I disagree. My comments are based primarily on empirical data, i.e. my own testing.That stepped affair in the images above, imo will be more like multiple diffraction steps than absorption, at the high freqs that they likely say it is intended for...

Diffraction Doesn't Have to be a Problem (audioXpress)

Rings are a far cry from what is shown here. The reason they don't work is that most commercial versions don't use felt, they're synthetic, and because a circle for diffraction control is the worst shape. But it also doesn't relate to the topic of a horn because they are not anywhere close to dimensions required for any sort of horn response. Rather off-topic to the thread I'd say.There were some articles and threads here as well that years back discussed the ring around the tweeter. Iirc, the conclusion was that they failed to work as expected and caused some problems - as typically employed.

Felt Rings vs. Felt Blocks

Dave

Dave, you would have to compare an ideally set up tweeter to the same tweeter with "treatment" to have the proper comparisons.

I agree that absorption, using the proper materials is a valuable tool. The examples in your articles show horrifically poor set ups and the improvements over that.

I'd like to see a high quality tweeter on a large baffle, alone, and then with and without "treatment".

I am not sure if you have taken into account in your rings vs. blocks that merely the geometry might be making your difference. The ring creates a cavity that is axisymmetric, so would be expected to have a "greater" negative effect on the frequency response IF there was an effect due to less than perfect absorption.

As far as the topic - the topic was Dunlavy and this other speaker system. Horns are a different topic it seems to me. Although I doubt strongly that Dunlavy intended to make a horn loading for his tweeters, it is possible I suppose. Look at the speaker in post #18, looks like a conical expansion, with steps = horn.

My comment on the multiple steps having diffraction is based on the idea that even good wool will have less than perfect absorption and so will present an edge to HF... how much is the question.

It is interesting that the real wool felt is enough different than the synthetic stuff. I'd like to see more tests and data to see the specifics and at what frequencies and to what extent they diverge. I've used both for different applications. Going back 40 years on the real wool felt. FYI.

_-_-bear

I agree that absorption, using the proper materials is a valuable tool. The examples in your articles show horrifically poor set ups and the improvements over that.

I'd like to see a high quality tweeter on a large baffle, alone, and then with and without "treatment".

I am not sure if you have taken into account in your rings vs. blocks that merely the geometry might be making your difference. The ring creates a cavity that is axisymmetric, so would be expected to have a "greater" negative effect on the frequency response IF there was an effect due to less than perfect absorption.

As far as the topic - the topic was Dunlavy and this other speaker system. Horns are a different topic it seems to me. Although I doubt strongly that Dunlavy intended to make a horn loading for his tweeters, it is possible I suppose. Look at the speaker in post #18, looks like a conical expansion, with steps = horn.

My comment on the multiple steps having diffraction is based on the idea that even good wool will have less than perfect absorption and so will present an edge to HF... how much is the question.

It is interesting that the real wool felt is enough different than the synthetic stuff. I'd like to see more tests and data to see the specifics and at what frequencies and to what extent they diverge. I've used both for different applications. Going back 40 years on the real wool felt. FYI.

_-_-bear

Last edited:

I'm not sure what you mean here.Dave, you would have to compare an ideally set up tweeter to the same tweeter with "treatment" to have the proper comparisons.

I have a 2mx2m baffle for testing. I've tested the difference with/without on this which limits the change to the impact of felt separate from any actual diffraction. There's no horn loading in any testing I've done, but it usually does add some degree of raggedness since it's not a perfect material for absorption. It does reflect a bit, more so at higher frequencies. Whatever horn loading is minimal and to my way of seeing it, insignificant in typical applications. I never tried it in thicknesses that might tend to load a driver this way.I agree that absorption, using the proper materials is a valuable tool. The examples in your articles show horrifically poor set ups and the improvements over that.

I'd like to see a high quality tweeter on a large baffle, alone, and then with and without "treatment".

I have taken that into account over time. I've used synthetics non-circular. They just don't work in any testing I've done.I am not sure if you have taken into account in your rings vs. blocks that merely the geometry might be making your difference. The ring creates a cavity that is axisymmetric, so would be expected to have a "greater" negative effect on the frequency response IF there was an effect due to less than perfect absorption.

Yeah, the OP did ask whether it was for diffraction, horn loading or something else, so I guess it's all on topic.]As far as the topic - the topic was Dunlavy and this other speaker system. Horns are a different topic it seems to me. Although I doubt strongly that Dunlavy intended to make a horn loading for his tweeters, it is possible I suppose.

