I noticed VituixCad early on and admired its potential as a complete package. I think kimmo and I, like so many of us here, want to see others progress.. and know much about what it takes to make a good speaker.kimmosto said:My policy is to hit right on target; as good and fast as possible

VituixCad seems to (EDIT: be trying to) remove the learning curve from the process, however I don't use it at present. I have specific concerns about the accuracy of DI calculations, as well as certain parts of how VituixCad does its geometric consolidation of power. It does, however, do many things very well.

Over time, VituixCad has come to focus on streamlining results over a common cross section of situations, but maybe at the expense of general suitability.. and presented in a way which is almost as though the user doesn't need to know. I have struggled to stay on top of development choices and the inevitable idiosyncrasies that all programmers face.. but as a DIYer of specialised speakers I found that it was moving in a different direction to myself.

I agree with you in principle, audiophile myths and legends can be a stumbling block...kimmosto said:but it would help if I wouldn't have to do close to everything related to VCAD alone. That could include also criticism of status quo and traditional "ANSI tools and methods".

I always found myself thinking "this can't be all there is, I want to learn more." The point is, I'm sure I'm not the only one

When a crossover is done well, acoustically and electrically, that means it can be voiced (as opposed to compensated).. and, during this final stage while I sit and listen with my hand hovering over the equaliser, I'm glad I learned the skill of adjustment by ear.

I think one problem is basic theory. It might be more important than introducing different design tools.

I couldn't agree more. I keep seeing novices plugging data into some computer tool, thinking the output of these tools will give them a great design. However, people often don't understand what the outputs of the computer tools really mean.

VituixCad seems to remove the learning curve from the process...

I am not sure what you mean by this. VituixCad as a software tool itself has quite a bit of a learning curve. Also, it certainly does not remove the curve of learning about electro-acoustics, and how to understand and interpret the data (both raw measurement data and data output from a software tool).

I am not familiar with many software packages related to loudspeaker design, except maybe a bit of VituixCad, and of course I am into my own software for electro-acoustic measurements (MATAA). Looking at VituixCad, the manual is written with a step-by-step recipe approach: to calculate some design parameter X, first do step 1, then step 2, ..., and after step N you see the result on your screen. The manual does not aim at explaining the basics of the electro-acoustics behind this. With MATAA, the documentation is even worse in this regard. The manual is just a (pathetic) attempt at providing some information to actually make the MATAA software work on a given computer system, and the various functions all have their own help / documentation text. That's about it -- there is zero information on electro-acoustic theory. This is simply because it's a lot of work to actually write the documentation, and it would be too much to also mix in electro-acoustic theory on a sufficiently complete level. The computer tools require the user to know the electro-acoustic background first!

I therefore think it would be very wrong to recommend using a specific computer tool to get started with loudspeaker design. It's a bit like if someone wanted to climb Mount Everest and an "expert" would recommend that, before thinking about anything else, he/she should first get this shiny new GPS instrument that just came out last week.

A much better approach is to ask novices to read (and understand!) good texts about electro-acoustics and loudspeaker design. There are a number of good references around already, but maybe the references should be made more prominent. How about a separate thread? People could post, recommend and discuss their (not-so) favorite texts, and the OP could keep and update a list of the relevant references in the first post. This would make it easy to refer novices to this thread and tell them to read and understand this stuff first.

In my opinion, another important recommendation would be to tell novices to actually go and build stuff, to take measurements, to modify their builds, hear how the sound changed, measure the differences, and understand how to measurements relate to what they hear. The experience of hearing the changes (or not hearing any difference in some cases) and relating this to the measurements was maybe the most important lesson for me that really helped me to get the grips with loudspeakers.

Finally, coming back to my point in the other thread. We should make a much stronger effort to tell people that the "anechoic on-axis SPL curve" does not tell you very much about how a loudspeaker will sound in a real-life situation. What you really hear is the the sound field in the listening room, which is largely controlled by the 3D dispersion of the speaker. This is why I advocate to look at the power response instead of just the on-axis SPL curve -- and of course this involves measuring a number of off-axis SPL curves.

