Pharos: thanks for your comments. I have a stack of NOS TAD mid-bass, 1201H. They work well sealed from about 160hz up to 800 or so. They also work very well horn loaded, but I'm not really interested right now in building a large horn. They work really well in a box as small as 1 cubic foot.

I agree with what you are saying...the woofer is going to be the issue. I see why these are so attractive to the Klipsch and Altec (and other) crowds. Do you think relieving a woofer of the duty of playing up higher would make it easier to find a good candidate for the bottom end?

Since I first posted, I talked to Rick out at ESS. I'm going to start by ordering a pair of the large drivers, and stick them on my vintage speaker.

What you are asking is the question facing designers when trying to get a two way to cover the range, hence the curvilinear approach, otherwise you are looking at three way, which ESS did in the early years. The curvilinear is an attempt to 'have it both ways', to stretch the frequency response, and of course is a compromise. I can tolerate three way but more, like JM Lab or Wilson I cannot. I presume you've bought their paper cone 12" ones.

ESS

Pharos: yes, I have the paper TAD mid-bass. I bought them originally for a 4-way. Well, the extra NOS ones were more of an impulse thing..... I really like 3 way speakers, and have not heard many 2 way that I like. It all comes down to what a person is exposed to. That being said, I've built, and heard speakers with a woofer playing up to around 1200hz, and the same ones handing off those duties to a mid-bass. I liked the mid-bass version better.

I really like 3 way speakers, and have not heard many 2 way that I like. It all comes down to what a person is exposed to. That being said, I've built, and heard speakers with a woofer playing up to around 1200hz, and the same ones handing off those duties to a mid-bass. I liked the mid-bass version better.

Well, I have a pair of the ESS coming soon. We shall see. I have on hand a pair of nice 15" that are 89 db/1watt but don't know if I'll bother replacing the alnico woofer. On some quiet passages, of mostly synthesizer type music, I occasionally hear a "raspy" "low pitch buzzing sound from the woofer, which at first made me worry about the cone being torn, or something similar. A friend suggested it might be a loose spider. (?)

pelanj: I'm with you on the whole stacked pair idea. I plan to buy extra units too, and put together a winged kit. I wonder if there is any performance difference in the 3 sizes available from ESS?

What you are asking is the question facing designers when trying to get a two way to cover the range, hence the curvilinear approach, otherwise you are looking at three way, which ESS did in the early years. The curvilinear is an attempt to 'have it both ways', to stretch the frequency response, and of course is a compromise. I can tolerate three way but more, like JM Lab or Wilson I cannot. I presume you've bought their paper cone 12" ones.

Pharos: yes, I have the paper TAD mid-bass. I bought them originally for a 4-way. Well, the extra NOS ones were more of an impulse thing.....

Well, I have a pair of the ESS coming soon. We shall see. I have on hand a pair of nice 15" that are 89 db/1watt but don't know if I'll bother replacing the alnico woofer. On some quiet passages, of mostly synthesizer type music, I occasionally hear a "raspy" "low pitch buzzing sound from the woofer, which at first made me worry about the cone being torn, or something similar. A friend suggested it might be a loose spider. (?)

pelanj: I'm with you on the whole stacked pair idea. I plan to buy extra units too, and put together a winged kit. I wonder if there is any performance difference in the 3 sizes available from ESS?

ESS

pelanj: That is too bad about the VAT. Here, they ship for that price. A bit of State tax, but very little. I ordered the large ones too, although I'm planning to cross at 800 anyway.

What do you think of this idea: my vintage speakers have a potted 800 hz crossover, which I have no idea of how the components have aged. My thought was to simply replace the horn, and put the ESS in its place. Start at low volume, and listen to the result. A couple people have told me the crossover is probably shot, and others have stated that the company used high quality components that don't age much. I don't know which to believe, so thought I'd start with just this step. Then remove the crossover, and use my TDM electronic crossover, which has level attenuation. Of course that means a multi channel amp, which I have. If this sounds good, I have a nice 2 way down to about 50hz. I have subs too, but would not use them for this "testing".

At some point, I'll likely end up with a DSP, but want to listen first.

By the way, how difficult was your learning curve with a 3d printer? I have another hobby that could really benefit from making small parts (say .5" up to 4") I'd prefer metal.

pelanj: That is too bad about the VAT. Here, they ship for that price. A bit of State tax, but very little. I ordered the large ones too, although I'm planning to cross at 800 anyway.

