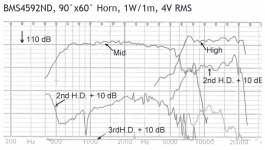

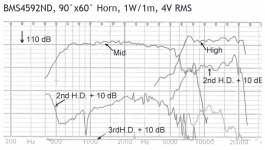

The next in line that I've personally heard would be a properly EQed (and perhaps bi-amped) BMS 4592ND dual diaphragm driver (i.e., the full 2" throat model).

Hi again Chris,

Concerning the BMS drivers. I have actually had a pair of the BMS 4592ND coax drivers, but I never managed to get them to sound right (to much sibilance...), but that may indeed have been due to lacking crossover skills on my side...

IF you consider these, I will recommend looking into BMS' new HE (High End) versions of these drivers, which should be considerably improved. The downside is, that the none of the new HE drivers have 2" throats (well there is one, but it only goes to 8k). So in that case a 1.4"/2" adaptor would be needed.

NEW HIGH END COMPRESSION DRIVERS

Best regards

Peter

The crossover of the BMS 4592ND is the problem that must be EQed properly. My default approach is to use DSP crossovers (Xilica, EV, Yamaha) to solve that problem. Sibilance is in the 4-8 kHz region, and if you don't correct for the hump in response in the tweeter at 7.5 kHz, you're going to hear it a lot. I'm also not sure what the relative phase is between the midrange and tweeter diaphragms at the 2" driver exit--it may need to be time aligned (i.e., I don't have the data). It's pretty straightforward to do that using a DSP crossover.

If all of this is too much to digest for your uses, or you're trying to use passive networks only with no correcting PEQs upstream, then I'd not recommend the BMS 4592ND. I'd probably try the Radian Be or some other driver instead.

As far as the Truextent Be "replacement" diaphragms--it's generally hit or miss as far as I can tell. All of the JBL drivers not designed for Be diaphragms seem to have varying difficulties making full use of them. That's all I'm saying. It's personal choice in terms of how much non-optimality is acceptable in using Be for the particular JBL driver model used.

Better is better but the Be diaphragms are not cheap and if I were going to pay the price again, I'd want to get as much as I could out of them.

Chris

If all of this is too much to digest for your uses, or you're trying to use passive networks only with no correcting PEQs upstream, then I'd not recommend the BMS 4592ND. I'd probably try the Radian Be or some other driver instead.

As far as the Truextent Be "replacement" diaphragms--it's generally hit or miss as far as I can tell. All of the JBL drivers not designed for Be diaphragms seem to have varying difficulties making full use of them. That's all I'm saying. It's personal choice in terms of how much non-optimality is acceptable in using Be for the particular JBL driver model used.

Better is better but the Be diaphragms are not cheap and if I were going to pay the price again, I'd want to get as much as I could out of them.

Chris

Thanks tmuikku! I understand about the assurances on a DIY MEH kit working as advertised. Most hobbyists wanting to tinker usually want the price to be extremely low.

The loudspeaker kit(s) that would result from the current effort in this thread would rather be in the category of "less tinkering...more hi-fi" than those other non-full-range MEH projects more typically discussed in threads here. The notion of a horn-loaded full range loudspeaker of the MEH type really is the driving idea here. There still are those readers that tend to confuse this idea with the other types of DIY MEHs found elsewhere on diyAudio. I find that the concept of a "full range MEH" can actually overlap the idea of a full-range direct radiating driver, of which we have an entire diyAudio forum dedicated to that purpose. So your comments about looking for a horn-loaded alternative to those designs is well founded here--even more so if you consider that the frequency response might extend down to 30 Hz or so and be much like a coaxial direct radiating full range driver in terms of its capabilities, albeit without the limitations of modulation distortion, compression distortion and the inabilities of controlling its polar coverage vs. frequency down to a truly useful frequency (about 100 Hz) that direct radiating drivers have.

I believe that those other MEH projects, e.g., "small syns" are excellent ones, but my personal needs are to avoid direct radiating woofers that have directivity issues below 400-500 Hz, as well as 10-25 dB higher levels of modulation distortion sidebands than good horn-loaded ones. This is horn-loading to the extent possible using MEH-type approaches.

[Note that the word "Synergy" is copyrighted by Danley Sound Labs in context of their MEHs and I try to respect that by not using that designation for my DIY efforts. Besides, most of their IP is really in the passive crossovers, of which I can see no one on diyAudio trying to replicate for their DIY MEH projects.]

