Japanese were at the leading edge regarding R&D from late 70's to mid 90's. TAD, Sony, Yamaha, Technics all produced some very technology advanced designs at the time.

And some even sounded very good too!

I think as long as there won't be a real paradigm change wrt driver technology ( a new kind of transducers) we will only reinterpret ideas from the past. Some very bright minds already contempled the same issues we face and found answers to them. And without computer assistance ( or the help and experience from a worldwide community). Respect.

Yes 3d printing is promising. I wait to see what the next generation of printers will be able to do.

And some even sounded very good too!

I think as long as there won't be a real paradigm change wrt driver technology ( a new kind of transducers) we will only reinterpret ideas from the past. Some very bright minds already contempled the same issues we face and found answers to them. And without computer assistance ( or the help and experience from a worldwide community). Respect.

Yes 3d printing is promising. I wait to see what the next generation of printers will be able to do.

Last edited:

By the way, an interesting story about TAD.

Several years ago I did some simulations with TAD low-frequency speakers and noticed some discrepancy in official electromechanical parameters stated as "free air". Upon closer analysis, I found that the added air mass was twice larger as should be for free-air condition (Мair = 0.565 * Sd ^ 1.5 in the free air). For example, for 1603 Mms = 117g and Mmd = 86g, thus Mair= 31 g, while Mair should be ~15g for 0.088 sq. cm. membrane under the free-air conditions. On the other hand, the value of Mair= 31 g well corresponds to the added air mass for infinite baffle conditions (Mair = 1.13 * Sd ^ 1.5).

I wrote a letter to TAD with an explanation and pointed out the discrepancy between the parameters. They confirmed, that Mmd corresponds to the actual value, while Mms corresponds to the infinite baffle conditions.

Well, I just looked at the TAD web site and the parameters are still incorrect, although 2.5 years have passed. I wonder if there are still physicists or engineers at TAD ?! ...

TADs drivers are some of the best PRO drivers, but be careful with the their official parameters because they are not quite correct.

Several years ago I did some simulations with TAD low-frequency speakers and noticed some discrepancy in official electromechanical parameters stated as "free air". Upon closer analysis, I found that the added air mass was twice larger as should be for free-air condition (Мair = 0.565 * Sd ^ 1.5 in the free air). For example, for 1603 Mms = 117g and Mmd = 86g, thus Mair= 31 g, while Mair should be ~15g for 0.088 sq. cm. membrane under the free-air conditions. On the other hand, the value of Mair= 31 g well corresponds to the added air mass for infinite baffle conditions (Mair = 1.13 * Sd ^ 1.5).

I wrote a letter to TAD with an explanation and pointed out the discrepancy between the parameters. They confirmed, that Mmd corresponds to the actual value, while Mms corresponds to the infinite baffle conditions.

Well, I just looked at the TAD web site and the parameters are still incorrect, although 2.5 years have passed. I wonder if there are still physicists or engineers at TAD ?! ...

TADs drivers are some of the best PRO drivers, but be careful with the their official parameters because they are not quite correct.

Its starting to look more attractive to me now...probably the with the installation of the front baffles on the subs. The veneer I have is black brushed aluminum. I think it will be very attractive when all said and done. Still more holes to drill and fill, but I'm getting there.

Attachments

Well, I just looked at the TAD web site and the parameters are still incorrect, although 2.5 years have passed. I wonder if there are still physicists or engineers at TAD ?! ...

TADs drivers are some of the best PRO drivers, but be careful with the their official parameters because they are not quite correct.

It seems TAD's Pro division is slowly dying now that their best drivers (4003, 1603 etc.) are out of production.

Pioneer uses B&C for their professional speakers.

Last edited:

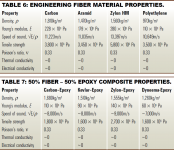

Dammit!!! Zylon, what is Zylon...

Zylon Fiber is a new high-performance fiber developed by Toyobo in Japan. It consists of rigid-rod chain molecules of poly(p-phenylene-2,6-enzobisoxazole)(PBO).

Zylon and Dyneema were developed for the ballistic and armor applications and like Kevlar have found their way into loudspeaker diaphragm applications already. Kenwood touts adding Zylon fibers to some of their PP cones and Dyneema’s manufacturer is recommending speaker cones as an application.

Zylon's properties are very appealing apart from the UV sensitivity.

Yamaha's solution is a Monel alloy coating that also serves another purpose.

