Thanks Toaster. 25 pounds on Ebay Peerless by Tymphany 830870 4" Inch PPB Cone HDS Woofer Speaker Loundspeaker | eBay

Is there any damping material in them?

Is there any damping material in them?

Last edited:

Last edited:

Anyone still peckish for some eggs? Another 5 pairs:

Pair of Egg Shaped Speaker Housings - Colour Red - (23) | eBay

I just asked them if they had the drivers but unfortunately not. Looks like this is where they could have come from: William George & Co | Music Studio Equipment - Liquidated Stock

I spent a long time looking at RS Components last night, deciding on tweeter protection caps before realising they don't do free delivery now unless you spend over 30 pounds. So I looked at the cheap polypropylene motor run caps on Ebay. A nugget of info I hope someone will find useful when Google coughs this up in years to come: Chinese CBB60 is polypropylene in resin in a plastic case, CBB65 is polypropylene in oil in a metal can. I bought a pair of 70uF (284Hz corner freq, well away from the crossover point) of the first type to avoid any potential leaks. CBB61 is polypropylene in resin in a square package. CD60 is electrolytic - avoid!

The Monacor DN-25N tweeters arrived today and they fit perfectly.

Pair of Egg Shaped Speaker Housings - Colour Red - (23) | eBay

I just asked them if they had the drivers but unfortunately not. Looks like this is where they could have come from: William George & Co | Music Studio Equipment - Liquidated Stock

I spent a long time looking at RS Components last night, deciding on tweeter protection caps before realising they don't do free delivery now unless you spend over 30 pounds. So I looked at the cheap polypropylene motor run caps on Ebay. A nugget of info I hope someone will find useful when Google coughs this up in years to come: Chinese CBB60 is polypropylene in resin in a plastic case, CBB65 is polypropylene in oil in a metal can. I bought a pair of 70uF (284Hz corner freq, well away from the crossover point) of the first type to avoid any potential leaks. CBB61 is polypropylene in resin in a square package. CD60 is electrolytic - avoid!

The Monacor DN-25N tweeters arrived today and they fit perfectly.

Last edited:

Hey chopchop, thanks for the heads up on these! Decided to go for a pair to do for my son's 18th birthday.

Descriptions say it has a 3khz passive crossover. Don't suppose anyone has a schematic please?

Cheers!

I think they have put the passive crossovers in the amp box. Manual says "OUTPUTS The speaker connectors are industry standard 4 way Speakons with unique (foolproof) polarity alignment."

If there's a schematic around or if someone like Toaster opens up their amp box we'd know what Munro used. Otherwise it's a job for the crossover experts on here! I've tested the DT-25N tweeters with my Visaton FR10s and 3k does seem right (with a Behringer active crossover), I can normally run my other tweeters at about 2 or 2 and a bit but these poke out slightly when run lower.

I think there's plenty of room in the egg for a passive crossover, accessed through the woofer hole. Having said that, those 70uF "motor run" tweeter protection caps (for active) I bought are massive, I might buy some smaller ones.

My MSH-115 mids have arrived. I think they will fit but it will take a lot of careful routing work to make an MDF/ply adapter plate. For a quiet life get the Peerless woofer!

Quite a few complete Egg systems on Ebay, maybe more bankrupt stock. Looks like the rubber stands don't get on with the rubbery paint finish on the eggs. I've got two stainless steel cat bowls from my deceased cat that I think will make reasonable egg cups, maybe with some padding.

Thanks chopchop!

I received the DT-25N's yesterday and hopefully should be receiving the Peerless 830870's this afternoon with the enclosures following on later this week.

I haven't got to finish these for a couple of months so fortunately plenty of time to measure and play around if schematics aren't available.

I'm not sure what I'll do about the stands yet. I'll wait and see once I receive the enclosures. Hoping to make something that can be bolted on, rather than just sitting the speakers on, but still allow for some adjustment for vertical tilt somehow.

All good fun!!

I received the DT-25N's yesterday and hopefully should be receiving the Peerless 830870's this afternoon with the enclosures following on later this week.

I haven't got to finish these for a couple of months so fortunately plenty of time to measure and play around if schematics aren't available.

I'm not sure what I'll do about the stands yet. I'll wait and see once I receive the enclosures. Hoping to make something that can be bolted on, rather than just sitting the speakers on, but still allow for some adjustment for vertical tilt somehow.

All good fun!!

chopchop just see what you started...

