Great. There's a lot of functionality to the program. Right now just concern yourself with the bottom and top modules.

The goal is to figure out what combination of your driver FR and the baffle diffraction response add to the best summed response. Mostly you don't want to have any peaks in the diffraction FR hit at the same place(s) as any peaks in the driver FR. Troughs or valleys too but they tend not to be so bad on the ears.

Start with the tweeter as this will determine the placement of everything else. What I do is open 3 programs:

- Response Modeler to look at diffraction and combining the 2 files

- Sketchup to mock up the front baffle and driver positions

- XSim as a a tool to view and compare the combined files

So in Response Modeler, "Import FRD File to Modify", play with the diffraction down below, "Use Baffle Data from Below" back up top and then "Save Modified Result to FRD". Your sketch will help to give you your baffle dimensions and accurate driver positions and then you can compare results by displaying the new frd files in XSim.

That's a very quick instructional. Let me know if you need anything in more detail.

BTW, sometimes this can be really important and sometimes there isn't going to be a whole lot of differences. I'm going through the process myself and finding that your MTM in your tower falls into this latter category.

The goal is to figure out what combination of your driver FR and the baffle diffraction response add to the best summed response. Mostly you don't want to have any peaks in the diffraction FR hit at the same place(s) as any peaks in the driver FR. Troughs or valleys too but they tend not to be so bad on the ears.

Start with the tweeter as this will determine the placement of everything else. What I do is open 3 programs:

- Response Modeler to look at diffraction and combining the 2 files

- Sketchup to mock up the front baffle and driver positions

- XSim as a a tool to view and compare the combined files

So in Response Modeler, "Import FRD File to Modify", play with the diffraction down below, "Use Baffle Data from Below" back up top and then "Save Modified Result to FRD". Your sketch will help to give you your baffle dimensions and accurate driver positions and then you can compare results by displaying the new frd files in XSim.

That's a very quick instructional. Let me know if you need anything in more detail.

BTW, sometimes this can be really important and sometimes there isn't going to be a whole lot of differences. I'm going through the process myself and finding that your MTM in your tower falls into this latter category.

Thank you, I am starting to get the hang of this. Oddly there are a lot of Run-time errors in the Response Modeler which makes believe I need to re-download it. But for the steps you have said, it worked out fine there. So yeah I'm not seeing any significant peaks or dips in the FR with the baffle step included. Only a dip of around -3dB @ ~3kHz. Also a hump at 900Hz. Not to extreme though.

I am noticing how when the tweeter is offset horizontally by 3/4", then the response is more smooth. But it does not seem super significant, yet if it helps with the FR then seems like a worthy design change. Yet, Ill run it by my brother if he likes the look or not of that.

Wondering if you're seeing the same in the baffle responses.

I'm going to check this with the rears now as well.

I am noticing how when the tweeter is offset horizontally by 3/4", then the response is more smooth. But it does not seem super significant, yet if it helps with the FR then seems like a worthy design change. Yet, Ill run it by my brother if he likes the look or not of that.

Wondering if you're seeing the same in the baffle responses.

I'm going to check this with the rears now as well.

The run-time errors aren't odd, it's just Microsoft's idiocy. Newer versions of Office/Excel are not as compatible with the older Excel programs. In Response Modeler, I'm able to close the offending message and go back to the "main" tab for most of the errors. I have more trouble with the Boundary and Diffraction Simulator which is pretty much the same program. I wanted to have a closer look at something this afternoon and I had to go back to an older computer with an older version of Office to make it work properly.

Initially I thought offsetting the tweeter in the towers could help but on a closer 2nd examination, it makes virtually no difference. So don't worry about it. Makes no difference to the mids either and it never makes a difference to the woofers in a 3-way. Notice also how rounding and chamfering the cabinet edges will smooth the response as well.

Going through this process helps you to solidify your front baffle dimensions and the driver positions. From there you can proceed to finish up the final design of your cabinets knowing that you are not doing any harm to the FR..

Initially I thought offsetting the tweeter in the towers could help but on a closer 2nd examination, it makes virtually no difference. So don't worry about it. Makes no difference to the mids either and it never makes a difference to the woofers in a 3-way. Notice also how rounding and chamfering the cabinet edges will smooth the response as well.

Going through this process helps you to solidify your front baffle dimensions and the driver positions. From there you can proceed to finish up the final design of your cabinets knowing that you are not doing any harm to the FR..

Oh nice haha, whipping out an older computer with Windows XP (or close to) on it?

I noticed offsetting the tweeter helped in the dip around 3kHz, but not too much to really stand out. So you are right.

And yes! I did notice how chamfering the edges really made a difference especially in the higher frequencies to smooth out the response. I incorporated that into my design.

So, we can simulate how the baffle changes the FR for single drivers. But are there softwares out there that can take into account all the drivers to see how phase and FR changes in accordance to all of the drivers working at the same time?

Also, side question and thought.

I have my woofers in the towers at about 28L. Using Unibox that checks out as a good volume for them. Also with the LDC. But! Parts Express has a part in the RS150P-8A description that with the use of Bass Box 6 Pro, a recommended volume for the driver in a ported box is 7.6L @ 71Hz. Which is much smaller volume than the towers.

So, my question is; am I able to have different volumes / tuning frequencies for the different boxes? Because my brother would like smaller rears, so this would work great! But I do not know if the voicing would be screwed up if that happened. To me, I feel like it should not make a difference as long as the final FR of each box is relatively equal. So, Im wondering your thoughts on that.

I noticed offsetting the tweeter helped in the dip around 3kHz, but not too much to really stand out. So you are right.

And yes! I did notice how chamfering the edges really made a difference especially in the higher frequencies to smooth out the response. I incorporated that into my design.

So, we can simulate how the baffle changes the FR for single drivers. But are there softwares out there that can take into account all the drivers to see how phase and FR changes in accordance to all of the drivers working at the same time?

Also, side question and thought.

I have my woofers in the towers at about 28L. Using Unibox that checks out as a good volume for them. Also with the LDC. But! Parts Express has a part in the RS150P-8A description that with the use of Bass Box 6 Pro, a recommended volume for the driver in a ported box is 7.6L @ 71Hz. Which is much smaller volume than the towers.

So, my question is; am I able to have different volumes / tuning frequencies for the different boxes? Because my brother would like smaller rears, so this would work great! But I do not know if the voicing would be screwed up if that happened. To me, I feel like it should not make a difference as long as the final FR of each box is relatively equal. So, Im wondering your thoughts on that.

