I think I can go later with the damping material. I have to build the box first.

Yesterday went to visit the friend who will build the boxes. He has mdf, plywood, lots of kinds of solid wood and a cnc machine.

Will make first a proto using 19mm mdf or cheap solid wood, tunning it, following your recommendations, to drivers fs. Plan on putting some stringers inside to reinforce the box and help internal "damping"

I think we can make the box bigger and get 40-45 liters. Are there any drawbacks using a bigger box?. I want a "punchier" speaker, with attack and detailed sound, not a "boomy" thing. Dont know if building a bigger box will be good for that.

I can do it 25-45liters. Any thoughts?

Thanks again for all your help!

David

Yesterday went to visit the friend who will build the boxes. He has mdf, plywood, lots of kinds of solid wood and a cnc machine.

Will make first a proto using 19mm mdf or cheap solid wood, tunning it, following your recommendations, to drivers fs. Plan on putting some stringers inside to reinforce the box and help internal "damping"

I think we can make the box bigger and get 40-45 liters. Are there any drawbacks using a bigger box?. I want a "punchier" speaker, with attack and detailed sound, not a "boomy" thing. Dont know if building a bigger box will be good for that.

I can do it 25-45liters. Any thoughts?

Thanks again for all your help!

David

I think the felt behaves better

I find acoustic foam to be almost ideal for ported boxes given its properties.

It absorbs almost everything above 250-500Hz (depending on density and thickness) while leaving frequencies below 125-250Hz almost completely unmolested which is what you want for the port to work as intended.

The purpose of damping in ported boxes is mainly to avoid reflections from inside the box getting out via the port or through the woofer cone.

Also helps to avoid standing waves.

That is to say that for example 500Hz has a wavelength of 68cm.

The OPs box will be smaller in every dimension but with foam lining absorption above 500Hz is pretty much 100%.

With that in mind it becomes clear why it is pointless to damp the baffle.

In fact the danger is overdamping (attenuating bass frequencies rather than just absorbing mids and highs) which impacts on the functioning of the port.

Extremely overdamped boxes behave like a sealed one.

Charles Darwin :

Well, I appreciate the answer, but my own experience tells me that it is not something that greatly influences sound.

The JBL brochure I enclosed, in effect, says that absorbent material should be placed on all the walls of the box. But then he explains how to assemble the baffle. (Front panel) ie the latter wall is excluded.

So far it all coincides with the general recommendation, and I did so.

I listened to the boxes for many years. One day I found the booklet on the net and read it again and there I thought:

Have I misunderstood? (There was no internet or Google translator, OK? Haha) Is not recommending to put absorbent material in the baffle too? Then I did. First only in a box and I compared the sound between them. I placed them close together and in the center of the room, the sound source in mono and passing the balance from left to right.

To my surprise, the bass was more controlled, less resounding, and the voices softened.

So I also made the extra stuffing in the second baffle, and it will look like this.

I'm sorry for the off topic. I'm still waiting for some reliable documentation on this point, I can not find anything on the net.

*Greetings, and thanks again for your kind response.

Drummer 35, sorry OT and very luck for you built !!

Well, I appreciate the answer, but my own experience tells me that it is not something that greatly influences sound.

The JBL brochure I enclosed, in effect, says that absorbent material should be placed on all the walls of the box. But then he explains how to assemble the baffle. (Front panel) ie the latter wall is excluded.

So far it all coincides with the general recommendation, and I did so.

I listened to the boxes for many years. One day I found the booklet on the net and read it again and there I thought:

Have I misunderstood? (There was no internet or Google translator, OK? Haha) Is not recommending to put absorbent material in the baffle too? Then I did. First only in a box and I compared the sound between them. I placed them close together and in the center of the room, the sound source in mono and passing the balance from left to right.

To my surprise, the bass was more controlled, less resounding, and the voices softened.

So I also made the extra stuffing in the second baffle, and it will look like this.

I'm sorry for the off topic. I'm still waiting for some reliable documentation on this point, I can not find anything on the net.

*Greetings, and thanks again for your kind response.

Drummer 35, sorry OT and very luck for you built !!

Not sure if this driver will work on a closed box.

I think the same. You will lose efficiency (less SPL) and will not get very low on bass frequencies. The speakers for enclosed cabinets (I remember very well the famous AR) must have very loose compliances. )

Two links that can be of great help in case of choosing a bass reflex system :

Bass reflex speaker design - easy explanation - Audio Judgement

Port Calculation

Bass reflex speaker design - easy explanation - Audio Judgement

Port Calculation

To my surprise, the bass was more controlled, less resounding, and the voices softened.

