If I have to be a snob for this, so be it...

Hi mr brennwa

Just found another one: Ematalieren - Leistungen - Oberflachentechnik | BWB Group

where I read about the "optical characteristics"...

sounds as if...

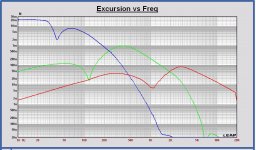

Better late than never, I made some maximum excursion plots of the Monkey Box design.

The woofer excursion is maximum 7.4 mm peak at 64.7 Hz for a voltage of 33 Vrms on the speaker, that is a SPL = 112 dB at 1m, free space.

Interesting to observe, at 33 Vrms, the midrange excursion is 976 um peak maximum at 387 Hz. The lineair Xmax limit is 1mm peak.

The tweeter maximum excursion at 33 Vrms is 81 um peak at 2920 Hz.

For those who are interested in, I made a low budget 3-way tower speaker design also with a dome midrange, all information here. I have no plans now to built it, waiting for the new Bliesma 3 inch Be dome to make a speaker with that one ! .

.

The woofer excursion is maximum 7.4 mm peak at 64.7 Hz for a voltage of 33 Vrms on the speaker, that is a SPL = 112 dB at 1m, free space.

Interesting to observe, at 33 Vrms, the midrange excursion is 976 um peak maximum at 387 Hz. The lineair Xmax limit is 1mm peak.

The tweeter maximum excursion at 33 Vrms is 81 um peak at 2920 Hz.

For those who are interested in, I made a low budget 3-way tower speaker design also with a dome midrange, all information here. I have no plans now to built it, waiting for the new Bliesma 3 inch Be dome to make a speaker with that one !

Attachments

Last edited:

Upgraded Chinese remake of the original ATC75-150S (and Esotar T330D + woofers).

Attachments

Last edited:

Yay! Another build!

There's a thousand details. All doable—I'd never built speakers before—but have been building things since childhood—take your time and think it all through....Matthias's drawings are very complete (and you won't have to convert from metric). Don't cut any baffle holes until you have the parts in hand....

There's a thousand details. All doable—I'd never built speakers before—but have been building things since childhood—take your time and think it all through....Matthias's drawings are very complete (and you won't have to convert from metric). Don't cut any baffle holes until you have the parts in hand....

Planet IX,

I am just ahead of you on the build, tower version. 2 comments.

1. It could easily take a month or two to get parts so be patient.

2. A lot of build details are discussed on this thread. Highly recommended reading. Most of what you'll need will be from post #1014 on.

Good luck,

Don

I am just ahead of you on the build, tower version. 2 comments.

1. It could easily take a month or two to get parts so be patient.

2. A lot of build details are discussed on this thread. Highly recommended reading. Most of what you'll need will be from post #1014 on.

Good luck,

Don

Thanks pfarrell and Don.

I already read most of this thread, some of it two times or more.

It was not an easy decision for this speaker, because it’s a whole lot of money to spend and

there is no possibility for me to listen to them before I start building.

I have build speakers before, but they did not look that good in the end, what was okay for me back then.

Now that my kids are old enough that they do not touch the speaker cones when I tell them they should not,

time has come for something more sophisticated…

I found a carpenter who will make the housings for me, but he wants me to tell him all the details on how to build them.

So any advice on how to build the cabinets is highly welcome.

Cheers, Boris

I already read most of this thread, some of it two times or more.

It was not an easy decision for this speaker, because it’s a whole lot of money to spend and

there is no possibility for me to listen to them before I start building.

I have build speakers before, but they did not look that good in the end, what was okay for me back then.

Now that my kids are old enough that they do not touch the speaker cones when I tell them they should not,

time has come for something more sophisticated…

I found a carpenter who will make the housings for me, but he wants me to tell him all the details on how to build them.

So any advice on how to build the cabinets is highly welcome.

Cheers, Boris

Now that my kids are old enough that they do not touch the speaker cones when I tell them they should not,

The trick is to tell them to stick their fingers in as hard as they can, every day! This made the whole thing so boring to my kids that they never thought of doing it. Not a single dented dome or cone from my kids!

Thanks pfarrell and Don.

I already read most of this thread, some of it two times or more.

It was not an easy decision for this speaker, because it’s a whole lot of money to spend and

there is no possibility for me to listen to them before I start building.

I have build speakers before, but they did not look that good in the end, what was okay for me back then.

Now that my kids are old enough that they do not touch the speaker cones when I tell them they should not,

time has come for something more sophisticated…

I found a carpenter who will make the housings for me, but he wants me to tell him all the details on how to build them.

So any advice on how to build the cabinets is highly welcome.

Cheers, Boris

What material and what thickness? I too have some B+Ws here with some slightly modified tweeters. LOL. Seems to not affect them, that I can tell anyway. She's almost 11 now though...has respect for the system—and puts on records at will.

As far as OSMC sound quality—well, my 2 cents is that I would have some trouble imagining a "better" speaker—"different" is probably easy and also a matter of taste/life factors—and likely it would then also be a BIGGER speaker... so... I think a big big factor is your room and placement therein—for any speaker. One thing I learned building the OSMCs is that I wouldn't hesitate to spend big bucks on speakers, commercially, If I had to. A speaker maker friend told to me 10x the parts cost and that would dictate a reasonable retail cost! Wow. Incredible value then if making a pair of OSMCs. Buying parts at wholesale pricing notwithstanding.

