It is bad engineering to design for the exception that few people want. Picking apart an argument in support of what 95+% of the situations require by focusing on a few% unique situations is not even worth discussing.

Oh well, I forgot, what's fit for 95% has to fit everyone. Yay, forget about everyone else, f**k them, your standards are for everyone, YAY!

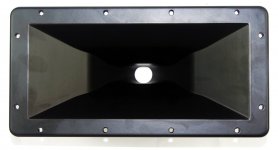

And another take on the biradials.

Not sure about the quality of the throat area.

If it is so important you can sand it.

That's an ancient diffraction slotted EV/JBL derived design, full of HOM's.

In general (read the works of Dr. Geddes): you don't want to use such a horn in your room.

This is an interpretation of the classic Manta Ray horn with a smoother throat/diffraction slot, which is likely to produce (somewhat) less HOMs.

Attachments

Last edited:

This is what a - pretty close to - perfect thoat looks like:

I like the matte black better compared to glossy (shiny) black painting of the one you can buy in the shops.

It would look even - and perform slightly - better after a nice coat of light grey Nextel.

I like the matte black better compared to glossy (shiny) black painting of the one you can buy in the shops.

It would look even - and perform slightly - better after a nice coat of light grey Nextel.

Attachments

Last edited:

That's an ancient diffraction slotted EV/JBL derived design, full of HOM's.

In general (read the works of Dr. Geddes): you don't want to use such a horn in your room.

This is an interpretation of the classic Manta Ray horn with a smoother throat/diffraction slot, which is likely to produce (somewhat) less HOMs.

5€ is great to wait for something else... and the horizontal dispersion is great and it loads pretty low (700Hz).

... i'm working on a mold in order to make a crystal clear translucid thermoformed oblate speroid horn.

By supperposing two sheets of polycarbonate with a thin oil film detween the two layers you can reach a very low self resonating frquency (a little like the hydraulic miltilayer mylar drumheads)

This is what a - pretty close to - perfect thoat looks like:

Which model is it ?

Do you have the datasheet?

How about something like this? The fiberglass clones are easily obtainable in Europe, which allow for some tweaks of the throat area. This WE/Altec-32b derivative is 120x100 degrees -6dB and has a cutoff frequency of 500Hz. In real life you'll want to XO closer to 1000Hz.

Attachments

An externally hosted image should be here but it was not working when we last tested it.

It's this one

The one I showed is from the manufacturer.

... i'm working on a mold in order to make a crystal clear translucid thermoformed oblate speroid horn.

By supperposing two sheets of polycarbonate with a thin oil film detween the two layers you can reach a very low self resonating frquency (a little like the hydraulic miltilayer mylar drumheads)

Do you have experience with molding waveguides?

I found this thread very interesting.

This guy actually made an enlarged clone from the above XT-1464 and called it the XT-1465. It has a 2" throat and the CAD design was simulated in Comsol with quite impressive results.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Interesting way of molding with concrete:

Last edited:

An angled horn, i should experience the worst homs, No?How about something like this? The fiberglass clones are easily obtainable in Europe, which allow for some tweaks of the throat area. This WE/Altec-32b derivative is 120x100 degrees -6dB and has a cutoff frequency of 500Hz. In real life you'll want to XO closer to 1000Hz.

No, and it is also why i'm interested until there is no commercial solution.Do you have experience with molding waveguides?

I found this thread very interesting.

This guy actually made an enlarged clone from the above XT-1464 and called it the XT-1465. It has a 2" throat and the CAD design was simulated in Comsol with quite impressive results.

403 - Forbidden: Access is denied.

Interesting way of molding with concrete:

Too long, the maximum overall deepness should not exceed 240mm and i need a wide horizontal dispersion (more than 60°) for a near field listening.

Edit : the XT1464 is also too long.

Last edited:

This guy actually made an enlarged clone from the above XT-1464 and called it the XT-1465. It has a 2" throat and the CAD design was simulated in Comsol with quite impressive results.

Very interesting horn, thx !!!

Wish he would make one for 1.4"

I have xti 1464, love it

An angled horn, i should experience the worst homs, No?

No, and it is also why i'm interested until there is no commercial solution.

Too long, the maximum overall deepness should not exceed 240mm and i need a wide horizontal dispersion (more than 60°) for a near field listening.

Edit : the XT1464 is also too long.

The original WE/Altec was indeed angled, with a bent throat, but the engineers at Western Electric Laboratories already knew a thing or two about pressure acoustics, so they made the bend with a gradual curvature. There are no further discontinuities in the horn path. According to many people, who have owned or listend to these horns, they are quite decent (which might be an understatement). These horns are highly sought after and often change hands for ridiculous amounts of money.