Yes, an ancient XP desktop that I keep sitting around just for this purpose. lol

In terms of helping all the drivers work together at the same time, that's the role of the xo. Xo programs like XSim, PCD and VituixCAD are all about getting the FR's and phase to work well together. As I said, the next step for me would be to do a xo simulation and make sure that the chosen drivers are happy enough working together but for you, it's better to complete the cabinet designs first. In fact though, I have simmed up your tower just to be sure and although it's not a driver combination that I would have chosen from the get go, the result looks decent enough but the xo takes just a little extra effort to make it so.

Re the RS150P-8A's, don't forget 28L net is for 2 of them. 7L is for one. Unibox suggests 10L for a single driver tuned to 56Hz. That will give the lowest F3 while keeping the response flat. You are free to change Vb and Fb to suit your needs and/or preferences. Generally though, I don't go much larger than the suggested box size because the quality of the response can suffer. Compare the step response in the "Vented Box" tab between 20L and 28L. You should see that the cone flops around more with the larger Vb before it comes back to rest. So not quite as clean. Now in this case the difference isn't huge so it probably won't matter much (kind of like offsetting the tweeter or not), but for me I'd want to have a good reason to do it. If you keep the same 56Hz tuning, you will get about a 1.3dB boost at 64Hz with 28L vs 20L. That's probably ok. However, if it was lower in frequency, I'd probably say it's not a good idea when you add room gain into the equation.

Now in terms of the woofers in both the surrounds and the CC, normally I would suggest going sealed and letting the sub(s) handle anything below 80Hz because you usually want those cabinets to be smaller and because a 2nd order rolloff (12dB/octave) in a sealed box blends better with the typical sub xo filter than with the steeper 4th order rolloff (24dB/octave) in a vented box. Unfortunately the RS150P's only go down to 105Hz sealed. Maybe that's a deal breaker, maybe it isn't. I've heard systems with the sub xo both higher and lower than 80Hz and I'm not sure it made that big a difference to me. Others will be adamant that the xo must be below 80Hz.

In any event, if you want to go vented, pick the combination of Vb and Fb that works for you. 7L tuned to about 60-65Hz works fine. Keep your eye on the port length though and make sure you can fit it in your box.

One other point about the surrounds. Have I mentioned this already - I can't remember? You might want to check with your brother if the surrounds will end up right against a wall. If so, it will make a difference in the xo design (6dB of baffle step compensation won't be necessary) and you may want to make the design thinner, ie. less deep, to make it look less obtrusive and that may help the FR too. In which case the front baffle would need to be taller, wider or both. And those are the variables you are working with when looking at baffle diffraction and then designing the cabinet. I'd be remiss to not also say though that with today's HT AVR's, the eq programs are automatically adjusting for FR aberrations anyways so you have some flexibility there. Again, the choices are up to you.

In terms of helping all the drivers work together at the same time, that's the role of the xo. Xo programs like XSim, PCD and VituixCAD are all about getting the FR's and phase to work well together. As I said, the next step for me would be to do a xo simulation and make sure that the chosen drivers are happy enough working together but for you, it's better to complete the cabinet designs first. In fact though, I have simmed up your tower just to be sure and although it's not a driver combination that I would have chosen from the get go, the result looks decent enough but the xo takes just a little extra effort to make it so.

Re the RS150P-8A's, don't forget 28L net is for 2 of them. 7L is for one. Unibox suggests 10L for a single driver tuned to 56Hz. That will give the lowest F3 while keeping the response flat. You are free to change Vb and Fb to suit your needs and/or preferences. Generally though, I don't go much larger than the suggested box size because the quality of the response can suffer. Compare the step response in the "Vented Box" tab between 20L and 28L. You should see that the cone flops around more with the larger Vb before it comes back to rest. So not quite as clean. Now in this case the difference isn't huge so it probably won't matter much (kind of like offsetting the tweeter or not), but for me I'd want to have a good reason to do it. If you keep the same 56Hz tuning, you will get about a 1.3dB boost at 64Hz with 28L vs 20L. That's probably ok. However, if it was lower in frequency, I'd probably say it's not a good idea when you add room gain into the equation.

Now in terms of the woofers in both the surrounds and the CC, normally I would suggest going sealed and letting the sub(s) handle anything below 80Hz because you usually want those cabinets to be smaller and because a 2nd order rolloff (12dB/octave) in a sealed box blends better with the typical sub xo filter than with the steeper 4th order rolloff (24dB/octave) in a vented box. Unfortunately the RS150P's only go down to 105Hz sealed. Maybe that's a deal breaker, maybe it isn't. I've heard systems with the sub xo both higher and lower than 80Hz and I'm not sure it made that big a difference to me. Others will be adamant that the xo must be below 80Hz.

In any event, if you want to go vented, pick the combination of Vb and Fb that works for you. 7L tuned to about 60-65Hz works fine. Keep your eye on the port length though and make sure you can fit it in your box.

One other point about the surrounds. Have I mentioned this already - I can't remember? You might want to check with your brother if the surrounds will end up right against a wall. If so, it will make a difference in the xo design (6dB of baffle step compensation won't be necessary) and you may want to make the design thinner, ie. less deep, to make it look less obtrusive and that may help the FR too. In which case the front baffle would need to be taller, wider or both. And those are the variables you are working with when looking at baffle diffraction and then designing the cabinet. I'd be remiss to not also say though that with today's HT AVR's, the eq programs are automatically adjusting for FR aberrations anyways so you have some flexibility there. Again, the choices are up to you.

Again, I greatly appreciate the extra effort that you are putting forth!

Yeah my initial thought for the surrounds and the CC was to go sealed. So, I dont know if I've asked this before, but why does the tuning need to be below 80Hz? So that the panel resonance is below the xo? Or is it that all the box tuning needs to be below the subwoofer xo point? And if so, why?

So while looking into doing vented for the surrounds, the port size is way too large for the design. With trying to get around 7.5L @ 60Hz. The port needs to be ~18in, which is way too long. But! what about a passive radiator? Which will yield a smaller box and not need to space for a port. I'll be reading up on them today and seeing if it is a worthy design choice. Or if I just go sealed. That is the question.

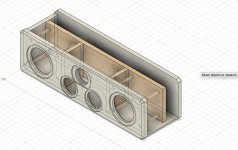

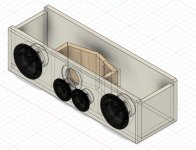

For now, I've been also working on the CC design, picture down below. But I got the woofers in their own sealed chamber of ~3.5L each, then the mids are in a volume of ~4L for both together. Then there is a 2" chamber in the back to fit the xo in. Also 1/2" dowel rods in the woofer chambers for extra bracing to help stiffen it up more to raise the panel resonance. No bracing in the mid chamber to lower to panel resonance.

