Those little Audax tweeters are quite a bargain, I’ve used them before as ‘ambience’ Super tweeters.

Yah, 4K is safe I’d say.

I think I ran just a small value cap that filled in over 12k or so.......love your work btw

The new ‘bread boards’ would look good on any kitchen counter!

Thanks @mountainman bob !

I think you mean this, if I understand correctly :

An externally hosted image should be here but it was not working when we last tested it.

For the moment, I did not do any finish on it, and I am hesitating between waxing, oiling... Well, something that would enhance the Beech wood grain.

A+!

Exactly!

Danish oil works really well on beech....brings out the depth.

Ah, OK : Danish Oil

A+!

Boiled linseed oil (BLO) looks great and gives a deep natural color. Use ultra fine steel wool or 800 grit sand paper to rub wet BLO on the wood on 2nd coat. Let each coat cure for a few days. The small particles of wood mixed with the linseed oil binder (same as oil paint used on paintings) have perfect self color blend and fill all little crevices with wood paste and binder. This gardens and gives a smooth satin like finish. Linseed oil can also be used on wooden surfaces used for cooking as it’s not toxic once cured and doesn’t have volatile organic compounds in it.

Here is example of BLO on Baltic birch ply.

Here is example of BLO on Baltic birch ply.

Last edited:

I have only tried it on maple, not beech, but iron nitrate dilute solution (test various dilutions on scrap of the same wood to see what concentration gives you a preferred effect) will (on maple), bring out a depth and 3 dimensionality of grain like no stain I have ever seen. You put the iron nitrate solution on, let it dry (it will look terrible, brownish/greenish, until the next step) and then heat it steadily (but not to scorching) with an electric heat gun, and the shade will turn to a warm ruddy medium brown with major accentuation of grain details. An oil finish over that (use an oil with little to no coloration) will make the grain delightfully vivid. Again, I have not tried it on anything other than maple, but on tiger-grain maple the effect is better than any other technique I've found or seen.

Not my projects, but a nice set of photos of the types of results the ferric nitrate creates:

Aqua Fortis for figured maple | Telecaster Guitar Forum

[use the real ferric nitrate crystals, which you can buy cheap and are relatively safe, there's tons of stuff on forums about 'aquafortis' and messing with nitric acid and steel wool, just skip the mess and hazard and get the ferric nitrate crystals on ebay, it's a fairly ordinary and not particularly hazardous lab chemical]

Not my projects, but a nice set of photos of the types of results the ferric nitrate creates:

Aqua Fortis for figured maple | Telecaster Guitar Forum

[use the real ferric nitrate crystals, which you can buy cheap and are relatively safe, there's tons of stuff on forums about 'aquafortis' and messing with nitric acid and steel wool, just skip the mess and hazard and get the ferric nitrate crystals on ebay, it's a fairly ordinary and not particularly hazardous lab chemical]

Last edited:

Thanks for the recipe, @kd1yt - I note it !

Yes, according to the link you posted, the results are amazing...

I have scrap sheets of the wood I used for the cabs so a test can be done.

For the moment, I'm working on the X-over, testing by ear different formulas, before going to meaurement and simulation, in the way "I heard this : why ?".

A+!

Yes, according to the link you posted, the results are amazing...

I have scrap sheets of the wood I used for the cabs so a test can be done.

For the moment, I'm working on the X-over, testing by ear different formulas, before going to meaurement and simulation, in the way "I heard this : why ?".

A+!

Beautiful work Tubelectron.

About the finish...

Since reading this article long time ago

Guitar Finishing Using Wiping Varnish

I had a great success completing many different projects, not just speakers.

Including my kitchen benchtops done 12 years ago.

You don't have to go to the extremes of applying 10 - 12 coats, for me 2-3 do just fine. But of course you can do as many as you like.

I never liked linseed oil, boiled or not. It has the tendency to go rancid, attracts mould and dries very slowly. Danish oil is mostly linseed oil with a few additives so I steer clear of it. Tung oil is great but it has its own problems.

About the finish...

Since reading this article long time ago

Guitar Finishing Using Wiping Varnish

I had a great success completing many different projects, not just speakers.

Including my kitchen benchtops done 12 years ago.

You don't have to go to the extremes of applying 10 - 12 coats, for me 2-3 do just fine. But of course you can do as many as you like.

I never liked linseed oil, boiled or not. It has the tendency to go rancid, attracts mould and dries very slowly. Danish oil is mostly linseed oil with a few additives so I steer clear of it. Tung oil is great but it has its own problems.

Thanks @Stanislav !

What you talk about is probably what we call in French le vernis au tampon, which is the utmost quality of finishing used in precious antique furniture.

Thanks for the link : this seems to be a simple method, where you go progressively, with patience. Perfect for me...

To be honest with you, Guys, I'm not very confident in my skills about achieving suitable finishes, being paint, coating, etc... Most of the time fronting failures and poor results...

My sole positive experience is buffing beeswax, sometimes preceeded by tinting...

