I can really only recommend trying the Meta PLA. I used to have problems with lifted corners as well, but since I started using Meta PLA, I don't see this anymore.

My only "problem" left is the overall precision of the printer in terms of X/Y/Z orthogonality and calibration, I guess. With the bigger prints I'm typically still off by a few 1/10s of millimeter here and there, but don't have the determination to try to fix this.

My only "problem" left is the overall precision of the printer in terms of X/Y/Z orthogonality and calibration, I guess. With the bigger prints I'm typically still off by a few 1/10s of millimeter here and there, but don't have the determination to try to fix this.

Last edited:

No proplem. I have posted some on my thread to the speaker project..

Main issue is the warped print starts hitting the nozzle and at some point it just clogs up....

I had problems with tearing up the print when removing support structures, but have introduced a support interface layer of 0,2mm. No problems since.

Main issue is the warped print starts hitting the nozzle and at some point it just clogs up....

I had problems with tearing up the print when removing support structures, but have introduced a support interface layer of 0,2mm. No problems since.

I'll produce test filament from Smile teeth aligners - TPU 64 Shore D. This material is dead when you knock it. Anyone interested to try? TPU is the only material known to me that prints easily in cold garage, no bed heating. It can maka banana after removal but prints safe and hard to destruct with hammer.

I put a cardboard box around my printer. My printer is next to a window and direct sunlight made my waveguide petal move by more than a millimeter.Did you try to heat up the chamber? (Or the other way)

https://www.diyaudio.com/community/threads/efficient-2-way.380822/post-7212361

PLA is over 70D. I have impact PET-G from Plastspaw that is much softer. TPU is max 85D. Acoustical properties much different, I printed once Iwata 300 (see below) out of Ravathane 3015 D65 (similar TPU) and my friend cried when do sanding and lacquering. It clogs paper. Just do fuzzy skin and forget post processing.

Attachments

I think you said that you have this printer: https://zaxe.com/en/3dprinters/zaxe-x3

By heating up the chamber I meant the interior of the printer. I have only a "semi-open" printer but I can imagine that the chamber temperature can have quite an effect. As for the fan speed, I've never experimeted with that a lot.

- Now I see it's "passive heated chamber", which I don't quite understand. Does it mean that it basically doesn't control the temperature inside the chamber?

By heating up the chamber I meant the interior of the printer. I have only a "semi-open" printer but I can imagine that the chamber temperature can have quite an effect. As for the fan speed, I've never experimeted with that a lot.

- Now I see it's "passive heated chamber", which I don't quite understand. Does it mean that it basically doesn't control the temperature inside the chamber?

Last edited:

Got a photo?I am currently using Sunluu PLA+, which is a big improvement to Amazon Basic PLA. My last failed print i used a fresh roll, straight out of the vaccum bag.

Print surface is a PEI sheet i have no problems with. Adhesion is great, overhangs are problematic even though i use supports everywhere.

Because this is always happening above 100mm z-height, i think one reason might be the temperature differential between fresh filament and the already printed part. I could decrease fan speed above 100mm to alleviate this, does anyone of you play with such parameters?

First things I would try:

1) Leave the printer door open, if it has a removable lid, take that off as well.

Could be that it's getting warm enough inside to push the PLA over it's glass transition temperature.

2) Second I would try plain PLA (generally had good luck filaments from eSun). Could be that your PLA+ mix a lot of ABS or other plastic that tends to warp in it.

Good luck!

