This thread will follow my build of the Halcyon speakers, designed by Curt Campbell. I'm not sure if this is technically a F.A.S.T design, but I think it is. There is a single Alpair 10p and two SB Acoustics SB17 midwoofers. Curt described the design: "The Alpair is housed in a semi open back cylindrical enclosure, while the SB17's perform in individual transmission lines that are merged at the port in a mass loaded configuration"

Curt shared that one of his friends, a professional opera singer, preferred the Halcyon's to any of his other higher-end designs. This raises my already high expectations that this is going to be a fine speaker indeed. Strangely, other than Curt and Jim Holtz, I don't know of anybody who has heard them and I don't know how many pairs have been built. Madisound says they have sold several kits, but I haven't been able to find a build thread or any pictures of completed Halcyons other than the original test mules.

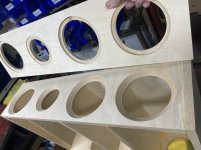

Bob Berner (bob@bigwoodstudio.net) made a terrific flat pack for the Halcyons. Everything fits perfectly and the BB plywood is very high quality. Bob is very helpful and prompt. From idea to delivery for a brand new design with no CAD drawings, Bob completed the whole process in just a few weeks. He is great to work with (he also built a FruglHorn XL kit for me) and I encourage anybody interested in a flat pack to contact him. He has good prices, great service, and a very supportive approach.

Here is Curt's website section on the Halcyons:

Speaker Design Works

This is the the only finished Halcyon I have seen images of:

Curt shared that one of his friends, a professional opera singer, preferred the Halcyon's to any of his other higher-end designs. This raises my already high expectations that this is going to be a fine speaker indeed. Strangely, other than Curt and Jim Holtz, I don't know of anybody who has heard them and I don't know how many pairs have been built. Madisound says they have sold several kits, but I haven't been able to find a build thread or any pictures of completed Halcyons other than the original test mules.

Bob Berner (bob@bigwoodstudio.net) made a terrific flat pack for the Halcyons. Everything fits perfectly and the BB plywood is very high quality. Bob is very helpful and prompt. From idea to delivery for a brand new design with no CAD drawings, Bob completed the whole process in just a few weeks. He is great to work with (he also built a FruglHorn XL kit for me) and I encourage anybody interested in a flat pack to contact him. He has good prices, great service, and a very supportive approach.

Here is Curt's website section on the Halcyons:

Speaker Design Works

This is the the only finished Halcyon I have seen images of:

Last edited:

Major league rookie mistake - advice needed!

Well, I finally got away from work and back to the fun of building speakers, and first thing i do, I glue the inner baffle on backwards. It’s glued in pretty tight, attached to no less than 6 other boards. And it’s backwards. I went to some trouble to make sure to get the baffle beveled properly and then I glued it in with the bevels on the outside. Jeez. Luckily, I guess, this is the inner baffle and there is an outer baffle to which the speakers will be attached.

Advice needed. What is best remedy? I can think of 3 options:

1. Ignore it and just proceed finishing the speakers.

2. Get a router bit and chamfer the remaining wood the other direction, then fill in the gap with Bondo and try to re-create the proper bevel.

3. Cut the baffle out and get another one.

Any other options and recommendations?

Well, I finally got away from work and back to the fun of building speakers, and first thing i do, I glue the inner baffle on backwards. It’s glued in pretty tight, attached to no less than 6 other boards. And it’s backwards. I went to some trouble to make sure to get the baffle beveled properly and then I glued it in with the bevels on the outside. Jeez. Luckily, I guess, this is the inner baffle and there is an outer baffle to which the speakers will be attached.

Advice needed. What is best remedy? I can think of 3 options:

1. Ignore it and just proceed finishing the speakers.

2. Get a router bit and chamfer the remaining wood the other direction, then fill in the gap with Bondo and try to re-create the proper bevel.

3. Cut the baffle out and get another one.

Any other options and recommendations?

Attachments

It doesn't really matter. According to Curt Campbell the inner baffle is probably not needed due to the stiffness of the 18mm BB ply. I can certainly make you a new baffle if you want to replace it. If looking at it thru the speaker cutouts bothers you, you could simply remove the bevel on the holes with a jigsaw. The bevels are there to give the drivers breathing room. Removing them would preserve this.

No one will ever see this mistake once you finish the speakers. And of course we will never say a word of this to anyone.

To reiterate. It won't matter. Personally, I would just trim the bevels off with a jigsaw, and install the other baffle correctly.

Bob

No one will ever see this mistake once you finish the speakers. And of course we will never say a word of this to anyone.

To reiterate. It won't matter. Personally, I would just trim the bevels off with a jigsaw, and install the other baffle correctly.

Bob

Ew, a bit of a goof! TBH, I have had enough disasters of this like...

Now you COULD fit the drivers to the inside of the inverted baffle. And I don't suppose it would sound much different. But access then becomes a severe problem. Maybe a screw -on side panel would give you some leeway here. Once you glue it, there is no access at all.

So it's unmaintainable. Bob Berner sounds like a top-notch guy with his routing skills. What do you think, Bob, about making a couple of extra front baffles?

Speaker Design Works

It's either that or a new cabinet, IMO. Gonna cost you, either way. In engineering terms it's a bit like building a Spitfire Fighter, and glueing the wings on upside down. Sorry.

Now you COULD fit the drivers to the inside of the inverted baffle. And I don't suppose it would sound much different. But access then becomes a severe problem. Maybe a screw -on side panel would give you some leeway here. Once you glue it, there is no access at all.

