Hello!

Has anyone attempted slicing of the SB midwoofers?

Since SBacoustics line and Revelator line have been designed by same designer (U.S.), SS or VIFA still own NRSC patent. (Non resonant *slit cone*)

Anyway, lots of googling revealed that the revelator designer (USXX) did a prototype design on the SB15:

full link:

Julefrokosthojttalere - SpeakerBuilder Forum - Page 1

SB and SS motors are similar (esp. SD motor in SS Classic line) (THanks to Mr. Pankov for teardown)

Distortion plots (from audioexcite):

SB:

SS:

Other measurements are available at HIFICOMPASS.

Imho motor should be as good as revelator - check out aluminum or ceramic cone measurements, with the same motor. According to USXX, MFC(poly driver) had some changes to surround, carbon/rohacell has even better spider... (Haven't heard any of the sb woofers, other than Satori.)

Okay, then someone did the same slicing thing to their Dayton PM180:

How to Train Your PM180-8 -

Techtalk Speaker Building, Audio, Video Discussion Forum - impressive results!

Then i was thinking about which slicing pattern to use? Something random, or triangle as did Ulrich with his prototype? Hmm, guess it was in front of me all the time (datasheet)!

Other thing was how to glue it together... a bit of googling revealed a wallpaper glue could be used! Also, I'd coat the surround with the same glue to try to remove some of the dip.

Anyways, new sb17nrx2c measurement is more linear and should be a perfect candidate for a rev surgery at one third of the price. (Thanks to Goran for testing) www.audioexcite.com >> Blog Archive >> SB17NRX2C35-4 vs SB17NRXC35-4

Personally I'm more interested in SB15 line because cone geometry looks to be very nice - check how SB15MFC (poly cone) has a nice even off-axis dispersion, without any serious breakups and phase problems. Rising response just means a bit more work in the xo.

I'm wondering if I should get Norex/papyrus cone instead, and attempt the surgery. OTOH, can anyone compare norex to poly soundwise, just a general impression?

Has anyone attempted slicing of the SB midwoofers?

Since SBacoustics line and Revelator line have been designed by same designer (U.S.), SS or VIFA still own NRSC patent. (Non resonant *slit cone*)

Anyway, lots of googling revealed that the revelator designer (USXX) did a prototype design on the SB15:

full link:

