I use CAD softwares, STEP is a prefect standardized geometric representation, STL is a mech (several point) with a definition of the original, more the definition is higher more it's close to the original model but more it's heavier and it will never be as the original, it will be infinitely tangential to the original more the definition grow.

Step is useful when you integrate (import) an external model to another model (the bubulle for me), that is my usage case.

It's the better format for transition also, meshing will be done at the end just before CNC/printig, it's like stay in numeric as far you can and pass to analogic at the very end, but I'm not in this usage case.

I doing also something that cannot be done with STL, I merge the two model then I do a variable chamfer for be at 180° vertically that doesn't have effet horizontally (because it's already 180° horizontally), that touch you profil only vertically, very few and at the end, and that have an effet on the bubulle.

Diffraction will be better. I also take the ellipse of the front as a transition, so she have to be geometric and not a mesh ^^

The down point is that I have to do it for each WG and cannot reuse what I have done to the previous.

The 6.5 with his bubulle is a little bit big in comparaison of the Ikea bowl speaker, it's why I would like to try with the 6", initially Aznowicz want something little (I start with the 4" but it's far to mach the woofer in directivity at the crossover region)

Thanks for you work and sorry for asking that ^^

Step is useful when you integrate (import) an external model to another model (the bubulle for me), that is my usage case.

It's the better format for transition also, meshing will be done at the end just before CNC/printig, it's like stay in numeric as far you can and pass to analogic at the very end, but I'm not in this usage case.

I doing also something that cannot be done with STL, I merge the two model then I do a variable chamfer for be at 180° vertically that doesn't have effet horizontally (because it's already 180° horizontally), that touch you profil only vertically, very few and at the end, and that have an effet on the bubulle.

Diffraction will be better. I also take the ellipse of the front as a transition, so she have to be geometric and not a mesh ^^

The down point is that I have to do it for each WG and cannot reuse what I have done to the previous.

The 6.5 with his bubulle is a little bit big in comparaison of the Ikea bowl speaker, it's why I would like to try with the 6", initially Aznowicz want something little (I start with the 4" but it's far to mach the woofer in directivity at the crossover region)

Thanks for you work and sorry for asking that ^^

Thanks for the explanation! step attached

Thanks, there a little problem, on this Step and also on the 6" Step on the websiste, it cannot be open by either AB Viewer or STP Viewer, in the case of STP viewer the software bug with a critical error, AB viewer show nothing on his side.

No problems for the 6.5" version, that works perfectly ^^

I will try other soft for investigate.

Oh, I also have some 6640 you could borrow. Not sure about the beryllium question though...My R2907/7000 are busy making great music in your waveguide, but I have some D3004/6600 collecting dust. I believe the main difference between the 6600 and the 7100 is the motor system.

Does it have to be those two models? If not, I have a D3004/6020 from an old speaker I don't use anymore that I can let you borrow if you want.

I prefer to work with one that you can remove the faceplate

Oh, I also have some 6640 you could borrow. Not sure about the beryllium question though...

Are they both the same underneath the faceplate? I'll work with whatever you are willing to send.

I believe the 6600 and the 6640 are the same underneath the faceplate, but I am not 100% sure. I haven't removed the faceplate of the 6640, because I know I'd accidentally punch the Be dome when I am doing that... As far as I can tell, the circular waveguide for the 7000 fits on the 6600 assembly as well.

Let me know (and send me a PM for the shipping details).

Let me know (and send me a PM for the shipping details).

Anyone using a T25B, please hold off on mounting it to a waveguide. A user had an issue which resulted in returning the tweeter to Bliesma. Bliesma thinks the dome assembly was offset due to the waveguide. We need to confirm with Bliesma the size of the faceplate hole the surround is glued to. I designed this to sit on the solid faceplate the surround is glued to, not on unsuspended surround, so I'm not sure what is happening yet. This shouldn't be an issue (if the throat is sized correctly) as typical tweeters have the surround glued to a top plate, and a faceshield is pressing down on that surround/faceplate area. Bliesma is a little different in that they glue to the faceplate directly since it is not removeable, but attaching the waveguide would still act as a typical tweeter assembly.

Couple other things to be aware of though. If you had these commercially printed in SLS nylon for example, the dimensional accuracy is right on. But on home printers, the throat may be just a hair smaller. I run a fine round file around the throat when I print at home and then make sure the throat is not touching the curved and free-floating part of the surround.

Also be sure to everything is centered before tightening down. If you are under pressure and shift the tweeter, I could see how you might shift the surround. The glue Bliesma uses is very flexible/soft, so it can move under pressure.

Couple other things to be aware of though. If you had these commercially printed in SLS nylon for example, the dimensional accuracy is right on. But on home printers, the throat may be just a hair smaller. I run a fine round file around the throat when I print at home and then make sure the throat is not touching the curved and free-floating part of the surround.