Granted it isn't perfect. I've tried steps in multiple forms with varying felt densities. It comes down to finding something optimal for the particular situation. There does not seem to be anything that is "the best", you just have to find "good enough".My comment on the multiple steps having diffraction is based on the idea that even good wool will have less than perfect absorption and so will present an edge to HF... how much is the question.

It is an "edge", but it's not the same as the edge of, say, wood that is stepped. The edge is transitional in a sense, since much of the wave arriving near the "edge" is traveling through the felt. The effective thickness of the felt through which any part of the wave travels is varying due to the angle of incidence. Much depends on that angle I suppose. But overall, I've found little problem unless the felt is too close to the dome of a tweeter. Beyond a certain distance, I've measured little change.

I highly suspect that Dunlavy stepped the felt for an optimal use. As deep as some of it is, were it just single pieces, there would be a "tunnel" and probably at true bit of horn loading, though it would be closer to being like a box and would have a tuning to it. Probably that more so than any real horn-like response.

The one thing I took away from my testing is that I would never use synthetics, unless it was a foam and that is limited in usage as well. At least it is in my testing. I've used foam for small incremental improvements at high frequency. The thing is, though, I don't believe the change is audible at that point, even though it's easily measured.It is interesting that the real wool felt is enough different than the synthetic stuff. I'd like to see more tests and data to see the specifics and at what frequencies and to what extent they diverge. I've used both for different applications. Going back 40 years on the real wool felt. FYI.

Dave

Thanks for more of your findings...

What I meant up top was that a tweeter, flush mounted, no gaps on a large enough baffle will be pretty close to optimal, then adding any treatment to it will show pretty clearly if the effect is beneficial and/or what the effects might be.

Ideally one would start with a darn good tweeter with a darn good, flat response, so that deviations would be clear... not to mention a darn good waterfall, etc...

if a wavefront encounters the felt, that part of the wave will be slowed down, and possibly absorbed (depending on frequency), while the stuff not going through that felt is at normal speed. I think that means bending and diffraction. Of course it may well be in a direction that has no audible effect and/or be too low of an amplitude. I'm guessing.

But with less effective absorption materials, I would expect that these effects become more pronounced and have a bigger impact on the sound.

The proof of the result is both in the listening and in the measurements, regardless of what I think. All too often what is apparent and intuitive proves to be just plain wrong anyhow.

_-_-bear

What I meant up top was that a tweeter, flush mounted, no gaps on a large enough baffle will be pretty close to optimal, then adding any treatment to it will show pretty clearly if the effect is beneficial and/or what the effects might be.

Ideally one would start with a darn good tweeter with a darn good, flat response, so that deviations would be clear... not to mention a darn good waterfall, etc...

if a wavefront encounters the felt, that part of the wave will be slowed down, and possibly absorbed (depending on frequency), while the stuff not going through that felt is at normal speed. I think that means bending and diffraction. Of course it may well be in a direction that has no audible effect and/or be too low of an amplitude. I'm guessing.

But with less effective absorption materials, I would expect that these effects become more pronounced and have a bigger impact on the sound.

The proof of the result is both in the listening and in the measurements, regardless of what I think. All too often what is apparent and intuitive proves to be just plain wrong anyhow.

_-_-bear

Overall I agree with one exception. The absolute quality of the tweeter is largely insignificant. It just must not be directional, as in an actual horn tweeter. All one need do is measure the raw driver and normalize all other measurements to that raw response. This will show the spectrum response of the alteration due to the tested material. Within limits of repeatability of a driver's response, normalized responses from one tweeter to another should be nearly identical up to the frequency where the driver is more directional. Small tweeters are the key, more output at 90 degrees to higher frequencies, thus more "illumination" of the felt, to use a Linkwitz phrase (I think).Thanks for more of your findings...

What I meant up top was that a tweeter, flush mounted, no gaps on a large enough baffle will be pretty close to optimal, then adding any treatment to it will show pretty clearly if the effect is beneficial and/or what the effects might be.

Ideally one would start with a darn good tweeter with a darn good, flat response, so that deviations would be clear... not to mention a darn good waterfall, etc...

if a wavefront encounters the felt, that part of the wave will be slowed down, and possibly absorbed (depending on frequency), while the stuff not going through that felt is at normal speed. I think that means bending and diffraction. Of course it may well be in a direction that has no audible effect and/or be too low of an amplitude. I'm guessing.

