The tractrix profile was never intended for horns while the spherical wave horn was.

Atttached you can find an SWH with 2" exit and cut-off 160Hz. This should load down for your driver sufficiently.

View attachment swh_rnd_160.zip

Atttached you can find an SWH with 2" exit and cut-off 160Hz. This should load down for your driver sufficiently.

View attachment swh_rnd_160.zip

And here the same base parameters but with progressive expansion T factor. This should also load sufficiently and beam less.

View attachment swh_rnd_160_pe.zip

View attachment swh_rnd_160_pe.zip

And the same as before but nearly squared profile...

View attachment swh_sq_160_pe.zip

View attachment swh_sq_160_pe.zip

So I need a way to be able to calculate the horn profile without bothering people to do it for me. I downloaded Ath4 and Abec/Vacview demo.....have no idea how to use it yet.

... or you could use the calculator that @docali is using and has made available at Download – Sphericalhorns

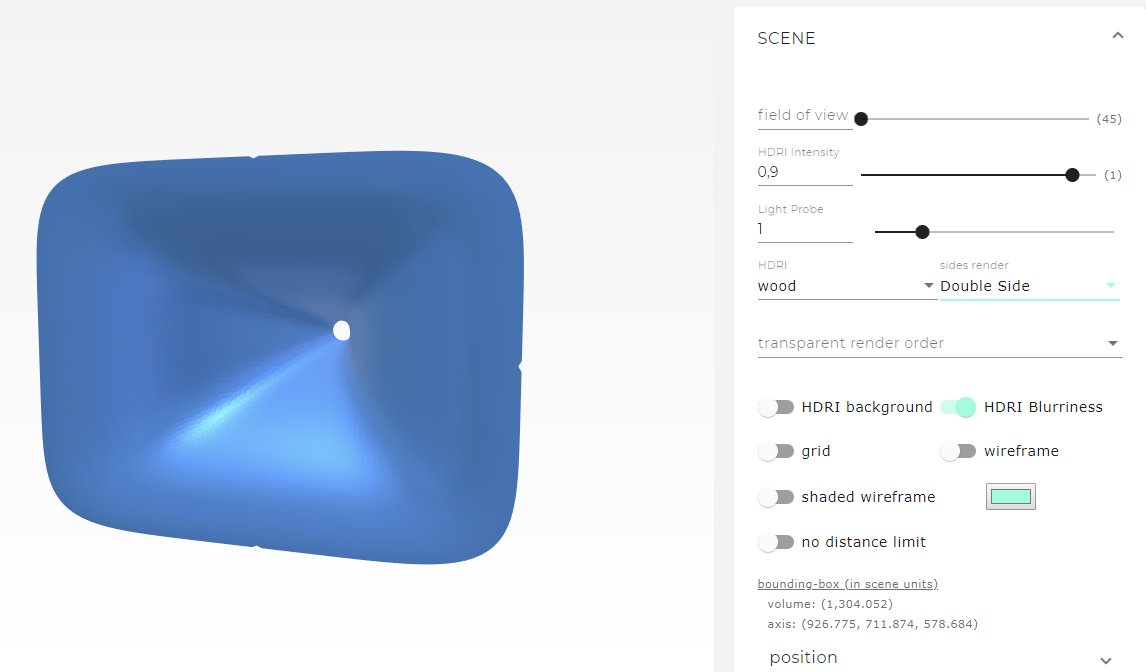

A variation with a slight stretch factor. Looks similar to the Celestion.

View attachment swh_ra_160_pe.zip

View attachment swh_ra_160_pe.zip

Did you get to see these horn models, camplo?

Here's a site that can easily view them online: Creators 3D

(this is the swh_ra_160_pe)

You can drag and drop the *.ply file to see the horn (just make sure to set sides render to "Double Side"). I have not checked if something like Fusion 360 supports the *.ply format, I know it can read *.stl.

This file is still a points cloud. To get it as a proper working model for CNC (or printing) it should be converted to a solid object by adding thickness etc.

When you've made a solid model from this you could slice it up again to create the information needed for a CNC tool (just as pictured in your post this would create a stepped model of the horn if you build it in slices).

Here's a site that can easily view them online: Creators 3D

(this is the swh_ra_160_pe)

You can drag and drop the *.ply file to see the horn (just make sure to set sides render to "Double Side"). I have not checked if something like Fusion 360 supports the *.ply format, I know it can read *.stl.

This file is still a points cloud. To get it as a proper working model for CNC (or printing) it should be converted to a solid object by adding thickness etc.

When you've made a solid model from this you could slice it up again to create the information needed for a CNC tool (just as pictured in your post this would create a stepped model of the horn if you build it in slices).

Attachments

Last edited:

So I need a way to be able to calculate the horn profile

AllenB said:Hornresp

Windows actually has a model viewer, never knew. Though I'm not sure what to do with it. I mean it looks cool, but I'll probably have to put it into autocad or something to get it represent real dimensions.

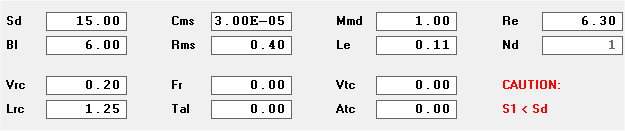

Allen....I was thinking that. I tried to make a horn the other day it keeps giving me issues because the thiel specs aren't optimal. Whens the last time you've seen thiel specs for a compression driver. I'm probably using it wrong.

Allen....I was thinking that. I tried to make a horn the other day it keeps giving me issues because the thiel specs aren't optimal. Whens the last time you've seen thiel specs for a compression driver. I'm probably using it wrong.

