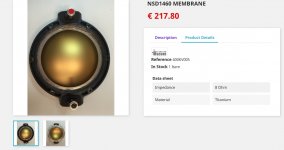

The diaphram of the ND3ST looks suitable:

The diaphragm assembly is made by joining the former directly to the titanium dome on its upper bend edge. In comparison with a usual straight former joint, the driver's design assures extended frequency energy transfer for improved response linearity and unparallel reliability. This feature facilitates proper motion control of the dome in real working conditions.

I have a better suggestion:

18s ND3N. More than acceptable distortions up to 16k. Maybe even better: ND3SN.

Again, the problem with using a driver on the convex side of a diaphragm is that if suspension gets into the compression chamber this degrades the performace. This is because the excursion of the suspension decreases towards the edge, where it is zero. I can't see how could any of the suggestions help in this regard.

On the concave side it is not much better, I guess, but at least ferrofluid can be used to overcome this.

On the concave side it is not much better, I guess, but at least ferrofluid can be used to overcome this.

Attachments

Last edited:

I have a better suggestion:

18s ND3N. More than acceptable distortions up to 16k. Maybe even better: ND3SN.

You're right. I erroneously assumed the ND3ST's diaphragm is also Nitride coated.

Again, the problem with using a driver on the convex side of a diaphragm is that if suspension gets into the compression chamber this degrades the performace. This is because the excursion of the suspension decreases towards the edge, where it is zero. I can't see how could any of the suggestions help in this regard.

On the concave side it is not much better, I guess, but at least ferrofluid can be used to overcome this.

Ok, now I think I understand what you're aiming at: suspending the diaphragm outside of the factual structure (diaphragm).

That looks quite usable, BTW

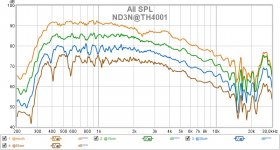

Indeed! One best performances of AL/Ti diaphragms I tested so far. The nitride coating seems to be more successful than for the bigger brother NSD4015N.

But these ND3x drivers are of very tiny format. I do not like such small outer dimension drivers. Mounted to the TH4001 horn they look really under-dimensioned. But the performance speak for themselves.

It seems quite a few guys in your country retreat from (Salmon-type) multiple hornsystems to more straightforward 2 ways (+ sub) with an increased focus on directivity.

The guy that goes by the moniker of Emokid takes the cake. He went from an ALE based multiple horn system including an Altec/GPA loaded bass array to a "modest" 2 way FLH system with 2x PD 15" (if I'm not mistaken) + TAD TD4003.

The midbass drivers are PHL 6321Nd. The cake is good.

Sincerly, "emokid" himself

Last edited:

Thanks for posting.

There's a hint of Bert Doppenberg and Wolf von Langa and in your midbass.

I suppose it is probably a lot easier to make this sound good (as in in homogeneous) compared to your previous Ale JMLC system?

Do you perhaps have (less smoothed) measurements of mid / high horn alone and of the combined system in your room?

There's a hint of Bert Doppenberg and Wolf von Langa and in your midbass.

I suppose it is probably a lot easier to make this sound good (as in in homogeneous) compared to your previous Ale JMLC system?

Do you perhaps have (less smoothed) measurements of mid / high horn alone and of the combined system in your room?

Last edited:

There's another type of transducer that comes to mind, but I don't think it emits a usable wavefront...

I have Manger driver and can help.

Indeed! One best performances of AL/Ti diaphragms I tested so far. The nitride coating seems to be more successful than for the bigger brother NSD4015N.

But these ND3x drivers are of very tiny format. I do not like such small outer dimension drivers. Mounted to the TH4001 horn they look really under-dimensioned. But the performance speak for themselves.

Looks can be deceiving

Is there any commersial large CD horn available (like Klipsch K402) with 1,5 inch throat where you dont need a tweeter? Or what is the closest you get? Highpass should be At 600 Hz with a JBL 2450SL/2451 beryllium.

I think that one of the interesting "takeaways" from our discussions on here is that it's almost required to match the exit of the compression driver to the entrance of the waveguide.

IE, you *could* go out and buy a JBL progressive transition waveguide that's nearly the size of a K402, and your JBL compression driver would fit on it just fine.

But if you want optimal performance, the waveguide throat should be designed to match. For instance, if the exit of your compression driver is 15 degrees and the entrance of the waveguide is zero degrees, you have a mismatch and that will impact performance.

Having said all the, the big JBL PT waveguides are probably the easiest bet, if you can't get your hands on a k402. I see the big JBL PT waveguides on Craigslist every week. Of course you'll have to buy the entire speaker to get the waveguide

Since Norwegians are participating in this thread and while we're discussing 18Sound's Nitride coated Titanium diaphragms, the Ø Icon came to mind.

There's a NSD (Nitride) driver mounted to the XR1464 and people seem to like this combo quite a lot and praise its smoothness, which is an indication the Nitride coating actually works.

There's a NSD (Nitride) driver mounted to the XR1464 and people seem to like this combo quite a lot and praise its smoothness, which is an indication the Nitride coating actually works.

Attachments

Last edited:

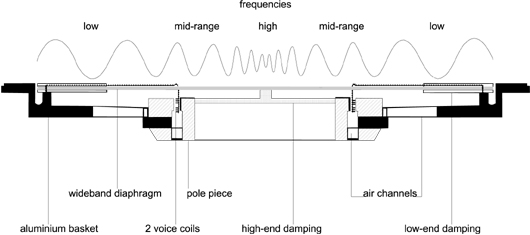

New insights are often obtained through coincidences, or extreme experiments.

A suggestion:

Consider the phase plug channels as 3 separate waveguides.

You already have the outer one. Make the middle one smaller and the center guide the smallest.

Perhaps an OS contour can be maintained.

I briefly searched for existing examples of "convexely used" compression drivers.

Below are a few examples, most of them are smaller diaphragms.

Tannoy Revolution XT series DC design

Attachments

The Tannoy features a center plug, it's both a clever and simple design that should work pretty well.

Small forward-radiating diaphragms are often integrated into the phaseplug, this way the issues with the surround and compression cavity can be (partly) mitigated.

I have listened to the 8" floor model XT8F the 6" floor model XT6F the XT6 bookshelf and the XT Mini (3.25I woofer). I now own both the XT6 and the XT Mini. I much prefer the XT Mini. Astounding little loudspeakers.

Let me summarize what I gathered so far from the endeavour -... But if you want optimal performance, the waveguide throat should be designed to match. For instance, if the exit of your compression driver is 15 degrees and the entrance of the waveguide is zero degrees, you have a mismatch and that will impact performance.

I agree that the two should match. But speaking just about the exit angle would be too simplistic, as it seems. Just look at the CDX1-1425 - one might think it has a negative exit angle and yet it is actually designed to match a 25 degrees diverging waveguide throat. That is because the exit of the phase plug is very near the interface between the driver and the waveguide. By doing that you can "curve" the summed wavefront just by proper positioning of the exits of the slots and their respective delays. The "mismatch" in wall curvatures at the point where the outer slot meets the waveguide doesn't present a problem as the slot is still sufficiently narrow compared to wavelengths involved.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)