But with less effective absorption materials, I would expect that these effects become more pronounced and have a bigger impact on the sound.

The proof of the result is both in the listening and in the measurements, regardless of what I think. All too often what is apparent and intuitive proves to be just plain wrong anyhow.

_-_-bear

Dave

Yes, John Dunlavy passed away a few years ago. A great designer IMO. I studied his efforts and had several in-depth conversations with him (there was a possibility of my going to work for him as a design engineer, the talks were going well and then he all of a sudden aged and died shortly after that.) He was a great guy to talk to, and very free with his knowledge. I learned a lot from him. Thank you, John!It is an "edge", but it's not the same as the edge of, say, wood that is stepped. The edge is transitional in a sense, since much of the wave arriving near the "edge" is traveling through the felt. The effective thickness of the felt through which any part of the wave travels is varying due to the angle of incidence. Much depends on that angle I suppose. But overall, I've found little problem unless the felt is too close to the dome of a tweeter. Beyond a certain distance, I've measured little change.

I highly suspect that Dunlavy stepped the felt for an optimal use. As deep as some of it is, were it just single pieces, there would be a "tunnel" and probably at true bit of horn loading, though it would be closer to being like a box and would have a tuning to it. Probably that more so than any real horn-like response.

Dave

As for the felt, he said it definitely reduced the reflections. He was talking about an improved version with triangular profiling on the edges, they would look like the cutouts RAAL uses on their tweeter faceplate. When I pressed him on the issue, he said that it wasn't enough of a difference to warrant the extra cost. But, in the few experiments I did with this, I saw measurable improvement of 0.25 to 0.5dB, but it seemed more audible than that. At the time, I couldn't use that approach in any of my commercial designs because Dunlavy owned the patent and his licensing fee was too high for me.

As for horn loading, I never saw any apparent gain in efficiency on or off axis that would correlate with that. The stepped felt absorbs enough of the wave to pretty much eliminate most of the reflections. The stepped felt with the triangular teeth seems to eliminate 'em just about completely. Those teeth in the felt are kind of like the triangular fiberglass wedges in anechoic chambers - pretty effective at absorbing the wave!

The area of design Dunlavy did not talk much at all was the issue of maintaining more constant directivity, even though his approach restricted the tweeter off -axis response by quite a lot.

I wish he could have been around to see some of the new designs using open baffles and constant directivity waveguides - he probably would have had some great new ways to implement these approaches. I also wish he could hear my phase-coherent Omni's, I think he would have liked 'em.

So anyway, to get back on topic, and in sum:

The felt in the cavity provides no significant horn-loading.

But it does help restrict the off-axis and provide a more constant directivity.

Properly implemented, it could be used to restrict the directivity to very small beam-widths, but without any additional gain - easier to cross over in some cases, as there is none of that on-axis waveguide gain or horn bump...

Last edited:

This will be fun!

My brother is giving me back my Dunlavy SC-1’s that I gave to him years ago. The first order crossovers are coming out, and digital crossovers and IcePower amp modules are going in. All kinds of possibilities as far as that goes. They’ll be used from 400hz high pass, to whatever I decide on for the crossover point. I’ve always dreamed of doing this!

My brother is giving me back my Dunlavy SC-1’s that I gave to him years ago. The first order crossovers are coming out, and digital crossovers and IcePower amp modules are going in. All kinds of possibilities as far as that goes. They’ll be used from 400hz high pass, to whatever I decide on for the crossover point. I’ve always dreamed of doing this!

Eh.

Those listeners prefer a triangle step response, both drivers moving front and back at the same time.

"Time alignment" phase aligned too.

Even better would be a 6db time aligned coax, now you are a point source too.

Were i not a midbass head, I'd be firmly planted with thiels, dunlavy, or vandersteen.

Or even 8" full range, but i need wider dispersion than a couch at 12'.

Those listeners prefer a triangle step response, both drivers moving front and back at the same time.

"Time alignment" phase aligned too.

Even better would be a 6db time aligned coax, now you are a point source too.

Were i not a midbass head, I'd be firmly planted with thiels, dunlavy, or vandersteen.

Or even 8" full range, but i need wider dispersion than a couch at 12'.

As Stereophile review of Dunlavey SC IV said, it’s only one of a handful ever tested to show a perfect step response as provided by a transient perfect speaker. That’s a speaker that has correct time and phase alignment. It reproduces percussion very accurately and has superb imaging.