My current speakers have several dents, but it doesn't affect the sound (they were dirt cheap anyway).

A couple of years ago I noticed a rattling noise when I moved one speaker. I opened it and found a lot of Lego which found its way through the BR ports

I'm planning to use 24mm Multiplex (I don't know how it's called in english, doesn't seem to be the same as plywood). I would like to have a black front baffle and the sides beening wood with a clear lacquer.

The original design from Matthias looks also great, but I don't know how to source the wood here.

A couple of years ago I noticed a rattling noise when I moved one speaker. I opened it and found a lot of Lego which found its way through the BR ports

I'm planning to use 24mm Multiplex (I don't know how it's called in english, doesn't seem to be the same as plywood). I would like to have a black front baffle and the sides beening wood with a clear lacquer.

The original design from Matthias looks also great, but I don't know how to source the wood here.

Like this?: 24mm birch multiply

I'd love to have access to actual 24mm material. Nominal Russian/Fin-Ply here is now under 19mm. I adjusted all of the Matthias's numbers to preserve the inner dimensions in his drawings. Which would make my OSMCs a little smaller in terms of outer dimensions than his...

I used dado joints and a few pins (wood) in my construction—a trick is to drill pilot holes and run in screws—saving on complex clamping during glueup—then after drying you remove the screw and drill a hole for a wood pin that replaces the screw—this technique will end up showing the pin through veneer over time however.... One could also use butt joints and pocket screws or perhaps better, Festools domino. The domino is MUCH better than a traditional biscuit. Interior supports I used 1/2" MDF. You can get as complex as you want with interlocking perfect 45 corners etc. Veneering the outside (I considered this), etc. If your baffle will be the same 24mm stock, pay attention to the depth noted for the Volt mid. It needs a 20mm thick front to be flush. I also cut all my baffle depths to account for foam sealing tapes throughout (woofer comes with foam). Hard to do the maths on that with foam compression and finish buildup for perfectly flush in the end. One kinda of has to make a good guess with some calipers and all the parts in hand. I also embedded magnets in the corners from the inside for adding grills later—probably won't ever add them—we love the look as is.

Re: finishes. I've been using this recently and it's incredible. We have the 2 part higher end version of this (Bona Traffic HD) on the floors in our house. The link is to a 1 part "use out of the container" version—incredible laydown with just a brush. Of course if you plan to spray a finish... you might use something different, or it might be possible to spray it—really not needed imo. I tried to keep things simple but high end look and feel in my build. The white I used was water-based and put on with a brush by hand with scrutiny—15 coats all told—4 coats of clear. Has some nice depth and isn't overly perfect looking—semi-matt in the end.

I'd love to have access to actual 24mm material. Nominal Russian/Fin-Ply here is now under 19mm. I adjusted all of the Matthias's numbers to preserve the inner dimensions in his drawings. Which would make my OSMCs a little smaller in terms of outer dimensions than his...

I used dado joints and a few pins (wood) in my construction—a trick is to drill pilot holes and run in screws—saving on complex clamping during glueup—then after drying you remove the screw and drill a hole for a wood pin that replaces the screw—this technique will end up showing the pin through veneer over time however.... One could also use butt joints and pocket screws or perhaps better, Festools domino. The domino is MUCH better than a traditional biscuit. Interior supports I used 1/2" MDF. You can get as complex as you want with interlocking perfect 45 corners etc. Veneering the outside (I considered this), etc. If your baffle will be the same 24mm stock, pay attention to the depth noted for the Volt mid. It needs a 20mm thick front to be flush. I also cut all my baffle depths to account for foam sealing tapes throughout (woofer comes with foam). Hard to do the maths on that with foam compression and finish buildup for perfectly flush in the end. One kinda of has to make a good guess with some calipers and all the parts in hand. I also embedded magnets in the corners from the inside for adding grills later—probably won't ever add them—we love the look as is.

Re: finishes. I've been using this recently and it's incredible. We have the 2 part higher end version of this (Bona Traffic HD) on the floors in our house. The link is to a 1 part "use out of the container" version—incredible laydown with just a brush. Of course if you plan to spray a finish... you might use something different, or it might be possible to spray it—really not needed imo. I tried to keep things simple but high end look and feel in my build. The white I used was water-based and put on with a brush by hand with scrutiny—15 coats all told—4 coats of clear. Has some nice depth and isn't overly perfect looking—semi-matt in the end.

Thanks for the detailed answer. Yes, birch multiply is the wood that I meant.

I made myself an Excel sheet, to calculate the right dimensions of the wood panels according to the wood thickness that I get.

I hope that I can leave all the construtional details to the carpenter. For the design I will let my wife make the final decision. Then I will ask the carpenter if it is doable. I would like to avoid doing the paintjob myself, I'm not good at this...

I made myself an Excel sheet, to calculate the right dimensions of the wood panels according to the wood thickness that I get.

I hope that I can leave all the construtional details to the carpenter. For the design I will let my wife make the final decision. Then I will ask the carpenter if it is doable. I would like to avoid doing the paintjob myself, I'm not good at this...

My current stock of waveguides for the ScanSpeak tweeter is gone. I'll order some new waveguides, but it would be useful to know how many I should aim for. Who is currently considering to make a Monkey Coffin? Please let me know either by posting here or by sending me a PM.

- Home

- Loudspeakers

- Multi-Way

- Open Source Monkey Box