Also be sure to everything is centered before tightening down. If you are under pressure and shift the tweeter, I could see how you might shift the surround. The glue Bliesma uses is very flexible/soft, so it can move under pressure.

I've verified my model is larger than the surround, and that the hole in the faceplate must be almost identical to the outside of the surround. Therefore the lip of the waveguide is resting on the part of the surround glued to the faceplate, which is in turn resting on solid metal. So the waveguide is behaving as any faceplate on a typical tweeter does.

I'm confirming with the user that his throat is actually 1.21", and not slightly smaller which can happen in DIY printers. This should leave .02" of clearance around the surround.

Once that is confirmed I've sent a variant with no lip for the user to try. I'll also print it, but won't be able to do measurements for about 2 weeks.

Also, I use foam between the clamp and tweeter so you have some measure of control of the pressure. If you just tighten rigid parts I could see applying very high pressures easily.

So at this point I'm leaning towards the throat on his particular print is just too small, or clamping pressure was too high. That said I need to test myself. Perhaps that cavity created between waveguide and faceplate due to the lip is doing something weird. Maybe clamping down too hard actually bent the waveguide enough that it started touching the faceplate where there should have been a gap (again, due to the lip around the throat) that is creating buzzing which showed up as higher harmonic distortion? (that is how he first noticed the issue)

I'm confirming with the user that his throat is actually 1.21", and not slightly smaller which can happen in DIY printers. This should leave .02" of clearance around the surround.

Once that is confirmed I've sent a variant with no lip for the user to try. I'll also print it, but won't be able to do measurements for about 2 weeks.

Also, I use foam between the clamp and tweeter so you have some measure of control of the pressure. If you just tighten rigid parts I could see applying very high pressures easily.

So at this point I'm leaning towards the throat on his particular print is just too small, or clamping pressure was too high. That said I need to test myself. Perhaps that cavity created between waveguide and faceplate due to the lip is doing something weird. Maybe clamping down too hard actually bent the waveguide enough that it started touching the faceplate where there should have been a gap (again, due to the lip around the throat) that is creating buzzing which showed up as higher harmonic distortion? (that is how he first noticed the issue)

Hello everyone,

I'm the user that Brandon mention in a previous message. As I see someone else is jumping in the T25B waveguide wagon, and to avoid any possible problem with the excellent Bliesma T25B, here are my preliminary suggestions (I learned the hard way).

T25B surround is glued flush to the faceplate, according to the manufacturer, it's done to get a smoother frequency response and less reflections in the top octave.

Acrylic glue is relatively soft so if some force is applied on the surround-faceplate joint, the surround can move and voice coil can change its position in the magnetic gap and start to rub. This is what happened to me. I had to send it back for repair ! SO be advised. So :

1) Double check the inner diameter of the throat, as Brandon wrote it should be 30.74 mm minimum. In my case, both printed by Xometry in Germany in Nylon PA12 were 30.4 to 30.5 mm only. I had to increase them by sanding (P120 and P500 paper)

2) Don't use Blue tack or similar to seal this tweeter I think it was suggested by someone in this thread. In case you pressed a little too much on the back of the tweeter to fix it the almost 0.8 to 0.9 mm clearance (2.4 - (2-0.5)) will allow the tack to migrate closer to the surround and if you dismount the tweeter for whatever reason from the waveguide, you have a risk to move the surround.

3) Don't exercise too much pressure on the back of the tweeter to hold it on the waveguide. Remember, all pressure will apply nearby the surround (2.64 cm²) on the faceplate via the the throat ring

So in short:

I'm the user that Brandon mention in a previous message. As I see someone else is jumping in the T25B waveguide wagon, and to avoid any possible problem with the excellent Bliesma T25B, here are my preliminary suggestions (I learned the hard way).

T25B surround is glued flush to the faceplate, according to the manufacturer, it's done to get a smoother frequency response and less reflections in the top octave.

Acrylic glue is relatively soft so if some force is applied on the surround-faceplate joint, the surround can move and voice coil can change its position in the magnetic gap and start to rub. This is what happened to me. I had to send it back for repair ! SO be advised. So :

1) Double check the inner diameter of the throat, as Brandon wrote it should be 30.74 mm minimum. In my case, both printed by Xometry in Germany in Nylon PA12 were 30.4 to 30.5 mm only. I had to increase them by sanding (P120 and P500 paper)

2) Don't use Blue tack or similar to seal this tweeter I think it was suggested by someone in this thread. In case you pressed a little too much on the back of the tweeter to fix it the almost 0.8 to 0.9 mm clearance (2.4 - (2-0.5)) will allow the tack to migrate closer to the surround and if you dismount the tweeter for whatever reason from the waveguide, you have a risk to move the surround.