I was tempted to make a bid on a pair that was recently for sale in my tiny country for only €500 including Altec 808-8b drivers, but they were gone within the blink of an eye. I included an image of the items and a nice project based on these horns and Altec drivers from a French artisan who built a clone of the Shindo Petite Latour for about €6000 instead of the $34.000 of the original. According to the owner, they beat his Harbeths M40.1 by quite a margin.

For near field listening, I would recommend a smaller horn with an 6-8" woofer (+ subs). This and this are 2 favorites and both around 80° in the horizontal.

Too many forums where these have been measured and used in projects, but you might start with googling "Econowave 18Sound".

Attachments

-

032847e7cc720a320205471c519a9a23.jpg507.3 KB · Views: 129

032847e7cc720a320205471c519a9a23.jpg507.3 KB · Views: 129 -

545325d77d478c87b2bf1316296c9149 (1).jpg288.8 KB · Views: 169

545325d77d478c87b2bf1316296c9149 (1).jpg288.8 KB · Views: 169 -

Altec Hoorns 32 plus 808-8b drivers_5.JPG26.6 KB · Views: 125

Altec Hoorns 32 plus 808-8b drivers_5.JPG26.6 KB · Views: 125 -

Altec Hoorns 32 plus 808-8b drivers_2.JPG30.1 KB · Views: 128

Altec Hoorns 32 plus 808-8b drivers_2.JPG30.1 KB · Views: 128 -

Altec Hoorns 32 plus 808-8b drivers_3.JPG37.9 KB · Views: 135

Altec Hoorns 32 plus 808-8b drivers_3.JPG37.9 KB · Views: 135

Last edited:

An angled horn, i should experience the worst homs, No?

Edit : the XT1464 is also too long.

I'm not sure what is meant by 'angled' here. The coverage angle?

EDIT: I just realised the answer - that multiple horns were being discussed in one post, not just the XT-1464 (18 sound) clone.

As for HOMs, when he was asked about a similar horn (XT1086), Dr Geddes said:

For the money that waveguide looks pretty good.

I would judge the mismatch of slope at the throat to be the worst offender regarding diffraction.

Something like this looks like a pretty good alternative, short and looks like a simple shape (no sharp angles / low HOM?). I like the flat front, which means one could possibly rear mount it + chamfer the baffle to get a smoother mouth edge, (and have less black plastic on view).

Seven dollars.

China Compression Driver Horn for PRO Audio Speaker (148) - China Compression Driver, Hf Horn

Attachments

Last edited:

I am not so sure about HOMs being a major issue with the XT1086. 18Sound (now owned by B&C) use very sophisticated tools (both hard- and software) in their labs.

Their horns are have all been developed based on extensive simulation and optimization in Comsol, similar to what Harman has done in developing their PT and Image Control waveguides. Kef and Celestion (also) use Siemens PLM to develop their waveguides, annular diaphragms and phase plugs, which is more or less comparable.

Take a look at this:

More than a few sudden discontinuities, but I haven't read any comments about the M2 suffering from HOMs so far.

Even with older drivers that were not (at all) developed for specific use with the M2 waveguide, people praise the "smoothness" it adds to the sound.

On the Audioheritage forum there are plenty of threads on the M2 waveguide.

Their horns are have all been developed based on extensive simulation and optimization in Comsol, similar to what Harman has done in developing their PT and Image Control waveguides. Kef and Celestion (also) use Siemens PLM to develop their waveguides, annular diaphragms and phase plugs, which is more or less comparable.

Take a look at this:

An externally hosted image should be here but it was not working when we last tested it.

More than a few sudden discontinuities, but I haven't read any comments about the M2 suffering from HOMs so far.

Even with older drivers that were not (at all) developed for specific use with the M2 waveguide, people praise the "smoothness" it adds to the sound.

On the Audioheritage forum there are plenty of threads on the M2 waveguide.

Last edited:

Their horns are have all been developed based on extensive simulation and optimization in Comsol

I'm sure they know what they are doing

Regarding HOM, Dr Geddes argues for reducing it (and diffraction) to an absolute minimum.

It looks like the 18 sound people compromise that a little to get the loading and coverage angle they need for pro use. The optimisation and amount of compromise is no doubt good, so maybe the difference between them and a Geddes clone of equivalent dimensions would be inaudible / only academic.

I haven't used an 18 Sound horn or a HOM optimised oblate spheroid, but I imagine I'd like both. The 1464 looks good here (maybe too good, is that distortion test a real thing)?

Test Bench: Eighteen Sound ND3ST 1.4” Compression Driver

- Home

- Loudspeakers

- Multi-Way

- How to Make a New Wave Biradial Horn