Yet, with such small chambers, I don't really see the panel resonances changing too much. Its all gunna be pretty dang stiff.

Anyways, maybe the woofers will get a PR in the CC as well to lower the tuning. One big thing for me is making a product that someone is very happy with, and my brother has always expressed more interest into smaller boxes for the CC and the surrounds. He's good with where they are now, but I'd rather try to get them smaller if I can.

Yeah my initial thought for the surrounds and the CC was to go sealed. So, I dont know if I've asked this before, but why does the tuning need to be below 80Hz? So that the panel resonance is below the xo? Or is it that all the box tuning needs to be below the subwoofer xo point? And if so, why?

So while looking into doing vented for the surrounds, the port size is way too large for the design. With trying to get around 7.5L @ 60Hz. The port needs to be ~18in, which is way too long. But! what about a passive radiator? Which will yield a smaller box and not need to space for a port. I'll be reading up on them today and seeing if it is a worthy design choice. Or if I just go sealed. That is the question.

For now, I've been also working on the CC design, picture down below. But I got the woofers in their own sealed chamber of ~3.5L each, then the mids are in a volume of ~4L for both together. Then there is a 2" chamber in the back to fit the xo in. Also 1/2" dowel rods in the woofer chambers for extra bracing to help stiffen it up more to raise the panel resonance. No bracing in the mid chamber to lower to panel resonance.

Yet, with such small chambers, I don't really see the panel resonances changing too much. Its all gunna be pretty dang stiff.

Anyways, maybe the woofers will get a PR in the CC as well to lower the tuning. One big thing for me is making a product that someone is very happy with, and my brother has always expressed more interest into smaller boxes for the CC and the surrounds. He's good with where they are now, but I'd rather try to get them smaller if I can.

Attachments

80Hz is about localization. It's generally considered that above that frequency, we can locate the source and that below that frequency we can't. So that allows you to put the sub anywhere in the room if it's only doing 80Hz and below. If you go above that, keeping the subs up in the front of the room may help to mitigate any problems. My feeling is that going sealed with a xo to the subs at 100Hz will be ok, but I always hesitate to make suggestions in a forum context that step outside of the norm.

Looking at vented again, what is the port diameter that requires 18" of length? That's the 1st thing to check.

But here's the other thing you need to take into account. Unibox is showing you the port speed for the speaker if you are playing it full range. In reality, as a HT speaker the AVR is high passing it at 80Hz. So the driver is actually going to be producing less LF content than the sim is showing you which means the port air speed is going to be diminished which means that a smaller diameter port will suffice.

Again, trying to keep things simple I could just tell you that you can probably get away with a 1.5" port diameter here. If you wanted to see this for yourself, another section of Response Modeler allows you to produce filter curves. If you produce an LR2 (Linkwitz-Riley 2nd order) HP filter at 80Hz and save it, and then next import it into Unibox in the "Frequency Response Correction Filter" box and then check the little box to activate external active filter, then you can see the effects for yourself.

Don't forget you only need an F3 of 80Hz here so you could even go with something like 5L tuned to 70Hz with a 1.5" x 5" port. And ports can be bent if space is tight. Probably need to be on the front of the surrounds and the CC though.

Looking at vented again, what is the port diameter that requires 18" of length? That's the 1st thing to check.

But here's the other thing you need to take into account. Unibox is showing you the port speed for the speaker if you are playing it full range. In reality, as a HT speaker the AVR is high passing it at 80Hz. So the driver is actually going to be producing less LF content than the sim is showing you which means the port air speed is going to be diminished which means that a smaller diameter port will suffice.

Again, trying to keep things simple I could just tell you that you can probably get away with a 1.5" port diameter here. If you wanted to see this for yourself, another section of Response Modeler allows you to produce filter curves. If you produce an LR2 (Linkwitz-Riley 2nd order) HP filter at 80Hz and save it, and then next import it into Unibox in the "Frequency Response Correction Filter" box and then check the little box to activate external active filter, then you can see the effects for yourself.

Don't forget you only need an F3 of 80Hz here so you could even go with something like 5L tuned to 70Hz with a 1.5" x 5" port. And ports can be bent if space is tight. Probably need to be on the front of the surrounds and the CC though.

The port diameter I was using for an 18" length was 3". Which is the same as the towers.

So something I've been seeing is that with a sealed box at 6L, I can get the Fb down to 80.37Hz. Looking at the cone excursion, it crosses the threshold right at 80Hz. So, if there is a HP filter at 80Hz, then the excursion should not be peaked much, if at all.

To be aware, for Unibox I do have the parameters that I measured for Fs, Re, Qms, Qes, Qts, and Vas. So, the simulation might looks slightly different on Unibox for you.

But to me, it seems like I can get away with a 6L sealed box tuned to 80.37Hz, right?

Also, to clarify; you said before that I should strive for an Fb or 80Hz, but the last post you said F3 of 80Hz. Which one should I be looking at for the tuning, Fb Im assuming?

Also, wouldnt a 1.5" port be too small? I've read in multiple places that for a 6" speaker the minimum port diameter should be ~2". Even with the equations on pg. 69 of the LDC, my minimum port diameter should be 1.75"

So, to me a 2" port should be where I want to go. Which actually works out, a 2" port diameter tuned to 70Hz with a box volume of 7L gives me a port length of 5".

Also, are you suggesting front ported due to the fact that it might be too close to the wall if it were rear ported?

So something I've been seeing is that with a sealed box at 6L, I can get the Fb down to 80.37Hz. Looking at the cone excursion, it crosses the threshold right at 80Hz. So, if there is a HP filter at 80Hz, then the excursion should not be peaked much, if at all.

To be aware, for Unibox I do have the parameters that I measured for Fs, Re, Qms, Qes, Qts, and Vas. So, the simulation might looks slightly different on Unibox for you.

But to me, it seems like I can get away with a 6L sealed box tuned to 80.37Hz, right?

Also, to clarify; you said before that I should strive for an Fb or 80Hz, but the last post you said F3 of 80Hz. Which one should I be looking at for the tuning, Fb Im assuming?

Also, wouldnt a 1.5" port be too small? I've read in multiple places that for a 6" speaker the minimum port diameter should be ~2". Even with the equations on pg. 69 of the LDC, my minimum port diameter should be 1.75"

So, to me a 2" port should be where I want to go. Which actually works out, a 2" port diameter tuned to 70Hz with a box volume of 7L gives me a port length of 5".

