Depends on the harmonic distortion of the driver. If there's a decent amount of let's say H4, H5, or H7, that happens to land on the breakup frequency (range), the actual level will be magnified by the extra sensitivity of the breakup peak. Look at H2, H3, and especially H5 here as a pretty classic example:If the crossover is steep enough to mean a driver is not playing anything at the point of break up, I thought that was job done, and the breakup would have no effect on the driver sound?

Was I wrong?

SEAS W22EX001 | HiFiCompass

I suspect that H4 magnification doesn't present just because the driver practically has no H4 distortion to magnify. You can see the slightest hint of the H4 peak around 1.3 kHz.

Some report that this distortion magnification can be largely eliminated by use of a notch, but there is not a huge body of data on this as yet.

Last edited:

I have dismantled the foam-box prototypes of post 606 / 620. I am starting the construction of the real cabinets.

As work progresses, I think I will start a dedicated thread on the build progress instead of tacking it onto this thread (720 posts and climbing...)

As work progresses, I think I will start a dedicated thread on the build progress instead of tacking it onto this thread (720 posts and climbing...)

Attachments

hifijim,

A diyAudio forum thanks for sharing your textreme build. Do you plan to build a double-thick beveled-edge front baffle identical to your SB-Acoustics ceramic cone speakers?

.... plans to compare ceramic vs. textreme in identical cabinets?

.... experiments with different crossovers for optimal textreme performance?

A diyAudio forum thanks for sharing your textreme build. Do you plan to build a double-thick beveled-edge front baffle identical to your SB-Acoustics ceramic cone speakers?

.... plans to compare ceramic vs. textreme in identical cabinets?

.... experiments with different crossovers for optimal textreme performance?

plans to compare ceramic vs. textreme in identical cabinets?

Similar cabinets, but not quite identical. I do plan to build a double thick front baffle, 1.5 inch thick. The sides will be profiled with a 1.5 inch radius round-over bit, exactly like the SB ceramic boxes. This new build will use a 2 layer plywood baffle instead of a composite solid wood / plywood baffle. Before I did not have enough experience with veneer to confidently apply it over a curve, so I used solid wood. Now I know I can do it with veneer. The top edge will be chamfered at 45 degrees to a depth of 1.5 inch.

The SB ceramic box is 13" H x 10" W x 9" D. The new box will be 13.5" H x 10" W x 9.75" D. So slightly taller, slightly deeper. The arrangement of the internal braces will be different. I learned a lot while making the first cabinets ("learning" is code word for screw-ups).

I do not have any digital representations of the cabinet design (CAD or Sketchup). I did that kind of thing for 30 years and it feels too much like work... I like pencil and paper.

As I optimize the filters, I will share my measurements, subjective opinions, and my thought process...

Rhale64, are you thinking 2-way or 3-way??? I plan on getting the MW13TX in the next few months. I will use these as mids but will first test as full range then as a small 2-way just to get a feel for what suitable bandwidth I can use. Ultimately, I would like a 3-way but since I have so much already invested in my current system, that is not likely to happen anytime soon. I'm curious to see the upcoming projects and designs for an all TexTreme 3-way...

When designing a midwoofer-cone, the manufactorers look for three key characteristics: lightness, rigidity/stiffness/velocity and internal damping. They stir/heat/dry-, vacuum-, compression-, injection-mold/press multidirectionally oriented (ply-layers) of light and strong carbon/kevlar/glass/mineral/polystyrene/cellulose-fibers, mixed with some epoxy binder for shaping and stiffness, added some polymer/foam/pulp for damping, this is is how 99% of non-metal/ceramic midwoofer membranes are made, and every manufactorer has their own secret receips. Don't want to sound more grumpy than I am, but the Satori Textreme is no revolution or holy grail, it's just another thin-fiber, black-art, fancy looking membrane, one among many.

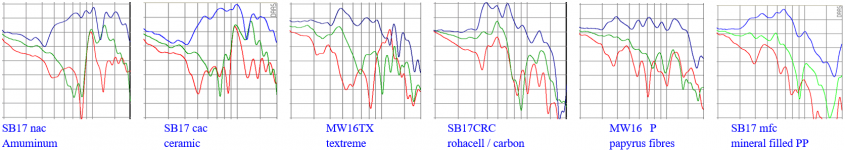

A measurement of a membrane's breakup modes, on-axis and off-axis, can tell how well damped the breakup is. The breakup behaviour does not tell how rigid the membrane is, (or what the breakup sounds like) but it can give an indication of the membrane's stiffness as well. When you look at the FR-plots of the SB Acoustics' different 6½" midwoofers below, between 2-20kHz, you see that the off-axis breakup of the new MW16tx is just as bad as aluminium and ceramic, very low internal damping indeed, don't be fooled by the nicer looking on-axis response, this driver rings! The new stiff cone of the MW16tx will add some low level resolution compared to the soft papercone of the brilliant MW16P, but at a cost.

