Hello Everyone,

First time posting on the forums. I recently got into speaker building and have found it to be a relaxing, fun and rewarding hobby. I am planning on building a pair of, what I consider to be, high end 3-Way tower speakers (equivalent of $2000+ retail speakers). I've done a lot of reading online and watching videos on YouTube to help guide me up to this point, but I think it's time to let some folks to review what I have and provide constructive feedback to make these the best speakers they can be.

Here are the drivers planned to be used:

1 Tweeter - Dayton Audio DSN25Ti-4

2 Mids - Dayton Audio RS125-4

2 Woofers - Dayton Audio RS225P-4A

Woofer to Mid Xover = 925 Hz (I know this is generally high, but this woofer can play very clean up to 1KHz)

Mid to Tweeter Xover = 3194 Hz

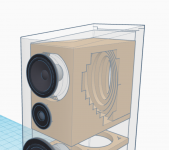

Speaker box dimensions are 10.25" (W) x 46" (H) x 14" (D). The front baffle will have a 1/2" chamfer all the way around to help some with diffraction. I have a 8.75" (W) x 1.5" (H) slot port at the bottom which cant be seen in the picture. Ends will be flared 1/2" on each end, which has been accounted for (port is 1" longer than needed since flare does not count towards port length). Mids and tweeter box is sealed.

The biggest things that I have learned are with respect to the center-to-center driver spacing of a MTM configuration (in this case, <= 4.24 inches at a Xover of 3194 Hz). There is 3/16" between the tweeter and mid, giving it a ctc distance of 4.075 inches so I should be good there.

The other big thing I learned about is baffle step compensation. This is really where I have the most questions. Given these will be fairly close to a wall (18" from the back wall and 24" from the side wall), I think somewhere between 3-4 dB of baffle step compensation seems appropriate. I calculated the F3 to be ~450 Hz. This is where I started the slope downward in my crossover. I assume, maybe incorrectly, that this should slope downward to the frequency where the wavelength is shorter than 1/2 baffle width. In this case, that is ~2600 Hz. I assume that as the wavelengths get shorter you will need to compensate less for baffle step until the frequencies can be modeled in 2pi space (i.e. all projected forward towards the listener). Does that makes sense or am I thinking about this all wrong?

Other questions

- Do you think it is acoustically beneficial to add the "Wedges" inside the mids/tweeter box to help diffract sound or should I get rid of them?

- Are there any other design considerations I need to make, like time alignment or something else?

- Any other recommendations based on past experience with speaker builds like this?

Thanks in advance for your help!

Speaker Box Design:

Frequency Graph:

Impedance Graph:

Crossover Design:

First time posting on the forums. I recently got into speaker building and have found it to be a relaxing, fun and rewarding hobby. I am planning on building a pair of, what I consider to be, high end 3-Way tower speakers (equivalent of $2000+ retail speakers). I've done a lot of reading online and watching videos on YouTube to help guide me up to this point, but I think it's time to let some folks to review what I have and provide constructive feedback to make these the best speakers they can be.

Here are the drivers planned to be used:

1 Tweeter - Dayton Audio DSN25Ti-4

2 Mids - Dayton Audio RS125-4

2 Woofers - Dayton Audio RS225P-4A

Woofer to Mid Xover = 925 Hz (I know this is generally high, but this woofer can play very clean up to 1KHz)

Mid to Tweeter Xover = 3194 Hz

Speaker box dimensions are 10.25" (W) x 46" (H) x 14" (D). The front baffle will have a 1/2" chamfer all the way around to help some with diffraction. I have a 8.75" (W) x 1.5" (H) slot port at the bottom which cant be seen in the picture. Ends will be flared 1/2" on each end, which has been accounted for (port is 1" longer than needed since flare does not count towards port length). Mids and tweeter box is sealed.

The biggest things that I have learned are with respect to the center-to-center driver spacing of a MTM configuration (in this case, <= 4.24 inches at a Xover of 3194 Hz). There is 3/16" between the tweeter and mid, giving it a ctc distance of 4.075 inches so I should be good there.

The other big thing I learned about is baffle step compensation. This is really where I have the most questions. Given these will be fairly close to a wall (18" from the back wall and 24" from the side wall), I think somewhere between 3-4 dB of baffle step compensation seems appropriate. I calculated the F3 to be ~450 Hz. This is where I started the slope downward in my crossover. I assume, maybe incorrectly, that this should slope downward to the frequency where the wavelength is shorter than 1/2 baffle width. In this case, that is ~2600 Hz. I assume that as the wavelengths get shorter you will need to compensate less for baffle step until the frequencies can be modeled in 2pi space (i.e. all projected forward towards the listener). Does that makes sense or am I thinking about this all wrong?

Other questions

- Do you think it is acoustically beneficial to add the "Wedges" inside the mids/tweeter box to help diffract sound or should I get rid of them?