Also, are you suggesting front ported due to the fact that it might be too close to the wall if it were rear ported?

Re the CC:

- if small is a priority, a separate chamber for the xo can be omitted, same applies for the other speakers too. It's a nice feature but it's not essential.

- the mids should be as close together as you can get them. Separated like that means that off-axis, phase differences will result in FR changes vs on-axis. That means though that the height will need to be increased.

- I think speakers sound better when their is enough depth to allow sufficient insulation to absorb the rear energy. And lower frequencies require more insulation. So I would go for more depth if you can.

- the dowels don't look like they are achieving anything.

- if small is a priority, a separate chamber for the xo can be omitted, same applies for the other speakers too. It's a nice feature but it's not essential.

- the mids should be as close together as you can get them. Separated like that means that off-axis, phase differences will result in FR changes vs on-axis. That means though that the height will need to be increased.

- I think speakers sound better when their is enough depth to allow sufficient insulation to absorb the rear energy. And lower frequencies require more insulation. So I would go for more depth if you can.

- the dowels don't look like they are achieving anything.

The port diameter I was using for an 18" length was 3". Which is the same as the towers.

Right, which has 2 woofers. The rears only have 1. Therefore port velocity will only be 1/2. Therefore port diameter can be reduced.

So something I've been seeing is that with a sealed box at 6L, I can get the Fb down to 80.37Hz. Looking at the cone excursion, it crosses the threshold right at 80Hz. So, if there is a HP filter at 80Hz, then the excursion should not be peaked much, if at all.

To be aware, for Unibox I do have the parameters that I measured for Fs, Re, Qms, Qes, Qts, and Vas. So, the simulation might looks slightly different on Unibox for you.

But to me, it seems like I can get away with a 6L sealed box tuned to 80.37Hz, right?

Fb is the box tuning frequency and only applies to vented boxes. Vb and Q are the important variables for a sealed box. Plus F3. Now if your measured TS parameters are showing an F3 of 80Hz sealed then no question go sealed and call it done. Much easier. (Well for the rears anyways. If size wasn't a limitation, I would go ported on the CC too to match the L&R) Plus the 80Hz HP filter will indeed ask for less cone excursion down at that frequency. LR2 HP at 80Hz will be another 6dB down at that frequency.

Also, to clarify; you said before that I should strive for an Fb or 80Hz, but the last post you said F3 of 80Hz. Which one should I be looking at for the tuning, Fb Im assuming?

For a vented box Fb is the tuning frequency but F3 is the -3dB point in the FR. That's what you should be more interested in - the actual FR. Sorry if I caused any confusion.

Also, wouldnt a 1.5" port be too small? I've read in multiple places that for a 6" speaker the minimum port diameter should be ~2". Even with the equations on pg. 69 of the LDC, my minimum port diameter should be 1.75"

So, to me a 2" port should be where I want to go. Which actually works out, a 2" port diameter tuned to 70Hz with a box volume of 7L gives me a port length of 5".

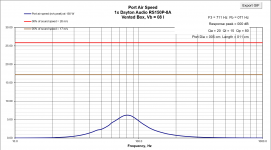

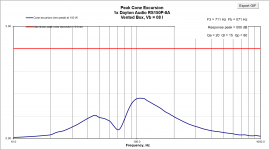

There is such a wide variability in any driver size that to state something as an absolute rule for them is mentally lazy. Imho. To be fair it may be true more frequently than not though. But in this case I was talking about what happens if you high pass the driver at 80Hz. Attached below, the 1st 3 pics are the RS150 in 5L tuned to 70Hz with 40W. F3 is 74Hz. Port is 1.5" x 5". The next 3 pics show the same alignment and power but with an LR2 HP filter at 80Hz. No good without the filter. Perfectly fine with the filter.

Also, are you suggesting front ported due to the fact that it might be too close to the wall if it were rear ported?

Exactly. So the front baffle dimensions would need to be large enough to accommodate it.

Attachments

-

VB PortAirSpeed Dayton RS150P-8A + filter.gif30.8 KB · Views: 29

VB PortAirSpeed Dayton RS150P-8A + filter.gif30.8 KB · Views: 29 -

VB Excursion Dayton RS150P-8A + filter.gif28.4 KB · Views: 197

VB Excursion Dayton RS150P-8A + filter.gif28.4 KB · Views: 197 -

VB Response Dayton RS150P-8A + filter.gif41.1 KB · Views: 200

VB Response Dayton RS150P-8A + filter.gif41.1 KB · Views: 200 -

VB PortAirSpeed Dayton RS150P-8A.gif32.9 KB · Views: 205

VB PortAirSpeed Dayton RS150P-8A.gif32.9 KB · Views: 205 -

VB Excursion Dayton RS150P-8A.gif31.3 KB · Views: 200

VB Excursion Dayton RS150P-8A.gif31.3 KB · Views: 200 -

VB Response Dayton RS150P-8A.gif42.3 KB · Views: 212

VB Response Dayton RS150P-8A.gif42.3 KB · Views: 212

Alright so I have got the surrounds done, taking everything I know into consideration.

First of all, my brother prefers the port in the back, and I told him that they would need to be away from a wall then. He ensured he would, so Im going with rear ported for the surrounds.

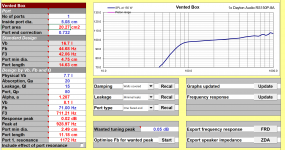

So, the surrounds have a net volume of 7.67L and is tuned to 71Hz. Unibox then suggested a 4.4in port with my choosing of a 2" diameter port. [Pic. 2]

I have applied the 80Hz HP filter to the woofer in Pic. 2, 3, 4, and 5.

I have also applied the FRD file from Dayton Audio in those responses.

While observing the effects from the baffle, it does not seem to add or subtract too much to make any substantial difference for a design change.

Then in Pic. 6 I have the baffle step FRD on the top for the DC28FS and then the FRD file from Dayton on the bottom. [Same goes for Pic. 5 for the RS150].

Wondering your thoughts. I will be looking into the CC now, I think I might be able to go sealed for that.

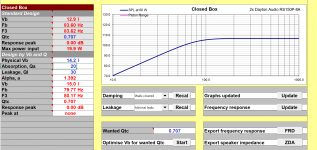

As a clarification, when I said that the RS150 was able to get down to 80Hz tuned in a sealed box. That was the Fb, but the F3 was still around 100Hz. But, I have found that I can get the F3 down to 83Hz in a 13.8L sealed box for the CC. Wondering if that's close enough to be acceptable or if I cannot do that, that it needs to be 80Hz or lower.