As far as your comments concerning "profit", I'm not sure what has been written in this thread that triggered that response. The real bottleneck that I see currently is full-range MEH loudspeaker horns that don't require significant modification from their as-bought condition to make them useful for MEH operation. To do that, a significant investment in the stuff to make the horns is required--several thousand dollars for each horn design. Is anyone else planning to do that (that I'm not already aware of)?

I need five horns for my listening room of the K-402 size. After that, my needs are satisfied. The mold itself will remain for others to enjoy the same resulting horn for their DIY projects. It would be nice if some of the cost of that mold is amortized in the price of the resulting horns that could be sold "at cost". This makes it much easier to justify to my significant other to do other MEH-type horn designs for their needs. It's not a small effort to do these horns, as it turns out.

Other horn sizes and shapes will also need their own investment in the molds. No one is "making money" in the current concept. I assume that you can see that.

If I later were to offer full-up MEH loudspeakers or screw-together-and-plugin MEHs, then that looks like a profit making exercise. Those loudspeakers would be for those without the time and/or expertise to build their own, and I believe it would be fair to expect some profit for the time spent on delivering those recurring efforts for each customer.

Chris

The loudspeaker kit(s) that would result from the current effort in this thread would rather be in the category of "less tinkering...more hi-fi" than those other non-full-range MEH projects more typically discussed in threads here. The notion of a horn-loaded full range loudspeaker of the MEH type really is the driving idea here. There still are those readers that tend to confuse this idea with the other types of DIY MEHs found elsewhere on diyAudio. I find that the concept of a "full range MEH" can actually overlap the idea of a full-range direct radiating driver, of which we have an entire diyAudio forum dedicated to that purpose. So your comments about looking for a horn-loaded alternative to those designs is well founded here--even more so if you consider that the frequency response might extend down to 30 Hz or so and be much like a coaxial direct radiating full range driver in terms of its capabilities, albeit without the limitations of modulation distortion, compression distortion and the inabilities of controlling its polar coverage vs. frequency down to a truly useful frequency (about 100 Hz) that direct radiating drivers have.

I believe that those other MEH projects, e.g., "small syns" are excellent ones, but my personal needs are to avoid direct radiating woofers that have directivity issues below 400-500 Hz, as well as 10-25 dB higher levels of modulation distortion sidebands than good horn-loaded ones. This is horn-loading to the extent possible using MEH-type approaches.

[Note that the word "Synergy" is copyrighted by Danley Sound Labs in context of their MEHs and I try to respect that by not using that designation for my DIY efforts. Besides, most of their IP is really in the passive crossovers, of which I can see no one on diyAudio trying to replicate for their DIY MEH projects.]

As far as your comments concerning "profit", I'm not sure what has been written in this thread that triggered that response. The real bottleneck that I see currently is full-range MEH loudspeaker horns that don't require significant modification from their as-bought condition to make them useful for MEH operation. To do that, a significant investment in the stuff to make the horns is required--several thousand dollars for each horn design. Is anyone else planning to do that (that I'm not already aware of)?

I need five horns for my listening room of the K-402 size. After that, my needs are satisfied. The mold itself will remain for others to enjoy the same resulting horn for their DIY projects. It would be nice if some of the cost of that mold is amortized in the price of the resulting horns that could be sold "at cost". This makes it much easier to justify to my significant other to do other MEH-type horn designs for their needs. It's not a small effort to do these horns, as it turns out.

Other horn sizes and shapes will also need their own investment in the molds. No one is "making money" in the current concept. I assume that you can see that.

If I later were to offer full-up MEH loudspeakers or screw-together-and-plugin MEHs, then that looks like a profit making exercise. Those loudspeakers would be for those without the time and/or expertise to build their own, and I believe it would be fair to expect some profit for the time spent on delivering those recurring efforts for each customer.

Chris

Regarding the Crites woofers

Hi Chris,

I hope this project is still alive .

.

I have a few questions regarding the Crites casted fra woofers you are using, that I hope you will respond to:

1. I understand that with a pair of these woofers for each horn you get a response down to around 30 Hz. How large a box for the pair do you need to get such a response? (I ask because the Klipsch mid-box you seem to use seem smaller that I would expect from simulations based on the T/S parameters from the 'large-Vas' Crites woofers.

