolysis, of which the resulting gases are normally recombined thanks to additives, but ordinary caps with a rubber seal always lose some of their hydrogen in the process, and in the end when the supply is exhausted (~water content), the capacitor dries up.

A completely tight seal prevents any loss, but also demands an extreme purity and stability of the materials inside, otherwise the pressure would build up and make the capacitor explode (I have seen such capacitors explode when subjected to reverse bias).

This demands very high standards of manufacturing, because you have no right to error.

This is typical of the german industry at the time, they were also the first to be able to produce plastic film caps of a consistently high quality, and this was no mean achievement (I have some Hunts samples of that time which by contrast were complete failures due to poor quality control at every stage)

Last edited:

Indeed, see pics. I also have earlier examples, contemporary of the EK, or even predating them (but here again, locating them might take some time).

But as far as I remember, the quality was.... let's say ordinary.

By contrast, the Siemens in Al case of that time were as outstanding as the GSF types

Attachments

I have found one more example: a 1000µ/16V (used)

Its esr @1KHz is 61mΩ

For comparison purposes, a modern 1000µ has 83mΩ, yet it unused and 25V.

Also included is a Siemens 1000µ/16V dated 03/74: 58mΩ. Yet it is an axial type and is thus disadvantaged (and probably older than the EK too).

So, this confirms EK caps are excellent, but Siemens are still superior

Its esr @1KHz is 61mΩ

For comparison purposes, a modern 1000µ has 83mΩ, yet it unused and 25V.

Also included is a Siemens 1000µ/16V dated 03/74: 58mΩ. Yet it is an axial type and is thus disadvantaged (and probably older than the EK too).

So, this confirms EK caps are excellent, but Siemens are still superior

Attachments

bad electrolytic caps

these capacitors were heavily used not only in TV set's, but also in high-end audio gear by Revox, Bang & Olufsen and others.

In my experience, these capacitors are the first things to replace when the equipment comes in for service.

The top surface of many is cracked and they are dried out.

Maybe these capacitors where O.K. when new, but after a couple of decades, in my view they are no good anymore.

Most Japanese elco's, and Philips elco's of the same age are still O.K.

The dull red ROE elco's are really bad components and need to be replaced!

these capacitors were heavily used not only in TV set's, but also in high-end audio gear by Revox, Bang & Olufsen and others.

In my experience, these capacitors are the first things to replace when the equipment comes in for service.

The top surface of many is cracked and they are dried out.

Maybe these capacitors where O.K. when new, but after a couple of decades, in my view they are no good anymore.

Most Japanese elco's, and Philips elco's of the same age are still O.K.

The dull red ROE elco's are really bad components and need to be replaced!

Mmm, these ROE caps may measure excellent but exactly this type was the reason I started recapping long ago. I experienced many faulty ones.

these capacitors were heavily used not only in TV set's, but also in high-end audio gear by Revox, Bang & Olufsen and others.

In my experience, these capacitors are the first things to replace when the equipment comes in for service.

The top surface of many is cracked and they are dried out.

Maybe these capacitors where O.K. when new, but after a couple of decades, in my view they are no good anymore.

Most Japanese elco's, and Philips elco's of the same age are still O.K.

The dull red ROE elco's are really bad components and need to be replaced!

Quite astonishing how user's experiences can differ.

For my part, compared to other contemporary types, I have seen very few faulty ones. As I mentioned earlier, I found some had cracked or even exploded, but it was caused by application of reverse bias.

Usually, ordinary Al caps tolerate a small percentage of reverse bias voltage during part of a cycle, but the EK do not tolerate well that kind of treatment, probably because of their hermetic construction.

There may be other factors: since they were low esr, some designers could have mistakenly thought that they were suitable for operation at high current, high temperature and high frequency. In fact, they must be 85° or perhaps 70° parts.

The equipment where I saw them were mainly professional, not consumer, conservatively designed and they weren't subjected to simultaneous stresses.

Under the same conditions, the Philips ones were awful (the ones with light blue sleeve): they simply dried up, without stress, and they even degraded under shelf storage conditions.

I cannot comment about "Japanese elco's", that is too broad.

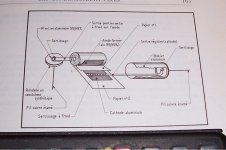

Why is the axial capacitor 'disadvantaged' ?