- Are there any other design considerations I need to make, like time alignment or something else?

- Any other recommendations based on past experience with speaker builds like this?

Thanks in advance for your help!

Speaker Box Design:

Frequency Graph:

Impedance Graph:

Crossover Design:

Last edited:

Oh my bad, did not look closely enough at the crossover. It's there loud and clear series. Same question, why series? What i understood, small differences in TSP will become a bigger problem in series. Try a simu with _+ 5% difference in Qts or Fs. That would be differences you see in real drivers.

An improvement would be to give each driver it's own enclosure. Especially the mids. I don't think the "reflector" is going to work.

An improvement would be to give each driver it's own enclosure. Especially the mids. I don't think the "reflector" is going to work.

Last edited:

No reason in particular for drivers in series other than to get a speaker with an impedance that is easy to drive. The Re of the 8 ohm version of these speakers are like 6.6 ohms so they would dip way below 4 ohms if wired in parallel.

I can model with some tolerances to see how things would look. My hope is that since they are Dayton's reference series they will have pretty tight tolerances, but you never know.

Why would individual enclosures sound better? I can definitely do it, just want to understand the benefit as I will be losing enclosure volume.

I can model with some tolerances to see how things would look. My hope is that since they are Dayton's reference series they will have pretty tight tolerances, but you never know.

Why would individual enclosures sound better? I can definitely do it, just want to understand the benefit as I will be losing enclosure volume.

Last edited:

'Bump' in the bass in one thing but from 80-500Hz 3-4dB too much, that's not "but that's my taste" anymore. Especally from 250-500Hz it will become annoying very quickly. You can flatten that with bigger coils or a 12dB (instead of 18dB) low pass (that would show a more symmetrical crossing to the mids too), a bump in the bass will remain then. Or take out some of the resistors.

The wedges don't help in the midrange. In theory a good idea but for redirecting the sound reflections the angle is too low (and the chamber too small) to be beneficial. A heavy acoustic foam on the back of the mid-chamber and polyester wadding ist much more effective.

The speakers are tall, you'll likely get standing waves in the bass. To fight that you could use resonant absorption chambers or an acoustical sump in the top or bottom (or both) with mineral wool or similar. I'm not that fond of glass wool and I usually don't like mineral wool that much either but since it's sealed it's okay-ish and that would be effective.

An additional reinforcement board above the woofer would improve the stability and vibrations of the back and the sides, that's the biggest non-reinforced area.

The wedges don't help in the midrange. In theory a good idea but for redirecting the sound reflections the angle is too low (and the chamber too small) to be beneficial. A heavy acoustic foam on the back of the mid-chamber and polyester wadding ist much more effective.

The speakers are tall, you'll likely get standing waves in the bass. To fight that you could use resonant absorption chambers or an acoustical sump in the top or bottom (or both) with mineral wool or similar. I'm not that fond of glass wool and I usually don't like mineral wool that much either but since it's sealed it's okay-ish and that would be effective.

An additional reinforcement board above the woofer would improve the stability and vibrations of the back and the sides, that's the biggest non-reinforced area.

Individual enclosures is an insurance against slightly different TSP's of the drivers. (in parallel).

Think of one driver beeing 1dB louder as the other and pushing the other around. That's the best that comes to mind to illustrate the idea of different TSP woofers and mids in a shared enclosure. 5% tolerance in TSP is pretty good. Take a look at this Tymphany high end subdriver and the tolerances. If i remember correctly, parallel halves the problem, series doubles the tolerance problem. Simulation will show this.

https://www.tymphany.com/drivers/driver_functions/specsheet.php?id=1817

Think of one driver beeing 1dB louder as the other and pushing the other around. That's the best that comes to mind to illustrate the idea of different TSP woofers and mids in a shared enclosure. 5% tolerance in TSP is pretty good. Take a look at this Tymphany high end subdriver and the tolerances. If i remember correctly, parallel halves the problem, series doubles the tolerance problem. Simulation will show this.

https://www.tymphany.com/drivers/driver_functions/specsheet.php?id=1817

Last edited:

Individual enclosures is an insurance against slightly different TSP's of the drivers. (in parallel).

In series.

Think of one driver beeing 1dB louder as the other and pushing the other around. That's the best that comes to mind to illustrate the idea of different TSP woofers and mids in a shared enclosure.

It's much worse in series. If one of the drivers got a lower impedance, the uneven voltage drop and therefore the power distribution is much worse. Separate enclosures is a good idea though. It requires angle cuts, maybe he wanted to avoid that.

'Bump' in the bass in one thing but from 80-500Hz 3-4dB too much, that's not "but that's my taste" anymore. Especally from 250-500Hz it will become annoying very quickly. You can flatten that with bigger coils or a 12dB (instead of 18dB) low pass (that would show a more symmetrical crossing to the mids too), a bump in the bass will remain then. Or take out some of the resistors.