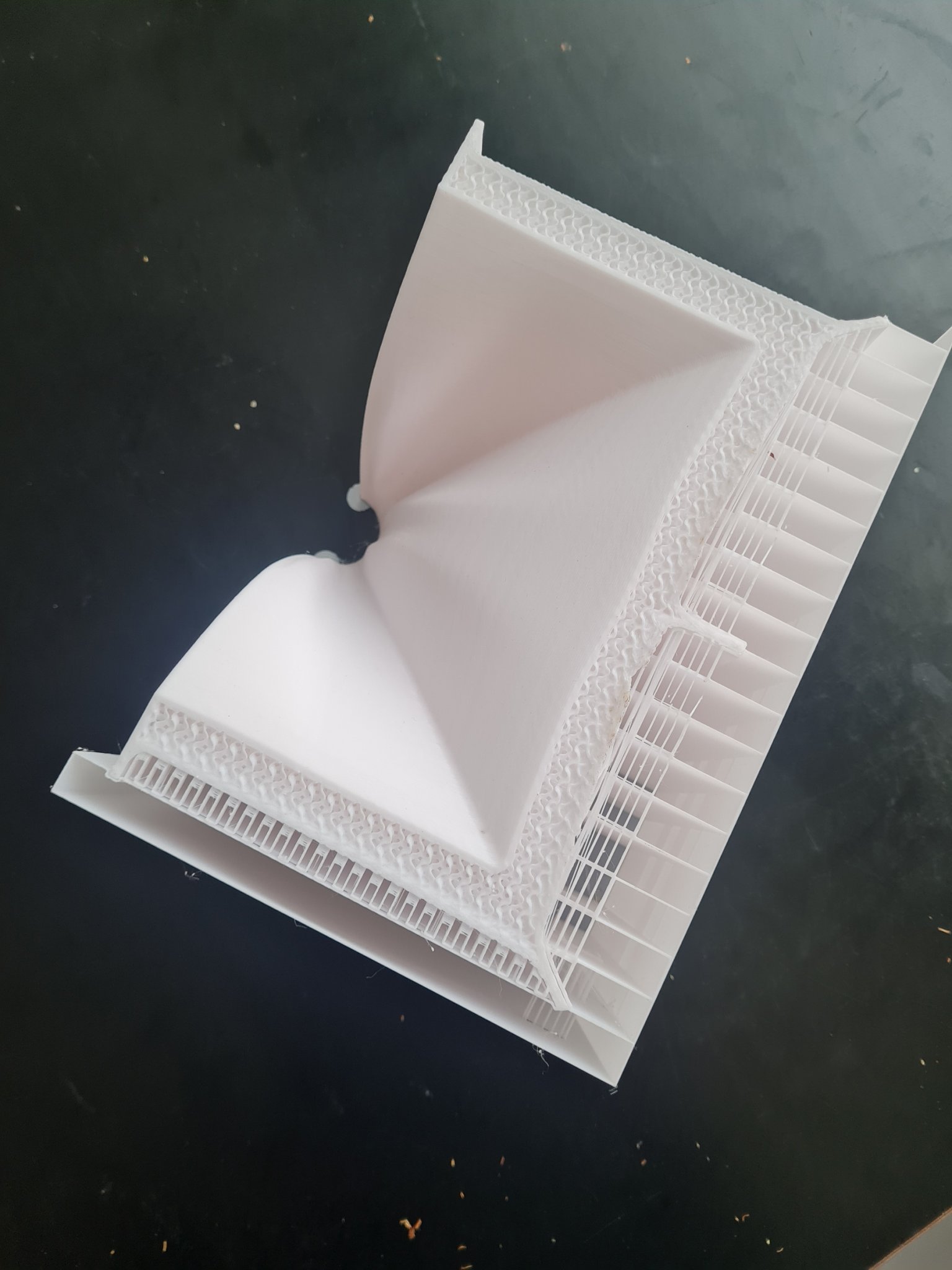

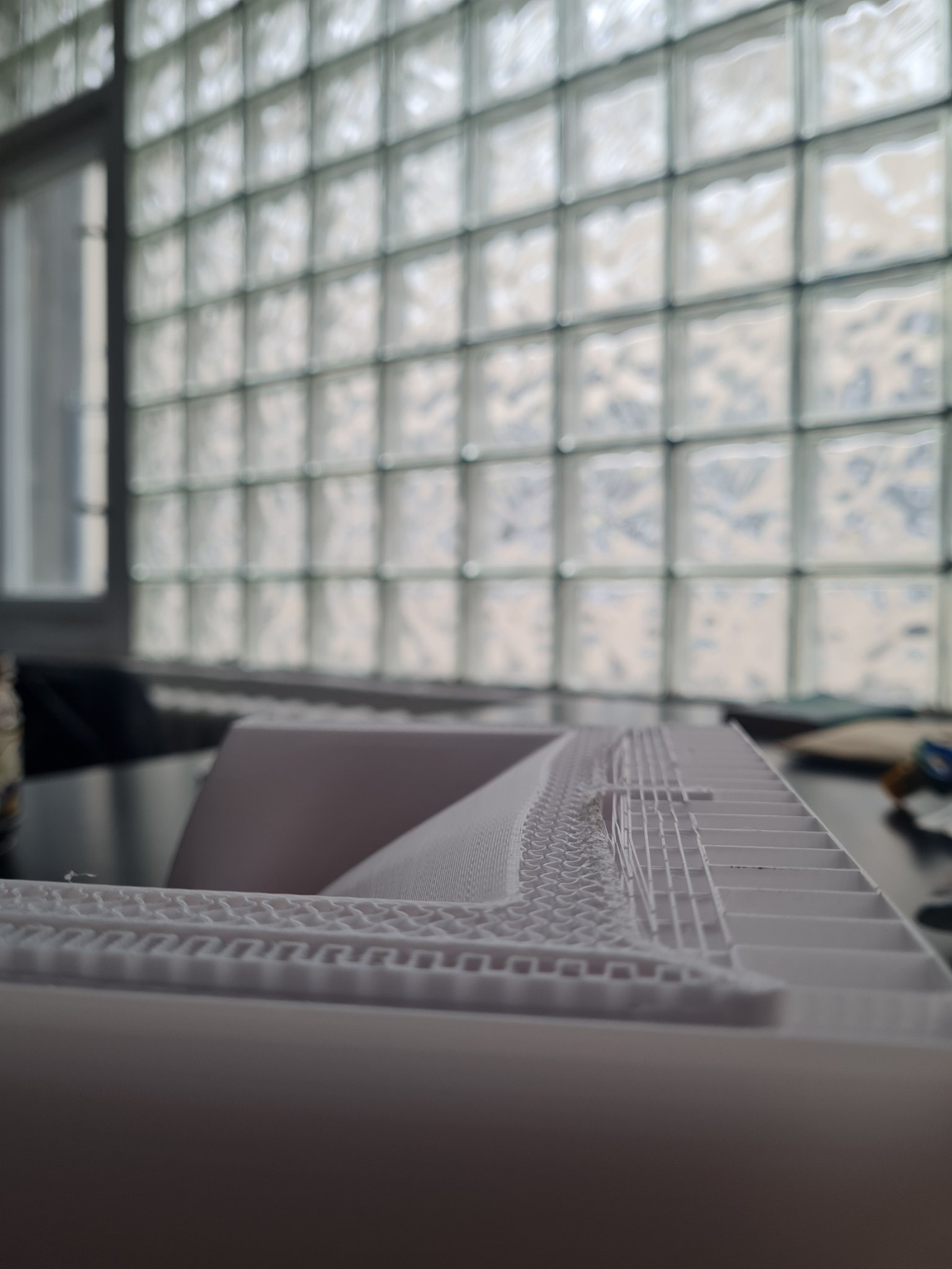

I have another 3 fails of PLA+ and will try open enclosure (lid and door) first, decreasing fan speed ABS style second. If this doesn´t deliver results i will try PLA meta as @mabat suggested. I really want to have a reliable process to be able to build 12" and 15" MEH waveguides for a no compromise speaker project..

I will report back.

I will report back.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)