Fortunately, I have some good friends that are skilled luthiers and woodworkers, so I wonder if I will not entrust them with the finish !

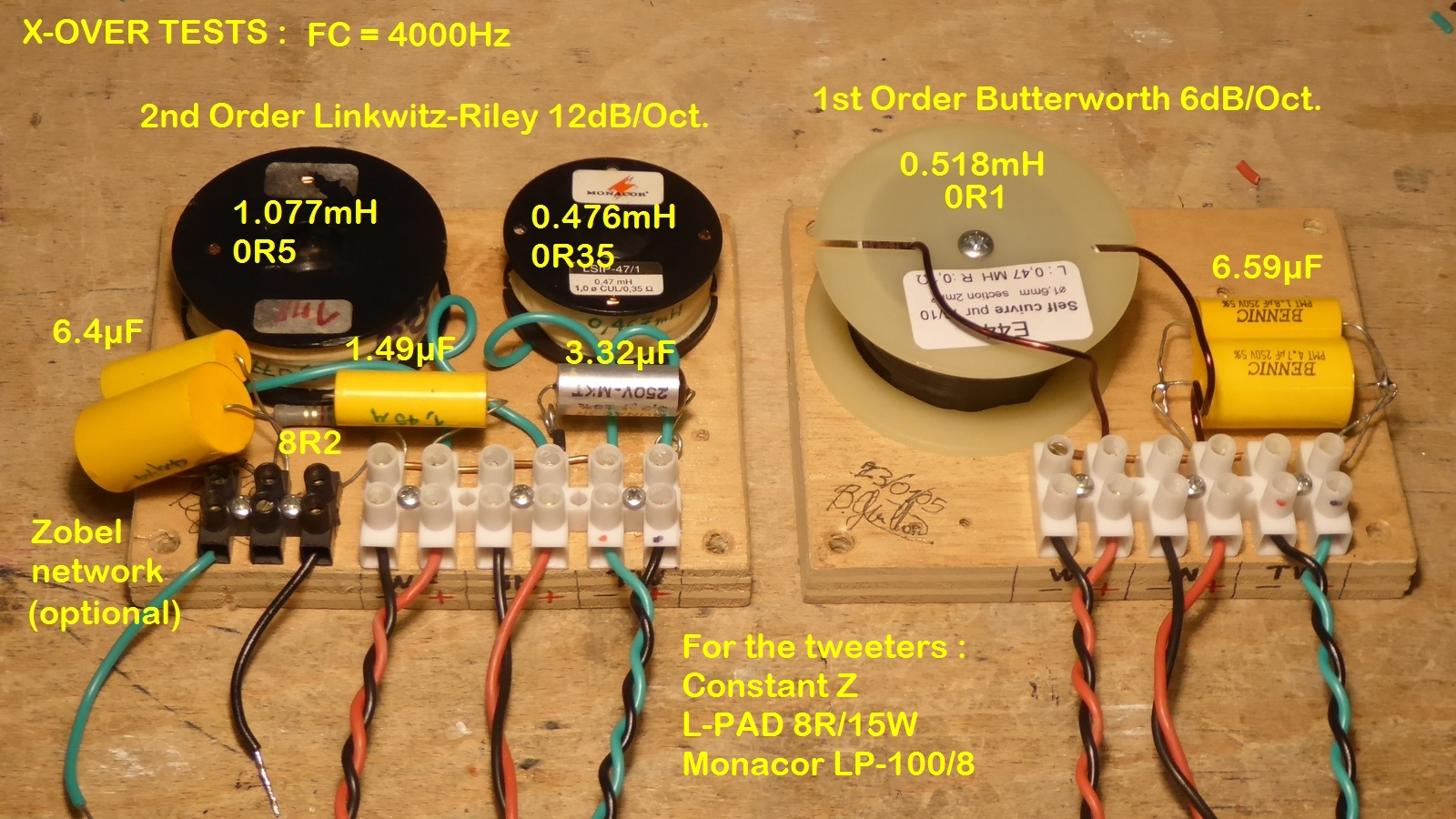

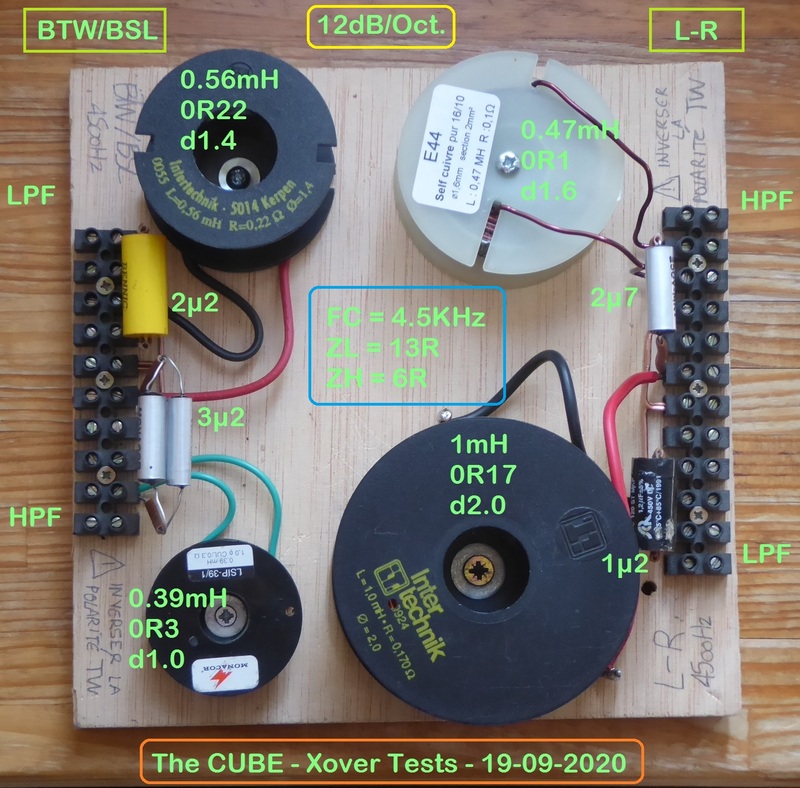

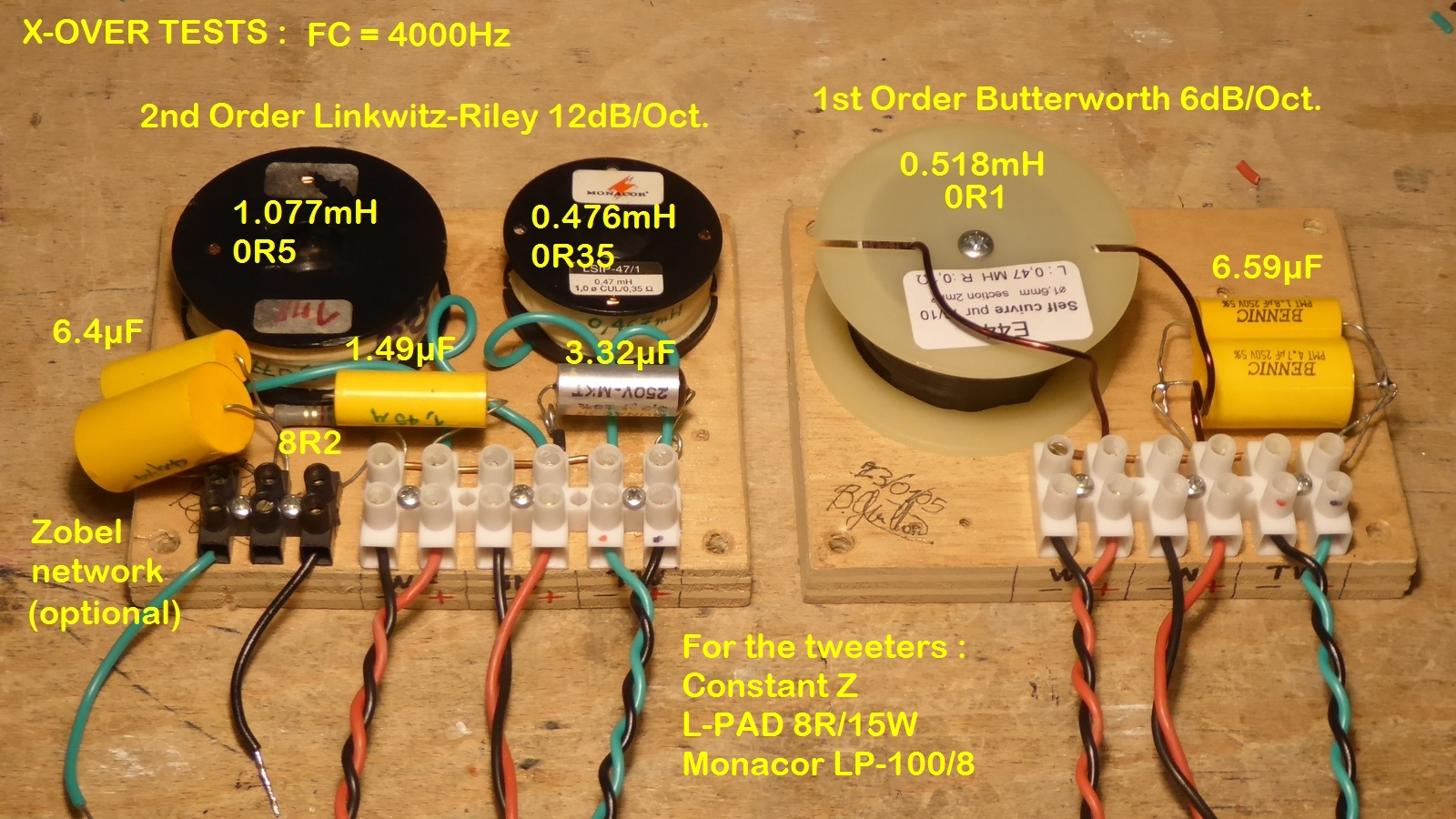

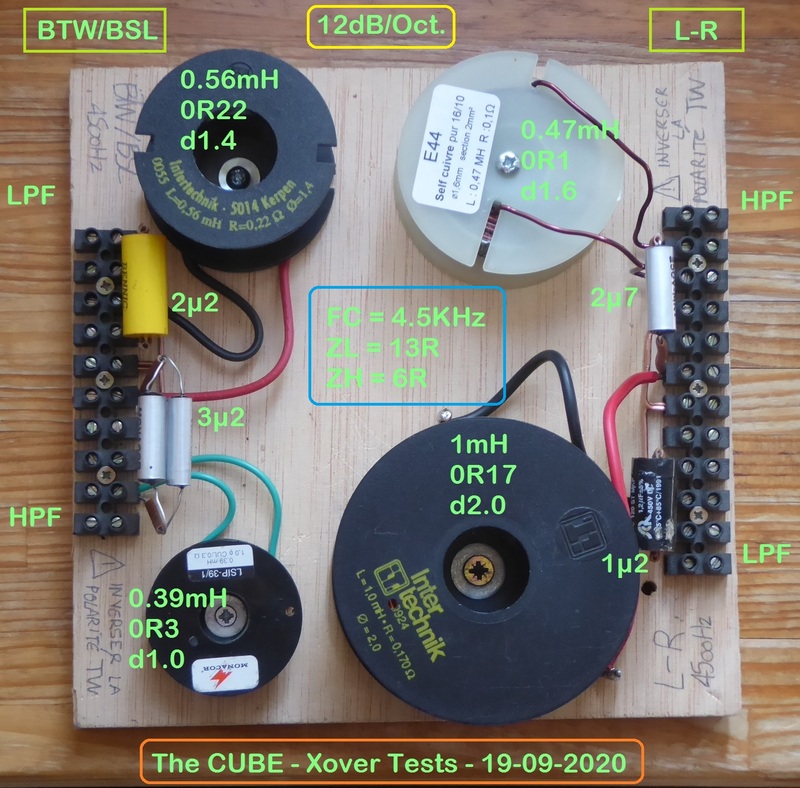

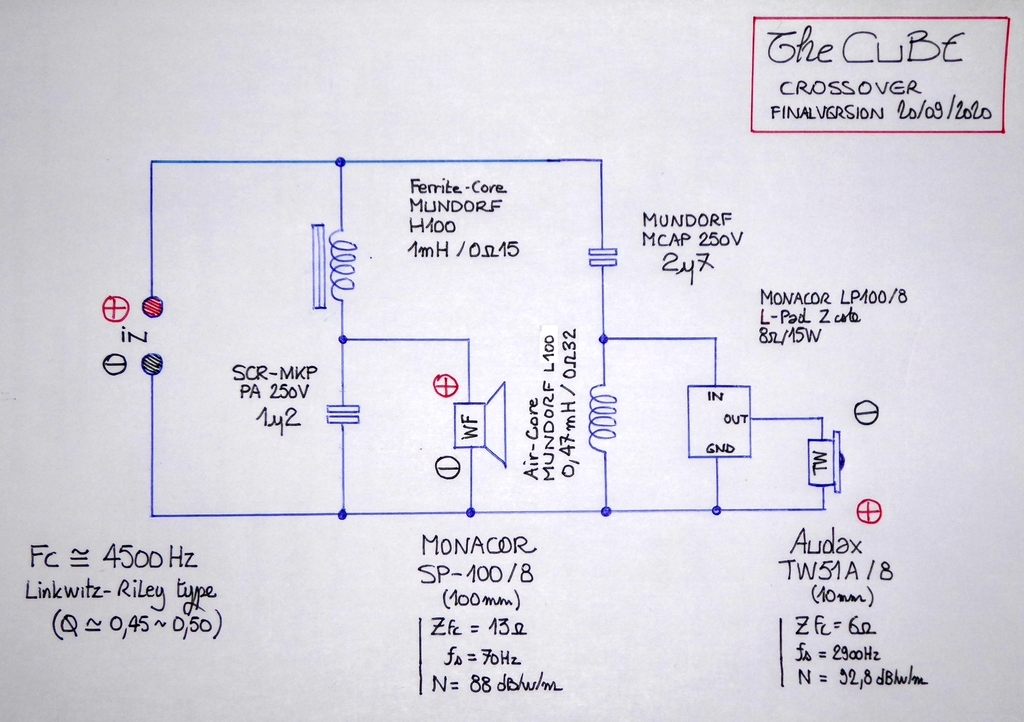

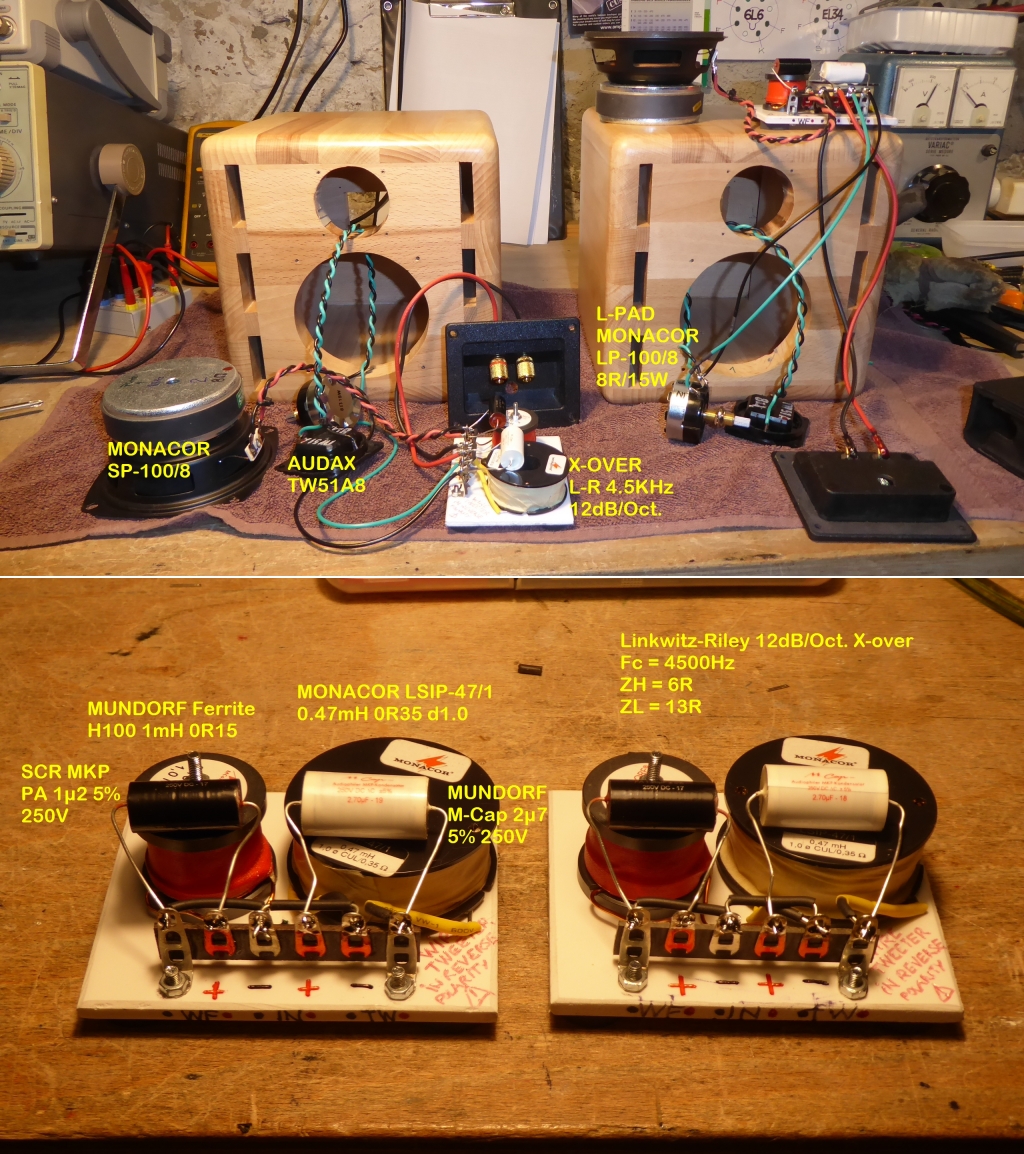

New crossover listening tests : 6 and 12dB/oct, FC = 4 and 4.5KHz, BTW / BSL / L-R / CHV...

I note my conclusions, and afterwards, I'll make measurements to understand, and check any correlations... Or not !

A+!

What you talk about is probably what we call in French le vernis au tampon, which is the utmost quality of finishing used in precious antique furniture.

Thanks for the link : this seems to be a simple method, where you go progressively, with patience. Perfect for me...

To be honest with you, Guys, I'm not very confident in my skills about achieving suitable finishes, being paint, coating, etc... Most of the time fronting failures and poor results...

My sole positive experience is buffing beeswax, sometimes preceeded by tinting...

Fortunately, I have some good friends that are skilled luthiers and woodworkers, so I wonder if I will not entrust them with the finish !

New crossover listening tests : 6 and 12dB/oct, FC = 4 and 4.5KHz, BTW / BSL / L-R / CHV...

I note my conclusions, and afterwards, I'll make measurements to understand, and check any correlations... Or not !

A+!