2. Have you tried other 15" candidate woofers and are the Crites woofers on par with, for instance, Faital 15PR400 or AE TD15H? (On this side of the Atlantic, I have never seen a pair of the Crites woofers, but the specs look great, and the price seems very reasonable!)

Thanks a lot!

Best regards

Peter

Hi Chris,

I hope this project is still alive

I have a few questions regarding the Crites casted fra woofers you are using, that I hope you will respond to:

1. I understand that with a pair of these woofers for each horn you get a response down to around 30 Hz. How large a box for the pair do you need to get such a response? (I ask because the Klipsch mid-box you seem to use seem smaller that I would expect from simulations based on the T/S parameters from the 'large-Vas' Crites woofers.

2. Have you tried other 15" candidate woofers and are the Crites woofers on par with, for instance, Faital 15PR400 or AE TD15H? (On this side of the Atlantic, I have never seen a pair of the Crites woofers, but the specs look great, and the price seems very reasonable!)

Thanks a lot!

Best regards

Peter

Thanks for the bump, Peter. The project is still alive and progressing, albeit a little slower than I'd envisioned. I hope to see a new horn this spring based on the second mold configuration.

The Crites woofers are good candidates based on their relatively low Fc and their mid-to-low Qts for horn loading--like the venerable K-33 from Klipsch. But there are many other woofers that work about as well in a DSP crossover environment. A notional Hornresp model for trying out different woofers for a K-402 sized horn configuration can be found here.

The box that I'm using is a modified Klipsch KPT-305. I would add sufficient internal damping material and perhaps a little stiffening (although this isn't nearly as critical as the horn itself being stiff) to keep internal reflections down to a reasonable level.

Chris

The Crites woofers are good candidates based on their relatively low Fc and their mid-to-low Qts for horn loading--like the venerable K-33 from Klipsch. But there are many other woofers that work about as well in a DSP crossover environment. A notional Hornresp model for trying out different woofers for a K-402 sized horn configuration can be found here.

The box that I'm using is a modified Klipsch KPT-305. I would add sufficient internal damping material and perhaps a little stiffening (although this isn't nearly as critical as the horn itself being stiff) to keep internal reflections down to a reasonable level.

Chris

Hi Chris,

Thanks, that sounds very interesting indeed! Is the up-coming horn based on the K-402 or a different design, and do you have any idea about the app. cost for this horn?

One Q about the Crites woofers: Am I correct that the Crites woofers are 4 Ohm, and if 'yes', do you wire these in parallel, and what is then the lowest impedance the amp sees?

Thanks again!!

Best regards

Peter

Thanks, that sounds very interesting indeed! Is the up-coming horn based on the K-402 or a different design, and do you have any idea about the app. cost for this horn?

One Q about the Crites woofers: Am I correct that the Crites woofers are 4 Ohm, and if 'yes', do you wire these in parallel, and what is then the lowest impedance the amp sees?

Thanks again!!

Best regards

Peter

I don't have such specifics on the costs yet. That usually comes after producing more than one or two pieces successfully to fully understand their manufacturability.

The weight of the second version of the K-402 is 25 pounds. The third version of the K-402 that Klipsch is now selling has reduced that weight further to 15 pounds--which is really too light for a full-range MEH. The MEH (the horn portion) will probably be in the 35-45 pound (16-20 kg) regime. You can guesstimate the raw material costs based on weight (similar to the PRICE parametric cost estimating tool's methodology) and the prices that Klipsch sells them for (replacement horns only). Complexity of the MEH is a bit higher than the basic K-402--i.e., it's really not a K-402 but rather a full-range MEH.

The initial shape of the horn will be more based on the K-402, but I expect variations to appear fairly soon after getting the initial recipe on making such large one-piece horns.

I use two Crites 15" woofers in series on the MEH (i.e., 8 ohms nominal input impedance). Input power and/or sensitivity is not an issue in my experience since I'm bi-amping using a DSP crossover.

Chris

The weight of the second version of the K-402 is 25 pounds. The third version of the K-402 that Klipsch is now selling has reduced that weight further to 15 pounds--which is really too light for a full-range MEH. The MEH (the horn portion) will probably be in the 35-45 pound (16-20 kg) regime. You can guesstimate the raw material costs based on weight (similar to the PRICE parametric cost estimating tool's methodology) and the prices that Klipsch sells them for (replacement horns only). Complexity of the MEH is a bit higher than the basic K-402--i.e., it's really not a K-402 but rather a full-range MEH.