This is what I don't understand. I built some small 2-way bookshelf speakers and didn't know about baffle step correction. They sound great and I was thinking maybe I got lucky. I've seen a couple of articles and videos talking about the need to adjust for loss in apparent SPL due to baffle step (wavelengths are so long that they wrap around behind the speaker, not towards the listeners ear). Is this not something I should worry about and just go for a flatter response? That would be easy for me to do, just thought I was doing the right thing trying to compensate for baffle step loss.

Sounds like wedges are gone! Easy enough.

The main chamber of the speakers are not sealed (ported at the bottom), but I was planning on using either open cell foam or denim insulation. Never used mineral wool before, but I could probably use that if people think its really that much better.

Yeah, when I posted the picture I realized the lack of bracing there too. Will need to address it in another design revision.

In series.

It's much worse in series. If one of the drivers got a lower impedance, the uneven voltage drop and therefore the power distribution is much worse. Separate enclosures is a good idea though. It requires angle cuts, maybe he wanted to avoid that.

What do you mean by "it requires angled cuts"? Are you saying that because I would need to do that in order to get equal enclosure volumes or some other reason?

Thanks again for your help. As I go through this journey I want to understand the reasoning behind things so I can incorporate that knowledge into future builds.

This is what I don't understand. I built some small 2-way bookshelf speakers and didn't know about baffle step correction. They sound great and I was thinking maybe I got lucky. I've seen a couple of articles and videos talking about the need to adjust for loss in apparent SPL due to baffle step (wavelengths are so long that they wrap around behind the speaker, not towards the listeners ear). Is this not something I should worry about and just go for a flatter response? That would be easy for me to do, just thought I was doing the right thing trying to compensate for baffle step loss.

You are right about the baffle step correction. But here it is a very steep step, I really doubt it will look like that when measuring, it rather leaves a bump, dip or other irregularity. More important: All the simulation softwares I know already account the simulation for the baffle step, you usually see how the drivers actually react to the enclosure or baffle. Maybe I'm wrong because your software does not do that? I don't know what you used and if it does or not. I personally would not use a software which does not actually accounts for and simulates the baffle dimensions.

The main chamber of the speakers are not sealed (ported at the bottom), but I was planning on using either open cell foam or denim insulation. Never used mineral wool before, but I could probably use that if people think its really that much better.

Do not use mineral wool on vented speakers! The micro fibers go into the lungs and you'll blow them out for YEARS! And no, I do not want to rely on the factory claims that the fiber particles are now bigger. If you get cancer, you still have to sue them and prove it's been from their product.

I was assuming the speakers are sealed because the impedance response only showed one maximum peak, ported got 2 (or more, depending on the type). The port placement is not ideal, you should bring it up because at the floor the room modes are excited (is that the right wording?) more. And the speaker will be more critical regarding the distance to the wall, not to talk about a corner.

What do you mean by "it requires angled cuts"? Are you saying that because I would need to do that in order to get equal enclosure volumes or some other reason?

There are mainly 3 reasons:

- As you already suspected, equal volume.

- An angled board defies the standing waves much better than straight boards. That way you could maybe avoid absorber resonators. In two separate enclosures you'd need two of them, which makes the speaker ofcourse bigger.

- Several straight (90°) boards could separate the volume equally too - but that would leave several niches and would lead to resonances on more different frequencies.

The two enclosures ofcourse need each their own port.

Thanks again for your help. As I go through this journey I want to understand the reasoning behind things so I can incorporate that knowledge into future builds.

I like to help but please keep in mind, there are sometimes different ways to do something and you have to weight, which compromise is the best for you. Some things are estimates and things that have happened in the past but may or may not be a problem in your case. There could also appear problems others and me did not think about or might have underestimated the relevance in this case. I always try to do my best though.

On its WMTMW, PBN Audio cuts baffle bevels around the TM section, which shows benefits in Baffle Sim.

Yes, that's effective. 45° bevels, generous rounding of the edges and asymmetrical driver placement helps to avoid or lessen the effect.

The 'egg crate' pattern of the layered enclosure is very effective against internal reflections because they are scattered in frequency and direction. That layered enclosure design is very expensive though and produces TONS of dust waste. The wear on the router bits is also terrible.

The biggest things that I have learned are with respect to the center-to-center driver spacing of a MTM configuration (in this case, <= 4.24 inches at a Xover of 3194 Hz). There is 3/16" between the tweeter and mid, giving it a ctc distance of 4.075 inches so I should be good there.

Do you have a way to model the off-axis response, particularly vertically? You have an acoustic center for your woofers that's at least 16" below the acoustic center for your mids, crossed over when the wavelength is about 14.66 inches. You're probably going to get some odd lobing going on there.

