Hey there,

I have heard you can save a lot of money and get great quality when you build your own LS. I own a pair of Canton Ergo 620 Speakers which are a nice start, but I cannot wait to upgrade. I thought about investing 2-3k in new speakers, but then I heard about DIY. I like woodworking, but am far from being a pro. Basically I am looking for a nice and easy to build speaker, that is approved and well-tested by other DIY users. I am looking for bookshelf speakers I can use at my desk. My basic criteria:

- Easy shape, maybe just a simple box, no curves or anything fancy

- 3 Drivers. I own an active sub, so base is less of a problem but rather a nice mid and high

- Ribbon Tweeter? Is this the best option nowadays?

- Well tested and approved by the community

- Crossovers pre-built available? I have no idea about electronics...

- Price? IDK, The tech can cost up to 1.5k€ per speaker, but then they should sound like 5k ones, right?

- I am from Mid Europe so I hope I can avoid any US shops with long delivery times...

I found this speaker here which looks kind of like that I imagine, but I am open to any suggestions, so thanks a lot.

I have heard you can save a lot of money and get great quality when you build your own LS. I own a pair of Canton Ergo 620 Speakers which are a nice start, but I cannot wait to upgrade. I thought about investing 2-3k in new speakers, but then I heard about DIY. I like woodworking, but am far from being a pro. Basically I am looking for a nice and easy to build speaker, that is approved and well-tested by other DIY users. I am looking for bookshelf speakers I can use at my desk. My basic criteria:

- Easy shape, maybe just a simple box, no curves or anything fancy

- 3 Drivers. I own an active sub, so base is less of a problem but rather a nice mid and high

- Ribbon Tweeter? Is this the best option nowadays?

- Well tested and approved by the community

- Crossovers pre-built available? I have no idea about electronics...

- Price? IDK, The tech can cost up to 1.5k€ per speaker, but then they should sound like 5k ones, right?

- I am from Mid Europe so I hope I can avoid any US shops with long delivery times...

I found this speaker here which looks kind of like that I imagine, but I am open to any suggestions, so thanks a lot.

Welcome to the forum!

Troels Gravesen is a respected designer so I would expect a quality performance from the speakers to which you refer.

All the cabinet and crossover construction details are included in the link so you will be able to gauge for yourself whether or not you are up for the job.

One thing though - aren't these speakers rather large for use at your desk?

Troels Gravesen is a respected designer so I would expect a quality performance from the speakers to which you refer.

All the cabinet and crossover construction details are included in the link so you will be able to gauge for yourself whether or not you are up for the job.

One thing though - aren't these speakers rather large for use at your desk?

The SB 3-way Classic what you linked is a medium sized loudspeaker intented for standmount use.

For desk use, the Bookshelf-3WC is a better choice because of its tuning and the arrangement of the drivers imo..

Bookshelf-3WC

For desk use, the Bookshelf-3WC is a better choice because of its tuning and the arrangement of the drivers imo..

Bookshelf-3WC

Hi and thanks for the replies. Well, yeah, it is big. Since my desk is in the middle of the room, I have plenty of space behind it so its not really standing "on" the desk. Do you think this would be a big problem for the larger boxes? I checked some other commercial speakers that I found interesting and they are also in this range, like a Nubert or a Harbeth. I would like to go with this size if it is feasible to have enough "power"...

Knochen... welcome....

You have the right philosophy..... study the recommendations and research... make an informed decision on a design which you can build. The woodshop capability often sets the design direction.

You have the right hardware budget of 1,500E per speaker.

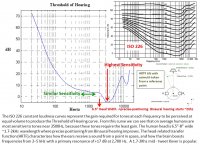

BUT...since your room shape is unique, and your hearing is unique, and since you want exceptional performance, and since you have space behind your desk, BUILDING a deep cabinet which leverages the Kii-Three engineering with side-side woofers is worth the extra education and construction challenges. (No rear cardiod woofers.)

"We live in the midrange." For close-up desktop listening many favor putting the human vocal range(~80-1700) on one exceptional 6" midrange like:

1) Satori MW16P-4 with the natural sound from a Papyrus paper cone

2) -OR - SB_Acoustics SB17NAC35-4 with the detailed sound from a ribbed aluminum cone

3) Satori TW29RDC-4 dimpled 1.1" dome tweeter ideal for crossovers around 1700Hz.

