other pictures

hi

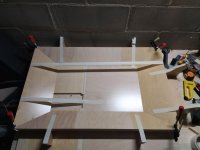

I've finished assembling first prototype without reflex ports only for testing.

I wired a 1w t-amp: one channel to midbasses and one to mid high directly and so I used Reaper for crossing over midbasses and mid-hi. the sensitivity is incredible. next week I will tune and analize.

thank you

hi

I've finished assembling first prototype without reflex ports only for testing.

I wired a 1w t-amp: one channel to midbasses and one to mid high directly and so I used Reaper for crossing over midbasses and mid-hi. the sensitivity is incredible. next week I will tune and analize.

thank you

Attachments

tuning

HI

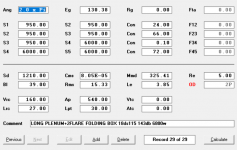

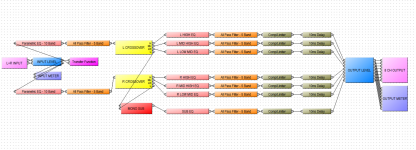

I searched a cheap alternative to processing and I found the BIAMP AUDIA SOLO 8X8 totally programmable (no fir) dsp for 85 euros in my town so I bought and it is perfect.

in my town so I bought and it is perfect.

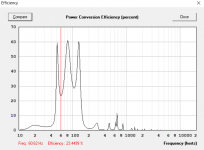

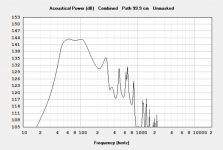

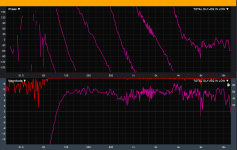

So I built a simple 4 way xover and the result in smaart is not so bad at 2flare mouth (I couldn't do at 1meter because of the room modes).

Maybe I decide to make reflex ports however.

I don't have spl calibrator but with 0.25 watt in one speaker is difficult to speak in the same room

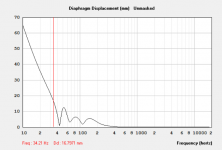

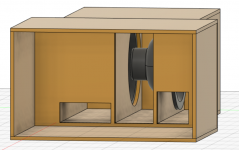

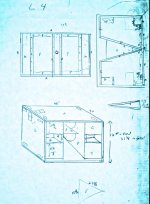

I designed a PPSL sub for the synergies, maybe I will create a new thread.

the sub is double 18ds115-8 capable of 143db at 6800w at re/2 within xmax 50-120hz (live rock music job at 90%).

with detachable 2° flare and right dimensions to transport in my car.

I would have some replies about the sub.

thank you very much

Ale

HI

I searched a cheap alternative to processing and I found the BIAMP AUDIA SOLO 8X8 totally programmable (no fir) dsp for 85 euros

So I built a simple 4 way xover and the result in smaart is not so bad at 2flare mouth (I couldn't do at 1meter because of the room modes).

Maybe I decide to make reflex ports however.

I don't have spl calibrator but with 0.25 watt in one speaker is difficult to speak in the same room

I designed a PPSL sub for the synergies, maybe I will create a new thread.

the sub is double 18ds115-8 capable of 143db at 6800w at re/2 within xmax 50-120hz (live rock music job at 90%).

with detachable 2° flare and right dimensions to transport in my car.

I would have some replies about the sub.

thank you very much

Ale

Attachments

Ale,

Looks like it could do what you want very well in the given transport space restriction.

Conceptually, not a fan of the push pull arrangement requiring different BR box/port volumes.

Personally, I'd put more volume in the BR chambers, less in the center plenum and go for a lower Fb, and trade some upper SPL loss for LF extension.

Anyway, brings back memories of my L4 quad 15" design, it worked quite well touring with all sorts of shows for a long time. Had around 20 of them out on the Beastie Boys "Check Your Head tour", though the 2020 Beastie Boys Story documentary didn't have a single picture of them in any tour photos.

Art

Looks like it could do what you want very well in the given transport space restriction.

Conceptually, not a fan of the push pull arrangement requiring different BR box/port volumes.

Personally, I'd put more volume in the BR chambers, less in the center plenum and go for a lower Fb, and trade some upper SPL loss for LF extension.

Anyway, brings back memories of my L4 quad 15" design, it worked quite well touring with all sorts of shows for a long time. Had around 20 of them out on the Beastie Boys "Check Your Head tour", though the 2020 Beastie Boys Story documentary didn't have a single picture of them in any tour photos.