Is there a reason you don't want to do WMTMW? Is there a reason you want to crossover so high? Are you worried about the power handling on the RS125 if crossed low?

Hello Everyone,

First time posting on the forums. I recently got into speaker building and have found it to be a relaxing, fun and rewarding hobby. I am planning on building a pair of, what I consider to be, high end 3-Way tower speakers (equivalent of $2000+ retail speakers). I've done a lot of reading online and watching videos on YouTube to help guide me up to this point, but I think it's time to let some folks to review what I have and provide constructive feedback to make these the best speakers they can be.

Here are the drivers planned to be used:

1 Tweeter - Dayton Audio DSN25Ti-4

2 Mids - Dayton Audio RS125-4

2 Woofers - Dayton Audio RS225P-4A

Woofer to Mid Xover = 925 Hz (I know this is generally high, but this woofer can play very clean up to 1KHz)

Mid to Tweeter Xover = 3194 Hz

Speaker box dimensions are 10.25" (W) x 46" (H) x 14" (D). The front baffle will have a 1/2" chamfer all the way around to help some with diffraction. I have a 8.75" (W) x 1.5" (H) slot port at the bottom which cant be seen in the picture. Ends will be flared 1/2" on each end, which has been accounted for (port is 1" longer than needed since flare does not count towards port length). Mids and tweeter box is sealed.

The biggest things that I have learned are with respect to the center-to-center driver spacing of a MTM configuration (in this case, <= 4.24 inches at a Xover of 3194 Hz). There is 3/16" between the tweeter and mid, giving it a ctc distance of 4.075 inches so I should be good there.

The other big thing I learned about is baffle step compensation. This is really where I have the most questions. Given these will be fairly close to a wall (18" from the back wall and 24" from the side wall), I think somewhere between 3-4 dB of baffle step compensation seems appropriate. I calculated the F3 to be ~450 Hz. This is where I started the slope downward in my crossover. I assume, maybe incorrectly, that this should slope downward to the frequency where the wavelength is shorter than 1/2 baffle width. In this case, that is ~2600 Hz. I assume that as the wavelengths get shorter you will need to compensate less for baffle step until the frequencies can be modeled in 2pi space (i.e. all projected forward towards the listener). Does that makes sense or am I thinking about this all wrong?

Other questions

- Do you think it is acoustically beneficial to add the "Wedges" inside the mids/tweeter box to help diffract sound or should I get rid of them?

- Are there any other design considerations I need to make, like time alignment or something else?

- Any other recommendations based on past experience with speaker builds like this?

Thanks in advance for your help!

Speaker Box Design:

Frequency Graph:

Impedance Graph:

Crossover Design:

Looks like great fun! Though I have some suggestions I think you should take on.

1st:

The crossover from the woofers to the mid is too high. I know they can play that high, but over 900 Hz is already well in the midrange area. This will pull the acoustic centre way down and it will ruin the imaging. I'm sure you will of best crossing around 300 Hz. This will give you the nice big Sd of the woofers to a high in the mid-bass so you really get a nice full bass and mid bass and nice chesty vocals.

2nd:

I think you should ditch the MTM configuration and use a single RS180 or RS180P. Which cone material to pick depends on your taste, though I wouldn't be surprised if you don't exactly know your taste yet. The aluminum cone will be more transparent and faster sounding. The paper cone will have slightly better damping making for better clarity and paper can be more natural and more musical sounding.

At first I also really was into the idea of the MTM configuration but with a dome tweeter it's often better to go with a single midrange.

The dome tweeter gives as bubble/round shaped radiating pattern, symmetrical both horizontally and vertically. A MTM configuration however narrows the vertical response of the midranges because of the vertical offset of the drivers making differences in phase. It works well to match with a ribbon tweeter which also has a narrower vertical response, but you're using a dome.

This way you don't get a constant off-axis radiating pattern, making for a narrower soundstage.

I know you might think it's good because there's a lot of high-end manufacturers like YG-Acoustics and Wilson Audio who use MTM configurations with domes but that's because they really know what they're doing, do it to meet very specific design goals and they are aiming for something really special. But in our case it will be better to use a single midrange.

Another advantage to the single bigger RS180 is simply the sound that it's size gives it. The bigger midrange will have a nice weight to the sound with nice snap and chestyness in the vocals.

3rd:

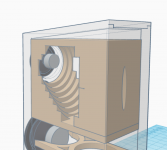

About the wedges: YES, YES YES YES! GOOD! The shape and acoustic treatment of the midrange chamber is something I pay HUGE attention to. If you have got the basics right, proper shape and acoustic treatment of the midrange chamber is key to great sound! Though, I think you should make your midrange chamber bigger. I always take 10 L per driver at a minimum, wether it's a tiny 4" or a 6,5". I use a 6,5" SB-Acoustics Satori MR16P-4 and I put it in a huge 15 L oval-shaped chamber with only the rear wall covered with some damping material.