What do you think of this idea: my vintage speakers have a potted 800 hz crossover, which I have no idea of how the components have aged. My thought was to simply replace the horn, and put the ESS in its place. Start at low volume, and listen to the result. A couple people have told me the crossover is probably shot, and others have stated that the company used high quality components that don't age much. I don't know which to believe, so thought I'd start with just this step. Then remove the crossover, and use my TDM electronic crossover, which has level attenuation. Of course that means a multi channel amp, which I have. If this sounds good, I have a nice 2 way down to about 50hz. I have subs too, but would not use them for this "testing".

At some point, I'll likely end up with a DSP, but want to listen first.

By the way, how difficult was your learning curve with a 3d printer? I have another hobby that could really benefit from making small parts (say .5" up to 4") I'd prefer metal.

I think that the AMT will have lower sensitivity than the horn, but it should work for the test.

It took me a few days to get usable prints with my cheap 3D printer kit. So not too difficult, it needs some experimenting in the beginning. I could pursue higher quality for the prints, but I am happy as it is now. Metal would be much more difficult I would guess.

It took me a few days to get usable prints with my cheap 3D printer kit. So not too difficult, it needs some experimenting in the beginning. I could pursue higher quality for the prints, but I am happy as it is now. Metal would be much more difficult I would guess.

I took the largest ones because they had the possibility of the lowest crossover point. One funny fact is, that the shipping and VAT cost me almost more than the pair of drivers...

It is always possible to use any driver over a smaller range than that which t is designed for, and its performance will almost certsinly be at its best in that range.

It is also desirable to choose any driver to have as wide a range as possible, preferably able to cover at least one and preferably two octaves outside its used range because even with the steepest Xover slopes, 24dB/Oct, there is still a considerable O/P outside the chosen range.Choosing woofers randomly is unwise, the frequency range specs are crucial.

IMO the largest Heil from ESS is easily the best.

Last edited:

This is the AMT I refer to: Original Great ESS Heil Air Motion Transformer™ I - LARGE

– ESS Speakers USA

thanks for posting this. did not know ESS was still around, much less the old Heil tweeters still available.

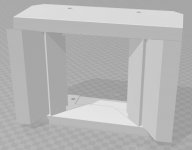

This is my first try for a 90x40 horn attachment - meant for 5mm foamcore or plywood. Do not print this one! It is provided only for viewing. There would be way too much filament wasted. It needs to be cut down, instead of the thick walls, vertical ribs will be used.

Attachments

That step is for the 5 mm thick side of the horn - if you mean the same step I do. The side walls are mounted from inside and the top and bottom can be rectangular for the first part of the horn. If a flange type attachment is needed, the front part can be simply cut off and there is a 140x140 mm square throat.

For “low density” I use 7% to 12% infill depending on how strong you need it. I use it with rectangular (square) crosshatching - but in an alternating 45 deg angles between layers for tighter porosity. I use Simplify 3D printing software. It’s really user friendly but not free.

Simplify3D Software | All-In-One 3D Printing Software

Totally worth the $150 I paid for it in reduced aggravation and less wasted time.

Simplify3D Software | All-In-One 3D Printing Software

Totally worth the $150 I paid for it in reduced aggravation and less wasted time.

Last edited:

If Slic3r works for you - that’s cool. I should check it out one day. This was 4 years ago when I got the Simply3d. In don’t think anything like slic3r was around in that easy to use of a format yet. The open source stuff back then felt very rough and would require hours of fiddling with.

terrydaktell: If there is a drawing of the horn available, I could check.

xrk971: I am a noob at 3D printing - Slic3r inside Repetitier Host was the first thing I tried and it worked. I just upgraded to the latest versions and it seems to work even better.

here's a link to the 236x series of constant directivity or bi-radial (butt cheek) horns.

https://adn.harmanpro.com/site_elem...l-constant-coverage-horns_manual_original.pdf

Related to ESS AMT, but slightly off topic. ESS makes an AMT hybrid headphone. I just got it and tested it. Sounds great! Awesome build quality too. If you are an AMT fan and know their signature, this headphone has it.

ESS 422H AMT Hybrid Headphones

ESS 422H AMT Hybrid Headphones

- Home

- Loudspeakers

- Multi-Way

- ESS AMT-1 in my projects