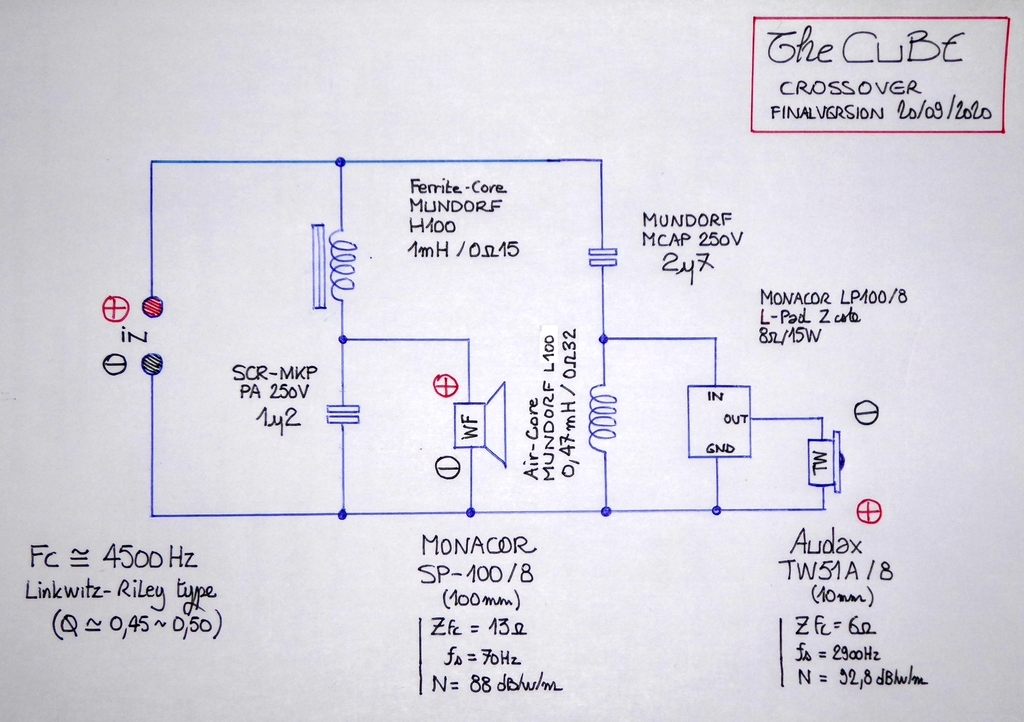

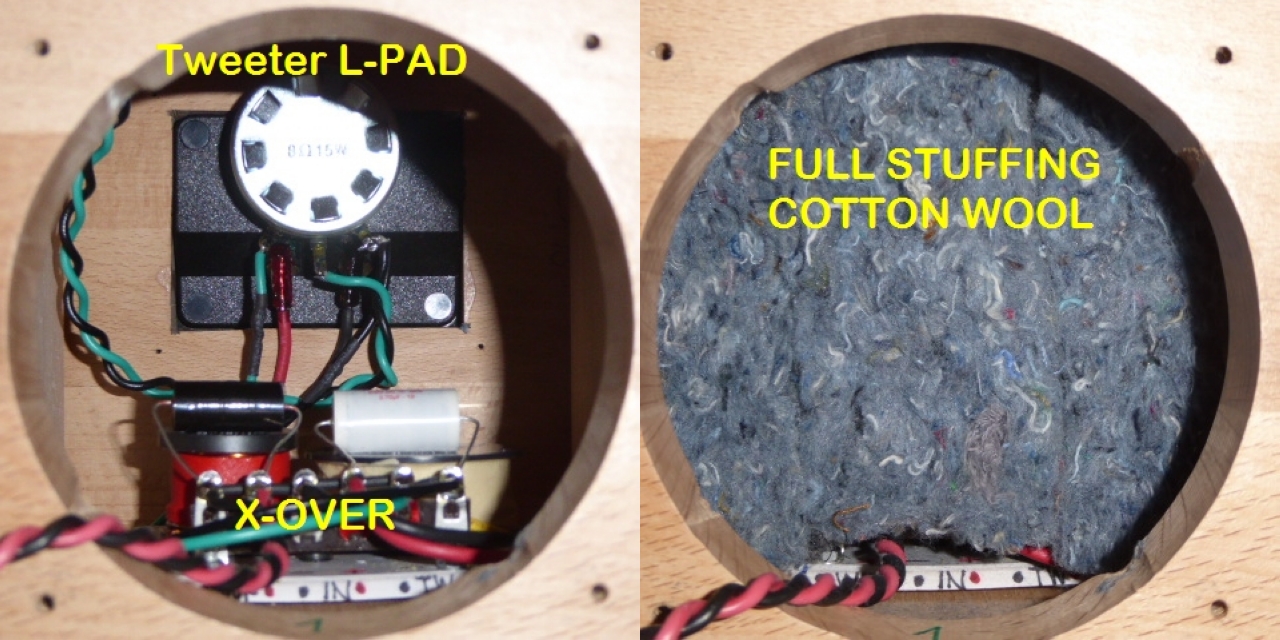

Brief sum-up about Xover listening tests...

Comparisons were done in mono (L+R), on a single enclosure.

1- Butterworth 6dB/oct @Fc=4000Hz

The medium register is put forward making even certain voices rather unpleasant, directivity lobes are obvious (at least at low distance circa 2m), intermodulation distortion appears at high volume. The Fc proved to be too low, as noticed in further tests.

2 - Butterworth HPF and Chebyschev LPF @Fc=4000Hz

The medium register is still forward, damping and Fc proved to be too low. Directivity is much less obvious, IMD is still noticeable at high level, due to a too low Fc.