Art

Attachments

Art covered about half what I was going to say. If I were to do it in the same for factor, I'd move the drivers to the front, make the manifold only as deep as the drivers, common the 2 rear chambers by opening up the area behind the new driver positions and port on the front baffles and narrow the manifold a bit to accomplish of necessary. Or exit the ports into the manifold if you need to.for me 50-120 is good.

Simulations brought me to have long distance between center of drivers and 2flare.

this is my 2° audio project can you help me to understand that this long distance will be a problem?

thank you

Ale

This will give you more box volume, or allow you to make it smaller, as well as better BW, which though you don't need it now, you might want in the future. It'll also make it easier for the xover dealing with the passband ripples at the top end.

Also remember it helped to reduce the Vrc as much as possible.

FWIW, in theory [and practice IME WRT regular compression horns] tune it to the mean between the horn's design Fl, Fh, which in theory reactance annuls it.

Hi Ale, your project is looking great !

Please pass on what you are doing with all the all-pass filters, and how well you think it's working.

I like your sub, with ditto type comments as made already by the guys.

Maybe your sims are right? Just intuitively, i've never looked at anything other than the smallest slot that physically works....to both maximize internal box volume, and to keep the slot as narrow as can be (drivers closeness), for moving usable response up in freq.

But in your application i dunno... will be interesting.

@GM, hi.

Not sure what or where my quote came from...or what you were meaning.

thx

Please pass on what you are doing with all the all-pass filters, and how well you think it's working.

I like your sub, with ditto type comments as made already by the guys.

Maybe your sims are right? Just intuitively, i've never looked at anything other than the smallest slot that physically works....to both maximize internal box volume, and to keep the slot as narrow as can be (drivers closeness), for moving usable response up in freq.

But in your application i dunno... will be interesting.

@GM, hi.

Not sure what or where my quote came from...or what you were meaning.

thx

Ale,

Looks like it could do what you want very well in the given transport space restriction.

Conceptually, not a fan of the push pull arrangement requiring different BR box/port volumes.

Personally, I'd put more volume in the BR chambers, less in the center plenum and go for a lower Fb, and trade some upper SPL loss for LF extension.

HI Art. I admit I start this project ispired by pm90 and your syntripp.

My drawings are rough. I will have same liters in both chambers calculating also

that one driver is inside chamber and the other is iide plenum.

Also BR ports seems different but have same area and lenght.

HI BrettArt covered about half what I was going to say. If I were to do it in the same for factor, I'd move the drivers to the front, make the manifold only as deep as the drivers, common the 2 rear chambers by opening up the area behind the new driver positions and port on the front baffles and narrow the manifold a bit to accomplish of necessary. Or exit the ports into the manifold if you need to.

This will give you more box volume, or allow you to make it smaller, as well as better BW, which though you don't need it now, you might want in the future. It'll also make it easier for the xover dealing with the passband ripples at the top end.

I think I don't understand perfectly your schematic. can you show a rough hands drawing?

thank you

HI MarkPlease pass on what you are doing with all the all-pass filters, and how well you think it's working.

thx

I implemented all pass filters to check if dsp capabilities were ok (6x 60mhz sharks) and to adjust some phase rotation due to xover but I didn't used. I used only 0,17ms dly between low and mid and 0,27 between low and hi according to smaart phase overlap in xover zone.

Now I use 48BW low/hi pass without overlap but I found the 12"s at 600hz are fooling down too early. I don't have the phase plugs installed at the moment however.

Thank you

The aspect ratio of the two ports are different, which will make them tune to slightly different frequencies, unless compensated for the lower tuning of the more narrow port. Asymmetry causes non-linearity, which increases THD (total harmonic distortion)Also BR ports seems different but have same area and lenght.

You plan to use good drivers, which have little or no improvement in THD using push-pull (which reduces even order HD) vs push-push.

Using push-push, the plenum shape and volume can be exactly what you decide appropriate, and the load on the drivers identical.

From a thermal perspective, using a port at the top and bottom of the chamber will "chimney" out heat better than a single port. If you do opt for a single port, centering it, or placing it on top would extract a bit more heat from the cabinet, as heat rises, and seeks cold.

