The material and shape of the cone makes it suitable for being used higher up in frequency than straight-sided cones, due to less severe cone breakup which is also happening higher up in frequency compared to straight-sided cones.

The improved IMD performance simply comes form the fact that they are alsmost idling if used at home listening levels. A 8" Driver has to move four times as much for the same listening level as a 15".

Regards

Charles

The improved IMD performance simply comes form the fact that they are alsmost idling if used at home listening levels. A 8" Driver has to move four times as much for the same listening level as a 15".

Regards

Charles

Yes, the HW/SW is "DATS" V2It looks like first gen DATS software doesn't it? "DATS" in the title bar and not DATS v2 or v3.

..is that 700 liters total per loudspeaker?

350 liters per driver is not so great as far as bass reflex is concerned (for this driver), unless you are "tailoring" the freq. response for a specific result (..boosted bass and truncated lower freq. (sub-bass) response relative to the average.) That amount of volume isn't bad for a sealed design though.

The box is about 350L and has 2 woofers.

I attach some photos to show you the construction.

as for the response of the system, I had already understood that the response curve would lower first as regards the lower frequencies.

Regarding the "boosted bass" I had seen through a simulation with the SW Hornresp that between 30-100hz a sort of "peak" was formed.

By tuning the box to 25hz this "peak" disappeared.

Clearly the F3 of the system is less good.

In any case, what I aim for is a correct sound, even at the expense of a less extensive response towards the lower notes.

I do not reject any hypothesis, from the closed case, to the reflex with the two woofers, until eventually switch to a single woofer.

-take out ALL of the fiber.

Then listen again and take another Impedance measurement.

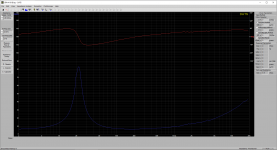

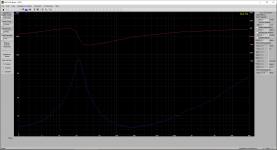

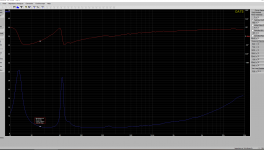

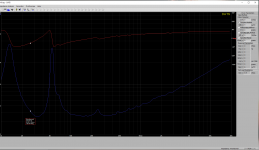

I removed all the internal fiber (what a sweat I did!); attached you can see the log and linear impedance curve.

As soon as I can I will try to listen again but now I don't like that peak around 250hz.

Thanks everyone for the help

Attachments

-

bass-parallel-no-fill-lin.png61.5 KB · Views: 228

bass-parallel-no-fill-lin.png61.5 KB · Views: 228 -

bass-parallel-no-fill-log.png63.2 KB · Views: 237

bass-parallel-no-fill-log.png63.2 KB · Views: 237 -

photo_2020-07-01_00-12-38.jpg57.6 KB · Views: 203

photo_2020-07-01_00-12-38.jpg57.6 KB · Views: 203 -

photo_2020-07-01_00-12-39.jpg75.1 KB · Views: 207

photo_2020-07-01_00-12-39.jpg75.1 KB · Views: 207 -

photo_2020-07-01_00-12-40.jpg43.8 KB · Views: 206

photo_2020-07-01_00-12-40.jpg43.8 KB · Views: 206 -

photo_2020-07-01_00-14-33.jpg78.1 KB · Views: 98

photo_2020-07-01_00-14-33.jpg78.1 KB · Views: 98 -

photo_2020-07-01_00-15-05.jpg43.8 KB · Views: 102

photo_2020-07-01_00-15-05.jpg43.8 KB · Views: 102 -

photo_2020-07-01_00-12-38 (3).jpg60.4 KB · Views: 97

photo_2020-07-01_00-12-38 (3).jpg60.4 KB · Views: 97 -

photo_2020-07-01_00-12-39 (2).jpg70.3 KB · Views: 84

photo_2020-07-01_00-12-39 (2).jpg70.3 KB · Views: 84

phase_accurate,

that optimistically extended frequency range embracing several heavy octaves will be muddled by resonant low frequency cone vibrations. Efficient systems are generally less well controlled, to be used at low listening levels, and there is no way to overcome this circumstance. Also, paralleled devices do not play in unison.

that optimistically extended frequency range embracing several heavy octaves will be muddled by resonant low frequency cone vibrations. Efficient systems are generally less well controlled, to be used at low listening levels, and there is no way to overcome this circumstance. Also, paralleled devices do not play in unison.

The box is about 350L and has 2 woofers.

By tuning the box to 25hz this "peak" disappeared.

IF the T/S parameters of each driver are close to GPA's product sheet then 25 Hz should be OK (..35 Hz isn't good). ..personally I'd like to see 600 liters and 20 Hz (assuming spec'ed T/S parameters).