So it's unmaintainable. Bob Berner sounds like a top-notch guy with his routing skills. What do you think, Bob, about making a couple of extra front baffles?

Speaker Design Works

It's either that or a new cabinet, IMO. Gonna cost you, either way. In engineering terms it's a bit like building a Spitfire Fighter, and glueing the wings on upside down. Sorry.

Whoops! I hate when that happens. Hey, we've all done something that qualifies as a brain fart when building speaker cabinets. I've built dozens odloudspeaker enclosures and every once in a while I'll do something like forgetting to tighten a router bit or screwing up a table saw setting. But you know what they say, "The mark of a good carpenter is covering one's mistakes". Glad to see you're using good birch plywood instead of the ubiquitous MDF. Plywood seems to add more of a presence and warmth to the sound of a speaker that MDF lacks. Although it's too late now, in the future I'd recommend using rabbit and dado joints instead of butt joints. That adds 50% more glue surface and makes joint alignment much easier.

Last edited:

I am full of admiration for 15mm 7-layer plywood.

I used to wander through the workshops of the Royal Navy on a dull night, just tapping this solid stuff. The only tougher stuff is what the old 200-y-o HMS. Victory was made of.

2 foot of solid OAK is very little different from solid concrete to the knuckle-test. Apparently quite capable of stopping a 32 Lb. cannonball at 1,000 MPH. Which is reassuring if you work on the bottom Gundeck, as I was known to do once.

But let's get back to plywood. You can build a De Havilland Mosquito out of it: de Havilland Mosquito - Wikipedia

Or a fast Italian Riva speedboat: Riva Aquarama - Wikipedia

TBH, chipboard and MDF has little more strength than cardboard.

My own interest is engineering: Aircraft of the Battle of Britain - Wikipedia

Everybody loved our nippy Spitfire against the Hun's Messerschmitt Bf109. But actually the Gun Platform and more rapidly serviceable Hurricane was more useful against the slow German bombers over London.

A great time to be had at the Science Museum in Kensington, London. You can see these most of these amazing planes there. For free.

I used to wander through the workshops of the Royal Navy on a dull night, just tapping this solid stuff. The only tougher stuff is what the old 200-y-o HMS. Victory was made of.

2 foot of solid OAK is very little different from solid concrete to the knuckle-test. Apparently quite capable of stopping a 32 Lb. cannonball at 1,000 MPH. Which is reassuring if you work on the bottom Gundeck, as I was known to do once.

But let's get back to plywood. You can build a De Havilland Mosquito out of it: de Havilland Mosquito - Wikipedia

Or a fast Italian Riva speedboat: Riva Aquarama - Wikipedia

TBH, chipboard and MDF has little more strength than cardboard.

My own interest is engineering: Aircraft of the Battle of Britain - Wikipedia

Everybody loved our nippy Spitfire against the Hun's Messerschmitt Bf109. But actually the Gun Platform and more rapidly serviceable Hurricane was more useful against the slow German bombers over London.

A great time to be had at the Science Museum in Kensington, London. You can see these most of these amazing planes there. For free.

If that baffle is not coming out easily, you may have to remove it (with a router) and get a new baffle from Bob. Those bevels on the backside are lovely thou.

I recenttly did similar with a build. BThe baffles needed to be backwards but i glued the back on backwards. I now have the rebat efor the terminal cup on the inside. Fortunately, unlike yours, it makes only a cosmetic differemce.

dave

I recenttly did similar with a build. BThe baffles needed to be backwards but i glued the back on backwards. I now have the rebat efor the terminal cup on the inside. Fortunately, unlike yours, it makes only a cosmetic differemce.

dave

Honestly, planet10, just when I start to wonder if I am losing it, you reassure me.

Also at the Science Museum, London is the Apollo 11 Moon lander. Well, obviously not the original, because that is still on the Moon, or in orbit.

But however they rustled up this replica, I can tell you it is HUGE! About the size of a double-decker London Bus.

Amazingly, the early Russian spaceships are tiny. About 6 feet across. Not many people know this, but I met the First Woman in Space many years back. Valentina Tereshkova. Nice lady. She gave me an autograph.

Also at the Science Museum, London is the Apollo 11 Moon lander. Well, obviously not the original, because that is still on the Moon, or in orbit.

But however they rustled up this replica, I can tell you it is HUGE! About the size of a double-decker London Bus.

Amazingly, the early Russian spaceships are tiny. About 6 feet across. Not many people know this, but I met the First Woman in Space many years back. Valentina Tereshkova. Nice lady. She gave me an autograph.

Last edited by a moderator:

All lovers of plywood should enjoy Howard Hughes' Spruce Goose, the largest wingspan until last year of any aircraft ever flown.

The nickname is fun but wrong, it is built mostly of birch ply.

Take a look at the interior fuselage photo on wikipedia. I periodically use the big side shot as desktop background.

The nickname is fun but wrong, it is built mostly of birch ply.

Take a look at the interior fuselage photo on wikipedia. I periodically use the big side shot as desktop background.

Last edited:

I'm not sure if this is technically a F.A.S.T design, but I think it is. There is a single Alpair 10p and two SB Acoustics SB17 midwoofers.

It is a Woofer Assisted Wideband (aka FAST but making a lot more sense).

1 or more woofers assisting a (nomnal) fullrange driver with an XO typically between 150 and 500 Hz.

IIRC the passive on these is 300Hz?

dave

WWII American media? Shirley you jest!

I'm not jesting and don't call me Shirley! It's Hedley, not Heddy!

- Home

- Loudspeakers

- Multi-Way

- Curt Campbell's Halcyon build thread