You should get 10kg of Swedag DG-A2 for trying out CLD.

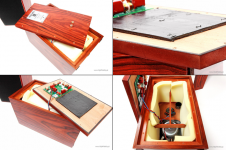

Here's also an interesting (and expired) patent (US7270215B2) you may want to check out.

Here's also an interesting (and expired) patent (US7270215B2) you may want to check out.

cool experiments.

While not being easiest panels to work with, you should consider in your test these : OSB and also chip board. Bamboo ply for wood floor or kitchen table are said to give good result as well.

A bit of topic : I have considered the polystyren 40 mm thick panels for floor and wall. It's very cheap and easy to transport. Need a little imagination for the cuttings though : hot metalic wire acting as a resistor to be heated, or fine saws with round wire (for ceramic for instance), harder being to make the recess behind the driver to let it breath.

While not being easiest panels to work with, you should consider in your test these : OSB and also chip board. Bamboo ply for wood floor or kitchen table are said to give good result as well.

A bit of topic : I have considered the polystyren 40 mm thick panels for floor and wall. It's very cheap and easy to transport. Need a little imagination for the cuttings though : hot metalic wire acting as a resistor to be heated, or fine saws with round wire (for ceramic for instance), harder being to make the recess behind the driver to let it breath.

Interesting. Know of a US source?

Basotect for damping BR-cabinet?!

For example:

100 BULK PACK Magic Sponge Eraser Melamine Cleaning Foam 3/4" Thick Ohio eBayer 656841720791 | eBay

Wait 3 weeks and half the price.

100 pcs/lot Melamine Sponge Magic Sponge Eraser Kitchen Melamine Sponge Cleaner Cleaning Sponge for Office Bathroom|nano sponge|magic spongemelamine sponge - AliExpress

Last edited:

cork with rubber has one of the best Young Modulus for damping but not structural hardness enough for a bafle or a cabinet, however why not as the external layer of a front baflre. We are off topic, augerpro can not test all,

It is good enough he is testing the most common wood for loudspeakers cabinets.

It is good enough he is testing the most common wood for loudspeakers cabinets.

I think it's good to stick to things that are known to work. Things that externally line the front baffle don't do much absorption to the waves, since absorption happens normal to the wave.

Rigid with high damping is the ideal cabinet spec. Good to test different ply, MDF, and other rigid cabinet materials. Then structural damping in the form of CLD, such as sikabond, sikabond + microspheres, and other viscoelastic materials. Then internal wave damping like fiberglass, cotton, rockwool, etc.

At least that's my .02

Rigid with high damping is the ideal cabinet spec. Good to test different ply, MDF, and other rigid cabinet materials. Then structural damping in the form of CLD, such as sikabond, sikabond + microspheres, and other viscoelastic materials. Then internal wave damping like fiberglass, cotton, rockwool, etc.

At least that's my .02

Last edited:

Yest but expensive in relation to the spirit of the thread. At least without massive contribution and time spent. Most of diyers use Mdf or Ply, for the courageous some veneering permits more choice that often stop with any ply wood on hands or MDF, rarely chip (alas) or osb (alas bis).

There is a a masive thread already at Diyaudio, believe the spirit of this thread is just about testing the most common solutions if I understood.

There is a a masive thread already at Diyaudio, believe the spirit of this thread is just about testing the most common solutions if I understood.

I definitely want to get into more interesting materials and methods. First I need to lay down a foundation of well known methods first.

Having changed jobs at a most inopportune time ended with me in the unemployment line in April. So I had planned on starting a gofundme, but thought I'd supply one round of data first so people can decide if it is worth while or not.

Having changed jobs at a most inopportune time ended with me in the unemployment line in April. So I had planned on starting a gofundme, but thought I'd supply one round of data first so people can decide if it is worth while or not.

Hey, corck should be verry cool material to smooth the edges with a slow shape in order to tame difraction and have a better soundstage ! Btw, look at a corck for wine bottle : a bafle should lookhalf the same for a better soundstage ! Not easy though, tear drop mold seems easier but that's another story

Last edited:

Set it up. Stuff ain't cheap, unfortunately.I definitely want to get into more interesting materials and methods. First I need to lay down a foundation of well known methods first.

Having changed jobs at a most inopportune time ended with me in the unemployment line in April. So I had planned on starting a gofundme, but thought I'd supply one round of data first so people can decide if it is worth while or not.

yeah but ... not very wear resistant. The hardwood will help protect the edges better so all the shaping will have to be done in the wood.Hey, corck should be verry cool material to smooth the edges with a slow shape in order to tame difraction and have a better soundstage !

I'm just looking to further damp the panel(s) and a new material to work with/try out.

Augerpro, really think you should stay on few common choiceS easy to find for convenience if you have a commercial project as Troels Gravsen for instance.

RenShape is a more modern material adivised by Gedles has it all : internal damping and structural and easy enough to work, though not common and perhaps not as cheap !

For diy a clean thin ply without veenering for external and a main chip board layer à la BBC is certainly easy to do, the glue in between (or why not double adhesive tape for convenience and rapid work) is feasible by most of unskilled people as I am and can e ordered from a local carpenter. Though your country is big enough maybe for flat packs you can manage à la DIYsoundgroup. Not feasible in CE as pointed T. Gravsen already.

Ply is a no brainer imho ! Can be thin, the greater number of layers the better.

my two cents, YMMV. looking forward to see your results once you measure

RenShape is a more modern material adivised by Gedles has it all : internal damping and structural and easy enough to work, though not common and perhaps not as cheap !

For diy a clean thin ply without veenering for external and a main chip board layer à la BBC is certainly easy to do, the glue in between (or why not double adhesive tape for convenience and rapid work) is feasible by most of unskilled people as I am and can e ordered from a local carpenter. Though your country is big enough maybe for flat packs you can manage à la DIYsoundgroup. Not feasible in CE as pointed T. Gravsen already.

Ply is a no brainer imho ! Can be thin, the greater number of layers the better.

my two cents, YMMV. looking forward to see your results once you measure

Yest but expensive in relation to the spirit of the thread. At least without massive contribution and time spent. Most of diyers use Mdf or Ply, for the courageous some veneering permits more choice that often stop with any ply wood on hands or MDF, rarely chip (alas) or osb (alas bis).

There is a a masive thread already at Diyaudio, believe the spirit of this thread is just about testing the most common solutions if I understood.

I agree it’s best to keep cost and time investment down. That’s why I recommended sticking to the the things I mentioned and not exotic rock boards, and specialty foams.

- Home

- Loudspeakers

- Multi-Way

- A Monster Construction Methods Shootout Thread