The initial shape of the horn will be more based on the K-402, but I expect variations to appear fairly soon after getting the initial recipe on making such large one-piece horns.

I use two Crites 15" woofers in series on the MEH (i.e., 8 ohms nominal input impedance). Input power and/or sensitivity is not an issue in my experience since I'm bi-amping using a DSP crossover.

Chris

Last edited:

MEHs with 15" Faital 15PR400

Hi Chris,

I got my hands on a pair of Klipsch K-402 horns .

.

I have made a simulation with a pair of 15" Faital 15PR400 woofers which should be excellent, suits your description for candidate woofers fairly well, and are at the same time very reasonably priced here in Europe.

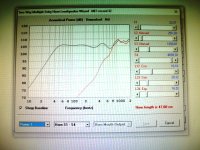

I simply copied your input parameters for the K-402 horn with the TAD 4002 and the Crites' woofers and only changed the T/S paramters for the woofers (i.e., from the Crites to the Faital woofers). Both the Input and the Power1 output is attached. If I am doing this right, the Faital seem to model well. Agree? (Note that since the Failtals are 8 Ohm, I intend to wire these in parallel - not in series as with the Crites)

I have a few questions regarding your MEHs that I hope you will respond to:

1. The depth of the throat entries for the woofers are 10.5 cm in your model. Is that correct? (to me this number seems rather large)

2. Where do I see the size AND the location of you input holes for the woofers in the model? (two input holes for each woofer, right?)

3. The K-402s look really great! However, I was a bit surprised to see that the throat transition from round to rectangular was not as smooth as I had expected. It is not terrible, nut it is not perfect either (see pic). Have you done anything yourself or considered to improve on the transition?

Thanks a lot!

Best regards

Peter

Hi Chris,

I got my hands on a pair of Klipsch K-402 horns

I have made a simulation with a pair of 15" Faital 15PR400 woofers which should be excellent, suits your description for candidate woofers fairly well, and are at the same time very reasonably priced here in Europe.

I simply copied your input parameters for the K-402 horn with the TAD 4002 and the Crites' woofers and only changed the T/S paramters for the woofers (i.e., from the Crites to the Faital woofers). Both the Input and the Power1 output is attached. If I am doing this right, the Faital seem to model well. Agree? (Note that since the Failtals are 8 Ohm, I intend to wire these in parallel - not in series as with the Crites)

I have a few questions regarding your MEHs that I hope you will respond to:

1. The depth of the throat entries for the woofers are 10.5 cm in your model. Is that correct? (to me this number seems rather large)

2. Where do I see the size AND the location of you input holes for the woofers in the model? (two input holes for each woofer, right?)

3. The K-402s look really great! However, I was a bit surprised to see that the throat transition from round to rectangular was not as smooth as I had expected. It is not terrible, nut it is not perfect either (see pic). Have you done anything yourself or considered to improve on the transition?

Thanks a lot!

Best regards

Peter

Attachments

1. I think that I was intending that parameter to mean the distance from the horn's throat to the off-axis ports. Correct me if I'm wrong.

Things in Hornresp (including the Multi-Entry Horn Wizard) might have changed since the fall of 2015 when I last used Hornresp.

2. I believe that 46. 2 cm^2 is the combined port size (the sum of two off-axis ports per woofer). If I got it wrong, please correct the value.

3. If you look at all the Klipsch HF horns, you'll see that same pattern around the throat. It's not a mistake and it doesn't need to be "corrected". If you do change it, the directivity vs. frequency will be strongly affected (negatively). I don't recommend messing with that area--no putty or thick paint coatings in that area. In other words--don't change it.

Chris

Things in Hornresp (including the Multi-Entry Horn Wizard) might have changed since the fall of 2015 when I last used Hornresp.

2. I believe that 46. 2 cm^2 is the combined port size (the sum of two off-axis ports per woofer). If I got it wrong, please correct the value.

3. If you look at all the Klipsch HF horns, you'll see that same pattern around the throat. It's not a mistake and it doesn't need to be "corrected". If you do change it, the directivity vs. frequency will be strongly affected (negatively). I don't recommend messing with that area--no putty or thick paint coatings in that area. In other words--don't change it.

Chris

I should point out that given the prototype MEH off-axis port dimensions and placement, I'd probably not change anything for other full-range MEHs built on the same horn profile.