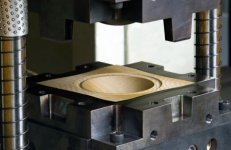

YAMAHA thought that all units of the new NS-5000 had to be made of the same material in order to create a new generation of music monitor speakers. Fortunately, Toyobo released "ZYLON, a high-strength fiber with sound quality comparable to that of berylium," and YAMAHA decided to use this "ZYLON" for the diaphragm of the speaker for the first time in the world. However, there was one problem that had to be solved when using Zylon.

Diamonds and beryllium can exist as "plates", but Zylon is a fiber and can only be used as "cloth". No matter how fast the speed of sound is, if it is processed into a "cloth" shape, the friction between the fibers will impair the sound velocity energy, and "air" will leak from the gaps between the fibers. YAMAHA responded to this problem by "depositing" "Monel alloy" on the fibers of Zylon shaped into a unit shape. In other words, the surface of Zylon was covered with metal (Monel alloy). Fortunately, ordinary fibers melt at that temperature when metal is vapor-deposited, but Zylon has a very high melting point of 600 degrees.

Attachments

Last edited:

You can cover the complete frequency spectrum 20 Hertz to 20Khz with just one driver with high spl:

Fane Sovereign 15-300 TC

I would cover both sides with aluminium foil (like with a Sica 12 D, also a good driver for high spl, here with foto, diaphragm covered with copper foil).

You can make a dsp correction of frequency response put the Fane 15-300 TC into a nice reflex box and it would cover the complete audio spectrum.

You can also take a real bass driver and put a crossover to 80 Hertz. And the Fane can get much louder if necessary.

Fane Sovereign 15-300 TC

I would cover both sides with aluminium foil (like with a Sica 12 D, also a good driver for high spl, here with foto, diaphragm covered with copper foil).

You can make a dsp correction of frequency response put the Fane 15-300 TC into a nice reflex box and it would cover the complete audio spectrum.

You can also take a real bass driver and put a crossover to 80 Hertz. And the Fane can get much louder if necessary.

Attachments

Last edited:

Its starting to look more attractive to me now...probably the with the installation of the front baffles on the subs. The veneer I have is black brushed aluminum. I think it will be very attractive when all said and done. Still more holes to drill and fill, but I'm getting there.

Nice work camplo!

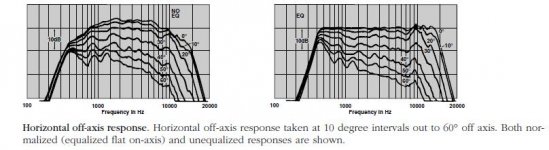

Have you measured the Axi2050 with the JBL 2386?

I still believe that an upscaled 2386-type horn (50 x 40°) will best suit your needs and also get the maximum bandwidth out of the Axi.

Attachments

You can cover the complete frequency spectrum 20 Hertz to 20Khz with just one driver with high spl:

Fane Sovereign 15-300 TC

Do you have measurements of the modified Fane?

You can make a dsp correction of frequency response put the Fane 15-300 TC into a nice reflex box and it would cover the complete audio spectrum.

nice to say but what would the the deviation be?... 1.5 , 3 , 6 db just how linear would this wind up being???

i would accept some deviation if it "voiced" it favourably for listening level...

Hello Ro808,

I just wanted to show a driver which is rarely built, a true 15 inch fullrange driver with high spl.

If you use dsp correction the driver will be linear on axis. Off axis is a different thing.

The modified driver will be always linear after dsp use.

On the Fane website is the data sheet

SOVEREIGN 15-300TC

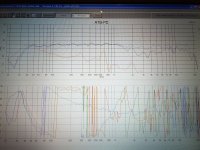

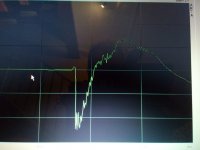

Here you can see a 10 inch driver fullrange going down to 35 Hertz in Reflex, dsp corrected, both sides of the diaphragm is aluminium covered. Dustcap is aluminium hand made. It is not optically perfect but acoustically its o.k.

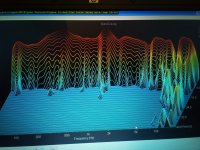

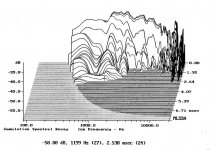

The ringing in the high frequencies (burst decay) is inaudible so I left the aluminium dust cap untreated.

I is phase linear from approx 200 Hertz to 8 Khz. This is due to the point source - always perfect time response after linearizing the frequency response.

Frequency response of this 10 inch fullrange sandwich driver:

Blue curve on axis

brown curve is 45 degrees off axis

red is bass reflex

There are no tweeters active. It is a fullrange driver.

Burst decay is measured down to -25db

I just wanted to show a driver which is rarely built, a true 15 inch fullrange driver with high spl.

