I don't suppose the life expectancy of ship builders in the 18th century was very high!

Around 6,000 trees were used in the construction of HMS Victory, of which 90% were oak.

Ship builders probably survived to a highish age, like my grandad who built sloops under 1.000 tons, it was the sailors who got it in the seasick stomach and neck from bad design, IMO.

The currently ugly and dismasted HMS. Victory, which FWIW is part of a 20 year plan to keep this baby alive for future generations, had Canadian Pine masts. Masts must bend in the wind, hopefully the English Oak chassis doesn't.

I am not averse to the "Tap-test" on structural members. I can tell you, from wandering round this fine old piece of engineering, that Oak is about as hard as concrete to the knuckles. Experience told that 2 foot of Oak could stop a 32 Lb. cannonball at 1,000 mph. This is why the lower gundeck of Victory experienced only one fatality at Trafalgar.

The reason the English crews won at Trafalgar, was not better engineered ships, but better training and practice. They reloaded in under a minute, with scant regard for safety. The French averaged 3 minutes. The Spanish 5 minutes.

Perfidious Albion also tended to fire at the body of ships, causing maximum disruption, rather than the top deck and rigging. Which frightened the Hell out of the opposition and threw them off their game and into paralysis and despondency.

I actually have a fairly open mind on the theories of lightness and rigidity and speed, versus the slightly over-engineered idea of matched and solid construction and a certain slowness.

They say there is "The Quick and the Dead." As an engineer I favour "The Quick". Faster to market and Cheaper too.

.

You will open opportunities, such as mounting the driver to the front of the rear piece, and the front piece to the cabinet.I have to buy 2 sheets of plywood and only need a sheet and a half so I plan on making the front baffle with 2 sheets of plywood with Decidamp between them.

Direct transmission of vibration from the basket to the whole cabinet, even through the mounting screws could be a concern especially with a full range driver.

It is the primary conduit for driver energy to pass to the enclosure. My philosophy is to brace well and directly connect the driver to more than just the baffle panel so as to spread its energy around. If you use a lossy fitment the driver basket will have significantly increase the movement of the basket to a relative fixed point decreasing the potential to reproduce the very small details, ie it degrades DDR.

dave

I really like the idea of attaching the driver to the inner baffle and attaching the outer baffle to the cabinet but I'm not sure if the Decidamp is strong enough to adhere the inner and outer baffle with out mechanical help.

If you take a look at the photo I posted, that's how I did it. There's no crime in shooting in a couple of screws to hold it all together. I think that box had about 70 or 80 screws in it... I made sure it wasn't coming apart!

But in hindsight, I probably should have made it fireproof. Lost the whole setup in a house fire in 1984.

It is the primary conduit for driver energy to pass to the enclosure...

If you use a lossy fitment the driver basket will have significantly increase the movement of the basket to a relative fixed point decreasing the potential to reproduce the very small details

That makes perfect sense, Dave. But without attaching some numbers to either side of the story, how can we make a decision about the magnitude of the effects of each approach?

Without accounting for panel flex, the simpliest analysis has M1 = driver mass vrs M2 = (driver mass + box mass). M2 >> M1.

With conservation of momentum M1 x V1 = M2 x V2. So V2, the driver movement w the box rigidly attached, is smaller, ie V2 = M1/M2 x V1.

Flexing of box panels will complicate the actual problem a bit.

dave

With conservation of momentum M1 x V1 = M2 x V2. So V2, the driver movement w the box rigidly attached, is smaller, ie V2 = M1/M2 x V1.

Flexing of box panels will complicate the actual problem a bit.

dave

That makes perfect sense, Dave. But without attaching some numbers to either side of the story, how can we make a decision about the magnitude of the effects of each approach?

Seems astonishing to think that any motion of a compliantly attached basket relative to your ears could be a good thing with or without numbers to prove it. Planet10 said it plainly enough in his post.

Either the basket is solidly mounted, or it is shaking in unplanned and unmusical ways. That's what "compliant" means, eh. Either the basket is a solid fixed foundation for the cone or it is just shaking as it pleases.

Here we have a long thread about a phenomenon of cab wall vibration everybody seems to believe in (and go to great effort and cost to address) but nobody has posted a link to show panel vibration is audible in ordinary nicely made cabinets (or even in lousy cabinets).

B.

Last edited:

Either the basket is a solid fixed foundation for the cone or it is just shaking as it pleases.

Here we have a long thread about a phenomenon of cab wall vibration everybody seems to believe in (and go to great effort and cost to address) but nobody has posted a link to show panel vibration is audible in ordinary nicely made cabinets (or even in lousy cabinets)

That's quite a black and white perspective. So a rigidly mounted basket doesn't vibrate/resonate/flex at all? I'm not disagreeing with your point, or with Dave. It just doesn't have to be zip ties and silly putty that we're talking about. There is a small world of methods and degrees of loss available in a less than perfectly rigid mount, if someone wants to explore that option.

I do agree with your second point, it's the essence of what my question was addressing.

So a rigidly mounted basket doesn't vibrate/resonate/flex at all?

It does. The idea is to hold it as rigid in space as possible. But there will always be some — hopefully vanishngly small — rocking motion of the cabinet as the speaker moves in and out.

dave

That's quite a black and white perspective. So a rigidly mounted basket doesn't vibrate/resonate/flex at all?….

At the risk of seeming rigid about drivers, any vibration of the basket has to be making for unwanted sound even if only Doppler modulating the audio signal, albeit in proportion, of course.

The edge gasket is needed to ensure an airtight fit to the motor board. But the basket shouldn't vibrate anywhere near the audio band - that's what the cone is supposed to do following the audio signal.

Data anyone?

B.

It does. The idea is to hold it as rigid in space as possible. But there will always be some — hopefully vanishngly small — rocking motion of the cabinet as the speaker moves in and out.

+1. At the risk of seeming rigid about my cabinets, I used to keep a larger-size cinder block on top of my Klipschhorn bass (sometimes a wine rack too). Rather "gilding the lily" I guess.

Does more good than those pointy feet folks put on the bottom.

B.

At the risk of seeming rigid about drivers

Indeed, it's intuitive that any disturbance due to vibration, etc in a rigid mount would be primarily in the longitudinal direction. Whereas a driver in a viscous attachment could lose focus more easily in 3D. And, IMHO that should make someone cautious, but no less prone to experiment with such approaches.

No-Rez

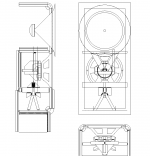

X-SLS Encore build

Installing the No-Rez. The last two pics are of the No-Rez that will be attached to the front baffle. It's a lot easier to put it in before gluing the baffle on.

Optimized and clarified

Big IMG: http://maty.galeon.com/WP-imagenes/hum/Big-X-SLS-no-rez-inside.jpg

X-SLS Encore build

Installing the No-Rez. The last two pics are of the No-Rez that will be attached to the front baffle. It's a lot easier to put it in before gluing the baffle on.

Optimized and clarified

An externally hosted image should be here but it was not working when we last tested it.

Big IMG: http://maty.galeon.com/WP-imagenes/hum/Big-X-SLS-no-rez-inside.jpg

Last edited:

It seems timely to post this again Issues in speaker design - 2 there is a very good argument for rigidly mounting the magnet and letting the basket float

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Is MDF or plywood better for speaker cabinets?