The current Danley-style crossover filters I'm using with the BMS 4592ND (dual diaphragm) driver cross to the woofers at 610 Hz (a natural crossover point, that is). The BMS driver itself prefers to cross at 5700 Hz between the two internal diaphragms.

Chris

The current Danley-style crossover filters I'm using with the BMS 4592ND (dual diaphragm) driver cross to the woofers at 610 Hz (a natural crossover point, that is). The BMS driver itself prefers to cross at 5700 Hz between the two internal diaphragms.

Chris

Hi Chris,

Thank you so much for the reply, including specifying the size of the entry holes for the woofers - I really appreciate it. I am also very pleased to hear that the geometry of the throat of the K-402s was actually intended . I still have some question, though:

. I still have some question, though:

1. Do you agree that the Faitals are suitable as woofers for a two-way MEH using the K-402? (MMD = 72.5 g; Qts = 0.32; Fs = 35Hz).

Regarding the entry ports for the woofers - would it be possible to have you specify:

2: The depth of these entry holes?

3: Do the entry holes maintain the same size all through (46.2 cm2 / 2), that is, from the woofer side to the horn itself, or...?

4: Are the entry holes circular in shape (it is a bit difficult to see from the pictures)?

5: The exact location of the entry holes?

I apologize for all the questions

Thanks a lot!

Best regards

Peter

Thank you so much for the reply, including specifying the size of the entry holes for the woofers - I really appreciate it. I am also very pleased to hear that the geometry of the throat of the K-402s was actually intended

1. Do you agree that the Faitals are suitable as woofers for a two-way MEH using the K-402? (MMD = 72.5 g; Qts = 0.32; Fs = 35Hz).

Regarding the entry ports for the woofers - would it be possible to have you specify:

2: The depth of these entry holes?

3: Do the entry holes maintain the same size all through (46.2 cm2 / 2), that is, from the woofer side to the horn itself, or...?

4: Are the entry holes circular in shape (it is a bit difficult to see from the pictures)?

5: The exact location of the entry holes?

I apologize for all the questions

Thanks a lot!

Best regards

Peter

1. I think that I was intending that parameter to mean the distance from the horn's throat to the off-axis ports. Correct me if I'm wrong.

Things in Hornresp (including the Multi-Entry Horn Wizard) might have changed since the fall of 2015 when I last used Hornresp.

2. I believe that 46. 2 cm^2 is the combined port size (the sum of two off-axis ports per woofer). If I got it wrong, please correct the value.

3. If you look at all the Klipsch HF horns, you'll see that same pattern around the throat. It's not a mistake and it doesn't need to be "corrected". If you do change it, the directivity vs. frequency will be strongly affected (negatively). I don't recommend messing with that area--no putty or thick paint coatings in that area. In other words--don't change it.

Chris

1. Just looking at Qts and Fs numbers, it looks good. MEH loudspeakers are actually tolerant of woofer parameters--woofers with bigger motors and lower relative moving mass. I've found that Hornresp doesn't really tell you the real frequency/phase response of the K-402-MEH woofers. Their real SPL response was wildly different than extrapolating the SPL response from the predicted power response from Hornresp. (I think that I've posted the raw response in the K-402-MEH thread on the K-forum.) The bottom line is that you're going to be EQing the woofers with one big attenuating PEQ centered at ~230 Hz (-15 or greater dB, bandwidth of ~0.6). The K-402-MEH woofer response is actually flatter than the Danley SH-50 woofers--quite a bit flatter in fact.

2. The off-axis ports in my prototype are actually 2.5 cm deep (1"), but I'd recommend they be much shallower. You can taper the woofer mounting pads in the off-axis port areas to thin them down to the horn's ABS material thickness, starting about 2.5 cm or more away from the through hole. This has advantages in terms of performance. The ports don't have to be any thinner than the horn's present thickness at the entrance to the horn itself, so you do need to maintain some structural integrity and stiffness around the woofer off-axis ports.

3. The ports are chamfered on the opposite side, and I'd chamfer them even more than the prototype used, as mentioned above.

4. The off-axis ports are elongated by about half their diameter, toward the mouth of the horn. I sized them for a 10:1 compression ratio of the woofer cone to port area. That's about as high as you want use in my experience (and is a little higher than the compression ratio in the SH-50 woofer off-axis ports). You want to maintain efficiency of the woofers on the horn, and there is a direct trade off of efficiency with compression ratio.

