Well, you're light years ahead of me regarding FIR I just measure drivers nearfield and equalise them flat as possible. Then apply crossover as wished or needed, it's almost always needed

I just measure drivers nearfield and equalise them flat as possible. Then apply crossover as wished or needed, it's almost always needed After that, I measure at listening position and adjust for my needs. I use DSP of course, and I have three settings: music, movies and news. Music is "fatter", movies leaner and news even leaner for speech intelligibility

After that, I measure at listening position and adjust for my needs. I use DSP of course, and I have three settings: music, movies and news. Music is "fatter", movies leaner and news even leaner for speech intelligibility

My "school" has been reading HobbyHifi, it's a german magazine for DIY's. It's excellent as they show raw driver measurements and filtered responses as final result and comments about the development.

But anyway, a three way is difficult. Start with a two way and build from there. I'm in the process of a two way with a horn, I find it less difficult as I managed to get a reasonable flat response without measurement than with a two way with a dome!!! Figure that out?

My "school" has been reading HobbyHifi, it's a german magazine for DIY's. It's excellent as they show raw driver measurements and filtered responses as final result and comments about the development.

But anyway, a three way is difficult. Start with a two way and build from there. I'm in the process of a two way with a horn, I find it less difficult as I managed to get a reasonable flat response without measurement than with a two way with a dome!!! Figure that out?

Well, you're light years ahead of me regarding FIRI just measure drivers nearfield and equalise them flat as possible. Then apply crossover as wished or needed, it's almost always needed

After that, I measure at listening position and adjust for my needs. I use DSP of course, and I have three settings: music, movies and news. Music is "fatter", movies leaner and news even leaner for speech intelligibility

My "school" has been reading HobbyHifi, it's a german magazine for DIY's. It's excellent as they show raw driver measurements and filtered responses as final result and comments about the development.

But anyway, a three way is difficult. Start with a two way and build from there. I'm in the process of a two way with a horn, I find it less difficult as I managed to get a reasonable flat response without measurement than with a two way with a dome!!! Figure that out?

I would say you are far ahead of anything I have done. I only know what I have read and no practical experience. I am only interested in FIR filters because of what I have read concerning them. Initially I will just set my crossovers and then adjust them to the best of my ability with using REW. My DSP allows me to save different configurations so I can try different things to try and improve the sound to my taste. If something does not work out I can always revert back to older settings. It is why I went active instead of passive. Building these speakers has added a lot of excitement for me and even though I only want to build 1 set, if they do not give me the sound I want first time around I know I can try again with new cabinets or add bigger woofers. Unlike a lot of people I have never heard any speakers with the drivers I have chosen, so I have no idea on the sound to expect from them. Part of my excitement is having no idea what to expect when they are completed.

You're in for quite a ride then There are some people here that could help you with FIR, wesayso and Byrtt come to mind.

There are some people here that could help you with FIR, wesayso and Byrtt come to mind.

I bought this one

Lucius 6K - A - 2U - MKII - Sitronik Industrie

It's expensive and a bit limited but I don't like the clutter with cables and boxes + it's actually made in Europe. Or I should say assembled at least, as most electronics origin from Asia today...

I bought this one

Lucius 6K - A - 2U - MKII - Sitronik Industrie

It's expensive and a bit limited but I don't like the clutter with cables and boxes + it's actually made in Europe. Or I should say assembled at least, as most electronics origin from Asia today...

In my experience, the driver is almost to big to result in a good power response together with some typical dome tweeters.

I use the C153-T8-82 and 24dB LR. I cant run it higher than around 2400hz, since the beaming effect starts to kick in. When my Seas Magnum tweeter takes over, it's fully beaming in all directions at 2400hz. So with your larger midrange, you will have beaming from maybe 2000hz.

All I'm saying is - measure it - explore and find out what your drivers are doing, not only on-axis but also off-axis.

I use the C153-T8-82 and 24dB LR. I cant run it higher than around 2400hz, since the beaming effect starts to kick in. When my Seas Magnum tweeter takes over, it's fully beaming in all directions at 2400hz. So with your larger midrange, you will have beaming from maybe 2000hz.

All I'm saying is - measure it - explore and find out what your drivers are doing, not only on-axis but also off-axis.

In my experience, the driver is almost to big to result in a good power response together with some typical dome tweeters.

I use the C153-T8-82 and 24dB LR. I cant run it higher than around 2400hz, since the beaming effect starts to kick in. When my Seas Magnum tweeter takes over, it's fully beaming in all directions at 2400hz. So with your larger midrange, you will have beaming from maybe 2000hz.

All I'm saying is - measure it - explore and find out what your drivers are doing, not only on-axis but also off-axis.

I will have lots to learn once I start testing the speakers and it what I am looking forward to. I have purchased everything I need to measure and will have plenty of time to adjust them. There are a lot of people with the knowledge on this forum and I am sure once I measure them I will require help. It is because of forums like this that I have decided to learn. I think I have picked good drivers and if my design for the cabinets is sound I should have no problems getting a sound I will enjoy. It is amazing that so many people will share their knowledge. I find it funny that the drivers I am now going to use are all different from the drivers I originally were going to use. I have remodeled the cabinets so many times I have lost count. Purchased parts and tools that I now know I will never use since I have decided to have the cabinets cnc’d. Bought all the recommend books to read and a lot is over my understanding right now but slowly my project is coming together so I am still excited

measurements - both on and off axis

Another issue I have never taken measurements before even though I have the equipment and software to measure. Probably another big learning curve.

For now I just plan to play around with the software and hook the DSP to an old set of 2 way speakers I plan to remove the crossover from.

