Can someone tell me what are the exact dimensions of 5" waveguide for SB26ADC? Is it 5.80 x 3.89 x 0.83" like in stl file? I want to assure because on waveguide there is printed 5" and 0.75" so this is confusing.

And it's curious that for 4" version on frequency responses is printed 1:1.67 as aspect ratio but in model from stl file aspect ratio is 1:1.379 (dimensions: 4.80/3.48").

I'm not sure if I can trust dimensions from stl file.

And it's curious that for 4" version on frequency responses is printed 1:1.67 as aspect ratio but in model from stl file aspect ratio is 1:1.379 (dimensions: 4.80/3.48").

I'm not sure if I can trust dimensions from stl file.

Great work here, it’s been awesome to catch up with the project! I’ve been trying to figure out a waveguide for my home theater project and one of these might be it. I have a 3D printer and I’m a long time Solidworks user.

Right now I’m looking at using the Dayton RS225-4 woofer with the RST28F tweeter with the 8” waveguide. My hope is that I can maintain ~91db sensitivity for the design after crossover filters, and I plan to make it a very shallow sealed box for wall mounting. This is for home theater so it will be highpassed at 80hz I think that I’ll be able to use the tweeter to cross over around 1.5khz to keep the cone breakup low enough.

Does anybody have any feedback if this tweeter in the 8” waveguide is a good match for an 8” woofer? I’m a bit worried that the directivity will still be too wide for an 8” woofer and it would be better to go smaller. What do you think?

If there isn’t a clear answer then hopefully I can do my part and build one and post measurements.

Right now I’m looking at using the Dayton RS225-4 woofer with the RST28F tweeter with the 8” waveguide. My hope is that I can maintain ~91db sensitivity for the design after crossover filters, and I plan to make it a very shallow sealed box for wall mounting. This is for home theater so it will be highpassed at 80hz I think that I’ll be able to use the tweeter to cross over around 1.5khz to keep the cone breakup low enough.

Does anybody have any feedback if this tweeter in the 8” waveguide is a good match for an 8” woofer? I’m a bit worried that the directivity will still be too wide for an 8” woofer and it would be better to go smaller. What do you think?

If there isn’t a clear answer then hopefully I can do my part and build one and post measurements.

I did a little more digging to answer my own question and found this: Speaker Directivity Simulators

It looks like if the RS225 stays pistonic then it will be some 8-10db down at 60 degrees off axis at 2khz, so it seems I need a smaller woofer or a larger waveguide. Perhaps a smaller woofer would do, but I’d like to keep the sensitivity and bass capability in a sealed box.

It looks like if the RS225 stays pistonic then it will be some 8-10db down at 60 degrees off axis at 2khz, so it seems I need a smaller woofer or a larger waveguide. Perhaps a smaller woofer would do, but I’d like to keep the sensitivity and bass capability in a sealed box.

That's the general 'rule of thumb', you use a waveguide that's the same diameter as the loudspeaker. Basically the driver is beaming at that diameter, so you use a waveguide that has the same beamwidth at the xover point.

Note that this doesn't necessarily mean that the beamwith of the waveguide must be the same across the board. For instance, a lot of JBL designs have a beamwidth that gets increasingly narrow as you go higher in frequency.