First of all, my brother prefers the port in the back, and I told him that they would need to be away from a wall then. He ensured he would, so Im going with rear ported for the surrounds.

So, the surrounds have a net volume of 7.67L and is tuned to 71Hz. Unibox then suggested a 4.4in port with my choosing of a 2" diameter port. [Pic. 2]

I have applied the 80Hz HP filter to the woofer in Pic. 2, 3, 4, and 5.

I have also applied the FRD file from Dayton Audio in those responses.

While observing the effects from the baffle, it does not seem to add or subtract too much to make any substantial difference for a design change.

Then in Pic. 6 I have the baffle step FRD on the top for the DC28FS and then the FRD file from Dayton on the bottom. [Same goes for Pic. 5 for the RS150].

Wondering your thoughts. I will be looking into the CC now, I think I might be able to go sealed for that.

As a clarification, when I said that the RS150 was able to get down to 80Hz tuned in a sealed box. That was the Fb, but the F3 was still around 100Hz. But, I have found that I can get the F3 down to 83Hz in a 13.8L sealed box for the CC. Wondering if that's close enough to be acceptable or if I cannot do that, that it needs to be 80Hz or lower.

Attachments

-

Rear Assembly Drawing v1.pdf168.2 KB · Views: 55

-

Surrounds with 11.25 from bottom.PNG112.3 KB · Views: 56

Surrounds with 11.25 from bottom.PNG112.3 KB · Views: 56 -

FR for baffle step and original.PNG116.7 KB · Views: 38

FR for baffle step and original.PNG116.7 KB · Views: 38 -

Port air speed with 80Hz HP and baffle step 6.5 from bottom.PNG69.6 KB · Views: 32

Port air speed with 80Hz HP and baffle step 6.5 from bottom.PNG69.6 KB · Views: 32 -

Excursion Capture with 80Hz HP and baffle step at 6.5 from bottom.PNG68.1 KB · Views: 38

Excursion Capture with 80Hz HP and baffle step at 6.5 from bottom.PNG68.1 KB · Views: 38 -

with 80Hz HP and baffle step and frd import.PNG148.4 KB · Views: 78

with 80Hz HP and baffle step and frd import.PNG148.4 KB · Views: 78 -

Screen Shot 2020-10-12 at 3.26.12 PM.jpg130.2 KB · Views: 208

Screen Shot 2020-10-12 at 3.26.12 PM.jpg130.2 KB · Views: 208

Okay, for the CC I have little time to explain my design fully, but wanted to put it out there for you to see.

The volume for the mid-chamber is 3.57L and the odd shape if to optimize for the volume of both chambers. Unibox says for a Qtc = 0.707 for the mids, I would want a V = 3.4L.

For the woofers, it says for a Qtc = 0.707, I should have a V = 14.6L. But, I have 14.18L net for the woofers right now. [Pic. 5]. And I was able to get the F3 to be around 80Hz for a sealed box!

I have also done the same as before for the drivers FR's. The original FRD is on the bottom and the baffle compensation FRD is on the top for Pic. 2,3, and 4.

Pic. 2 is for the tweeter

Pic. 3 is for the mids

Pic. 4 is for the woofers.

I was also able to squeeze the mids closer together.

Anyways, again just wondering your thoughts!

The volume for the mid-chamber is 3.57L and the odd shape if to optimize for the volume of both chambers. Unibox says for a Qtc = 0.707 for the mids, I would want a V = 3.4L.

For the woofers, it says for a Qtc = 0.707, I should have a V = 14.6L. But, I have 14.18L net for the woofers right now. [Pic. 5]. And I was able to get the F3 to be around 80Hz for a sealed box!

I have also done the same as before for the drivers FR's. The original FRD is on the bottom and the baffle compensation FRD is on the top for Pic. 2,3, and 4.

Pic. 2 is for the tweeter

Pic. 3 is for the mids

Pic. 4 is for the woofers.

I was also able to squeeze the mids closer together.

Anyways, again just wondering your thoughts!

Attachments

-

Center Assembly Drawing v2.pdf238.7 KB · Views: 34

-

Unibox Capture of woofers without 80Hz HP.PNG127.4 KB · Views: 44

Unibox Capture of woofers without 80Hz HP.PNG127.4 KB · Views: 44 -

Woofer FR with baffle comp and 80Hz HP.PNG117 KB · Views: 36

Woofer FR with baffle comp and 80Hz HP.PNG117 KB · Views: 36 -

Mids with baffle comp.PNG114.7 KB · Views: 40

Mids with baffle comp.PNG114.7 KB · Views: 40 -

Tweeter FR with baffle compensation.PNG115.6 KB · Views: 68

Tweeter FR with baffle compensation.PNG115.6 KB · Views: 68 -

Screen Shot 2020-10-12 at 5.52.10 PM.jpg186.7 KB · Views: 68

Screen Shot 2020-10-12 at 5.52.10 PM.jpg186.7 KB · Views: 68

Looks like you are well on your way to understanding the process involved in cabinet design. The devil they say though is always in the details. Let's start with the box modeling of the RS150P.

First I'm not quite sure exactly what files you imported but I've never seen a response quite like that in Unibox. Doesn't make any sense to me. Not a big worry in my mind though as it's a minor detail. On the other hand, the numbers I'm seeing in Unibox are so different than what the spec sheet lists, I have to question them. Dayton is known for being pretty accurate so I'm going to suggest that you go with those and leave your own measurements of the TS parameters for another time. For a beginner, measuring TS parameters is way, way down on my list of priorities, especially when the drivers specs are known to be reliable. And in the end, it's almost always best to tune the ports by ear anyways. And if anything, the real TS parameters usually raise the F3 and maybe Vb too, not the other way around.

In terms of the measurements you posted, I can't make sense of the RS150P's baffle diffraction response (in red) for either the rear or the CC? I also can't identify the FR of the CC tweeter as being the DC28FT? But I did just notice that you are using the RS100P instead of the regular RS100. As I said, the devil is in the details. Works both ways and I like the RS100P's response better too btw.

Suggestions for your cabs:

1. countersink all your drivers - your diagrams look like only the tweeters are flush with the front baffle. Definitely do it for the mids too and imo it looks better for the woofers too.

2. try not to position a driver (not including closed back tweeters) so close to a side or top or bottom wall. If you can. So the mids in the CC should be raised up from the bottom panel a bit. Maybe put the bottom of the faceplate 1" above the bottom of the speaker at minimum.

3. give yourself access to the insides of the speakers with removable backs. As a novice, being able to get in and out of the speaker is going to be an advantage.