I've got myself a pair too. Not sure I'm a fan of the rubbery paint. I like the idea but I've seen so many things done in it get all sticky with age. Might consider a different paint.

Where do we think the crossover is located? I'm thinking it must be in the amp just because they are using 4-pole speaker connectors.This amp might make a good pairing given the DSP & 4 channels for an active crossover.

Given that internal reflections should be minimised I'm considering just lining it with 5-6mm felt. Will be fun to cut and glue though. Actually I have some lambs wool maybe some spray glue on the inside and press it against the walls might work although it would not be as dense as felt.

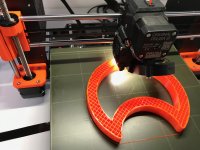

While I'm waiting for parts I've been designing a pair of egg cups. For now they are in a hard PETG for prototyping but I might look at a flexible filament although I have never printed in that as it might offer some damping and stop the speakers sliding around.

I've got myself a pair too. Not sure I'm a fan of the rubbery paint. I like the idea but I've seen so many things done in it get all sticky with age. Might consider a different paint.

Where do we think the crossover is located? I'm thinking it must be in the amp just because they are using 4-pole speaker connectors.This amp might make a good pairing given the DSP & 4 channels for an active crossover.

Given that internal reflections should be minimised I'm considering just lining it with 5-6mm felt. Will be fun to cut and glue though. Actually I have some lambs wool maybe some spray glue on the inside and press it against the walls might work although it would not be as dense as felt.

While I'm waiting for parts I've been designing a pair of egg cups. For now they are in a hard PETG for prototyping but I might look at a flexible filament although I have never printed in that as it might offer some damping and stop the speakers sliding around.

Attachments

Last edited:

Ah, I didn't realise they were soft coated. I'll be repainting then for the same reason, it's a dust magnet, lol!

I've got mixed impressions from reviews regarding crossover. Most give the impression it's handled within the amp but one or two have said it's mounted within the cabinet?

Nice idea with the stand!

I've got mixed impressions from reviews regarding crossover. Most give the impression it's handled within the amp but one or two have said it's mounted within the cabinet?

Nice idea with the stand!

That stand looks great!

Yes, I'd say the crossover is in the amp and 4 wires going to the drivers per side. They did that with the Egg 150s too, except it was an amp per driver instead of an amp and a passive crossover. The Egg 150s also have an LED in them, so they must need 6 connections. Speakons can be 2, 4 and 8 way, so maybe they just used 6 on an 8 way.

The rubbery paint on these seems alright, no sign of stickiness yet. I do agree, it can generally be a problem but these are British made so maybe they have decent paint on them! Inside there's a sticker with a manufacturing date of 2015 so that's 5 years with no stickiness yet. Maybe they've been kept in ideal conditions though. Claims of Tecni-form's superior plastic painting here tecni-form.com | Finishes

Yes, I'd say the crossover is in the amp and 4 wires going to the drivers per side. They did that with the Egg 150s too, except it was an amp per driver instead of an amp and a passive crossover. The Egg 150s also have an LED in them, so they must need 6 connections. Speakons can be 2, 4 and 8 way, so maybe they just used 6 on an 8 way.

The rubbery paint on these seems alright, no sign of stickiness yet. I do agree, it can generally be a problem but these are British made so maybe they have decent paint on them! Inside there's a sticker with a manufacturing date of 2015 so that's 5 years with no stickiness yet. Maybe they've been kept in ideal conditions though. Claims of Tecni-form's superior plastic painting here tecni-form.com | Finishes

I was considering a 3D egg speaker but with my printers print bed dimensions the enclosure would be limited. Then this thread came up.

The stand was the best I could fathom from the pictures and my limited 3D CAD skills. The Egg does slip and slide so I have ordered some TPU and will see how my first flexible print comes out. Hopefully there will be some news later in the week.

The stand was the best I could fathom from the pictures and my limited 3D CAD skills. The Egg does slip and slide so I have ordered some TPU and will see how my first flexible print comes out. Hopefully there will be some news later in the week.

Cheers, I just printed it with what was loaded on the printer at the time, Prusa Orange. Filament wise printing is CHEEP its just very time consuming. These were printed in draft mode and took 5.5 hours each. It would have been a 13hr print if it were a quality job. I'm led to belive when using TPU it is better to go slower so we will see.

For now I have some stands to work with and stop the Eggs from rolling around. After all I would not like to break them, that really would be the last yoke.

For now I have some stands to work with and stop the Eggs from rolling around. After all I would not like to break them, that really would be the last yoke.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Egg-closures