VituixCad seems to remove the learning curve from the process

Measurement method and post processing of response data is designed and documented to remove learning curve from creating measurement data for crossover simulation.

As already mentioned, there is no basic theory about acoustics and transducers, recommendations for shaping enclosure or baffle, selecting drivers, locating drivers, selecting XO points by non-linearities etc. No help how simulated curves should initially look in order to get balanced sound. This is very important know-how, though almost every diy enthusiast understands measurements of speakers published in magazines

Proper tools and methods for capturing measurement data has been real game changer for me. I've designed speakers since the middle of 80s', but crossover designing and sound balancing was slow and painful requiring lots of time, but results were still unsatisfactory or moving speakers to different place or room caused some trouble. Decent room acoustics and proper design methods changed no less than everything so nowadays designing of basic speakers is very easy and usually there's no need to adjust anything by listening. Total quality depends on quality of components and selected radiator type, but crossover is not significant variable anymore so efforts are possible to focus to components and acoustical concept/structure. Someone could call tweaking of passive XO as a hobby, but it's wasting of time and money in my opinion

This might explain why it's impossible to trust and respect anything based on traditional measurements, design tools and methods by axial responses or no more than few off-axis in horizontal plane or measurement data by manufacturer or simulations only. Output is unreliable if limited view is obvious no matter how many decades or models designer has published here or diy kits in magazines or web sites.

Naturally this applies also to commercial designers and manufactures, but who knows how they measure and design. I can't reveal other than myself. Shouldn't be big secret how I design and how many hours XO requires assuming that quality of drivers and other components and acoustical concept/structure is accepted.

I have specific concerns about the accuracy of DI calculations, as well as certain parts of how VituixCad does its geometric consolidation of power

Reality with users is so complicate that the biggest challenge is to adapt program close to infinite amount of different off-axis angle combinations. Obedient designer measures by instructions: 0...180 or -170...+180 deg with 10 deg steps, in both planes if necessary. Unfortunately all users are not obedient so program accepts also any angles with constant or variable angle step, and user can select whether program interpolates (and shows) off-axis directions to selected constant angle step or calculates and shows measured directions only. Interpolation is required if radiators are rotated or tilted because dual plane measurement data does not cover rotation/tilting to off-axis. Interpolation is one error source. In addition, program can calculate in horizontal or vertical plane only, mirror left-right, up-down or hor-ver, use normal RMS without radial to spherical conversion with weighting factors, limit to half space or use full space data, calculate DI with reference angle or listening window. Power and DI calculation tries to adapt all this freaking mess.

Basic accuracy of DI and power calculation is about 0.01 dB with generated ideal test material including single radiator with DI typical for direct radiators. Beam is very narrow with DI > 15dB reducing accuracy with typical 10 deg angle step. Strong directivity reduces significance of DI and it's accuracy because axial and listening window rule.

Anyway, accuracy is easy to verify with generated ideal data. I haven't checked that in a year, but should be still exact because changes are minimal. Please let me know in VituixCAD thread or by e-mail if something is wrong.

This might explain why it's impossible to trust and respect anything based on traditional measurements, design tools and methods by axial responses or no more than few off-axis in horizontal plane or measurement data by manufacturer or simulations only. Output is unreliable if limited view is obvious no matter how many decades or models designer has published here or diy kits in magazines or web sites.

Naturally this applies also to commercial designers and manufactures, but who knows how they measure and design. I can't reveal other than myself. Shouldn't be big secret how I design and how many hours XO requires assuming that quality of drivers and other components and acoustical concept/structure is accepted.

Thanks Kimmo, There is a huge spectrum between perfection and awful

I'm somewhere in the middle at the moment. I know I could do better, but I'm pretty damn happy with what I have at the moment, so the motivation to improve it is not as high as it once was. The crossover design I have at present, is complicated and was designed using on axis only data, but when I have revisited with off axis data and vituix cad, I have struggled to improve on it. That is I think largely due to some issues with the mids, which limit the choices of the crossovers, issues that could not be found from manufacturers measurements.

I guess my point is that whilst using on axis only measurements to design a crossover may not result in the best crossover for a particular speaker, it will be a LOT better than if a newbie went to PE or somewhere else and bought a pre-made off the shelf crossover.