4. way back on page 1, I suggested that you establish the maximum acceptable cabinet sizes. Flexibility can work for the front L&R and the rears but often the CC has some very specific restrictions. If you don't already, you need to know what these are. If there are any.

5. For the RS150P-8 I would go with:

CB - 5-8L for an F3 around 103Hz

VB - 7-10L with a 2" diameter port about 6 or 7" long

Depends on cabinet size constraints I guess.

6. For the RS100P-8 I would go with about 3-4L per driver sealed.

7. For the front baffles of the surrounds, I would go anywhere from about 7.5" x 13" to 8.5" x 15". For me the choice might depend on how deep I wanted the speaker to be and if I was going to go sealed or ported. If I went ported, I would probably tune it as low as it can go, ie. ~10L tuned to ~55Hz, so that if desired at any point in the future, it could be used as a stand alone speaker as well. In other words, the lower extension would be an advantage. I would probably also add a 2nd brace in there too.

8. For the front baffle of the CC, see the pic below. I could live with the woofers being sealed although I think ported would be better. Port(s) on the front would probably be best but that probably won't work for your brother. You could however use slot ports instead of the usual round variety. One on each side might work best on the front and would be relatively unobtrusive. Choose the depth of the speaker again according to driver alignment choices. I would probably take the mid chamber right to the back of the speaker. Again, allows access from the back. That would mean each woofer gets its own separate chamber as well. Maybe I'd angle the walls of the mid chamber inward a little too depending on box depth and Vb requirements. I might put the xo into the mid chamber too or break it up onto 2 boards and put each of them in a woofer chamber. Bracing strategy will depend on the final design's subpanel dimensions.

That's all I can think of right now. Hope that helps.

First I'm not quite sure exactly what files you imported but I've never seen a response quite like that in Unibox. Doesn't make any sense to me. Not a big worry in my mind though as it's a minor detail. On the other hand, the numbers I'm seeing in Unibox are so different than what the spec sheet lists, I have to question them. Dayton is known for being pretty accurate so I'm going to suggest that you go with those and leave your own measurements of the TS parameters for another time. For a beginner, measuring TS parameters is way, way down on my list of priorities, especially when the drivers specs are known to be reliable. And in the end, it's almost always best to tune the ports by ear anyways. And if anything, the real TS parameters usually raise the F3 and maybe Vb too, not the other way around.

In terms of the measurements you posted, I can't make sense of the RS150P's baffle diffraction response (in red) for either the rear or the CC? I also can't identify the FR of the CC tweeter as being the DC28FT? But I did just notice that you are using the RS100P instead of the regular RS100. As I said, the devil is in the details. Works both ways and I like the RS100P's response better too btw.

Suggestions for your cabs:

1. countersink all your drivers - your diagrams look like only the tweeters are flush with the front baffle. Definitely do it for the mids too and imo it looks better for the woofers too.

2. try not to position a driver (not including closed back tweeters) so close to a side or top or bottom wall. If you can. So the mids in the CC should be raised up from the bottom panel a bit. Maybe put the bottom of the faceplate 1" above the bottom of the speaker at minimum.

3. give yourself access to the insides of the speakers with removable backs. As a novice, being able to get in and out of the speaker is going to be an advantage.

4. way back on page 1, I suggested that you establish the maximum acceptable cabinet sizes. Flexibility can work for the front L&R and the rears but often the CC has some very specific restrictions. If you don't already, you need to know what these are. If there are any.

5. For the RS150P-8 I would go with:

CB - 5-8L for an F3 around 103Hz

VB - 7-10L with a 2" diameter port about 6 or 7" long

Depends on cabinet size constraints I guess.

6. For the RS100P-8 I would go with about 3-4L per driver sealed.

7. For the front baffles of the surrounds, I would go anywhere from about 7.5" x 13" to 8.5" x 15". For me the choice might depend on how deep I wanted the speaker to be and if I was going to go sealed or ported. If I went ported, I would probably tune it as low as it can go, ie. ~10L tuned to ~55Hz, so that if desired at any point in the future, it could be used as a stand alone speaker as well. In other words, the lower extension would be an advantage. I would probably also add a 2nd brace in there too.

8. For the front baffle of the CC, see the pic below. I could live with the woofers being sealed although I think ported would be better. Port(s) on the front would probably be best but that probably won't work for your brother. You could however use slot ports instead of the usual round variety. One on each side might work best on the front and would be relatively unobtrusive. Choose the depth of the speaker again according to driver alignment choices. I would probably take the mid chamber right to the back of the speaker. Again, allows access from the back. That would mean each woofer gets its own separate chamber as well. Maybe I'd angle the walls of the mid chamber inward a little too depending on box depth and Vb requirements. I might put the xo into the mid chamber too or break it up onto 2 boards and put each of them in a woofer chamber. Bracing strategy will depend on the final design's subpanel dimensions.

That's all I can think of right now. Hope that helps.

Attachments

Last edited:

The devil sure is in the details.

As far as the T/S parameters I measured, I was honestly surprised that they turned out to be different than the spec sheets. All the results from 6 of the RS150P's were consistent. But I do want to ensure you that I was closely following how to measure those parameters, cross referencing three books and using my own knowledge and experience in measuring. I have been doing measurements for four years now, all throughout college. Also, with my new oscilloscope and function generator, I am honestly pretty confident in my results. As I am a beginner in speaker design, but not in testing and measuring.

So that does have me in a pickle, because I was shocked how the results varied from the specs, yet I also do trust the specs as well since Dayton made the driver after all!

What about the FR graphs I sent do not make sense, if there is anything I can clarify for you please let me know!

I originally had all my drivers countersinked, yet I have a few reasons why I decided to only countersink the tweeters.

1. Since I do not have an extra baffle for the woofers to bring them out farther for time alignment, I decided to front-flush mount them to help with that. Even though I know that little bit of space (~0.18") is basically negligible, to me it's atleast something.

2. Even though I am experienced in wood working, one of the things I am not so experienced in is routing. So any chance to not have to route out more countersinks is a win to me.

3. My brother wants a dust cover over all the speakers, so the aesthetic value of the countersinks wont be noticed much at all. I was thinking on doing a dust cover with small magnets to keep it in place, just like Klipsch does to their speakers. But, for now, Im only focusing on the box design.

4. For the mids on the CC, being able to raise them over the tweeter frame is a win in my book in order to put the mids closer together and not sacrifice making the CC taller.