I had a very similar experience with my Tannoy LRMs but I just added acoustic foam to the back of the box as I found the original damping (1inch glassfibre) insufficient for the job.

Drummer 35 when you build your boxes make sure there is a clear path free from obstructions and damping material between the back of the woofer cone and the port tube!

30L looked good to me. I don't think there is any point in going bigger and 25L might be just as good.

Last edited:

Will order an acoustic foam roll, some rear connectors and an sliding vent for testing.

The speakers will be next to the wall so the vent will be located on the front.

After I get a good box tune, I want to make the front with a slotted vent. I can make a big one with a long throat or a smaller one with shorter throat, correct?

Wich is the best solution to avoid the vent producing air sound?

Thanks

The speakers will be next to the wall so the vent will be located on the front.

After I get a good box tune, I want to make the front with a slotted vent. I can make a big one with a long throat or a smaller one with shorter throat, correct?

Wich is the best solution to avoid the vent producing air sound?

Thanks

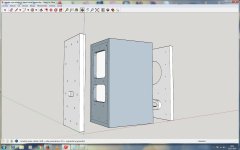

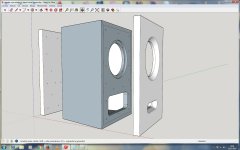

Hi again!

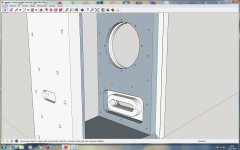

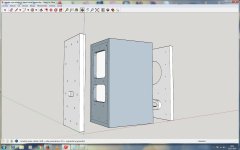

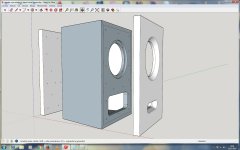

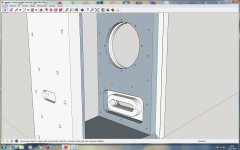

Been working on the cabinet design, and want to show you what I got so far.

As you can see, it´s a kind of "sandwich". An inner mdf cabinet and a front and rear solid wood panels.

Now the vent.

The vent will be screwed to the front panel, so I´ll build different sizes (25-30-35mm) so I can try different tunings.

Let me know what you think about or if you would change on that design.

Thanks!

David

Been working on the cabinet design, and want to show you what I got so far.

As you can see, it´s a kind of "sandwich". An inner mdf cabinet and a front and rear solid wood panels.

Now the vent.

The vent will be screwed to the front panel, so I´ll build different sizes (25-30-35mm) so I can try different tunings.

Let me know what you think about or if you would change on that design.

Thanks!

David

Last edited:

I own the same driver and used it for some active crossover experiments a few years ago. I used them in a small closed box and EQed them for -6 dB @ 40 Hz.

Although intended for very close-field listening that setup ate power for breakfast and max SPL was definitely lacking. But within their limits they sounded very nice with very good Imaging.

I always wanted to put those in a larger box with a 12" woofer but haven't found the time for that so far.

Regards

Charles

Although intended for very close-field listening that setup ate power for breakfast and max SPL was definitely lacking. But within their limits they sounded very nice with very good Imaging.

I always wanted to put those in a larger box with a 12" woofer but haven't found the time for that so far.

Regards

Charles

Yeah, I did.

I like how they sound. Very detailed mids and good imaging, but lacks low end with a passive xover, even in a big box.

I think those speakers would benefit from using an active xover as Phase did, or use them with a 12-15 woofer. If using them alone, you will strugle getting down 60hz-65hz

The Dynamikks monitor 8 speaker, uses this same driver, but with a dopped cone. (added weight to help it reach lower freqs) I thought I could try that on mines, but I´ll have to redo the xover, and Im scared I could ruin the cones with dopping, and those are not cheap ones...

I like how they sound. Very detailed mids and good imaging, but lacks low end with a passive xover, even in a big box.

I think those speakers would benefit from using an active xover as Phase did, or use them with a 12-15 woofer. If using them alone, you will strugle getting down 60hz-65hz

The Dynamikks monitor 8 speaker, uses this same driver, but with a dopped cone. (added weight to help it reach lower freqs) I thought I could try that on mines, but I´ll have to redo the xover, and Im scared I could ruin the cones with dopping, and those are not cheap ones...

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Help 8" coax project.