Even simple concepts like getting people to fit the drivers to acoustic targets, not just blindly applying electrical filters to the drivers, makes a big difference. It is a journey and you have progressed further along it than I have

If you do have the time, and you believe there is any fundamentally wrong information in the thread, please point it out. I do not want to propagate any myths or false information. If it is more that there are better ways to design, then yes, that is accepted, and the thread has not progressed that far as yet. Part of the reason I didn't progress was that I won't post if I'm not 100% certain that what I am posting is correct, and the design data that I do have is not appropriate for this thread, and I really need to do a new design from scratch. That just hasn't happened. Perhaps I should make that a new years resolution

Tony.

Kimmo. There is alot in what wintermute says. I believe you have much to offer.

OK - VituixCADkimmosto said:Please let me know in VituixCAD thread or

Kimmo, your posts are like graduate level course work for people who are already quite experienced. The audience for your writings will be small (but experienced and well versed).

A great example... Anyone with a firm grasp of all this is probably quite experienced already. It would be a rare newbe who could understand all these nuances in phase and directivity measurement.

I ran a team of engineers, and our main product was a structural analysis software package and the various analyses which stemmed from that software. I find it difficult to comprehend how you could write Vituixcad, offer it for free, support it and update it for free, all while maintaining a real job. I appreciate how difficult and time consuming this kind of project is. So when Allen B says you have a lot to offer, that is an understatement.

In my years of leading an engineering team, I found the best instructors for new engineers were those team members with 2-5 years experience. The 5 year folks were best taught by the 10 year folks. In my later years I spent a lot of time coaching people who had 15 to 30 years experience. So I understand your frustration... it can be difficult to offer advice or guidance to people when there is a large gulf in knowledge.Frustration is continuous state of mind for me

I think one problem is basic theory. ..... What are differences between the following and key features related to measurement data for crossover design:

- minimum phase extraction

- minimum phase response

- response (minimum phase or not) with constant delay offset in seconds

- response (minimum phase or not) with constant location offset in meters

- response (minimum phase or not) with variable sound flying time from origin of the radiator to mic/observer, depending on direction in 3D space

- response (minimum phase or not) with variable polarity depending on frequency and direction in 3D space.

A great example... Anyone with a firm grasp of all this is probably quite experienced already. It would be a rare newbe who could understand all these nuances in phase and directivity measurement.

I ran a team of engineers, and our main product was a structural analysis software package and the various analyses which stemmed from that software. I find it difficult to comprehend how you could write Vituixcad, offer it for free, support it and update it for free, all while maintaining a real job. I appreciate how difficult and time consuming this kind of project is. So when Allen B says you have a lot to offer, that is an understatement.

Last edited:

Not to put too fine a point on it, but there is also a difference between audio professionals and audio hobbyists... namely budget and schedule. As a recreational speaker designer, I do not have a schedule, I do not answer to a client, If I have to make multiple attempts to get something right, well so what. I can do things which no client would tolerate

It certainly is, if I am being paid by an employer or client. But if this activity is just for my own fun and entertainment... It's not really a waste, it's the whole point.Someone could call tweaking of passive XO as a hobby, but it's wasting of time and money in my opinion

As a recreational speaker designer, I do not have a schedule...

I have not designed DIY speakers in five years. Commercial only. Strange and maybe funny DIY experiments ended quite soon after VituixCAD 0.1 was released, and co-operation with few 'Bob the Builders' started.

Primary problem with uncontrolled, too subjective and location/environment-dependent method is uncertainty about compatibility with other environments and listeners imo. We all could be confident for few days...months to sound based on our familiar room, placements and golden ears. But price tag of 25...40 k€/pair and setting speakers in front of numerous listeners in hifi exhibition and stores so that almost everyone is happy (except the price of course) might need something more than just master listener at home. If all that happens almost naturally without long tweaking-listening loop and returning backing to square one, it will be also schedule and cost advantage - without forgetting our only life and planet.

Perfect speakers do not exist and different models will sound different for sure so my 'less than a workday for measurements and XO design' method produces different sounding and imperfect products, but expected amount of bad feedback outside "R&D facility".