I think I said this before, but being able to get into the back of the speaker is important. My thought is putting a foam gasket around the back of the speakers and clamping or strapping the back panel onto the gaskets, for testing purposes. That way I dont need any special brackets or extra wood to make them removable after the testing checks out. After testing is good, I'd like to have the speaker completely sealed. To me, that more professional and anyway I can make these speakers be more (and look more) professional would be a win.

So I'm curious on how the front L/R and the rears have flexibility, yet the CC can have more specific restrictions?

Also, when you say to find the maximum cabinet sizes, I am guessing that is raising the box volume in Unibox until the results are undesirable. i.e A peak in the FB, or the excursion being too great, or the step response being too long?

So for the RS150P's, you suggest that I go with an F3 around 103Hz. Though I am a little confused, because before you said that with my measured T/S parameters in Unibox getting an F3 around 80Hz, that I should go with that. I have been hearing that I need to get these boxes for the woofers tuned below 80Hz, and this is achievable. So, should I focus on that and ditch a tuned box of ~100Hz?

So for the RS100P's in the towers we came to ~8.5L for the both of them. And that checks out in Unibox and makes sense for the amount of volume in the tower to be used. Yet, for the CC I am trying to make it as small as I can while of course also making it as good as I can. So, in Unibox when I press the button "Optimize Vb for wanted Qtc" with Qtc - 0.707, it tells me that the Vb would be 3.4L for both. And I have the damping to "Heavy Fill".

So, for me, I dont see a problem in the smaller volume for the RS100P's in the CC. I know before we talked about the RS100P's prefer a vented alignment and that it was "pretty much impossible to go too large". But for the CC, again, Id like to keep it smaller if I can.

I guess my main question is, do you see a problem with the mids being in a smaller box?

Furthermore, being able to have the surrounds be flexible if they were to be monitors at some point is a good idea. So, I will definitely look into what I can do to tune them even lower, like 55Hz that you suggested. And yeah I was also thinking about a second brace.

Im with you on a ported CC, but my brother did not like the look of a side port. But the slot ports are an interesting idea, yet they seem like they would be harder to design and incorporate into the design. I will see what I can do!

This does help @jReave, as always thank you for the help and suggestions! Your guidance has been very needed and so greatly appreciated. I would not be where I am today in these designs without this help. We are slowly, but surely, getting there!! Which is not mean slowly is bad, actually expected and needed in order to process all the information haha.

As far as the T/S parameters I measured, I was honestly surprised that they turned out to be different than the spec sheets. All the results from 6 of the RS150P's were consistent. But I do want to ensure you that I was closely following how to measure those parameters, cross referencing three books and using my own knowledge and experience in measuring. I have been doing measurements for four years now, all throughout college. Also, with my new oscilloscope and function generator, I am honestly pretty confident in my results. As I am a beginner in speaker design, but not in testing and measuring.

So that does have me in a pickle, because I was shocked how the results varied from the specs, yet I also do trust the specs as well since Dayton made the driver after all!

What about the FR graphs I sent do not make sense, if there is anything I can clarify for you please let me know!

I originally had all my drivers countersinked, yet I have a few reasons why I decided to only countersink the tweeters.

1. Since I do not have an extra baffle for the woofers to bring them out farther for time alignment, I decided to front-flush mount them to help with that. Even though I know that little bit of space (~0.18") is basically negligible, to me it's atleast something.

2. Even though I am experienced in wood working, one of the things I am not so experienced in is routing. So any chance to not have to route out more countersinks is a win to me.

3. My brother wants a dust cover over all the speakers, so the aesthetic value of the countersinks wont be noticed much at all. I was thinking on doing a dust cover with small magnets to keep it in place, just like Klipsch does to their speakers. But, for now, Im only focusing on the box design.

4. For the mids on the CC, being able to raise them over the tweeter frame is a win in my book in order to put the mids closer together and not sacrifice making the CC taller.

I think I said this before, but being able to get into the back of the speaker is important. My thought is putting a foam gasket around the back of the speakers and clamping or strapping the back panel onto the gaskets, for testing purposes. That way I dont need any special brackets or extra wood to make them removable after the testing checks out. After testing is good, I'd like to have the speaker completely sealed. To me, that more professional and anyway I can make these speakers be more (and look more) professional would be a win.

So I'm curious on how the front L/R and the rears have flexibility, yet the CC can have more specific restrictions?

Also, when you say to find the maximum cabinet sizes, I am guessing that is raising the box volume in Unibox until the results are undesirable. i.e A peak in the FB, or the excursion being too great, or the step response being too long?

So for the RS150P's, you suggest that I go with an F3 around 103Hz. Though I am a little confused, because before you said that with my measured T/S parameters in Unibox getting an F3 around 80Hz, that I should go with that. I have been hearing that I need to get these boxes for the woofers tuned below 80Hz, and this is achievable. So, should I focus on that and ditch a tuned box of ~100Hz?

So for the RS100P's in the towers we came to ~8.5L for the both of them. And that checks out in Unibox and makes sense for the amount of volume in the tower to be used. Yet, for the CC I am trying to make it as small as I can while of course also making it as good as I can. So, in Unibox when I press the button "Optimize Vb for wanted Qtc" with Qtc - 0.707, it tells me that the Vb would be 3.4L for both. And I have the damping to "Heavy Fill".

So, for me, I dont see a problem in the smaller volume for the RS100P's in the CC. I know before we talked about the RS100P's prefer a vented alignment and that it was "pretty much impossible to go too large". But for the CC, again, Id like to keep it smaller if I can.

I guess my main question is, do you see a problem with the mids being in a smaller box?

Furthermore, being able to have the surrounds be flexible if they were to be monitors at some point is a good idea. So, I will definitely look into what I can do to tune them even lower, like 55Hz that you suggested. And yeah I was also thinking about a second brace.

Im with you on a ported CC, but my brother did not like the look of a side port. But the slot ports are an interesting idea, yet they seem like they would be harder to design and incorporate into the design. I will see what I can do!

This does help @jReave, as always thank you for the help and suggestions! Your guidance has been very needed and so greatly appreciated. I would not be where I am today in these designs without this help. We are slowly, but surely, getting there!! Which is not mean slowly is bad, actually expected and needed in order to process all the information haha.

Re T/S parameters - I'm at a bit of a loss on what to tell you here. You're experience and the consistency in the data suggest valid results. But Dayton's reputation for spec accuracy and the fact that consistency could also mean you are doing the same thing wrong every time might suggest otherwise. The best thing to do would be to throw a driver into a test box and measure the results. That I'm afraid you don't have time for. I don't know.