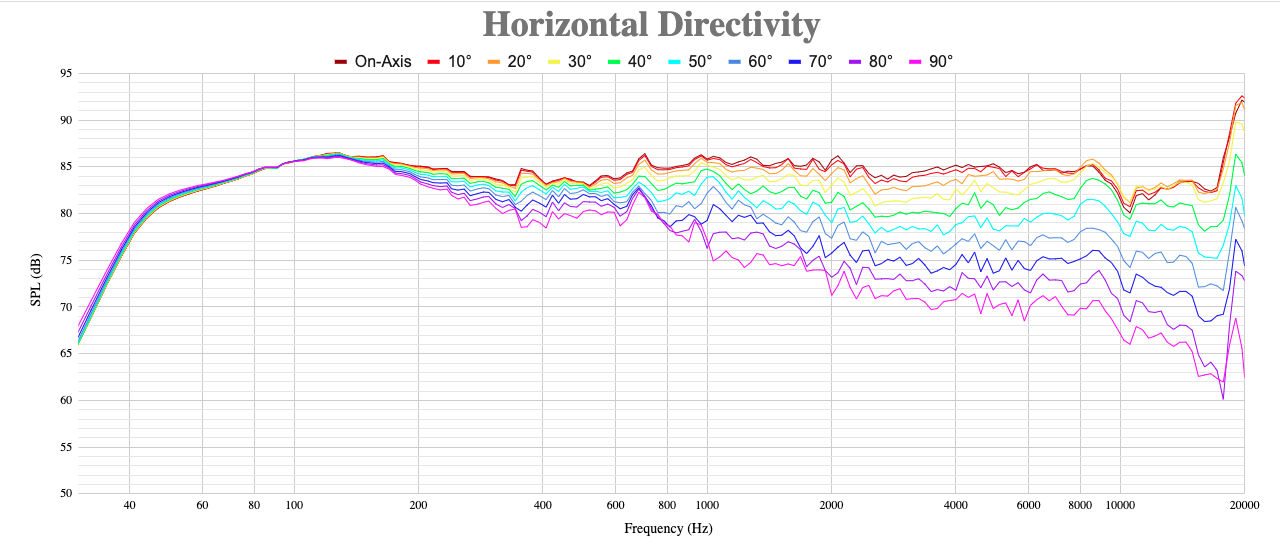

Here's a measurement of the JBL HDI-1600, note how the beamwidth narrows progressively at higher frequencies. The xover point is 2khz (6.75") and the woofer is 6.5" in diameter.

Note that this doesn't necessarily mean that the beamwith of the waveguide must be the same across the board. For instance, a lot of JBL designs have a beamwidth that gets increasingly narrow as you go higher in frequency.

Here's a measurement of the JBL HDI-1600, note how the beamwidth narrows progressively at higher frequencies. The xover point is 2khz (6.75") and the woofer is 6.5" in diameter.

Attachments

joe,

I am using the 8" with the SB26ADC with an 8" woofer (scanspeak 22W 4534G)

I haven't done explicit directionality measurements, but the directivities "should" match in the 1700 Hz range based on comparing augerpros charts and the measurements I've seen of the 22W.

Subjective listening on and off axis has me slightly preferring a lower cross. I settled on 1350 LR4.

I assume 1350 XO center freq. doesn't look as pretty as a 1600 or 1700 cross in the full series of off-axis plots, but the design axis is ~23 deg off-axis and sounds quite good. I think running the cross below the ideal directivity match is much less of an issue than crossing above that ideal, and the SB26ADC has zero issues playing low. THD in the 8" waveguide looked quite good down to 1000 Hz, even at high volume, and listening to low cross, my ears agree, it doesn't sound overly strained.

This is in ~22L boxes using Hypex Fusion amps so I can adjust the FR and XO at will. These are really just temporary boxes, they will eventually be built into a media center that will add subs as well (also powered by the Hypex fusion amps,) so essentially will be used as on-wall speakers like you're planning.

FYI, the 22W I'm using is not staying pistonic. It starts deviating from pistonic just under 1000Hz, but it has a graceful poly breakup that just exhibits some rising 3rd order distortion. I think an RS225 should work fine as long as you can bury the breakup peak of the aluminum cone, but like in my case, you will probably want to cross lower than at the ideal directivity match. I really don't think it's THAT big a deal to cross below the ideal directivity match.

I am using the 8" with the SB26ADC with an 8" woofer (scanspeak 22W 4534G)

I haven't done explicit directionality measurements, but the directivities "should" match in the 1700 Hz range based on comparing augerpros charts and the measurements I've seen of the 22W.

Subjective listening on and off axis has me slightly preferring a lower cross. I settled on 1350 LR4.

I assume 1350 XO center freq. doesn't look as pretty as a 1600 or 1700 cross in the full series of off-axis plots, but the design axis is ~23 deg off-axis and sounds quite good. I think running the cross below the ideal directivity match is much less of an issue than crossing above that ideal, and the SB26ADC has zero issues playing low. THD in the 8" waveguide looked quite good down to 1000 Hz, even at high volume, and listening to low cross, my ears agree, it doesn't sound overly strained.

This is in ~22L boxes using Hypex Fusion amps so I can adjust the FR and XO at will. These are really just temporary boxes, they will eventually be built into a media center that will add subs as well (also powered by the Hypex fusion amps,) so essentially will be used as on-wall speakers like you're planning.

FYI, the 22W I'm using is not staying pistonic. It starts deviating from pistonic just under 1000Hz, but it has a graceful poly breakup that just exhibits some rising 3rd order distortion. I think an RS225 should work fine as long as you can bury the breakup peak of the aluminum cone, but like in my case, you will probably want to cross lower than at the ideal directivity match. I really don't think it's THAT big a deal to cross below the ideal directivity match.

Last edited:

Jon's relatively recent measurements of the ceramics at HTGuide have also shown incredibly low THD.

A bit of an off topic request but could you give a link to these measurements of the SB26ADC by Jon ? I would be interested. Thanks !