Anyway, I would design also DIY with schedule advantages though it would not matter much.

No doubt there will be "Golden Ears" chiming in with their opinions and theories, but you have your job to do. How can we blame you? DIY is a hobby and taking it too seriously is a Buzz-Kill! As you say: "Perfect speakers do not exist and different models will sound different for sure so my 'less than a workday for measurements and XO design' method produces different sounding and imperfect products, but expected amount of bad feedback outside "R&D facility."

I can relate to my former field of work, Structural Ironwork! The insurance companies have done to our trade as the software has done to yours! With all the safety protocols and procedures, it's no wonder the cost to build has "Skyrocketed" Pun intended...LOL, We used to say "If this job gets any easier, my grandmother can do it!" Now she can.

The satisfaction afforded to me through DIY speaker building is greatly attributed to affordable software/hardware directed to amateurs. Almost anybody can be a "Speaker Designer" And in my listening room, there is no better enjoyment to be had... till the next best thing (Not exclusive to insiders) comes available!

I can relate to my former field of work, Structural Ironwork! The insurance companies have done to our trade as the software has done to yours! With all the safety protocols and procedures, it's no wonder the cost to build has "Skyrocketed" Pun intended...LOL, We used to say "If this job gets any easier, my grandmother can do it!" Now she can.

The satisfaction afforded to me through DIY speaker building is greatly attributed to affordable software/hardware directed to amateurs. Almost anybody can be a "Speaker Designer" And in my listening room, there is no better enjoyment to be had... till the next best thing (Not exclusive to insiders) comes available!

If the theory is too deep at the beginning then folks can get discouraged and overwhelmed. Being able to design their own box and shortly thereafter do a x-over and frankly easily whip most of what passes for hi-fi at the big box stores, excites and draws them into the hobby. Sure, it won’t be perfect, but it will likely be pretty decent (especially if the base it in a previous sorted model).

I’ve been building speakers off and on for 30 years, but mostly kits or designs that someone else did. Many of these tools (and many good free ones!) are quite recent and have got be interested in designing my own all the way through (even if it is similar to something else). What I have found so far is that many of the tools have gotten very sophisticated, but the documentation is quite weak, and getting started for the noob is difficult. Vituix has been a very bright spot for me because it seems rather intuitive, and with the help of a shot YouTube video I was off and running. Many thanks to kimmosto! You’re a lifesaver man!!

Anyway I’m finished with the box design and moving next to the x-over. I realize that I should have a lot of test equipment, but that’s a big commitment in money for something I might use a couple of three times a year. I’m confident I’ll get at least close with the simulation. Anyway, for me the biggest help to noobs would be better documentation and a few YouTube videos that cover each type basic design to help jump start the beginners. After they’ve gone through a few examples they’ll get pumped up and excited, and that’s what this is really all about!

I’ve been building speakers off and on for 30 years, but mostly kits or designs that someone else did. Many of these tools (and many good free ones!) are quite recent and have got be interested in designing my own all the way through (even if it is similar to something else). What I have found so far is that many of the tools have gotten very sophisticated, but the documentation is quite weak, and getting started for the noob is difficult. Vituix has been a very bright spot for me because it seems rather intuitive, and with the help of a shot YouTube video I was off and running. Many thanks to kimmosto! You’re a lifesaver man!!

Anyway I’m finished with the box design and moving next to the x-over. I realize that I should have a lot of test equipment, but that’s a big commitment in money for something I might use a couple of three times a year. I’m confident I’ll get at least close with the simulation. Anyway, for me the biggest help to noobs would be better documentation and a few YouTube videos that cover each type basic design to help jump start the beginners. After they’ve gone through a few examples they’ll get pumped up and excited, and that’s what this is really all about!

If the theory is too deep at the beginning then folks can get discouraged and overwhelmed. Being able to design their own box and shortly thereafter do a x-over and frankly easily whip most of what passes for hi-fi at the big box stores, excites and draws them into the hobby. Sure, it won’t be perfect, but it will likely be pretty decent (especially if the base it in a previous sorted model).