Julefrokosthojttalere - SpeakerBuilder Forum - Page 1

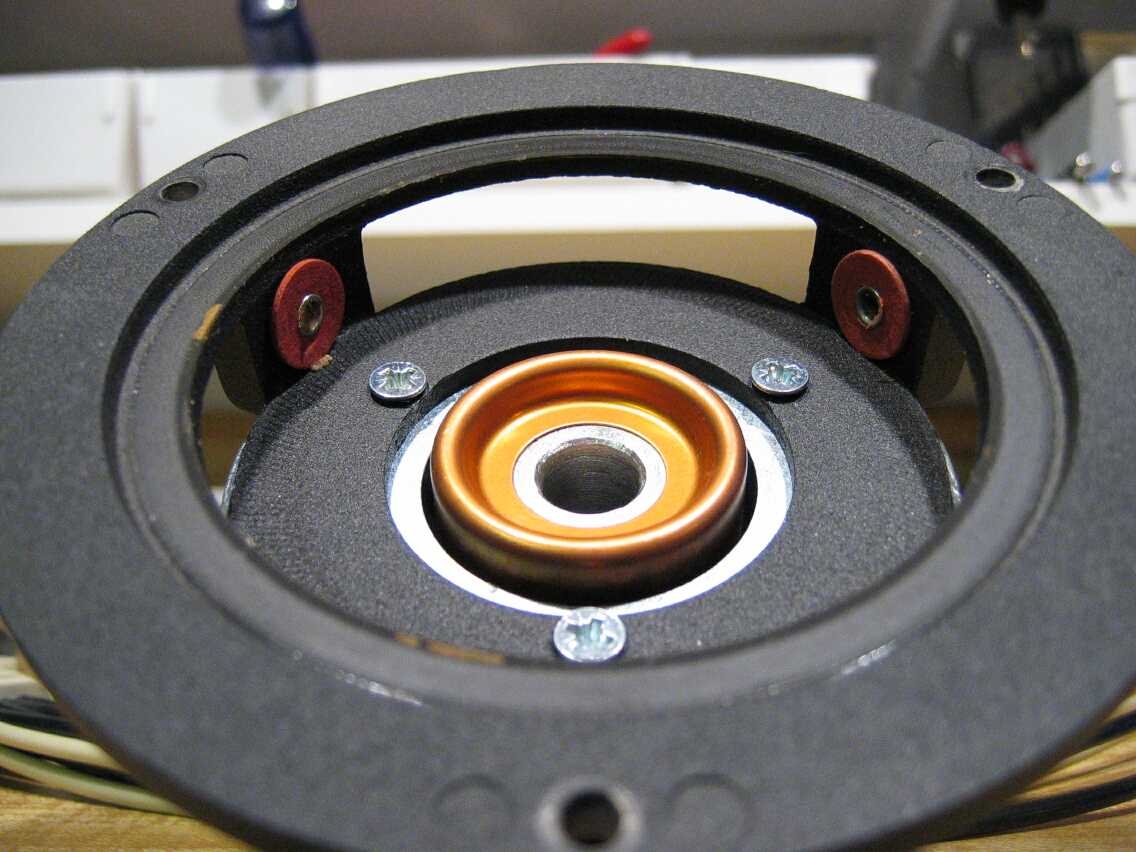

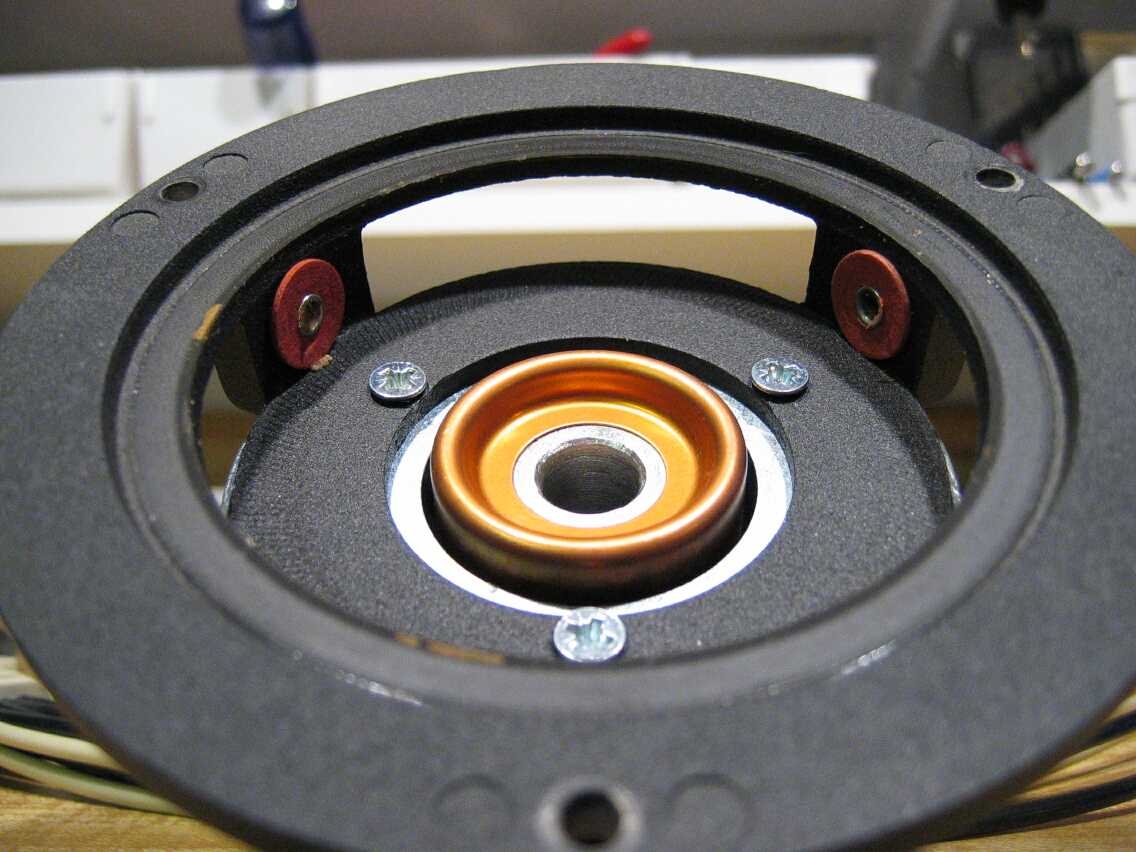

SB and SS motors are similar (esp. SD motor in SS Classic line) (THanks to Mr. Pankov for teardown)

Distortion plots (from audioexcite):

SB:

SS:

Other measurements are available at HIFICOMPASS.