I think a wedge in the back would also make for a great diffuser. Also I would make a sloped entrance behind the midrange so the back wave gently travels along it's sides into the chamber instead of just falling of a cliff.

So if you're going for the single RS180, and believe me you should, I would make a ~15 L chamber with that wedge in the back with only the wedge and maybe just a bit of the side walls in the back covered with some damping material. Don't use too much. Using to much damping material in the midrange chamber to my experience makes the sound overly bright, lose all it's weight, snap and body/chestyness and it ruins the imaging. Also you should drill maybe three or five 5-8 mm holes in the midrange chamber. This way there will be no form of compression in the midrange chambers whatsoever even at high volumes. This way the midrange can breathe completely freely making for a nice airy unrestrained sound. It can also again slightly improve vocals and body to my experience.

4th:

Make your baffles double layered. You're gonna want to make those real stiff.

Here's what I did with the midrange chamber:

Attachments

Looks like great fun! Though I have some suggestions I think you should take on.

1st:

The crossover from the woofers to the mid is too high. I know they can play that high, but over 900 Hz is already well in the midrange area. This will pull the acoustic centre way down and it will ruin the imaging. I'm sure you will of best crossing around 300 Hz. This will give you the nice big Sd of the woofers to a high in the mid-bass so you really get a nice full bass and mid bass and nice chesty vocals.

Yes, the lower crossover frequency will likely sound much better and it will be much easier to get the response linear in the mids or keep a bump in the bass if that's desired.

2nd:

I think you should ditch the MTM configuration and use a single RS180 or RS180P. Which cone material to pick depends on your taste, though I wouldn't be surprised if you don't exactly know your taste yet.

[...]

At first I also really was into the idea of the MTM configuration but with a dome tweeter it's often better to go with a single midrange.

The dome tweeter gives as bubble/round shaped radiating pattern, symmetrical both horizontally and vertically. A MTM configuration however narrows the vertical response of the midranges because of the vertical offset of the drivers making differences in phase.

[...]

This way you don't get a constant off-axis radiating pattern, making for a narrower soundstage.

[...]

Another advantage to the single bigger RS180 is simply the sound that it's size gives it. The bigger midrange will have a nice weight to the sound with nice snap and chestyness in the vocals.

That's a pretty bad idea. At the desired 3kHz crossover frequency the 180mm mid-woofer already starts to beaming which leads to a very uneven dispersion because the tweeter goes much wider above it and the RS180*4 also drops in sensitivity above 2kHz. And you hardly gain anything by using the RS1804 either, the RS125 got a SD of 52,8cm², so two of them got 105,6 cm², the RS1804 got a SD of 124,7cm², that's less than 19% more cone surface! Definitely not a that big advantage sound wise since it's tied to deficites in other areas. Compromises which are not actually neccessary.

It is true that the vertical dispersion is narrower but that is exactly what's desired because the reflections of the floor and ceiling are muddying the location of the sound stage. The sound stage does not get narrower by that arrangement because the width of it is given by the horizontal dispersion (not the vertical one!) which is a lot narrower below the upper XO of the RS180! So the proposed RS180 does exactly the opposite! Plus, the location improves very much by avoiding the reflections in the mid. On top of that, the dispersion with the smaller mid drivers will be much more even and homogene with the smaller drivers.

Lowering the XO frequency of the tweeter to compensate for that? Your idea of the speaker is obviously a 2-way with some woofers below it. That's not what Packman09 wants.

3rd:

About the wedges: YES, YES YES YES! GOOD! The shape and acoustic treatment of the midrange chamber is something I pay HUGE attention to. If you have got the basics right, proper shape and acoustic treatment of the midrange chamber is key to great sound!

[...]

I think a wedge in the back would also make for a great diffuser. Also I would make a sloped entrance behind the midrange so the back wave gently travels along it's sides into the chamber instead of just falling of a cliff.

Acoustic treatment is important. The shallow angle of the wedges does absolutely noting because the reflection in that angle still returns to the membrane and it only takes absorption depth away from the wadding. To use heavy open pore foam on the back works a lot better than reflecting it in a that low angle. And since the angle doesn't change, it does not become more diffuse either. So the wedges are indeed a bad idea, at least in this enclosure layout.

A different approach would be much more promising, an angled board from the baffle towards the back/top. That would reflect the sound back into the wadding and on top of that it greatly helps against the standing waves in the bass compartment.

So if you're going for the single RS180, and believe me you should, I would make a ~15 L chamber with that wedge in the back with only the wedge and maybe just a bit of the side walls in the back covered with some damping material. Don't use too much. Using to much damping material in the midrange chamber to my experience makes the sound overly bright, lose all it's weight, snap and body/chestyness and it ruins the imaging.