I have uploaded picture of finished crossover

Attachments

I have also a project based the C160 mid. The measurements made by hificompass are not that great, but I wonder if the cut out profile was correct (I think this driver is picky about this)

You have done a great job, to respect the accuton guidelines for the cut out profile : it should work. For the cabinet size, my own calculations say a 10 litres closed box. According to accuton, this driver is not prone to backside reflections.

I also recommand a notch filter at 6-8 khz : it will reduce the distorsion above 2 khZ.

I will follow your project with much interest.

You have done a great job, to respect the accuton guidelines for the cut out profile : it should work. For the cabinet size, my own calculations say a 10 litres closed box. According to accuton, this driver is not prone to backside reflections.

I also recommand a notch filter at 6-8 khz : it will reduce the distorsion above 2 khZ.

I will follow your project with much interest.

Hello

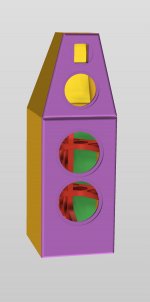

This will be the first set of speakers I have built

2 Closed Boxed Cabinets - Using 1" Baltic Birch

Accuton Drivers

C30-6-358 Tweeter

C168-6-990 Mid

AS250-8-552 Bass

DSP 192-4-111

[...]

Mid Range Cabinet

Vb = 2.672 liters

Qtc = 0.441

QL = 7

F3 = 236 Hz

I am pretty sure size for the Bass cabinet is ok for size but not too sure the Mid because of the QTC. Some of the post I read makes me think I do not need to worry about the QTC for Mid cabinet.

Have you thought about aperiodic venting? A long time ago, I made a pair of 15L boxes for 7" Accuton C7xx (forgot thel exact model number) mid-woofers. The boxes were sealed, and strong, and tough to tame.

IMO there were a lot of things wrong with the boxes: the back-wave seemed to strongly resonate in the air cavity. It wasn't loud, just a bit fatiguing. The active filters with a 5kHz notch helped, I think, but I never ended up doing a couple of basic tests like adding series resistance to check if the class-AB amplifier ("infinity dampings"!

Since then, I've built a couple of other speakers, and they all seem to benefit from additional mechanical damping (aperiodic), combined with down-tuned electrical damping. For instance, I have a pair of Dayton's 3.5" point source 'bullet' style speakers running in 1L boxes with a 'grill' of small holes in the back, blocked with felt, and 10 ohm in series. The subtle but interesting improvement in sound motivated me to start developing my own current-drive amplifier.

I have also a project based the C160 mid. The measurements made by hificompass are not that great, but I wonder if the cut out profile was correct (I think this driver is picky about this)

You have done a great job, to respect the accuton guidelines for the cut out profile : it should work. For the cabinet size, my own calculations say a 10 litres closed box. According to accuton, this driver is not prone to backside reflections.

I also recommand a notch filter at 6-8 khz : it will reduce the distorsion above 2 khZ.

I will follow your project with much interest.

Thanks to Danny he recommended a 10lit box for the mid so I adjusted the size to the 10lit.

+1 for a bigger aperiodic mid cabinet

Extract of my to post v2 refspeaker:

For the mid cabinets I went from a 3.5 liter closed box to a 10 liter aperiodic vented cone shaped box, this made a huge update to the sound:

with the small closed box in the v1 I didn't get the Accutons C173-6-090 to sound completely good, sometimes it sounded nasal, congested,

I suspect it was due to the backwaves of the cone bouncing around in the small closed box.

with the new 10 liter cone shape tapered box (45cm long), the backwave is completely absorbed, also thanks to the phenomenal Twaron Angelhair (stuffed 3gr/l)

Now it sounds much more natural, open and dynamic.

Inspiration for the larger cone shaped mid comes from Troels, the venturi vent in the Avalon clone and XTZ divine.

My findings correspond to Troels ones, see halfway "Mid cab vent"

Extract of my to post v2 refspeaker:

For the mid cabinets I went from a 3.5 liter closed box to a 10 liter aperiodic vented cone shaped box, this made a huge update to the sound:

with the small closed box in the v1 I didn't get the Accutons C173-6-090 to sound completely good, sometimes it sounded nasal, congested,

I suspect it was due to the backwaves of the cone bouncing around in the small closed box.

with the new 10 liter cone shape tapered box (45cm long), the backwave is completely absorbed, also thanks to the phenomenal Twaron Angelhair (stuffed 3gr/l)

Now it sounds much more natural, open and dynamic.

Inspiration for the larger cone shaped mid comes from Troels, the venturi vent in the Avalon clone and XTZ divine.

My findings correspond to Troels ones, see halfway "Mid cab vent"

Last edited:

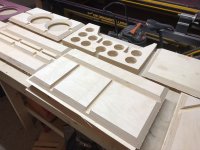

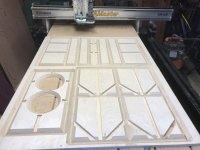

Assembly Pictures

Assembly of cabinets is complete. Next Friday binding post and damping to be added before gluing the baffles

Assembly of cabinets is complete. Next Friday binding post and damping to be added before gluing the baffles

Attachments

The CNC work on those cabinets is NUTS! Are you a professional cabinet maker? What is your design tool chain? So very impressed.

Originally I was planning to cut and do my own cabinets but after reading all the forums I came across cabinets made with a CNC and knew that I could never build cabinets that accurate. I designed the speakers and gave the cad file to a person locally with a CNC machine and he did all the cutting. I felt that the drivers I picked deserved a nice cabinet to house them.

The speakers have turned out fantastic and l look forward to start tuning them next week.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- first Time Build Accuton Active 3way