Yep, agree. my first project in 1987 was a madisound kit using an 8" peerless woofer and a 1" audax tweeter, an assembled crossover was part of the kit. Total cost was less than $ 150, which was within a college kid's budget. It was as good as anything less than $500 at the local hifi shop. But it was not great, merely good. The $900 Mission speakers were better, and the $2000+ Infiniti and Klipsch systems were very much better... And that was just fine for me at that time.

Early rewards are essential when learning anything. Does 2 things.

1. Confirms I am on the right track

2. Hey - I built something that works!... and encourages me to do more.

hifijim summed it up quite well. Uber experienced people forget what it's like to understand the basics. It's like describing how to change gear in a manual car.. One must think about it consciously when describing to someone. The other thing... Experienced people need their own learning / teaching balance. getting a newbie up to speed doesn't really do much for the very experienced persons learning part of their equation.

A lot can be achieved by a method. You may not invent anything new without wandering off the path.... but you can get predictable results. Newbies often want to jump into the deep end (e.g. large WMTMW or similar). The trick here is laying out the concepts that must be understood for the different design outcomes.

A simple 6.5"/1" 2 way for example will not need to worry about steps required for an OB design. Sure - some concepts are common, but showing the newbie the length of the path with each design type - might make them understand (and test their training commitment) or choose another goal.

1. Confirms I am on the right track

2. Hey - I built something that works!... and encourages me to do more.

hifijim summed it up quite well. Uber experienced people forget what it's like to understand the basics. It's like describing how to change gear in a manual car.. One must think about it consciously when describing to someone. The other thing... Experienced people need their own learning / teaching balance. getting a newbie up to speed doesn't really do much for the very experienced persons learning part of their equation.

A lot can be achieved by a method. You may not invent anything new without wandering off the path.... but you can get predictable results. Newbies often want to jump into the deep end (e.g. large WMTMW or similar). The trick here is laying out the concepts that must be understood for the different design outcomes.

A simple 6.5"/1" 2 way for example will not need to worry about steps required for an OB design. Sure - some concepts are common, but showing the newbie the length of the path with each design type - might make them understand (and test their training commitment) or choose another goal.

My targets and actions have been quite simple:

Provide tools and methods targeting good sound per modern knowledge about reproduction with loudspeakers (1), and depreciate everything which does not support that.

(1) For example Floyd E. Toole: Sound Reproduction, though close to equal information has been available for few decades - at least locally.

Also beginners have good possibilities to read and understand about significant parameters (other than on-axis response). No need to start so that everything should be learned the hardest way by making and listening and returning back to square one, over and over again. The most unfortunate situation imo is that someone recommends combination of method and tool which does not support exiting knowledge or support requires too much work and time while valid and fast method and tool is available for free. No so responsible especially on public platform such as discussion forum.

Provide tools and methods targeting good sound per modern knowledge about reproduction with loudspeakers (1), and depreciate everything which does not support that.

(1) For example Floyd E. Toole: Sound Reproduction, though close to equal information has been available for few decades - at least locally.

Also beginners have good possibilities to read and understand about significant parameters (other than on-axis response). No need to start so that everything should be learned the hardest way by making and listening and returning back to square one, over and over again. The most unfortunate situation imo is that someone recommends combination of method and tool which does not support exiting knowledge or support requires too much work and time while valid and fast method and tool is available for free. No so responsible especially on public platform such as discussion forum.

It’s starting to take shape..

Hope you guys are having a good time and staying healthy and safe..

Hello Friends, sorry I’ve been missing, life happened, but now I am back on track with some progress. I had a bike paint shop did the paint job for the enclosure. It was beautiful, but it started to sink, due to the porous nature of plywood. It’s alright, adds to the character.

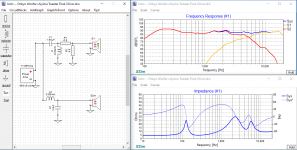

Next, I’ve made measurements, factored in the offset (is it Z offset?) and measured at tweeter height. I designed a crossover in XSim and built it as attached. It is functioning well, it made music. It sounded just okay with the back of the box still open and no stuffing added. Happy I got this far.