I did not suggest press tight wadding. Your design of the layered boards of the mid-chamber is indeed a very promising approach since it diffuses the sound and the reflections get a lot of different runtime/distance, which scatters the resonances to a lower level over a very wide frequency range. Unfortunately that makes the relatively slim speaker very top heavy which I would strongly recommend to avoid because of obvious practical reasons. It's a good idea though and can be implemented with relatively low effort if no other arguments speak against it.

Also you should drill maybe three or five 5-8 mm holes in the midrange chamber. This way there will be no form of compression in the midrange chambers whatsoever even at high volumes. This way the midrange can breathe completely freely making for a nice airy unrestrained sound. It can also again slightly improve vocals and body to my experience.

In the midrange there is not enough excursion to cause compression. If there would be some, the 5mm holes would create air noises. And that creates a Helmholtz resonator, which may or may not fall into a frequency range where it's potentially not actually wanted to resonate.

An opening to the back makes the sound stage go deeper but also reduces the location greatly because of the mid-reflections from the back wall. Closed or open is a personal preference, I suggest to try it but in the most cases it runs boring quickly (like any effect) and the precise location is then recognized as missing. Another point against that is the unhomogeneous depth compared to the highs, which would require a back tweeter to compensate for it.

4th:

Make your baffles double layered. You're gonna want to make those real stiff.

That is indeed a good suggestion, but poses also a big impact in sound quality on small drivers because the air becomes compressed between baffle cutout and magnet. To bevel-widening the cutout on the back can help but that often makes the mounting of the driver complicated because the lack of an even surface/material for the drive-in nuts is an actual problem. Using wood screws isn't solving the problem because the particle board 'gives in' over time and they become loose more or less which is audible (even when the drivers basket itself isn't able to visibly move) and results in a loss of details and precision. There are some ways around it which require good planning and good craftmanship though.

Of course you gotta decide what you want to do, this is your project and honestly I know how annoying it can be when you're putting something together thinking it is good and people keep saying you should do something different but let me do some more recommendations.

For the drivers. You already were on the right path, really. Dayton Audio makes great drivers for their price and the Reference series drivers are very capable, but if you want to lift the performance of your speakers up one notch, you should look at SB-Acoustics their NRX and NBAC line depending on if you want paper or aluminum cones, they use the same motor, just a different cone.

For the woofers, I would recommend the SB23NRXS45-4 or SB23NBACS45-4 and for the midrange the SB17NRX2C35-8 or SB17NBAC35-8.

Why these? Well, as I said Dayton drivers are quite nice but these are on another level in performance yet cost the same. The have WAY lower distortion, some of the lowest on the market. Especially the SB17, either NRX2C or NBAC actually comes quite close to that of my Satori's. The Daytons can't even dream of coming anywhere near that. Also in terms of real-world sound the SB-Acoustics drivers potentially offer the clarity, speed, snap and overall sound quality the Daytons simply don't have up their sleeve. This just comes down to the fact that the SB-Acoustics are brilliantly engineered by former Scan-Speak engineers, who are just unbeatable

Also, again it's your project, but I'm gonna ORDER you to invest more in your tweeter. That DSN25Ti does not at all live up to the potential the other drivers in this system offer, seriously, it will be a HUGE restriction of the performance of this system. In terms of quality that 15 buck thing is more at the level of something like the Dayton Classic Series.

There's very good tweeters on the market for less than €40.

Again, it depends on your preference. Hard domes, at this price that will be a aluminum dome, offer great speed, transparency and detail. Soft domes will sound smoother but not at transparent or detailed, especially at this price range.

I'll give you some very good options.

Soft:

SB-Acoustics SB29SDAC, Seas Prestige 27TDFC

Hard:

Seas Prestige 27TBFC/G

There are many more options on the market, these are just some that came up in my mind.

If I may, I'm gonna do another suggestion: unless you really want to make passive speakers, go active with plate amps. I also went active with my built. I know three-way DSP-driven plate amps might seem expensive. But when making passive speakers, the crossover components can be surprisingly expensive, hundreds of euros. And you will buy a lot of components which you at the end of the day might not even use while fine-tuning the crossover. On top of that, you will need obviously still need an external amp, which will also be a few hundred euros if you want something decent like the entry-level Marantz or Dennon amps, and you'll need cables.

Fine-tuning the passive crossover will be a painstaking trail and error process that will consume a lot of time and be very complex.

When going active, I recommend the Hypex Fusionamps. They are very, very good quality amps used in other active systems like Grimm and Bowers & Wilkins speakers and subwoofer and their modules even get used in Marantz amps. And they have lots of connectivity and a very nice working DSP with which you can literally perfect the performance of the system with a couple of mouse clicks.

