In the end, the drivers will be decoupled from the baffle(including the driver mounting bolts), and the constrained layer damped baffle will be decoupled from the cabinet (including the baffle mounting bolts), by using relatively high durometer rubber washers and where the baffle meets the cabinet, sorbothane gaskets.

Last edited:

About twenty five years ago, I went through my audio mad scientist phase. I'm still amazed about what my wife let me get away with in our living room. Eventually she put a stop to it, so now everything I do has to go through the WAF filter. It needs to be aesthetically pleasing or the project is dead in its tracks

Last edited:

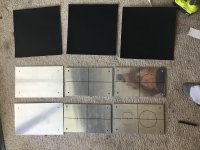

In order to get the high density acoustic felt behind the vertically aligned cabinet brace, I had to cut a large hole in the back of the speaker, which obviously required more 1/4” aluminum Plates as covers to match the fronts.

Attachments

You did that with woodworking tools? I've worked with leather for 30 years, I'm not sure it's as good as cork but I use hard 1/4 inch thick ( ox hide ) sole leather, softer stuff might be much better, pigs belly wouldn't be to bad. I'll be glad when they're finished and you can give your impressions on how they sound.Chamfering wasn’t perfect, but it’ll worklopsided look is just from the camera angle

You did that with woodworking tools? I've worked with leather for 30 years, I'm not sure it's as good as cork but I use hard 1/4 inch thick ( ox hide ) sole leather, softer stuff might be much better, pigs belly wouldn't be to bad. I'll be glad when they're finished and you can give your impressions on how they sound.

After doing a few experiments with the leather, I decided it would be suboptimal for what I'm trying to achieve with CLD, so sorbothane it will be. I'll still use it on the front though.

First speaker to ever use constrained layer damping, with a patent(now expired) issued to the designer/Sony

Sony ES SS-M9 loudspeaker | Stereophile.com

US5949033A - Constrained layer damped loudspeaker enclosure

- Google Patents

Sony ES SS-M9 loudspeaker | Stereophile.com

US5949033A - Constrained layer damped loudspeaker enclosure

- Google Patents

Sony's second attempt with CLD with what looks to be the same cabinet style. The cabinet sidewall resonance measurements are pretty extraordinary..

Sony ES SS-M9ED loudspeaker | Stereophile.com

interesting supertweeter mount..

SONY SS-M9ED VERY RARE Audiophile Speakers Photo #2590930 - US Audio Mart

Sony ES SS-M9ED loudspeaker | Stereophile.com

interesting supertweeter mount..

SONY SS-M9ED VERY RARE Audiophile Speakers Photo #2590930 - US Audio Mart

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Midrange experiment with Auto sound panel deadener and high density acoustic felt..