Regarding the foam/fuzz around the tweeter - it helps smooth diffraction ripples. I don’t think it can act as a waveguide or horn - try making a horn out of porous foam or Scotchbrite pads. Does it work?

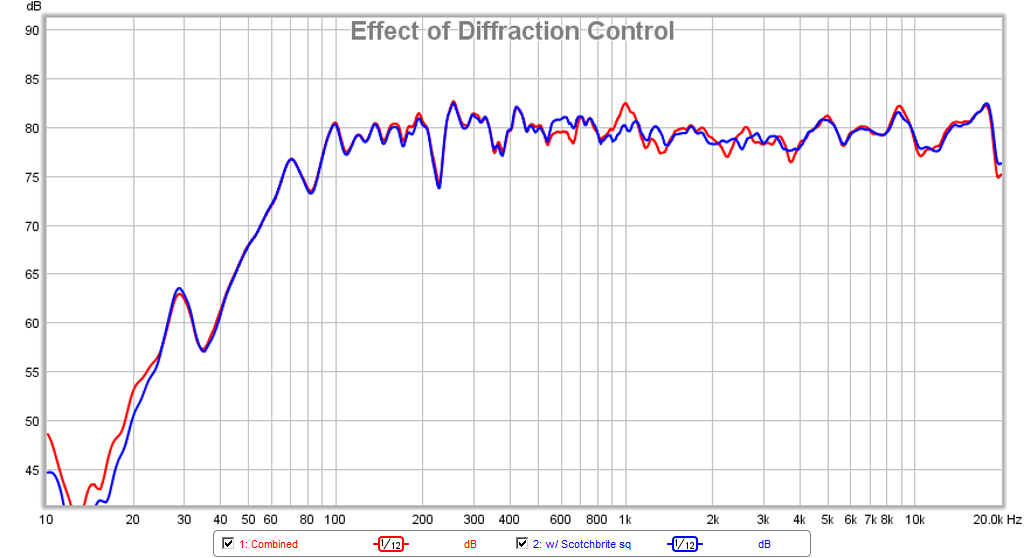

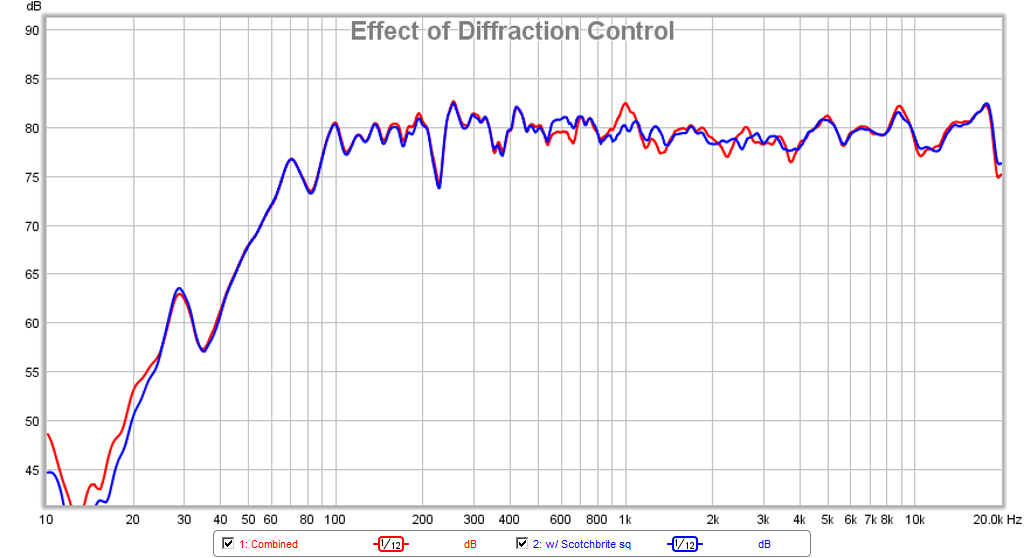

Here were some of my experiments with Scotchbrite pads around a tweeter.