3) Don't exercise too much pressure on the back of the tweeter to hold it on the waveguide. Remember, all pressure will apply nearby the surround (2.64 cm²) on the faceplate via the the throat ring

So in short:

- use foam to seal the tweeter on the waveguide (I use 2 mm foam see picture)

- check and adjust the inner throat diameter to the proper value (>30.74 mm)

- Don't press the back of the tweeter too hard to avoid excessive pressure on the faceplate nearby the surround via the annular ring. On my side I added an 0.5 mm thick washer on the 3 centering dots to reduce the clearance slightly

PS: Bliesma T25B are incredibly good tweeter in my opinion (I use a pair (no waveguide) in another system for the past 6 months

Sorry for the long post

Jean Claude

Attachments

Last edited:

Mine just arrived from printing company, looks fabolous

thanks for this project!

View attachment 898829

View attachment 898830

Could you do a couple tests to shed some light on Jean Claude's issue? Perhaps a frequency response and HD of the factory tweeter, then one attached to the waveguide. I want to see if the HD changes in a negative way. Impedance may be informative too. Clamp with just enough pressure so the tweeter is snug and not moving and be sure to use foam between clamp and tweeter.

Hello everyone,

Do you remember the surround having any wrinkles at all? It should be pretty obvious if the throat ring pushed it around at all.

I just read your email about changing HD, it just seems strange since as far as I can tell, it is the metal body of the tweeter taking all the force of the throat ring. Does anyone know how these are constructed?

No wrinkles on the surround at all.

I spent the past couple of days on that and I found that adding foam between the waveguide and the faceplate will introduce a dip in frequency curve. I tested 2 different foam ring, one introduced a 4 kHz dip and the second à 12 kHz dip. So at the end I removed the foam.

The best results in my case were obtained with no fixing on the back, a small 0.5 mm thick washer on the centering dots and blue tack at the periphery of the face plate to hold the tweeter and seal the combo. I also have A have melamine foam in the enclosure just behind the waveguide pushing gently the back of the tweeter (just in case).

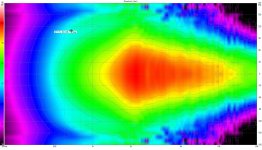

You can see an untouched horizontal +/-180° polar map.

Jean Claude

I spent the past couple of days on that and I found that adding foam between the waveguide and the faceplate will introduce a dip in frequency curve. I tested 2 different foam ring, one introduced a 4 kHz dip and the second à 12 kHz dip. So at the end I removed the foam.

The best results in my case were obtained with no fixing on the back, a small 0.5 mm thick washer on the centering dots and blue tack at the periphery of the face plate to hold the tweeter and seal the combo. I also have A have melamine foam in the enclosure just behind the waveguide pushing gently the back of the tweeter (just in case).

You can see an untouched horizontal +/-180° polar map.

Jean Claude

Attachments

I've corresponded with Stanislav from Bliesma and confirmed the faceplate hole is 30mm while the waveguide throat is 30.7mm, so I'm certain the throat ring is resting on the faceplate. Also he confirmed the faceplate is 3mm aluminum, so that is solid foundation.

So, my own feeling is this should behave as any tweeter where the faceplate is pressed down on the glued area of the surround (SB26 for example). If you are thoughtful on centering everything and applying just enough pressure to keep the tweeter from moving, it should behave as every other tweeter. Jean Claude said the distortion change is repeatable, I just can't quite understand how that is happening. But, I'm printing a new version with no throat ring to see what I can figure out. Bit of head scratcher for me.

So, my own feeling is this should behave as any tweeter where the faceplate is pressed down on the glued area of the surround (SB26 for example). If you are thoughtful on centering everything and applying just enough pressure to keep the tweeter from moving, it should behave as every other tweeter. Jean Claude said the distortion change is repeatable, I just can't quite understand how that is happening. But, I'm printing a new version with no throat ring to see what I can figure out. Bit of head scratcher for me.

Last edited:

Brandon,

I will confirm my findings with the second tweeter coming back home soon.

Anyway, in the specific case of the Bliesma T25B, I don't see the real purpose of the throat ring.

From a mechanical point of view all the pressure will be exercised on the very small surface (#2.6 cm²) at a few tenth of mm of the surround versus the #36 cm² of the whole face plate.

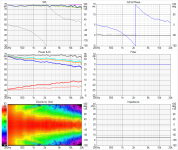

Don't get me wrong Brandon is doing a fantastic job for us diyers and his waveguide along with the Bliesma is really shining both at measurements (freq/distortion) but also on ear, I spent half of the last night listening on mono my new system. Below are some preliminary results

Jean Claude

I will confirm my findings with the second tweeter coming back home soon.

Anyway, in the specific case of the Bliesma T25B, I don't see the real purpose of the throat ring.

From a mechanical point of view all the pressure will be exercised on the very small surface (#2.6 cm²) at a few tenth of mm of the surround versus the #36 cm² of the whole face plate.

Don't get me wrong Brandon is doing a fantastic job for us diyers and his waveguide along with the Bliesma is really shining both at measurements (freq/distortion) but also on ear, I spent half of the last night listening on mono my new system. Below are some preliminary results

Jean Claude

Attachments

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!