Because the cathode connection has to be made through a thin aluminium strip welded to the bottom of the case, having a length ~150% of the cap's body.

Attachments

Hi Elvee

You're not related to Albert Einstein by any chance ?

N I C E diagram of the axial !

EXACTLY !...

...Pro-applications.

I'm sure they were used by all sorts of designers, for all sorts of purposes...

...my interest in them is mainly from a 'sonic' point of view...

...in apps. such as microphones & low-level preamps.

No over-current, no reverse-voltage, & no large amount of heat.

Obviously in a switch-mode PSU say, there are better-contenders.

They do appear to be favoured for 'sonics' ( at least in their day )...

...question is...

...do they live up to modern equivallents ?

I have some to test here...

...but it will be a while before I am able to do so.

Cheers

Si.

Elvee...

...Know anything about the bi-polar ones ?

Obviously WAY less uF/size...

...I keep meaning to look into this...

...But non-polar, I believe, are supposed to be way-lower noise...

...thing is, I've never known WHY ?

You're not related to Albert Einstein by any chance ?

N I C E diagram of the axial !

EXACTLY !...

...Pro-applications.

I'm sure they were used by all sorts of designers, for all sorts of purposes...

...my interest in them is mainly from a 'sonic' point of view...

...in apps. such as microphones & low-level preamps.

No over-current, no reverse-voltage, & no large amount of heat.

Obviously in a switch-mode PSU say, there are better-contenders.

They do appear to be favoured for 'sonics' ( at least in their day )...

...question is...

...do they live up to modern equivallents ?

I have some to test here...

...but it will be a while before I am able to do so.

Cheers

Si.

Elvee...

...Know anything about the bi-polar ones ?

Obviously WAY less uF/size...

...I keep meaning to look into this...

...But non-polar, I believe, are supposed to be way-lower noise...

...thing is, I've never known WHY ?

Yes, definitelyI'm sure they were used by all sorts of designers, for all sorts of purposes...

...my interest in them is mainly from a 'sonic' point of view...

...in apps. such as microphones & low-level preamps.

No over-current, no reverse-voltage, & no large amount of heat.

Obviously in a switch-mode PSU say, there are better-contenders.

They do appear to be favoured for 'sonics' ( at least in their day )...

...question is...

...do they live up to modern equivallents ?

I have never seen bipolars in this series (which doesn't mean they don't exist).Elvee...

...Know anything about the bi-polar ones ?

Obviously WAY less uF/size...

...I keep meaning to look into this...

...But non-polar, I believe, are supposed to be way-lower noise...

...thing is, I've never known WHY ?

I have never heard about bi-polars having a lower noise (same remark). Ordinary, good quality caps already have a rather low noise: it is caused by the reforming of the oxide layer, and very small once the equipment has been up and running for some time. And obviously, it is heavily low pass filtered thanks to the capacitance.

Thanks ALBERT !

It might...

...in fact...IS...

...a slightly different series to the EK ones in the red/brown Bakelite.

I have seen 10uF bi-polars...

...about the same size, as a 'regular' say, 220uF Roe-cap.

The ones I've seen are in the ORANGE Bakelite casing...

...but I've no idea of the series #.

There were some interesting pics in the thread you pointed to Elvee...

...some of those were in the Orange Bakelite casing...

...no one said what the pre-amp ( or whatever it was ) was in the text though...

Was it a Naim Audio...something ?

Cheers.

Si.

It might...

...in fact...IS...

...a slightly different series to the EK ones in the red/brown Bakelite.

I have seen 10uF bi-polars...

...about the same size, as a 'regular' say, 220uF Roe-cap.

The ones I've seen are in the ORANGE Bakelite casing...

...but I've no idea of the series #.

There were some interesting pics in the thread you pointed to Elvee...

...some of those were in the Orange Bakelite casing...

...no one said what the pre-amp ( or whatever it was ) was in the text though...

Was it a Naim Audio...something ?

Cheers.

Si.

Good to knowI have seen 10uF bi-polars...

...about the same size, as a 'regular' say, 220uF Roe-cap.

Yeah, to complicate matters further, I have also seen Siemens in a dull brick case, and also some in stone-grey color case, I don't remember if they were Sie or ROEThe ones I've seen are in the ORANGE Bakelite casing...

...but I've no idea of the series #.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- Roederstein 'BAKELITE' series EK capacitors - "Living Legend" OR "Looney Legacy" ...?