So perhaps you can split the difference - for the RS150's in the front L&R and the rears, port them in about 12L per driver tuned to about 56Hz and then you can tune by ear. If your parameters are correct, leaving the port as is or shortening it a little should work. If Dayton's parameters are correct, a little LF peaking may be tolerable or a liter or 2 of something solid added to the woofer chambers will fix that.

For the CC, you could do the same as above or if size is a major factor, go sealed. If the F3 hits about 80Hz, then that will be perfect. If it only hits about 105Hz, it's not ideal but I think it's workable.

Re countersinking. Diffraction occurs at all sharp edges near a driver. Well, depending on what wavelengths we're talking about. So the small wavelengths of the tweeter will definitely 'see' the 1/4" flange of the mids. Not so much probably for the mid frequencies down at the woofer flanges. So it's an acoustical effect at HF's that I'm concerned about. But it's just a small detail. In the end, speaker quality can be all about the addition of many small little details, but speaker building is also about compromises based on your design goals. So decisions like these are up to you.

Phase alignment for non physically aligned drivers is achieved by the xo. So not countersinking them achieves no function re phase alignment.

Personally I find routering very easy. When I find something difficult, my approach is to very often do more of it, not to do less through avoidance. Practicing on scraps would be recommended first. But including grills negates any aesthetic detractions.

Nobody sees the backs of speakers. So I don't find screws back there to be a negative. But gluing the whole thing together is quite common so that's fine if that's your choice.

Re the CC - the lack of flexibility is about placement. Height restrictions because of the bottom of a screen. Height, width and/or depth restrictions because it needs to fit into the shelf/cubbyhole of the console type thingy the tv sits on. And so forth and so on. You kind of need to know if something like that is the case. If not, then you're left with the same flexibility as the other speakers.

Re CC mid chamber size - for HT, 1 of the most important things is dialog intelligibility. Or in other words, your CC. So in that respect getting the mids right in the CC is actually more important than in the L&R. And in my experience, the impression of a speaker's size is determined by its front baffle dimensions. Adding depth is often not noticed. Again, the extra volume and insulation and back wave absorption is a small improvement not a deal breaker. But they can add up. Again, your choice.

Slot ports are super simple - usually just the addition of an extra piece of wood depending on the length necessary and an opening in the baffle to accommodate it/them. May be a little harder to adjust their length though in terms of making any fine tuning adjustments.

Let's see if that helps move you forward.

So perhaps you can split the difference - for the RS150's in the front L&R and the rears, port them in about 12L per driver tuned to about 56Hz and then you can tune by ear. If your parameters are correct, leaving the port as is or shortening it a little should work. If Dayton's parameters are correct, a little LF peaking may be tolerable or a liter or 2 of something solid added to the woofer chambers will fix that.

For the CC, you could do the same as above or if size is a major factor, go sealed. If the F3 hits about 80Hz, then that will be perfect. If it only hits about 105Hz, it's not ideal but I think it's workable.

Re countersinking. Diffraction occurs at all sharp edges near a driver. Well, depending on what wavelengths we're talking about. So the small wavelengths of the tweeter will definitely 'see' the 1/4" flange of the mids. Not so much probably for the mid frequencies down at the woofer flanges. So it's an acoustical effect at HF's that I'm concerned about. But it's just a small detail. In the end, speaker quality can be all about the addition of many small little details, but speaker building is also about compromises based on your design goals. So decisions like these are up to you.

Phase alignment for non physically aligned drivers is achieved by the xo. So not countersinking them achieves no function re phase alignment.

Personally I find routering very easy. When I find something difficult, my approach is to very often do more of it, not to do less through avoidance. Practicing on scraps would be recommended first. But including grills negates any aesthetic detractions.

Nobody sees the backs of speakers. So I don't find screws back there to be a negative. But gluing the whole thing together is quite common so that's fine if that's your choice.

Re the CC - the lack of flexibility is about placement. Height restrictions because of the bottom of a screen. Height, width and/or depth restrictions because it needs to fit into the shelf/cubbyhole of the console type thingy the tv sits on. And so forth and so on. You kind of need to know if something like that is the case. If not, then you're left with the same flexibility as the other speakers.

Re CC mid chamber size - for HT, 1 of the most important things is dialog intelligibility. Or in other words, your CC. So in that respect getting the mids right in the CC is actually more important than in the L&R. And in my experience, the impression of a speaker's size is determined by its front baffle dimensions. Adding depth is often not noticed. Again, the extra volume and insulation and back wave absorption is a small improvement not a deal breaker. But they can add up. Again, your choice.

Slot ports are super simple - usually just the addition of an extra piece of wood depending on the length necessary and an opening in the baffle to accommodate it/them. May be a little harder to adjust their length though in terms of making any fine tuning adjustments.

Let's see if that helps move you forward.

And some additional thoughts:

- if the woofers are surface mounted, make sure that the depth of the grill frame is deep enough to accommodate for the flange thickness, the surround height and the max movement of the cone, probably about about 15 mm to be safe.

- maybe post the T/S parameters for the RS150 that you measured or screen grab the upper left corner of Unibox for the driver.

- concerning the proximity of drivers to cab walls - you want to make sure that the inside 45 degree chamfer that should be around the driver opening in the back of the baffle is not blocked by the nearest wall. See the pics below if that isn't clear. First pic is a surface mounted driver with the bottom panel too close. Second pic is flush mounted with the driver the correct minimum height above the bottom panel.

- and just out of curiosity, how is your brother going to know if the port is on the front or on the back if the speaker has the front covered with a grill?

- if the woofers are surface mounted, make sure that the depth of the grill frame is deep enough to accommodate for the flange thickness, the surround height and the max movement of the cone, probably about about 15 mm to be safe.

- maybe post the T/S parameters for the RS150 that you measured or screen grab the upper left corner of Unibox for the driver.

- concerning the proximity of drivers to cab walls - you want to make sure that the inside 45 degree chamfer that should be around the driver opening in the back of the baffle is not blocked by the nearest wall. See the pics below if that isn't clear. First pic is a surface mounted driver with the bottom panel too close. Second pic is flush mounted with the driver the correct minimum height above the bottom panel.

- and just out of curiosity, how is your brother going to know if the port is on the front or on the back if the speaker has the front covered with a grill?

Attachments

If you can get the side supports of the grille around the corner a bit, then no problem. Eg. maybe using a wire-frame support from the frame to hold the cloth out in front of the drivers.

If not, by keeping the grille frame supports small it can still be worth it to chamfer.

If not, by keeping the grille frame supports small it can still be worth it to chamfer.

- Home

- Loudspeakers

- Multi-Way

- First-Timer Home Theater Speaker Build