Now if you would kindly share any comments or input on the crossover design, I’d be most grateful, especially since the crossover as it’s mocked up now does not fit inside the enclosure!

- Are the inductors laid out correctly?

- Can I get away with let’s say 5W or 10W resistor for L-Pad? (I am simulating for 40W amp into 8 Ohm, since the midwoofers are 50W 4 Ohm)

- Should I look into ferrite core inductor to be put in series with the midwoofer?

Any input on crossover tuning and layout will be most appreciated. Thank you so much!

Attachments

Last edited:

Hey Jonathan, it's been a while.

The last time I locked one of my own crossovers inside a box I regretted it. I can't remember whether you are using factory responses here but with some of these techniques, since they show you only some of what is happening, you may want to tweak them later if you begin to understand there is an issue.

Your crossover makes me wonder.. has your measurement considered the in cabinet response? Should the tweeter be crossed that high? Can you get the midrange response to tilt downward or level rather than rise again?

You seem to be able to handle Xsim. If in doubt you could post your *.dxo file here.

The last time I locked one of my own crossovers inside a box I regretted it. I can't remember whether you are using factory responses here but with some of these techniques, since they show you only some of what is happening, you may want to tweak them later if you begin to understand there is an issue.

Your crossover makes me wonder.. has your measurement considered the in cabinet response? Should the tweeter be crossed that high? Can you get the midrange response to tilt downward or level rather than rise again?

You seem to be able to handle Xsim. If in doubt you could post your *.dxo file here.

Hi Allen, been a while.  How are you, I hope you and yours are well.

How are you, I hope you and yours are well.

Since the woofer is a relatively undocumented driver, I've taken the T/S parameters and impedance measurements myself. The tweeter is the same story, too bad I didn't take the T/S parameters and impedance (not sure how to add weight to the silk dome tweeter).

I installed them in the box, in the final position, raised them 1.2m above ground with more than 1.2m clearance in all direction. Mic was 1m away at tweeter height. The box was closed with the back in position, woofer and tweeter leads out through the rear port. I took some sweeps from 200Hz upwards, to protect the tweeter, and it is my understanding that my room and measurement rig don't support accurate measurement below that frequency.

I took the tweeter frequency sweep, then the woofer, then both in parallel. I used the parallel to find the acoustic center*. Woofer is at 0.64inch delay in relations to the tweeter. I settled on this current design after trying different combination, it seems reasonably flat, and if polarity is reversed, there is a nice dip right around the crossover frequency. I've read that it's a good indication of well-summing drivers at crossover point? I've taken great care to have the polarity correctly throughout these measurements, and I've read conventional wisdom says for 2nd order filter I must reverse one of the drivers. However with mine it doesn't seem to be the case. Regardless, I will measure carefully in the production stage, to make sure whether I have a nice summation or a dip, and then I will reverse my tweeter accordingly. Please feel free to confirm or correct me in any of these points

I'd really love to have your input on my design, I attach my dxo zipped. Thanks Allen for being generous with your time and expertise.

I welcome anyone who wants to play around and expose my noob-ness, please have a go at my dxo. Thank you guys!

*Speaker acoustic center - How to find it | Audio Judgement

Since the woofer is a relatively undocumented driver, I've taken the T/S parameters and impedance measurements myself. The tweeter is the same story, too bad I didn't take the T/S parameters and impedance (not sure how to add weight to the silk dome tweeter).

I installed them in the box, in the final position, raised them 1.2m above ground with more than 1.2m clearance in all direction. Mic was 1m away at tweeter height. The box was closed with the back in position, woofer and tweeter leads out through the rear port. I took some sweeps from 200Hz upwards, to protect the tweeter, and it is my understanding that my room and measurement rig don't support accurate measurement below that frequency.