5. The beginning of the off-axis port radius is 6.5" (16.5 cm) from the edge of the throat radius. Make sure that there is sufficient wall remaining between the two spaced ports next to the top and bottom walls of the horn. The wider the wall thickness, the better the off-axis polars around 400-500 Hz. The trade-off is the chamfer on the reverse side of the horn for the off-axis ports to make the effective depth of the ports as small as practical. I used elongated circular ports of about 2.4-2.6 inches (6-6.6 cm) diameter, and that seems to be a good compromise, but it's certainly not the only compromise that will work.

Since K-402 horns tend to be a little expensive, I'd not take too many liberties making the ports into long, thin slits--like that German MEH loudspeaker (DynamiKKs Ultima!...the very expensive ones). I think that efficiency still matters, and the slits really don't support efficiency. (Danley also doesn't do that either with their Synergy horns.) I'd also orient the elongation axis radially away from the throat, not across the horn wall as the Ultima! has them.

Chris

2. The off-axis ports in my prototype are actually 2.5 cm deep (1"), but I'd recommend they be much shallower. You can taper the woofer mounting pads in the off-axis port areas to thin them down to the horn's ABS material thickness, starting about 2.5 cm or more away from the through hole. This has advantages in terms of performance. The ports don't have to be any thinner than the horn's present thickness at the entrance to the horn itself, so you do need to maintain some structural integrity and stiffness around the woofer off-axis ports.

3. The ports are chamfered on the opposite side, and I'd chamfer them even more than the prototype used, as mentioned above.

4. The off-axis ports are elongated by about half their diameter, toward the mouth of the horn. I sized them for a 10:1 compression ratio of the woofer cone to port area. That's about as high as you want use in my experience (and is a little higher than the compression ratio in the SH-50 woofer off-axis ports). You want to maintain efficiency of the woofers on the horn, and there is a direct trade off of efficiency with compression ratio.

5. The beginning of the off-axis port radius is 6.5" (16.5 cm) from the edge of the throat radius. Make sure that there is sufficient wall remaining between the two spaced ports next to the top and bottom walls of the horn. The wider the wall thickness, the better the off-axis polars around 400-500 Hz. The trade-off is the chamfer on the reverse side of the horn for the off-axis ports to make the effective depth of the ports as small as practical. I used elongated circular ports of about 2.4-2.6 inches (6-6.6 cm) diameter, and that seems to be a good compromise, but it's certainly not the only compromise that will work.

Since K-402 horns tend to be a little expensive, I'd not take too many liberties making the ports into long, thin slits--like that German MEH loudspeaker (DynamiKKs Ultima!...the very expensive ones). I think that efficiency still matters, and the slits really don't support efficiency. (Danley also doesn't do that either with their Synergy horns.) I'd also orient the elongation axis radially away from the throat, not across the horn wall as the Ultima! has them.

Chris

Last edited:

I know that there are many people that want them, but at a lower price point than Klipsch wants to sell you its K-402s with attached compression drivers.

You could do as I did and buy KPT-305-MBs, then cut the off-axis ports, attach the woofer mounting pads and woofers, and use a good 2" compression driver (e.g., FaitalPRO HF20AT or HF2000, Radian 950pB or 950BePB, BMS 4592 dual diaphragm, TAD 4001/4002, among others that have good HF performance and don't chatter above 13 kHz.). Then cover the hole in the back of the box. The KPT-305 alone will set you back about $1400(US) each, however.

My plan is to make that price lower. But the horn itself has to molded. That's my part of the plan. I'm on mold iteration #2 and hope to have something this summer...but no promises (I've learned the hard way). Progress has been good lately. It's a big complex part to pour (~35 lbs/15.8 kg of resin each) with integral off-axis port capabilities.

The box itself is no big deal--just something fairly stiff and non-resonant that the horn can seal against and take the depth of the horn+chosen 2" compression driver stack up. I'd recommend local fabrication if outside North America--to save on shipping costs. You can also run the horn on a larger open baffle, like that of the old Klangfilm Bionor, but with a single horn aperture instead of two, or built-in, something like William Cowan installed in his listening room, again with a single horn aperture per side.