Last edited:

Autocad wouldn't be the tool I'd recommend. Fusion 360 (also from AutoDesk and free to use for DIY) is a much better tool for that job. There you could build it up as a proper horn with a wall thickness etc. This ply file just represents the inner surface. The online viewer does give you the bounding box, in other words it shows the outside dimensions.

(my Windows did not have that cute 3D viewer, still at Win 7 Pro here )

)

(my Windows did not have that cute 3D viewer, still at Win 7 Pro here

Hello. Almost a year to the day since I've visited. I have been using Altec Lansing 416 model woofers (15") and an 808 and 811 horn and lens for years as one of my 2 way systems and listening to ALL kinds of music. They suit me and yes, they will play Lima Charlie (loud and clear.) they're not for everyone. I also have Altec crossovers. I believe they are the 500's. SPL is up there, too. I bought them in the 1st place to use with a low power DHT SET amplifier. Now, I use them with a solid state 20w Exposure 2010s2. I hope this helps.Thanks.

Thanks for the preparation of the ply file. I just recognize that the point cloud is not perfect at all. There are some artifacts on the outer edge which are not intended. My calculator was never tested with such large horns

The progressive expansion algorithm has two advantages. The horn opens faster in the mouth region and the length is reduced while the mouth diameter is nearly the same. Several parameters can be varied to influence the transition. It is a very advanced spherical wave horn. Still need to find the time to document this on my web page.

The progressive expansion algorithm has two advantages. The horn opens faster in the mouth region and the length is reduced while the mouth diameter is nearly the same. Several parameters can be varied to influence the transition. It is a very advanced spherical wave horn. Still need to find the time to document this on my web page.

I was thinking, if I printed it, I could make it hollow, cut into layers and the layuers into segments, print those out, assemble them, and then fill them with sand as well. Seems that 3d printing has its own challenges main...warping?

Docali, who are you thanking? My thanks goes out to you for sharing though. Sounds like the files sent are not the ones to use because of artifacts?

Docali, who are you thanking? My thanks goes out to you for sharing though. Sounds like the files sent are not the ones to use because of artifacts?

Try these.Whens the last time you've seen thiel specs for a compression driver.

Attachments

Challenges like warping can be overcome mostly. You'd have to ask yourself if you'd want to use a horn made out of PLA, ABS or PETG etc.

To have it printed commercially, like at Shapeways or i.materialise gets expensive fast but they have a far superior material library to choose from.

Maybe the key would be to use a home 3D printer as a mould maker to make horns with.

To have it printed commercially, like at Shapeways or i.materialise gets expensive fast but they have a far superior material library to choose from.

Maybe the key would be to use a home 3D printer as a mould maker to make horns with.

That's not an error, it's a warning and it's not a bad thing and it's not the reason you can't use the loudspeaker wizard.Yeah were it shows the red, it won't let me go into the loudspeaker wizard if thats red.

Challenges like warping can be overcome mostly. You'd have to ask yourself if you'd want to use a horn made out of PLA, ABS or PETG etc.

To have it printed commercially, like at Shapeways or i.materialise gets expensive fast but they have a far superior material library to choose from.

Maybe the key would be to use a home 3D printer as a mould maker to make horns with.

I was speaking of printing at home. Maybe use wood and concrete filament. I could still finish the outside surfaces with something else, if needed, and filling with sand, sounds like a great idea. I'm just worried about warping, it wouldn't matter if the horn was printed in ABS, if its filled with sand and the inside was finished with epoxy, or some various top/finish coat.

Hi

I used black mat camouflage paint. They disappear visually even when I have on the projector in the dark room. The original white was like sitting between two bathtubs.annoying

Midbass is Emilar horn with floor/sidewall placed with B&C 8".

I also use the EV big 60 degree horns with JBL 2450SL.. both sound very good.

Crossover is 500 Hz - upper range driver is Radian 835 1.4" with BE

POOH, this is the second time within 24 hours that such a coincidence occurs

You have updated your message with the information that I was curious about.

Moreover, after researching Emilar drivers and horns, I came to the conclusion that the best drivers "overall" (wrt sound quality) available today are probably the Radian 745/760 and 835/850. These are the successors to the Emilar EC175/MC320 and respectively MK175/MC320 drivers - when Plus One Engineering took over Emilar.

Do you happen to have any measurements of the 835 with the HR9045?

Last edited:

That's not an error, it's a warning and it's not a bad thing and it's not the reason you can't use the loudspeaker wizard.

A better question would be, what should I put into the speaker specs to build a horn....how do I building a horn without including speaker specs?

Those specs are fine. You make a horn and press calculate. You switch back to the input screen from the menu at the top to make changes then recalculate.

I don't use the wizard so I read the fine manual and found out it only works with C/P/E and multi section horns. LeCleach, OS and Hyp/Ex are examples of horns that hornresp will only do with a single section operating at a time.

and found out it only works with C/P/E and multi section horns. LeCleach, OS and Hyp/Ex are examples of horns that hornresp will only do with a single section operating at a time.

I understand hornresp is a little old school. It harks back to a time when this information was only available at a library, all calculations by hand and near no chance of finding anybody to help you with it. As a result DIY horns were not as common as they could have been, but many were brilliant just like their designers. Information is information even when you have to dig.

I don't use the wizard so I read the fine manual

I understand hornresp is a little old school. It harks back to a time when this information was only available at a library, all calculations by hand and near no chance of finding anybody to help you with it. As a result DIY horns were not as common as they could have been, but many were brilliant just like their designers. Information is information even when you have to dig.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Is it possible to cover the whole spectrum, high SPL, low distortion with a 2-way?