If you use dsp correction the driver will be linear on axis. Off axis is a different thing.

The modified driver will be always linear after dsp use.

On the Fane website is the data sheet

SOVEREIGN 15-300TC

Here you can see a 10 inch driver fullrange going down to 35 Hertz in Reflex, dsp corrected, both sides of the diaphragm is aluminium covered. Dustcap is aluminium hand made. It is not optically perfect but acoustically its o.k.

The ringing in the high frequencies (burst decay) is inaudible so I left the aluminium dust cap untreated.

I is phase linear from approx 200 Hertz to 8 Khz. This is due to the point source - always perfect time response after linearizing the frequency response.

Frequency response of this 10 inch fullrange sandwich driver:

Blue curve on axis

brown curve is 45 degrees off axis

red is bass reflex

There are no tweeters active. It is a fullrange driver.

Burst decay is measured down to -25db

Attachments

Last edited:

If you want a big fullrange driver to open up more in the high frequencies you can use indirect tweeters beaming to the sides or up or put the tweeter on the backside of the box.

You can use tweeters like Audax copies often used in cars (mix of dome and cone with ferrofluid) they work with just one capacitor perfectly.

They should work only above 5khz - then they will not disturb the correct time response of a fullrange driver.

You can use tweeters like Audax copies often used in cars (mix of dome and cone with ferrofluid) they work with just one capacitor perfectly.

They should work only above 5khz - then they will not disturb the correct time response of a fullrange driver.

It seems TAD's Pro division is slowly dying now that their best drivers (4003, 1603 etc.) are out of production.

Pioneer uses B&C for their professional speakers.

It's sad. But I am not surprised since they had a strange sales policy. The drivers were really excellent, but they practically did not sell them to the masses

Here you can see a 10 inch driver fullrange going down to 35 Hertz in Reflex, dsp corrected, both sides of the diaphragm is aluminium covered. Dustcap is aluminium hand made. It is not optically perfect but acoustically its o.k.

The ringing in the high frequencies (burst decay) is inaudible so I left the aluminium dust cap untreated.

I is phase linear from approx 200 Hertz to 8 Khz. This is due to the point source - always perfect time response after linearizing the frequency response.

Frequency response of this 10 inch fullrange sandwich driver:

Blue curve on axis

brown curve is 45 degrees off axis

red is bass reflex

There are no tweeters active. It is a fullrange driver.

Burst decay is measured down to -25db

Thanks for the data.

It looks decent up to about 10k, the top octave is quite messy though. That doesn't necessarily means it sounds bad, but I'd prefer less ringing.

The point source nature is desirable, true.

This is the CSD of a 3" comp. driver that I considered buying, because it's suitable for a low crossover point. However, imo the top octave isn't clean enough.

Attachments

Last edited:

It's sad. But I am not surprised since they had a strange sales policy. The drivers were really excellent, but they practically did not sell them to the masses

Today there are plenty of drivers available at a fraction of the price of TAD drivers, that may not be quite as good, but good enough.

The production of TAD drivers is presumably expensive and therefore only profitable if larger quantities can be sold at once.

Last edited:

The production of TAD drivers is presumably expensive

They are even assembled by hand (in a country with high wages) while many other professional brands rely in automated manufacture.

Regards

Charles

I really appreciate the use of beryllium for TAD high frequency drivers.

What i wonder is why they just use simple paper diaphragms for the bass drivers.

As far as I know paper has not enough stiffness for a really good sound reproduction - especially big drivers suffer from bending forces in the diaphragm.

If they would have very big dustcaps this would bring lots of stability like with a 13cm paper diaphragm bass driver I tweaked with a big paper dustcap for getting true piston motion.

What i wonder is why they just use simple paper diaphragms for the bass drivers.

As far as I know paper has not enough stiffness for a really good sound reproduction - especially big drivers suffer from bending forces in the diaphragm.

If they would have very big dustcaps this would bring lots of stability like with a 13cm paper diaphragm bass driver I tweaked with a big paper dustcap for getting true piston motion.

Attachments

Last edited:

If they would have very big dustcaps this would bring lots of stability like with a 13cm paper diaphragm bass driver I tweaked with a big paper dustcap for getting true piston motion.

Hi Dragan

While the assumption that a dome is stiffer than a cone could be right I assume that the whole setup is less than ideal. Your dome is driven by the outer edge of the cone which is probably not following the voice-coil motion exactly. Furthermore the added weight is incleasing the effect.

It would work well if the dome was driven by the voice-coil directly. But this would make an expensive driver.

regards

Charles

- Home

- Loudspeakers

- Multi-Way

- Is it possible to cover the whole spectrum, high SPL, low distortion with a 2-way?