Chris

You could do as I did and buy KPT-305-MBs, then cut the off-axis ports, attach the woofer mounting pads and woofers, and use a good 2" compression driver (e.g., FaitalPRO HF20AT or HF2000, Radian 950pB or 950BePB, BMS 4592 dual diaphragm, TAD 4001/4002, among others that have good HF performance and don't chatter above 13 kHz.). Then cover the hole in the back of the box. The KPT-305 alone will set you back about $1400(US) each, however.

My plan is to make that price lower. But the horn itself has to molded. That's my part of the plan. I'm on mold iteration #2 and hope to have something this summer...but no promises (I've learned the hard way). Progress has been good lately. It's a big complex part to pour (~35 lbs/15.8 kg of resin each) with integral off-axis port capabilities.

The box itself is no big deal--just something fairly stiff and non-resonant that the horn can seal against and take the depth of the horn+chosen 2" compression driver stack up. I'd recommend local fabrication if outside North America--to save on shipping costs. You can also run the horn on a larger open baffle, like that of the old Klangfilm Bionor, but with a single horn aperture instead of two, or built-in, something like William Cowan installed in his listening room, again with a single horn aperture per side.

Chris

Last edited:

Hi Chris,

Thank you so much for an elaborated reply!

You wrote: "1. Just looking at Qts and Fs numbers, it looks good. MEH loudspeakers are actually tolerant of woofer parameters--woofers with bigger motors and lower relative moving mass."

Thanks, that sounds great!

You wrote: "2. The off-axis ports in my prototype are actually 2.5 cm deep (1"), but I'd recommend they be much shallower. You can taper the woofer mounting pads in the off-axis port areas to thin them down to the horn's ABS material thickness, starting about 2.5 cm or more away from the through hole. This has advantages in terms of performance. The ports don't have to be any thinner than the horn's present thickness at the entrance to the horn itself, so you do need to maintain some structural integrity and stiffness around the woofer off-axis ports."

Thanks, that's noted! Q: How does it affect the response, if I make the depth shallower than 2.5 cm?

You wrote: "5. The beginning of the off-axis port radius is 6.5" (16.5 cm) from the edge of the throat radius."

Thanks! Q: Is the edge of the throat radius measured from the wall-side of the throat or from the 'mid-point' of the throat? (I assume the former...)

You wrote: "I used elongated circular ports of about 2.4-2.6 inches (6-6.6 cm) diameter, […]"

Just to make sure I get it right: So, the ports start at about 16.5 cm from the throat edge, and given that they are elongated 'circles' (D = 6-6.6 cm) extended with half their diameter, they must end app. 26 cm from the throat edge - right?

Thank you so much for offering all this great info - I really appreciate it!

Best regards

Peter

Thank you so much for an elaborated reply!

You wrote: "1. Just looking at Qts and Fs numbers, it looks good. MEH loudspeakers are actually tolerant of woofer parameters--woofers with bigger motors and lower relative moving mass."

Thanks, that sounds great!

You wrote: "2. The off-axis ports in my prototype are actually 2.5 cm deep (1"), but I'd recommend they be much shallower. You can taper the woofer mounting pads in the off-axis port areas to thin them down to the horn's ABS material thickness, starting about 2.5 cm or more away from the through hole. This has advantages in terms of performance. The ports don't have to be any thinner than the horn's present thickness at the entrance to the horn itself, so you do need to maintain some structural integrity and stiffness around the woofer off-axis ports."

Thanks, that's noted! Q: How does it affect the response, if I make the depth shallower than 2.5 cm?

You wrote: "5. The beginning of the off-axis port radius is 6.5" (16.5 cm) from the edge of the throat radius."

Thanks! Q: Is the edge of the throat radius measured from the wall-side of the throat or from the 'mid-point' of the throat? (I assume the former...)

You wrote: "I used elongated circular ports of about 2.4-2.6 inches (6-6.6 cm) diameter, […]"

Just to make sure I get it right: So, the ports start at about 16.5 cm from the throat edge, and given that they are elongated 'circles' (D = 6-6.6 cm) extended with half their diameter, they must end app. 26 cm from the throat edge - right?

Thank you so much for offering all this great info - I really appreciate it!