I took the tweeter frequency sweep, then the woofer, then both in parallel. I used the parallel to find the acoustic center*. Woofer is at 0.64inch delay in relations to the tweeter. I settled on this current design after trying different combination, it seems reasonably flat, and if polarity is reversed, there is a nice dip right around the crossover frequency. I've read that it's a good indication of well-summing drivers at crossover point? I've taken great care to have the polarity correctly throughout these measurements, and I've read conventional wisdom says for 2nd order filter I must reverse one of the drivers. However with mine it doesn't seem to be the case. Regardless, I will measure carefully in the production stage, to make sure whether I have a nice summation or a dip, and then I will reverse my tweeter accordingly. Please feel free to confirm or correct me in any of these points

I'd really love to have your input on my design, I attach my dxo zipped. Thanks Allen for being generous with your time and expertise.

I welcome anyone who wants to play around and expose my noob-ness, please have a go at my dxo. Thank you guys!

*Speaker acoustic center - How to find it | Audio Judgement

Attachments

Yes, we're great thanks. My son is getting into blogging and is currently learning about microphones.

I like how much you've been learning. It's a steep learning curve. Firstly I'd say that you don't need T/S for the tweeter, just impedance and appropriate response measurements.

Indeed you can't do lower frequency measurements the normal way in a room. However even for higher frequencies it is best to 'gate' them, after putting them away from nearby surfaces.

You shouldn't need to find acoustic centres unless you cannot get proper timed measurements. This piece of knowledge is not so well known it would seem.

I'd say similar about finding a null. Not necessary if you have a simulator that shows phase. Besides, it only shows you whether the drivers are in phase, not how well they sum as part of the system.

How's that for a start

I like how much you've been learning. It's a steep learning curve. Firstly I'd say that you don't need T/S for the tweeter, just impedance and appropriate response measurements.

Indeed you can't do lower frequency measurements the normal way in a room. However even for higher frequencies it is best to 'gate' them, after putting them away from nearby surfaces.

You shouldn't need to find acoustic centres unless you cannot get proper timed measurements. This piece of knowledge is not so well known it would seem.

I'd say similar about finding a null. Not necessary if you have a simulator that shows phase. Besides, it only shows you whether the drivers are in phase, not how well they sum as part of the system.

How's that for a start

Very important point that Allen makes above. The various simulation programs that allow you to put in driver offsets, only need you to do this if you are using minimum phase frd files. These have no offset information built into them.

If the measurements you have done have the relative phase built in, then you actually need to make sure the sim software has NO offsets entered.

Also I believe with Xsim, when importing the frd, there are different options, one of which extracts I think the minimum phase.

The methods I have used are to take all measurements on the tweeter axis. If using holmimpulse after doing the tweeter measurement, finding time zero, and then locking it, so that all other measurements are relative to that.

In REW same thing, take all measurements on tweeter axis and then use dual channel method to ensure phase is correctly captured. You can also do this with a reference signal if you have a USB mic (not something I have tried).

If you prefer to do the offsets, then you can measure each driver on it's own axis, extract the minimum phase, and enter all of the offset information into the sim.

Both I think have their pros and cons. I like the simplicity of having the phase incorporated into the measurements themselves

Tony.

If the measurements you have done have the relative phase built in, then you actually need to make sure the sim software has NO offsets entered.

Also I believe with Xsim, when importing the frd, there are different options, one of which extracts I think the minimum phase.

The methods I have used are to take all measurements on the tweeter axis. If using holmimpulse after doing the tweeter measurement, finding time zero, and then locking it, so that all other measurements are relative to that.

In REW same thing, take all measurements on tweeter axis and then use dual channel method to ensure phase is correctly captured. You can also do this with a reference signal if you have a USB mic (not something I have tried).

If you prefer to do the offsets, then you can measure each driver on it's own axis, extract the minimum phase, and enter all of the offset information into the sim.

Both I think have their pros and cons. I like the simplicity of having the phase incorporated into the measurements themselves

Tony.

I began to look at the sim, and then what I wrote.. hoping to prioritise it better.

What stood out to me at first was the unusual response of the woofer. I think what would be helpful here is datasheets for both drivers. This is partly for comparison purposes, and partly for determining reasonable crossover points.

What stood out to me at first was the unusual response of the woofer. I think what would be helpful here is datasheets for both drivers. This is partly for comparison purposes, and partly for determining reasonable crossover points.

- Home

- Loudspeakers

- Multi-Way

- Design your own speaker from scratch discussion thread