Going active really has big benefits. As I said, setting a DSP is MUCH simpler than making a passive crossover. And, no matter how good a passive crossover is. Even those in Tidal, Kharma, Wilson Audio or whatever brand among the best in the world. A passive crossover can never be as good as an active crossover because no matter how good it is, there will always be a loss of sound quality in the passive components, let alone at this price point. With active DSP driven trip-amping the signal gets split up digitally, with no theoretical loss, goes into the amps, straight to the drivers. This is a simply superior way of doing things, especially on this price point where the quality of the otherwise passive components in restrained.

Also, you can tailor the sound of the speakers in the room and play with the bass response. If you're really going for it you could even put the woofers in a sealed box like I did and boost the lower bass with the DSP to compensate (or even more than compensate) for the higher roll-off. Why? Because sealed enclosure offer much tighter and faster bass and are less b*itchy in terms of placement.

Again, this is your project and I know how annoying it can be when people keep saying you should do things differently. But believe me, following my tips, at least those about the drivers (I'm begging you, at least upgrade your tweeter) you're gonna end up with a MUCH nicer result.

For the drivers. You already were on the right path, really. Dayton Audio makes great drivers for their price and the Reference series drivers are very capable, but if you want to lift the performance of your speakers up one notch, you should look at SB-Acoustics their NRX and NBAC line depending on if you want paper or aluminum cones, they use the same motor, just a different cone.

For the woofers, I would recommend the SB23NRXS45-4 or SB23NBACS45-4 and for the midrange the SB17NRX2C35-8 or SB17NBAC35-8.

Why these? Well, as I said Dayton drivers are quite nice but these are on another level in performance yet cost the same. The have WAY lower distortion, some of the lowest on the market. Especially the SB17, either NRX2C or NBAC actually comes quite close to that of my Satori's. The Daytons can't even dream of coming anywhere near that. Also in terms of real-world sound the SB-Acoustics drivers potentially offer the clarity, speed, snap and overall sound quality the Daytons simply don't have up their sleeve. This just comes down to the fact that the SB-Acoustics are brilliantly engineered by former Scan-Speak engineers, who are just unbeatable

Also, again it's your project, but I'm gonna ORDER you to invest more in your tweeter. That DSN25Ti does not at all live up to the potential the other drivers in this system offer, seriously, it will be a HUGE restriction of the performance of this system. In terms of quality that 15 buck thing is more at the level of something like the Dayton Classic Series.

There's very good tweeters on the market for less than €40.

Again, it depends on your preference. Hard domes, at this price that will be a aluminum dome, offer great speed, transparency and detail. Soft domes will sound smoother but not at transparent or detailed, especially at this price range.

I'll give you some very good options.

Soft:

SB-Acoustics SB29SDAC, Seas Prestige 27TDFC

Hard:

Seas Prestige 27TBFC/G

There are many more options on the market, these are just some that came up in my mind.

If I may, I'm gonna do another suggestion: unless you really want to make passive speakers, go active with plate amps. I also went active with my built. I know three-way DSP-driven plate amps might seem expensive. But when making passive speakers, the crossover components can be surprisingly expensive, hundreds of euros. And you will buy a lot of components which you at the end of the day might not even use while fine-tuning the crossover. On top of that, you will need obviously still need an external amp, which will also be a few hundred euros if you want something decent like the entry-level Marantz or Dennon amps, and you'll need cables.

Fine-tuning the passive crossover will be a painstaking trail and error process that will consume a lot of time and be very complex.

When going active, I recommend the Hypex Fusionamps. They are very, very good quality amps used in other active systems like Grimm and Bowers & Wilkins speakers and subwoofer and their modules even get used in Marantz amps. And they have lots of connectivity and a very nice working DSP with which you can literally perfect the performance of the system with a couple of mouse clicks.

Going active really has big benefits. As I said, setting a DSP is MUCH simpler than making a passive crossover. And, no matter how good a passive crossover is. Even those in Tidal, Kharma, Wilson Audio or whatever brand among the best in the world. A passive crossover can never be as good as an active crossover because no matter how good it is, there will always be a loss of sound quality in the passive components, let alone at this price point. With active DSP driven trip-amping the signal gets split up digitally, with no theoretical loss, goes into the amps, straight to the drivers. This is a simply superior way of doing things, especially on this price point where the quality of the otherwise passive components in restrained.

Also, you can tailor the sound of the speakers in the room and play with the bass response. If you're really going for it you could even put the woofers in a sealed box like I did and boost the lower bass with the DSP to compensate (or even more than compensate) for the higher roll-off. Why? Because sealed enclosure offer much tighter and faster bass and are less b*itchy in terms of placement.

Again, this is your project and I know how annoying it can be when people keep saying you should do things differently. But believe me, following my tips, at least those about the drivers (I'm begging you, at least upgrade your tweeter) you're gonna end up with a MUCH nicer result.