Imho motor should be as good as revelator - check out aluminum or ceramic cone measurements, with the same motor. According to USXX, MFC(poly driver) had some changes to surround, carbon/rohacell has even better spider... (Haven't heard any of the sb woofers, other than Satori.)

Okay, then someone did the same slicing thing to their Dayton PM180:

How to Train Your PM180-8 -

Techtalk Speaker Building, Audio, Video Discussion Forum - impressive results!

Then i was thinking about which slicing pattern to use? Something random, or triangle as did Ulrich with his prototype? Hmm, guess it was in front of me all the time (datasheet)!

Other thing was how to glue it together... a bit of googling revealed a wallpaper glue could be used! Also, I'd coat the surround with the same glue to try to remove some of the dip.

Anyways, new sb17nrx2c measurement is more linear and should be a perfect candidate for a rev surgery at one third of the price. (Thanks to Goran for testing) www.audioexcite.com >> Blog Archive >> SB17NRX2C35-4 vs SB17NRXC35-4

Personally I'm more interested in SB15 line because cone geometry looks to be very nice - check how SB15MFC (poly cone) has a nice even off-axis dispersion, without any serious breakups and phase problems. Rising response just means a bit more work in the xo.

An externally hosted image should be here but it was not working when we last tested it.

I'm wondering if I should get Norex/papyrus cone instead, and attempt the surgery. OTOH, can anyone compare norex to poly soundwise, just a general impression?

I don't know about slicing the cones. I think slit in this case refers to lines rather than sliced. I think the revelators look more like they are embossed rather than sliced through.

The SB aluminium and ceramic cones already come with slits (I have a pair). But they look like they were formed rather than cut.

One possibility is to draw the lines using epoxy, that would stiffen the area and break up the resonant pattern without destroying the cone.

Oon

The SB aluminium and ceramic cones already come with slits (I have a pair). But they look like they were formed rather than cut.

One possibility is to draw the lines using epoxy, that would stiffen the area and break up the resonant pattern without destroying the cone.

Oon

Attachments

Now that's a tweak! Can't wait to see how they measure

And/or how long they last.

Having using the SB ceramic cones and the revelators cone, I think the revelators are a level above the SB ceramic. The revelators sound a bit more "special" - sort of like a BMW sport car vs. a Lexus sport car with the revelators being the BMW. In the same thought, the Accuton ceramic drivers are probably the supercar in comparison to the revelators and SB ceramic.

And/or how long they last.

Some of my sliced drivers have been in continuous use for 6 years. No problems or changes in measured performance.

My sliced PM180's have been in use in the Vapor Derecho for over 4 years. How to Train Your PM180-8 -

Techtalk Speaker Building, Audio, Video Discussion Forum

zzzzrev and sb15 sliced.jpg

When the glue cures fully, I'll try to do a comparison with the revelator.

When the glue cures fully, I'll try to do a comparison with the revelator.

Attachments

jbruner: I read the threads linked before, and found your results interesting and convincing

Since you have been doing a lot of these, would you consider doing a 'how to'/'how not to' summary? It would probably save us novices s few drivers..

I have a pair of SB 13PFC drivers I would like to try this on. They have a hard paper cone (similar to the ones in this thread) with some breakup around 6k that I don't like, and they are not too expensive if I fail.

However the latex glue (if I remember correctly?) you referred to is not sold in Europe. Any thoughts on alternatives? I was planning to try some flexible glue I have for gluing speaker surrounds..

Since you have been doing a lot of these, would you consider doing a 'how to'/'how not to' summary? It would probably save us novices s few drivers..

I have a pair of SB 13PFC drivers I would like to try this on. They have a hard paper cone (similar to the ones in this thread) with some breakup around 6k that I don't like, and they are not too expensive if I fail.

However the latex glue (if I remember correctly?) you referred to is not sold in Europe. Any thoughts on alternatives? I was planning to try some flexible glue I have for gluing speaker surrounds..

Whats the problem and how is it being solved?

I ve read this thread and seen the one at PE also, How to Train Your PM180-8 -

Techtalk Speaker Building, Audio, Video Discussion Forum

Are breakups the problem? But I thought when the wavelengths got smaller than the cone dia then breakup was a way to extend the highs and improve off axis performance (beaming)

Is lack of damping a problem? When a cone is composed of 2 layers with glue in between, the glue layer provides a high damping, CLD.