Best regards

Peter

1. Just looking at Qts and Fs numbers, it looks good. MEH loudspeakers are actually tolerant of woofer parameters--woofers with bigger motors and lower relative moving mass. I've found that Hornresp doesn't really tell you the real frequency/phase response of the K-402-MEH woofers. Their real SPL response was wildly different than extrapolating the SPL response from the predicted power response from Hornresp. (I think that I've posted the raw response in the K-402-MEH thread on the K-forum.) The bottom line is that you're going to be EQing the woofers with one big attenuating PEQ centered at ~230 Hz (-15 or greater dB, bandwidth of ~0.6). The K-402-MEH woofer response is actually flatter than the Danley SH-50 woofers--quite a bit flatter in fact.

2. The off-axis ports in my prototype are actually 2.5 cm deep (1"), but I'd recommend they be much shallower. You can taper the woofer mounting pads in the off-axis port areas to thin them down to the horn's ABS material thickness, starting about 2.5 cm or more away from the through hole. This has advantages in terms of performance. The ports don't have to be any thinner than the horn's present thickness at the entrance to the horn itself, so you do need to maintain some structural integrity and stiffness around the woofer off-axis ports.

3. The ports are chamfered on the opposite side, and I'd chamfer them even more than the prototype used, as mentioned above.

4. The off-axis ports are elongated by about half their diameter, toward the mouth of the horn. I sized them for a 10:1 compression ratio of the woofer cone to port area. That's about as high as you want use in my experience (and is a little higher than the compression ratio in the SH-50 woofer off-axis ports). You want to maintain efficiency of the woofers on the horn, and there is a direct trade off of efficiency with compression ratio.

5. The beginning of the off-axis port radius is 6.5" (16.5 cm) from the edge of the throat radius. Make sure that there is sufficient wall remaining between the two spaced ports next to the top and bottom walls of the horn. The wider the wall thickness, the better the off-axis polars around 400-500 Hz. The trade-off is the chamfer on the reverse side of the horn for the off-axis ports to make the effective depth of the ports as small as practical. I used elongated circular ports of about 2.4-2.6 inches (6-6.6 cm) diameter, and that seems to be a good compromise, but it's certainly not the only compromise that will work.

Since K-402 horns tend to be a little expensive, I'd not take too many liberties making the ports into long, thin slits--like that German MEH loudspeaker (DynamiKKs Ultima!...the very expensive ones). I think that efficiency still matters, and the slits really don't support efficiency. (Danley also doesn't do that either with their Synergy horns.) I'd also orient the elongation axis radially away from the throat, not across the horn wall as the Ultima! has them.

Chris

Last edited:

2. Danley mentioned in his DSL patent that shorter port lengths with chamfered edges allowed smaller port areas. There are a host of physical reasons to keep the port air volume as low as possible and to keep the air resistance of the port itself to a "knife edge", just like in pneumatics to reduce viscous effects.

5. The 6.5" (16.5 cm) is to the edge of the radius port, not its centerline. This is also true for the throat measurement datum--to the edge of the throat radius. The farthest distance of the off-axis port radius from the edge of the throat radius is 9.1" (23 cm).

Chris

5. The 6.5" (16.5 cm) is to the edge of the radius port, not its centerline. This is also true for the throat measurement datum--to the edge of the throat radius. The farthest distance of the off-axis port radius from the edge of the throat radius is 9.1" (23 cm).

Chris

Hi again Chris,

Thanks a lot - I really appreciate it!

Best regards

Peter

Thanks a lot - I really appreciate it!

Best regards

Peter

2. Danley mentioned in his DSL patent that shorter port lengths with chamfered edges allowed smaller port areas. There are a host of physical reasons to keep the port air volume as low as possible and to keep the air resistance of the port itself to a "knife edge", just like in pneumatics to reduce viscous effects.

5. The 6.5" (16.5 cm) is to the edge of the radius port, not its centerline. This is also true for the throat measurement datum--to the edge of the throat radius. The farthest distance of the off-axis port radius from the edge of the throat radius is 9.1" (23 cm).

Chris

I don't want to derail this thread, but has anyone tried or thought about a MEH using the JBL 2384 waveguide? It's a good sized horn, (width of 30 inches, height of 15 inches, ~13 inches deep) fairly inexpensive (~$130) and readily available last time I checked. I have three of them that I'm currently using for my LCR with JBL 2453H-SL CDs and dual twelve inch Lavoce WAF123.01 below the waveguide with plans for another pair above in a dual horizontal/vertical MTM. I keep getting intrigued by the MEH approach though. Feasible, maybe with 12 inch or 10 inch woofers?

- Home

- Loudspeakers

- Multi-Way

- Full-Range Synergy Kit Questions