Art

HI

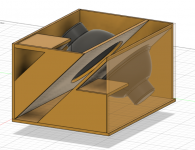

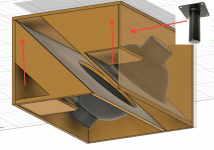

According to your suggestions I made another version in push-push.

Here I have same external dimensions, almost same plenum volume in different form factor(less distance between to sides but higher(maybe is a problem?), equal triangular BR ports that are in upper side for better heat exchange.

When I stock sub I will put in vertical so cone gravity won't be a problem.

Thank you

Ale

According to your suggestions I made another version in push-push.

Here I have same external dimensions, almost same plenum volume in different form factor(less distance between to sides but higher(maybe is a problem?), equal triangular BR ports that are in upper side for better heat exchange.

When I stock sub I will put in vertical so cone gravity won't be a problem.

Thank you

Ale

Attachments

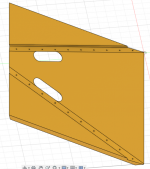

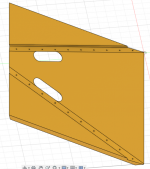

Ale, could you please post some pictures on how you designed the horn flare panels in 3D for CNC - especially how the panels fit together, which sides are angled and which not? Do you machine two sides or just one. I am just putting together my first small CNC'd 2 way synergy horn - and I am looking for any hints on how to improve my design.

Ale,HI

According to your suggestions I made another version in push-push.

Here I have same external dimensions, almost same plenum volume in different form factor(less distance between to sides but higher(maybe is a problem?),

Looks good, don't see anything problematic. You might flip the design vertically, with ports moved to the top, so installation of a "Top Hat" pole mount could be installed to support the top cabinets.

Art

Attachments

@pelanj

HI

I show some screenshots of this part. Cuts are in both size for this part

and every part is designed in order to use only 4 tools for few manual tool changes. 30minutes cutting for one flare side. Better wood is not only for better acoustic performance but also more precision and finishing of the parts and joints, less sandng and quicker assembling, I think. I found the only Baltic birch plywood manufacturer in italy is 15km to my house but that time had only industrial pre-painted 1° quality BB. With CNC you can cut painted wood without scratching , designing hidden joints.

but that time had only industrial pre-painted 1° quality BB. With CNC you can cut painted wood without scratching , designing hidden joints.

Thanks

@art

Hi

I was thinking to put a pole mount maybe when I need only one top.

I don't understand why you flip the sub upside down. Is symetric and moving the ports up I obtain the same sub, Sorry

Thanks

Ale

[/ATTACH]

[/ATTACH]

HI

I show some screenshots of this part. Cuts are in both size for this part

and every part is designed in order to use only 4 tools for few manual tool changes. 30minutes cutting for one flare side. Better wood is not only for better acoustic performance but also more precision and finishing of the parts and joints, less sandng and quicker assembling, I think. I found the only Baltic birch plywood manufacturer in italy is 15km to my house

Thanks

@art

Hi

I was thinking to put a pole mount maybe when I need only one top.

I don't understand why you flip the sub upside down. Is symetric and moving the ports up I obtain the same sub, Sorry

Thanks

Ale

[/ATTACH]

[/ATTACH]

Last edited:

Nice, thank you. I was trying to cut from one side only and with one tool. I think I need to reconsider this strategy a bit - yours looks much easier to assemble. Do you use wooden dowels for aligning the machining from both sides? The other parts are machined single side only?

@pelanj

Only this particular is dobule side milled, I designed the others thinking to 1 side cutting only.

In this part I cut driver side first and horn side after. I keep the G54 origin in center of part in both sides. When I flip I'm sure one side is parallel to machine because on machine bed ( MDF) I have a pattern of 10mm holes parallel to x and y axis for dowels against which I put a finished side. I need only to search the new G54 in center of flipped part.

Ale

Only this particular is dobule side milled, I designed the others thinking to 1 side cutting only.

In this part I cut driver side first and horn side after. I keep the G54 origin in center of part in both sides. When I flip I'm sure one side is parallel to machine because on machine bed ( MDF) I have a pattern of 10mm holes parallel to x and y axis for dowels against which I put a finished side. I need only to search the new G54 in center of flipped part.

Ale

I was suffering from an optical delusionI don't understand why you flip the sub upside down. Is symetric and moving the ports up I obtain the same sub, Sorry

Thanks

- Home

- Loudspeakers

- Multi-Way

- 2x12 and 1,4 coax CD Synergy