How did it sound without the stuffing? (..the impedance is closer to what I'd expect without it, but still less in magnitude.)

Yes, the 250 Hz "bump" in impedance is worrying. With this design I'd be hanging (off of all interior surfaces) a 4 inch "sheet" of rockwool (mineral wool insulation) at about 3/4's of the way into the interior (from the drivers). The sheet at almost the same size of the rear cabinet panel. I'd also be thinking about a diagonal (relative to the side-panels) sheet of rockwool. (..and yes, I realize that it's more difficult to do so with the bracing.)

The foam you had wasn't particularly good for anything.

Last edited:

I'd also have an "open-frame" stand that elevates the cabinet by at least 5 inches, probably another frame that lifts the horn about the same (and angled-down as needed relative to the listener).

Finally, I'd want a good area carpet with good padding in front of the cabinets.

Finally, I'd want a good area carpet with good padding in front of the cabinets.

With regard to the impedance "bump" at about 250 Hz.

It's the driver. GPA's other drivers display similar problems (..the 12" 414 has it around 160 Hz), and yes it does generate higher levels of non-linear distortion.

Still, that shouldn't be a problem resulting in the subjective quality he's having problems with (..as others who have similar drivers would have noted).

Making sure the drivers are properly coupled to the cabinet with a good air-tight seal is of course a priority.

It's the driver. GPA's other drivers display similar problems (..the 12" 414 has it around 160 Hz), and yes it does generate higher levels of non-linear distortion.

Still, that shouldn't be a problem resulting in the subjective quality he's having problems with (..as others who have similar drivers would have noted).

Making sure the drivers are properly coupled to the cabinet with a good air-tight seal is of course a priority.

Last edited:

Loose sheets of mineral wools (or other flexible absorption materials) are prone to nonlinear behavior. The sheets will resonate themselves at certain frequencies. Locating the stuff in the center of the enclosure is a good suggestion, but it has to be braced.With this design I'd be hanging (off of all interior surfaces) a 4 inch "sheet" of rockwool (mineral wool insulation) at about 3/4's of the way into the interior (from the drivers).

..and yet it works well in this capacity.

It does not have to be *braced, a very basic "tie-down" (like 4 corners) suspending the "sheet" (..more of a panel really) does the job well. I should note that I've done this sort of suspension before with a very open-weave thin fiber poly net (..cheap fish net).

It will generate turbulence, but that turbulence interferes very little with the driver's motion because it's not well coupled to the driver (..not being on-wall).

It does need to be off of the walls though, or you start into mechanical motion losses of the driver. (..in this respect the sheet should be about 4" less than the interior of the rear panel on all sides: in total 8" less horizontally and 8" less vertically at a minimum.)

4 inch rockwool has decent absorption down to below 200 Hz (almost 150 Hz).

*moreover, frame or "window-pane" bracing common to supporting a rockwool panel creates turbulence that does interfere with the motion of the driver.

It does not have to be *braced, a very basic "tie-down" (like 4 corners) suspending the "sheet" (..more of a panel really) does the job well. I should note that I've done this sort of suspension before with a very open-weave thin fiber poly net (..cheap fish net).

It will generate turbulence, but that turbulence interferes very little with the driver's motion because it's not well coupled to the driver (..not being on-wall).

It does need to be off of the walls though, or you start into mechanical motion losses of the driver. (..in this respect the sheet should be about 4" less than the interior of the rear panel on all sides: in total 8" less horizontally and 8" less vertically at a minimum.)

4 inch rockwool has decent absorption down to below 200 Hz (almost 150 Hz).

*moreover, frame or "window-pane" bracing common to supporting a rockwool panel creates turbulence that does interfere with the motion of the driver.

Last edited:

I would tend to exclude the problem about the mechanical solidity between the front panel and the woofer, or the sealing between the woofer and the panel.

The woofer seat is obtained with a CNC machine and is "perfectly" planar.

Each bolt is inserted into the wood with a kind of "spider" that couples the bolt to the wood itself.

I attach a photo hoping it will be a little clearer.

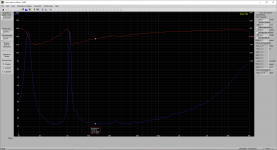

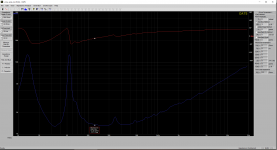

ScottG wrote that it could be the woofer itself that manifested that peak around 250hz, I tried to take a measurement of its impedance (free air) but I don't see peaks around that frequency.

Ah I also tried to take an impedance measurement with the two woofers in series, but the trend of the curve does not seem very different (clearly they are now 16 ohms nominal).

Attached are the graphics of the woofer and the curves of the woofers in the cabinet connected in series.