----a T-M crossover ~1700Hz has an 8" wavelength which helps produce a "point-source" image

The SB Acoustics 8" SB23NACS45-8 woofer uses a new ribbed aluminum cone for both extra stiffness and significantly reduced cone breakup. Reviews are all positive.

Crossover Options:

3w-passive TM-WW

2w-passive TM + bi-amp WW (proven passive TM Xover is available)

2w-passive TM + DSP WW

3w-DSP T-M-WW

If you can build a wooden Kii-Three shaped cabinet, there is enough knowledge on diyAudio to help you achieve success..

You have the right philosophy..... study the recommendations and research... make an informed decision on a design which you can build. The woodshop capability often sets the design direction.

You have the right hardware budget of 1,500E per speaker.

BUT...since your room shape is unique, and your hearing is unique, and since you want exceptional performance, and since you have space behind your desk, BUILDING a deep cabinet which leverages the Kii-Three engineering with side-side woofers is worth the extra education and construction challenges. (No rear cardiod woofers.)

"We live in the midrange." For close-up desktop listening many favor putting the human vocal range(~80-1700) on one exceptional 6" midrange like:

1) Satori MW16P-4 with the natural sound from a Papyrus paper cone

2) -OR - SB_Acoustics SB17NAC35-4 with the detailed sound from a ribbed aluminum cone

3) Satori TW29RDC-4 dimpled 1.1" dome tweeter ideal for crossovers around 1700Hz.

----a T-M crossover ~1700Hz has an 8" wavelength which helps produce a "point-source" image

The SB Acoustics 8" SB23NACS45-8 woofer uses a new ribbed aluminum cone for both extra stiffness and significantly reduced cone breakup. Reviews are all positive.

Crossover Options:

3w-passive TM-WW

2w-passive TM + bi-amp WW (proven passive TM Xover is available)

2w-passive TM + DSP WW

3w-DSP T-M-WW

If you can build a wooden Kii-Three shaped cabinet, there is enough knowledge on diyAudio to help you achieve success..

Attachments

It appears you have no problem with box size as long as the enclosures don't overwhelm the room. However, a smaller enclosure is more in keeping with your intention to use an active sub. Large enclosures generally produce sufficient bass on their own, so the extra size is a bit of a waste if you intend to use an active sub.

@Galu: True, thats a valid point indeed.

@LineSource: Thanks a lot for the suggestion. I researched this a bit and I guess the problem is that this does not only require the speakers, but a quite complex system around, like a active crossover with several amplifiers to adjust each channel separately? If this is the case, I believe this is some high end stuff that is way above my level

@LineSource: Thanks a lot for the suggestion. I researched this a bit and I guess the problem is that this does not only require the speakers, but a quite complex system around, like a active crossover with several amplifiers to adjust each channel separately? If this is the case, I believe this is some high end stuff that is way above my level

Over the last 40 years I have tried very hard to avoid crossovers.

This was quite difficult to do in the past as there were no full range single drivers.

In more recent years quite a few have been produced.

I use a pair of Fane 12-250TC's full rangers in a simple sealed box.

No expensive crossovers so less to go wrong.

Its a little top frequency heavy but is more than good enough for my listening.

I usually cover my cabinets in thin carpet as it is inexpensive and easy to work with.

A basic 18mm plywood box with 2 by 2 inch bracing works well.

This was quite difficult to do in the past as there were no full range single drivers.

In more recent years quite a few have been produced.

I use a pair of Fane 12-250TC's full rangers in a simple sealed box.

No expensive crossovers so less to go wrong.

Its a little top frequency heavy but is more than good enough for my listening.

I usually cover my cabinets in thin carpet as it is inexpensive and easy to work with.

A basic 18mm plywood box with 2 by 2 inch bracing works well.

@LineSource: Thanks a lot for the suggestion. I researched this a bit and I guess the problem is that this does not only require the speakers, but a quite complex system around, like a active crossover with several amplifiers to adjust each channel separately?