I'm not 100% sure HTGuide links work right if you're not signed in to your account, which is why I edited that out of my comment... but here is his post on the SB26CDC follow-up in case it does work out:

Driver Evaluations for a new project - Page 11

Actually I guess it's Evil Twin who posted it, not JonMarsh... So Mr Hyde, not Dr Jekyll.

Driver Evaluations for a new project - Page 11

Actually I guess it's Evil Twin who posted it, not JonMarsh... So Mr Hyde, not Dr Jekyll.

Hey, thanks a bunch for the replies! You’ve given me hope that this could be a fairly viable project. I use the RS180 in the Modula MT right now and I’m a fan of the drivers in general. If I can make it work here then it’s potentially a fairly high value project. Heck, maybe I can take some inspiration from one of Jon Marsh’s crossovers to keep the break down! In the meanwhile I have a minidsp for prototyping.

Warming up the printer now!

Warming up the printer now!

One is done at 15% infill! This is just my random PLA. The surface is a bit rougher than I would like, but with some elbow grease I suppose it can be better. It feels sturdy, I bet that at 100% infill it will be great.

I’m still thinking the RS225-4 with the RST28F-4 aiming for a crossover below 1500hz. It would be great if I can make that work low enough to avoid some of the more expensive crossover considerations.

I’m still searching around for better drivers, but I don’t know what I can get that will be much more sensitive and such low distortion without quadrupling the price.

I’m still thinking the RS225-4 with the RST28F-4 aiming for a crossover below 1500hz. It would be great if I can make that work low enough to avoid some of the more expensive crossover considerations.

I’m still searching around for better drivers, but I don’t know what I can get that will be much more sensitive and such low distortion without quadrupling the price.

Attachments

Router Required with round base.

Tip: How To Flush Mount Irregular Shape Driver -

Techtalk Speaker Building, Audio, Video Discussion Forum

Basically;

1. Fix the object being installed to a large scrap piece of 5mm MDF or similar.

2. Using 1/4” bit, run the router around the work piece to create a main “template”.

3. Make another round router base 1/2” larger than original used for trace.

4. Fix template to baffle or frame the object is being installed to

5. Route hole or recess using larger base on router around inside of “template”.

6. Make larger router bases for smaller holes or cutouts within “template”.

Tip: How To Flush Mount Irregular Shape Driver -

Techtalk Speaker Building, Audio, Video Discussion Forum

Basically;

1. Fix the object being installed to a large scrap piece of 5mm MDF or similar.

2. Using 1/4” bit, run the router around the work piece to create a main “template”.

3. Make another round router base 1/2” larger than original used for trace.

4. Fix template to baffle or frame the object is being installed to

5. Route hole or recess using larger base on router around inside of “template”.

6. Make larger router bases for smaller holes or cutouts within “template”.

If you have a bushing plate, you can cut the big template as noted, then use that to cut a smaller template with the same base, then use a bushing to adjust for the bit diameter spacing to cut the recess into the baffle. The final template ends up smaller and is a bit easier to clamp and work with on the baffle, plus you don't have to make a base... sure it's not too hard to make a bigger base, but it's not totally simple, especially to get it concentric.

It's what I did... it was outlined earlier in the thread by someone.

It's what I did... it was outlined earlier in the thread by someone.

After over a weeks listening to the speaker and tweaking xo, (i settled on 2.4khz) I can safely say every box speaker I make from now on will have one of these waveguides. Get it right and it is just mind blowing the improvements over a flush mounted tweeter.

Hi mainframe,

Really nice project. That's a huge step from your initial XO@1.6khz. Have you done new directivity measurements with the XO @ 2.4khz or it is based on your listening experience ?

Regards

If you have a bushing plate, you can cut the big template as noted, then use that to cut a smaller template with the same base, then use a bushing to adjust for the bit diameter spacing to cut the recess into the baffle. The final template ends up smaller and is a bit easier to clamp and work with on the baffle, plus you don't have to make a base... sure it's not too hard to make a bigger base, but it's not totally simple, especially to get it concentric.

It's what I did... it was outlined earlier in the thread by someone.

If you cut the bigger base with a Jasper jig then getting it concentric is a doddle since the centering hole is already where it should be. The only thing to remember is cutting a circle two bit widths larger than the desired base size since the J.J. is calibrated for hole sizes, not offcut widths.

If you cut the bigger base with a Jasper jig then getting it concentric is a doddle since the centering hole is already where it should be. The only thing to remember is cutting a circle two bit widths larger than the desired base size since the J.J. is calibrated for hole sizes, not offcut widths.

Bingo. This one got me more than once too.

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!