FR58EX and AC130F1 micro-FAST / WAW

With and without Scotchbrite around tweeter:

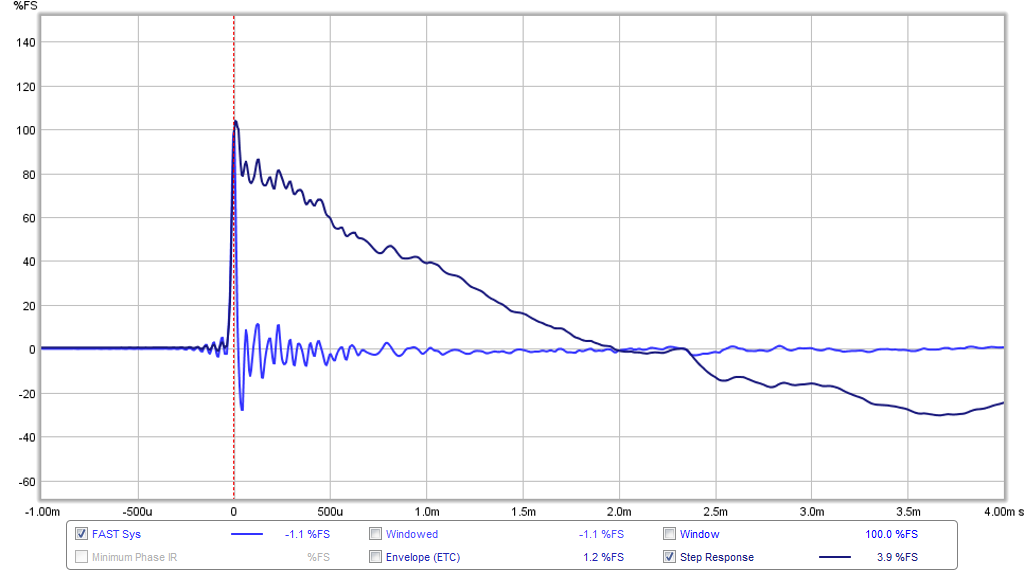

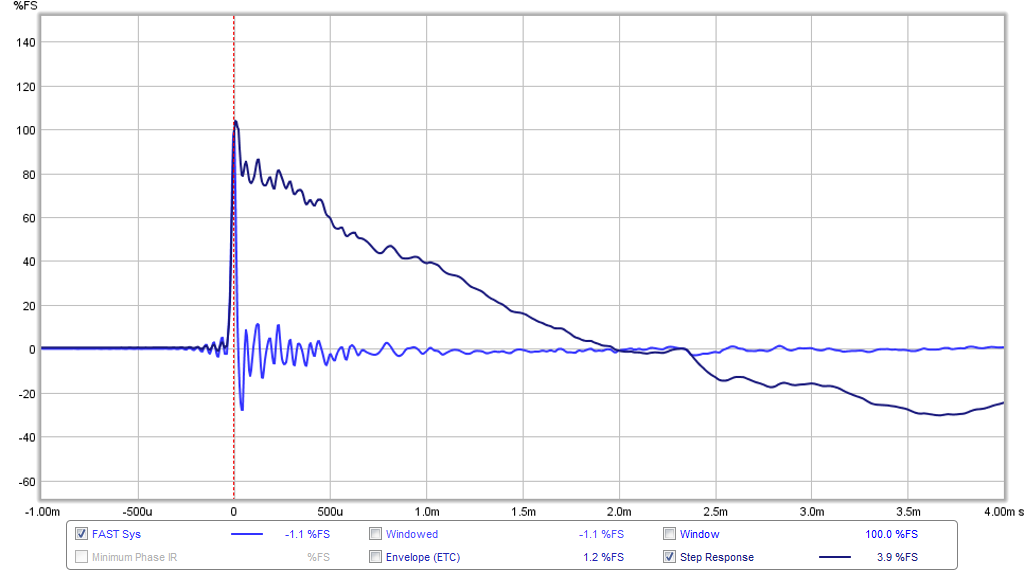

Step response:

Regarding the foam/fuzz around the tweeter - it helps smooth diffraction ripples. I don’t think it can act as a waveguide or horn - try making a horn out of porous foam or Scotchbrite pads. Does it work?

Here were some of my experiments with Scotchbrite pads around a tweeter.

FR58EX and AC130F1 micro-FAST / WAW

With and without Scotchbrite around tweeter:

Step response:

I have owned Sonique Encore speakers which were very much a Duntech type speaker.Sonique was owned by ex Duntech employees.They were very good WMTMW speakers using two Dynaudio D52 dome mids and Dynaudio Esotec tweeters in a felt surrounded stepped baffle arrangement.The felt was attached by velcro so could be removed.In some ways they sounded better without the felt-certainly more "air" and atmospheric sounding and a bit more involvng.The imaging was more pinpoint with the felt in place but was still very good without it.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Theory behind Dunlavy and Lipinski speakers?