3 - Linkwitz-Riley 12dB/oct @Fc=4500Hz

The increase of Fc to 4500Hz solves the forward midrange problem, alongwith the L-R type probably, giving now a nice tonal balance. Directivity problem and IMD are not noticeable, comparatively to tests N°1 and 2.

4 - Linkwitz-Riley tentative 6dB/oct @Fc=4500Hz (LPF=0.8mH, HPF=3.3µF)

The midrange is less put forward than in the BTW 6dB/oct. version, but directivity lobes and IMD are still here, although attenuated and so may be considered acceptable.

With the loudspeakers used here, and in my small listening room conditions, the best result is achieved by the L-R @4500Hz X-over of the test N°3.

I expected the L-R tentative at 6dB/oct 4500Hz of test N°4 to provide a dynamic, in-phase supplement, but nothing significant was heard over the directivity lobes and IMD drawbacks.

Tests about Zobel networks in Tests N°1 and 2 on the Woofer-Midrange showed only a small improvement in the hi-mid register correction.

So the X-over will be this, from the test N°3 :

I keep the different versions to check by some measurements if it goes in the direction of the listenings...

A+!

Comparisons were done in mono (L+R), on a single enclosure.

1- Butterworth 6dB/oct @Fc=4000Hz

The medium register is put forward making even certain voices rather unpleasant, directivity lobes are obvious (at least at low distance circa 2m), intermodulation distortion appears at high volume. The Fc proved to be too low, as noticed in further tests.

2 - Butterworth HPF and Chebyschev LPF @Fc=4000Hz

The medium register is still forward, damping and Fc proved to be too low. Directivity is much less obvious, IMD is still noticeable at high level, due to a too low Fc.

3 - Linkwitz-Riley 12dB/oct @Fc=4500Hz

The increase of Fc to 4500Hz solves the forward midrange problem, alongwith the L-R type probably, giving now a nice tonal balance. Directivity problem and IMD are not noticeable, comparatively to tests N°1 and 2.

4 - Linkwitz-Riley tentative 6dB/oct @Fc=4500Hz (LPF=0.8mH, HPF=3.3µF)

The midrange is less put forward than in the BTW 6dB/oct. version, but directivity lobes and IMD are still here, although attenuated and so may be considered acceptable.

With the loudspeakers used here, and in my small listening room conditions, the best result is achieved by the L-R @4500Hz X-over of the test N°3.

I expected the L-R tentative at 6dB/oct 4500Hz of test N°4 to provide a dynamic, in-phase supplement, but nothing significant was heard over the directivity lobes and IMD drawbacks.

Tests about Zobel networks in Tests N°1 and 2 on the Woofer-Midrange showed only a small improvement in the hi-mid register correction.

So the X-over will be this, from the test N°3 :

I keep the different versions to check by some measurements if it goes in the direction of the listenings...

A+!

Last edited:

The End of the CUBE Story approaches...

Oiling with SYNTILOR (local production) water-solvent incolor kitchen furniture and counter oil (3-layers) :

Wiring the definitive harness :