What are we achieving by first slitting (increasing stiffness) and then damping?

Will it not spoil the off axis performance?

I ve read this thread and seen the one at PE also, How to Train Your PM180-8 -

Techtalk Speaker Building, Audio, Video Discussion Forum

Are breakups the problem? But I thought when the wavelengths got smaller than the cone dia then breakup was a way to extend the highs and improve off axis performance (beaming)

Is lack of damping a problem? When a cone is composed of 2 layers with glue in between, the glue layer provides a high damping, CLD.

What are we achieving by first slitting (increasing stiffness) and then damping?

Will it not spoil the off axis performance?

Wow - skills!

@jbruner. I did I similar experiment some 15 years ago, but was far less succesful. Your results seem excellent!

A few questions: is this strictly copying the Scan pattern, or is there some underlying strategy or calculation to place the slits?

Have you also cobbled with the midwoofer surrounds in other project?

BTW: are you familiar with the Spangler and McKenzie modification of TB W3 poly driver as described in AudioXpress around 2002?

A few questions: is this strictly copying the Scan pattern, or is there some underlying strategy or calculation to place the slits?

Have you also cobbled with the midwoofer surrounds in other project?

BTW: are you familiar with the Spangler and McKenzie modification of TB W3 poly driver as described in AudioXpress around 2002?

I started on one of the SB 13PFC's today, keeping the other one as reference. Cut and glued the dust cap first, but that did almost nothing, some minor difference in the treble area that is way down in level anyway. Next up was four slices in the cone, that are drying now.

I experimented on some really old and cheap woofers too, that have a nasty dust cap resonance, and an even nastier edge/surround dip around 1k. Slicing the dust cap did surprisingly little, but some glue on the back of the surround/cone edge improved the 1k dip significantly. I did try to put some silicone on the front (cone edge&surround) to dampen this a long time ago, but it did not do much. This time I put the surround glue in angled lines from the back of the cone edge and about half way on the surround, and that did cut the dip from abt 6dB to abt 3dB.

I have a pair of old Dynaudio woofers that have a pretty nasty resonance too, and that appears to come from the big plastic dust cap. Just tapping on it sounds bad.. They also seem to have some problems from the surround.

I experimented on some really old and cheap woofers too, that have a nasty dust cap resonance, and an even nastier edge/surround dip around 1k. Slicing the dust cap did surprisingly little, but some glue on the back of the surround/cone edge improved the 1k dip significantly. I did try to put some silicone on the front (cone edge&surround) to dampen this a long time ago, but it did not do much. This time I put the surround glue in angled lines from the back of the cone edge and about half way on the surround, and that did cut the dip from abt 6dB to abt 3dB.

I have a pair of old Dynaudio woofers that have a pretty nasty resonance too, and that appears to come from the big plastic dust cap. Just tapping on it sounds bad.. They also seem to have some problems from the surround.

I actually remember I saw this on some cheap Nokia woofers, now that you mentioned it.. There was one sharp peak around 4 or 5k, but when I removed the dust cap, the problem was as good as gone. I tried to make a 'phase plug' to improve the looks, but then the problem was there again, though slightly better than with dust cap. Never understood why..

I have seen some adding felt to the pole piece to some woofers, claiming improvement, but I'm thinking it would take more absorption than a thin layer of felt? I have seen some improvements in dome tweeters with felt on a naked pole piece, but then it has been in the top octave. Even there, some more 'fluff' filling the cavity has improved things compared to just a felt pad. Sheep wool or Monacor MDM (part sheep wool), seemed to work best there. Problem is to keep it from touching the dome or going in the gap, the Monacor stuff is better in that respect. Ok, tweeters are OT in this thread..

I have seen some adding felt to the pole piece to some woofers, claiming improvement, but I'm thinking it would take more absorption than a thin layer of felt? I have seen some improvements in dome tweeters with felt on a naked pole piece, but then it has been in the top octave. Even there, some more 'fluff' filling the cavity has improved things compared to just a felt pad. Sheep wool or Monacor MDM (part sheep wool), seemed to work best there. Problem is to keep it from touching the dome or going in the gap, the Monacor stuff is better in that respect. Ok, tweeters are OT in this thread..

- Home

- Loudspeakers

- Multi-Way

- SBacoustics + slit cone (poor man's revelator)?