Well obviously the RS180 can't go to 3 kHz. It should be crossed at 2 kHz. However the tweeter might not be able to handle that but again, the tweeter should be upgraded. I don't want to be annoying but using that tweeter in combination with all these other great driver is just ridiculous. In case of the RS180, cross it at 2 kHz and its dispersion will blend in just fine with the tweeter. And no it's not that much bigger in Sd, but it is bigger, but that's not the point. The way the midrange sounds is not determined by Sd. The single bigger driver will have weight, body and linearity to it that smaller ones simply won't, no matter how many you have ore how they are implemented. This statement is gonna be very controversial but a smaller number of bigger drivers is preferable over a bigger number of smaller drivers for a give total Sd.

Back to the acoustics of the midrange chamber. Yes, when using the wedge, it has to be much deeper with a much steeper angle, but if my suggestion of the much bigger chamber is being followed that should be possible. And thanks for congratulating my design of the midrange chamber. If OP is willing to implement it in his design and is willing to make the effort of eventually building, I think it's the best one could possibly do with the midrange chamber. It offers a soundstage and imaging that is just unparalleled, seriously. Here in The Hague we have a hifi shop called Chattelin. They are on of the highest-end stores in the Netherlands and have absolute top of the world gear including Wilson Audio, KEF (their high-end models like the Blade), Grimm and their signature brand is Kroma Audio. They've got their entire line in store including their €200k / pair Elektra. Even the best systems I've heard there do not offer the same soundstage and maybe even imaging as my speakers do, and I'm not exaggerating.

The holes in the back, they are not necessary and might not be favorable in every scenario. Just in my case they made it just slightly better. However they don't bleed midrange to the back wall and are not intended to. I've got damping in front of the holes to prevent midrange bleeding out of them. They are not meant to make the speaker a dipole, only to give the midrange chamber a slight bit of ventilation.

But if the intention is to limit the vertical dispersion to prevent floor and ceiling reflections, a MTM will indeed be the right way to go but then I wouldn't use a dome tweeter either. Again, this would narrow the vertical midrange dispersion but then the tweeter will still have perfect dispersion, the dispersion won't match. If I where you, I would use a ribbon or planar tweeter, there's some pretty good ribbon and planar tweeters for relatively little money. OR use two domes in a MTTM configuration.

A ribbon/planar tweeter will have a narrower vertical dispersion which I just understood in intended in this system, and it will match the dispersion pattern of the MTM configuration.

Then if you're going MTM after all, you could use smaller midranges, this way the centers of the drivers won't get to far apart.

I think you should use two dome tweeters in a MTTM configuration. There's ribbon like the Fountek NeoCD1.0 for €51 but these are so small and low quality that they have to be crossed at over 4 or even 5 kHz which unreachable.

I think you'll of very well using two of one of the tweeter I suggested.

Let me do a suggestion for a driver selection:

Back to the acoustics of the midrange chamber. Yes, when using the wedge, it has to be much deeper with a much steeper angle, but if my suggestion of the much bigger chamber is being followed that should be possible. And thanks for congratulating my design of the midrange chamber. If OP is willing to implement it in his design and is willing to make the effort of eventually building, I think it's the best one could possibly do with the midrange chamber. It offers a soundstage and imaging that is just unparalleled, seriously. Here in The Hague we have a hifi shop called Chattelin. They are on of the highest-end stores in the Netherlands and have absolute top of the world gear including Wilson Audio, KEF (their high-end models like the Blade), Grimm and their signature brand is Kroma Audio. They've got their entire line in store including their €200k / pair Elektra. Even the best systems I've heard there do not offer the same soundstage and maybe even imaging as my speakers do, and I'm not exaggerating.

The holes in the back, they are not necessary and might not be favorable in every scenario. Just in my case they made it just slightly better. However they don't bleed midrange to the back wall and are not intended to. I've got damping in front of the holes to prevent midrange bleeding out of them. They are not meant to make the speaker a dipole, only to give the midrange chamber a slight bit of ventilation.

But if the intention is to limit the vertical dispersion to prevent floor and ceiling reflections, a MTM will indeed be the right way to go but then I wouldn't use a dome tweeter either. Again, this would narrow the vertical midrange dispersion but then the tweeter will still have perfect dispersion, the dispersion won't match. If I where you, I would use a ribbon or planar tweeter, there's some pretty good ribbon and planar tweeters for relatively little money. OR use two domes in a MTTM configuration.

A ribbon/planar tweeter will have a narrower vertical dispersion which I just understood in intended in this system, and it will match the dispersion pattern of the MTM configuration.

Then if you're going MTM after all, you could use smaller midranges, this way the centers of the drivers won't get to far apart.

I think you should use two dome tweeters in a MTTM configuration. There's ribbon like the Fountek NeoCD1.0 for €51 but these are so small and low quality that they have to be crossed at over 4 or even 5 kHz which unreachable.

I think you'll of very well using two of one of the tweeter I suggested.

Let me do a suggestion for a driver selection:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- 3-Way Tower Design Review