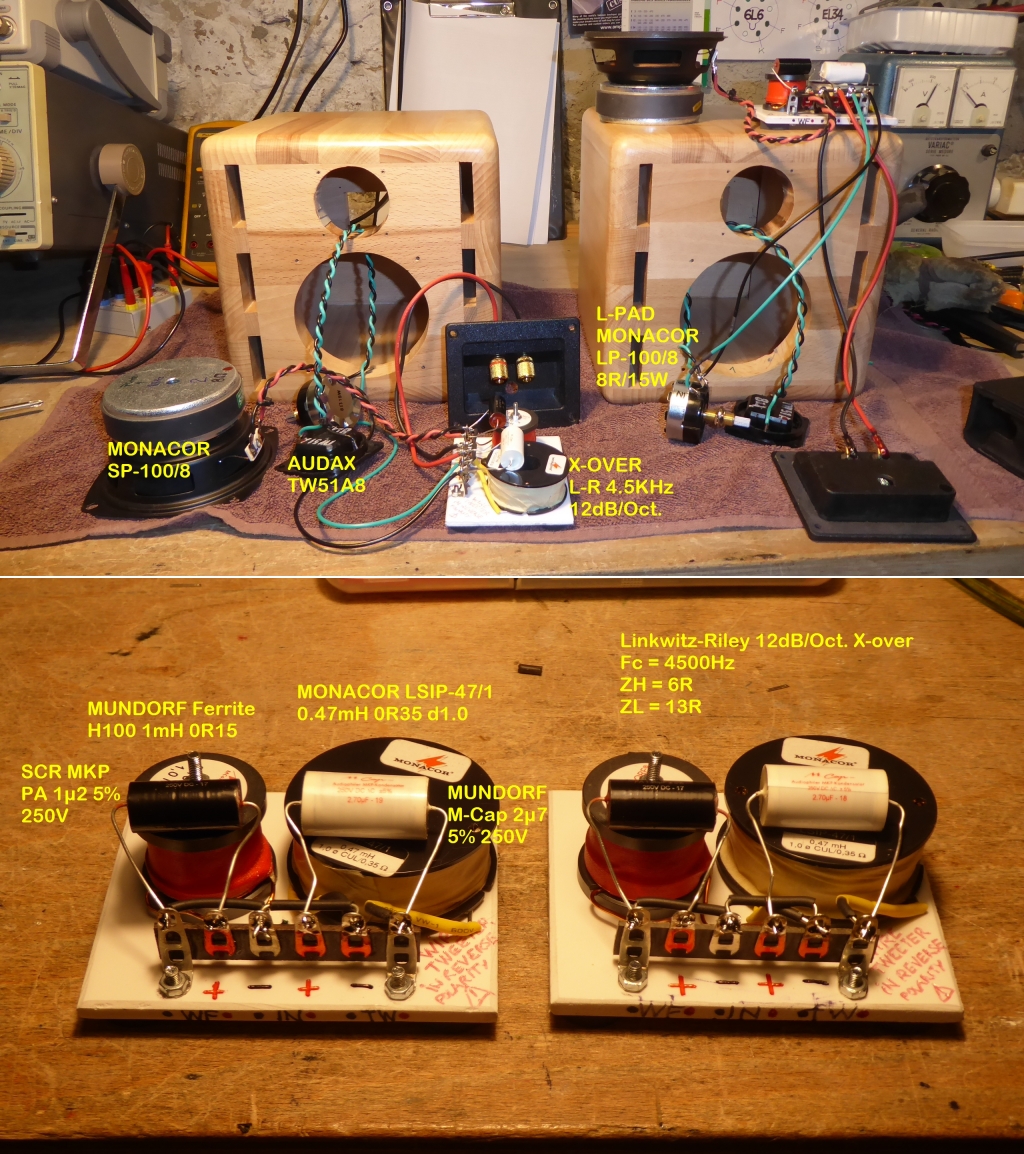

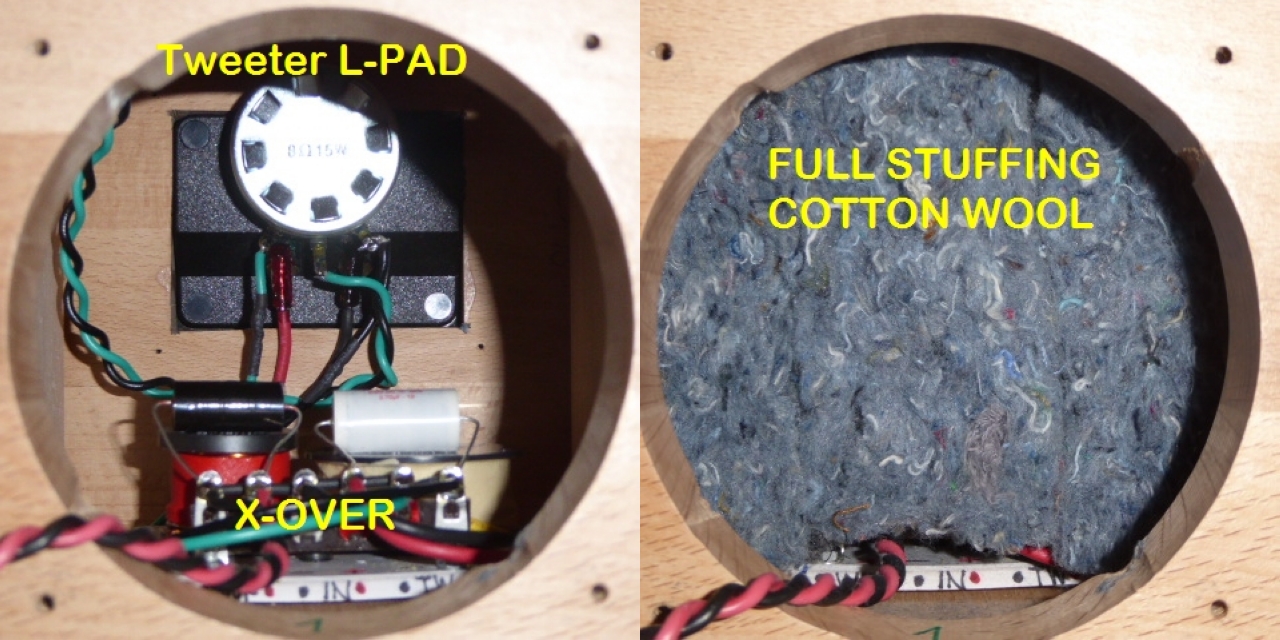

Installing the X-over and stuffing :

1st pics once finished :

Next steps : listening and measurements...

A+!

Oiling with SYNTILOR (local production) water-solvent incolor kitchen furniture and counter oil (3-layers) :

Wiring the definitive harness :

Installing the X-over and stuffing :

1st pics once finished :

Next steps : listening and measurements...

A+!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- The CUBE