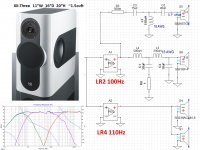

If you can bi-amp with either basic LR2/LR4 slopes, or with software/hardware DSP, a modest complexity passive component crossover is possible. -example-

If you can tri-amp with software/hardware DSP the (no passive parts) crossover can be accurate for time and room effects.

Attachments

Another question regarding construction: have a look at this speaker plan:

http://www.troelsgravesen.dk/SBA-741/SBA-741_cabinet.png

How would you cut this design? I mean, there are several angles to consider and the shape is not rectangle. Would a saw like this be good for cutting this?

http://www.troelsgravesen.dk/SBA-741/SBA-741_cabinet.png

How would you cut this design? I mean, there are several angles to consider and the shape is not rectangle. Would a saw like this be good for cutting this?

I have read that the drivers in a commercial which costs $1000 at the dealer cost the manufacturer about $50. Go figure...

It's not usually quite that extreme, but yes, there's substantial markup because the dealer, distributor, manufacturer all have to eat.

Another question regarding construction: have a look at this speaker plan:

http://www.troelsgravesen.dk/SBA-741/SBA-741_cabinet.png

How would you cut this design? I mean, there are several angles to consider and the shape is not rectangle. Would a saw like this be good for cutting this?

A circular saw used in conjunction with guides/straightedges is a pretty powerful and flexible tool, and would allow you to do much of that cabinet. A router is also an important tool. Triton brand are my recc there.

Another question regarding construction: have a look at SBA-741_cabinet speaker plan: How would you cut this design? I mean, there are several angles to consider and the shape is not rectangle.

There are several circular saw expert websites which explain how to cut compound angles. You tube even has a few videos. Most builders construct a custom angle miter box jig which slides the saw base(shoe) along one angle, while the blade is tilted at the second angle.

For the optimum miter-cutting accuracy and ease, use a compound-angle power miter saw.

A few Avalon cabinet builders have used a carpenter's hand saw with good results.

===========

======== Web example

1 Clamp the board to a solid surface, such as a workbench, table or saw horses. Position the board so that the piece you are about to cut off will drop to the floor, and with the cut line about 3 inches or so from the solid surface to which you’ve clamped the board. Use two clamps to hold the board steady while you cut.

2 Clamp a large right-angle square (such as a framing square) or a straightedge to the board with two more clamps. Position the square so that the straight, 90-degree leg is parallel to the cut you want to make.

3 Adjust the saw to make a XX-degree angle. Circular saws typically have a miter adjustment toward the bottom, back of the saw, with a screw or pressure clamp to lock the cutting angle. The adjustment moves the shoe, which positions the saw at the proper angle for a miter cut. Always unplug the saw before adjusting the blade angle.

4 Hold the edge of the circular saw’s shoe -- the bottom plate from which the blade protrudes -- against the square, and cut through the board, running the saw's shoe along the edge of the square throughout the cut.

Thanks for the reply, there are indeed some excellent videos. Another question regarding this build:

SBA-741

As you see, the front panel with the drivers has some chamfering. Is this only optical or with a function? Troels writes:

"As always: Any change to front panel dimensions or drivers' placement and you need a new crossover - and I can't help."

Does this also concern the chamfering? I could imagine this speaker but with a nice veneer, therefore I would want to keep the surfaces straight.

SBA-741

As you see, the front panel with the drivers has some chamfering. Is this only optical or with a function? Troels writes:

"As always: Any change to front panel dimensions or drivers' placement and you need a new crossover - and I can't help."

Does this also concern the chamfering? I could imagine this speaker but with a nice veneer, therefore I would want to keep the surfaces straight.

As you see, the front panel with the drivers has some chamfering. Is this only optical or with a function?

The chamfering is functional, it reduces edge baffle distortion, BUT a good designer seeks artistic value in the edge bevels - or- rounds edge cuts.

In a comparison test, most listeners can hear a difference between cabinets with sharp edges vs. deep edge bevels or edge quarter round router cuts. There are several good baffle edge simulators which a designer can use to grade the value vs. complexity. -OR- you can just copy off the smart kids and mimic a proven design (Avalon truncated pyramid), (Magico Q5 large radius quarter rounds)

Understanding Cabinet Edge Diffraction

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Newbie wants to build a speaker