My experience with kevlar/epoxy-midwoofers, which may have lots in common with the new Satori textrene, is that for one; they need to be crossed low and steep, and two; they need really large cabinets (give them a small cabinet and some high SPL bass/lower-midrange, and they ring like hell). I never crossed a ScanSpeak 8546 or 8554 above 1400Hz, and I'm afraid that it will be the same with the MW16tx (some prefer the added "details" that echoes down from an uncontrolled breakup, but that’s another story). This might explain why SB Acoustics hasn't implemented Textrene in their Satori midrange drivers?

SB17 rohacell/carbon-fiber costs $34 more than SB17 aluminium/paper/polypropylen. MW16tx costs $114 more than MW16P, and I don't for a second belive that a textrene cone costs 3 times more to produce than a rohacell/carbonfiber-sandwich cone. In 2011 the new MW16P was $290 and the 15WU was $340. Today the MW16P is $148 and the 15WU is still $340. Danes are known for being clever in business, and this is a good example, SB Acoustics teased the marked a year ahead with this textrene-secret, building expectations, rumours, excitements, forum-discussions, etc etc, … and whoops, they can get away with $270 for a driver that is only "worth" around $170.

For midrange duties I don't like the unnatural upper-midrange sound from carbon/kevlar/glass-fiber + epoxy, I prefer Audio Technology's PP, Seas' tpx-PP, Dynaudio's PP, and Eton's Hexacone-sandwich, they all can be crossed rather high, with clean, high level detail and nice sounding breakup modes.

A measurement of a membrane's breakup modes, on-axis and off-axis, can tell how well damped the breakup is. The breakup behaviour does not tell how rigid the membrane is, (or what the breakup sounds like) but it can give an indication of the membrane's stiffness as well. When you look at the FR-plots of the SB Acoustics' different 6½" midwoofers below, between 2-20kHz, you see that the off-axis breakup of the new MW16tx is just as bad as aluminium and ceramic, very low internal damping indeed, don't be fooled by the nicer looking on-axis response, this driver rings! The new stiff cone of the MW16tx will add some low level resolution compared to the soft papercone of the brilliant MW16P, but at a cost.

My experience with kevlar/epoxy-midwoofers, which may have lots in common with the new Satori textrene, is that for one; they need to be crossed low and steep, and two; they need really large cabinets (give them a small cabinet and some high SPL bass/lower-midrange, and they ring like hell). I never crossed a ScanSpeak 8546 or 8554 above 1400Hz, and I'm afraid that it will be the same with the MW16tx (some prefer the added "details" that echoes down from an uncontrolled breakup, but that’s another story). This might explain why SB Acoustics hasn't implemented Textrene in their Satori midrange drivers?

SB17 rohacell/carbon-fiber costs $34 more than SB17 aluminium/paper/polypropylen. MW16tx costs $114 more than MW16P, and I don't for a second belive that a textrene cone costs 3 times more to produce than a rohacell/carbonfiber-sandwich cone. In 2011 the new MW16P was $290 and the 15WU was $340. Today the MW16P is $148 and the 15WU is still $340. Danes are known for being clever in business, and this is a good example, SB Acoustics teased the marked a year ahead with this textrene-secret, building expectations, rumours, excitements, forum-discussions, etc etc, … and whoops, they can get away with $270 for a driver that is only "worth" around $170.

For midrange duties I don't like the unnatural upper-midrange sound from carbon/kevlar/glass-fiber + epoxy, I prefer Audio Technology's PP, Seas' tpx-PP, Dynaudio's PP, and Eton's Hexacone-sandwich, they all can be crossed rather high, with clean, high level detail and nice sounding breakup modes.

Attachments

Danes are known for being clever in business, and this is a good example, SB Acoustics teased the marked a year ahead with this textrene-secret, building expectations, rumours, excitements, forum-discussions, etc etc, … and whoops, they can get away with $270 for a driver that is only "worth" around $170.

I am currently considering the MW19TX-4 for a dipole project, that is if I can ever buy one. Manufacturing and distribution seems to be delayed, but hey there is this pandemic thing going on I guess. This particular driver does seem to be overpriced by the clever Danes. Of course they are a company and not a philanthropic organization, so they want to build up the excitement and launch the product with as high a price as the market will support. This is nothing new. The question is whether the driver will perform at the very high level that we have been told to expect. If not, there are other very good drivers out there for much less coin. Time will tell.