I don't know if I'm wrong but I'm more and more convinced that it's an internal resonance problem.

Do you think it would be a good idea to try to fix some pyramid-shaped wooden blocks on the bottom of the case (opposite side of the front panel) to try to break the wave front?

The idea of the panel suspended diagonally to me seems good to try!

The woofer seat is obtained with a CNC machine and is "perfectly" planar.

Each bolt is inserted into the wood with a kind of "spider" that couples the bolt to the wood itself.

I attach a photo hoping it will be a little clearer.

ScottG wrote that it could be the woofer itself that manifested that peak around 250hz, I tried to take a measurement of its impedance (free air) but I don't see peaks around that frequency.

Ah I also tried to take an impedance measurement with the two woofers in series, but the trend of the curve does not seem very different (clearly they are now 16 ohms nominal).

Attached are the graphics of the woofer and the curves of the woofers in the cabinet connected in series.

I don't know if I'm wrong but I'm more and more convinced that it's an internal resonance problem.

Do you think it would be a good idea to try to fix some pyramid-shaped wooden blocks on the bottom of the case (opposite side of the front panel) to try to break the wave front?

The idea of the panel suspended diagonally to me seems good to try!

Attachments

1st driver is really clean, 2nd has a very minor "bump" around 130 Hz.

The 414 (which is why I thought it would have been the driver's):

https://5e8772ee-a-62cb3a1a-s-sites...eqFikTBPdKM_p1eXQfmabRrzOAUGE=&attredirects=0

The 414 (which is why I thought it would have been the driver's):

https://5e8772ee-a-62cb3a1a-s-sites...eqFikTBPdKM_p1eXQfmabRrzOAUGE=&attredirects=0

I don't know if I'm wrong but I'm more and more convinced that it's an internal resonance problem.

Do you think it would be a good idea to try to fix some pyramid-shaped wooden blocks on the bottom of the case (opposite side of the front panel) to try to break the wave front?

The idea of the panel suspended diagonally to me seems good to try!

I think you are correct. You might try calculating your interior cabinet dimensions with this app:

Internal Standing Wave Calculator for Loudspeaker Enclosures and Rooms

Other than the double-sheet of 4" rockwool solution, you could put in blocks of honeycomb ceramic (break-up standing waves).

Another idea would be bag's of perlite. Blocks (or panels) of perlite should also work.

In all instance though, make sure the bags or blocks are off of the interior cabinet surfaces as much as possible. (..again, 4" minimum.)

The more stiff the fill, the lower the reduction in reflections though. ..and you could always do a combination of that rear interior panel + bag/blog to alter the standing wave AND reduce reflections.

Last edited:

I would tend to exclude the problem about the mechanical solidity between the front panel and the woofer, or the sealing between the woofer and the panel.

The woofer seat is obtained with a CNC machine and is "perfectly" planar.

Each bolt is inserted into the wood with a kind of "spider" that couples the bolt to the wood itself.

I attach a photo hoping it will be a little clearer.

Yeah, it looks good. I'd make sure that I caulked a seal around it for final installation though.

Note though that it COULD be the baffle itself.

That panel is large and there is a lot of stress/vibration put on it with the two drivers (..and the ports).

Sorry I did not specify that the two measures were referred to the same woofer.1st driver is really clean, 2nd has a very minor "bump" around 130 Hz.

The second was in log scale.

Other than the double-sheet of 4" rockwool solution, you could put in blocks of honeycomb ceramic (break-up standing waves).

Another idea would be bag's of perlite. Blocks (or panels) of perlite should also work.

In all instance though, make sure the bags or blocks are off of the interior cabinet surfaces as much as possible. (..again, 4" minimum.)

The more stiff the fill, the lower the reduction in reflections though. ..and you could always do a combination of that rear interior panel + bag/blog to alter the standing wave AND reduce reflections.

I think that by using perlite or honeycomb ceramic blocks or geometric shapes (wood) it is still going to "consume" internal volume, right?

There are now around 350L (2 woofers), up to what minimum internal volume do you think the cabinet can be used?

I think perlite or honeycomb ceramic blocks are more effective at higher frequencies, compared to the peak that I assume is responsible for the "dirty" sound (the one at 250hz).

On the other hand, geometric shapes to be effective perhaps should have very long sides to be effective at that frequency.

So in the end I don't think I can "steal" too many liters, and consequently the geometric shapes or the insertable material are limited.

Attached is a drawing of a hypothesis on the rear side of the box (pyramidal geometric shape).

Might it make sense to give it a try? (for me it would be the easiest one to make)

Could it make sense to do it on the sides of the box (left and right) instead of the back side?

If it doesn't make too much sense, I would immediately try the solution with rockwool panels (positioned in the way you explained to me).

Thanks a lot to everyone

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Bass reflex not so good