Thanks for the easy-to-review comparison photo.When designing a midwoofer-cone, the manufactorers look for three key characteristics: lightness, rigidity/stiffness/velocity and internal damping. They stir/heat/dry-, vacuum-, compression-, injection-mold/press multidirectionally oriented (ply-layers) of light and strong carbon/kevlar/glass/mineral/polystyrene/cellulose-fibers, mixed with some epoxy binder for shaping and stiffness, added some polymer/foam/pulp for damping, this is is how 99% of non-metal/ceramic midwoofer membranes are made, and every manufactorer has their own secret receips. Don't want to sound more grumpy than I am, but the Satori Textreme is no revolution or holy grail, it's just another thin-fiber, black-art, fancy looking membrane, one among many.

A measurement of a membrane's breakup modes, on-axis and off-axis, can tell how well damped the breakup is. The breakup behaviour does not tell how rigid the membrane is, (or what the breakup sounds like) but it can give an indication of the membrane's stiffness as well. When you look at the FR-plots of the SB Acoustics' different 6½" midwoofers below, between 2-20kHz, you see that the off-axis breakup of the new MW16tx is just as bad as aluminium and ceramic, very low internal damping indeed, don't be fooled by the nicer looking on-axis response, this driver rings! The new stiff cone of the MW16tx will add some low level resolution compared to the soft papercone of the brilliant MW16P, but at a cost.

My experience with kevlar/epoxy-midwoofers, which may have lots in common with the new Satori textrene, is that for one; they need to be crossed low and steep, and two; they need really large cabinets (give them a small cabinet and some high SPL bass/lower-midrange, and they ring like hell). I never crossed a ScanSpeak 8546 or 8554 above 1400Hz, and I'm afraid that it will be the same with the MW16tx (some prefer the added "details" that echoes down from an uncontrolled breakup, but that’s another story). This might explain why SB Acoustics hasn't implemented Textrene in their Satori midrange drivers?

SB17 rohacell/carbon-fiber costs $34 more than SB17 aluminium/paper/polypropylen. MW16tx costs $114 more than MW16P, and I don't for a second belive that a textrene cone costs 3 times more to produce than a rohacell/carbonfiber-sandwich cone. In 2011 the new MW16P was $290 and the 15WU was $340. Today the MW16P is $148 and the 15WU is still $340. Danes are known for being clever in business, and this is a good example, SB Acoustics teased the marked a year ahead with this textrene-secret, building expectations, rumours, excitements, forum-discussions, etc etc, … and whoops, they can get away with $270 for a driver that is only "worth" around $170.

For midrange duties I don't like the unnatural upper-midrange sound from carbon/kevlar/glass-fiber + epoxy, I prefer Audio Technology's PP, Seas' tpx-PP, Dynaudio's PP, and Eton's Hexacone-sandwich, they all can be crossed rather high, with clean, high level detail and nice sounding breakup modes.

My take on Textreme is that it's going to be a rigid cone material with a more-controlled breakup than what you'd find on a conventional rigid material like aluminum or ceramic. Seems to do the job, although I also question if there is any significant advantage vs aluminum or ceramic (as long as the application allows for adequate mitigation of the breakup), especially given the cost differential.

From a practical standpoint, SB coming out with the Textreme lineup essentially gives the end user accessibility to the wonderful Satori motor (though perhaps equalled by the NAC/NBAC series) but with a cone that doesn't suffer from surround-edge resonance and has breakup at a slightly higher frequency.

Last edited:

Don't want to sound more grumpy than I am, but the Satori Textreme is no revolution or holy grail, it's just another thin-fiber, black-art, fancy looking membrane, one among many.

You may be right... time will tell.

454Casull's thoughts match my own. My test data revealed that the Mw16TX driver has a first mode resonance that is almost as high as the SB17CAC ceramic cone, but the resonance is more damped than SB17CAC. Is this enough to make the MW16TX sound better than the SB17CAC or the MW16P? I don't know... again, time will tell.

Me too. I am hoping they are game changers. If not maybe the Kairos build with the bass section would match or beat my Aerial 6t's which have Egyptian papyrus drivers for mid and woofers. These speakers are great sounding. Just wanted to build something again. But it has to beat these or it's not worth the effort. And I haven't heard many speakers at any price that I like more.Waiting in suspense.

Highly doubt it. If anything, they will just be an incremental improvement over their SOTA.Me too. I am hoping they are game changers

- Home

- Loudspeakers

- Multi-Way

- SB Acoustics Textreme