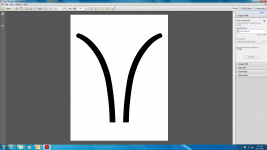

OK, I've ditched my kirfing MDF horn project...and today I collected 68 individual pieces of CNC'd 25mm MDF horn flares....with mouth 600mm wide....and axial length 600mm.

I'll laminate these using 12mm dowel.

Then decide to finish by applying thin bendy ply or MDF for painting or staining.

I'll decide if I "angle" cut the horn side sections to create a traditional horn shape...or keep as is, then add a flat top/bottom piece....a bit like the attached pic of a Klipsch horn (Volti).

Angle horizontal horn sections will be made in thin cardboard/MDF to create tricky shape first.

Driver is the famous Altec "Giant Voice" 290 phenolic model, which is designed for low freq...hence the 200Hz horn cut off. I'll test with 300Hz using active xover initially, then quality passive later. Goal is 300Hz to 3,000Hz...which is comfortable range for domestic setting.

http://www.greatplainsaudio.com/vintage_altec/GiantVoice_saleslit_outdoor_Part_3.pdf

Bass is re-coned 420A Altec in large 250 liter cab....which is sounding excellent so far.

Future bass will be 817 or similar, maybe Klipsch Jubilee...or Fastlane Audio dual 12 front loaded horn (JWC Mini Punch).

JWC Mini Punch

Tweeter horn to be decided.

A fun project.

Andrew

I'll laminate these using 12mm dowel.

Then decide to finish by applying thin bendy ply or MDF for painting or staining.

I'll decide if I "angle" cut the horn side sections to create a traditional horn shape...or keep as is, then add a flat top/bottom piece....a bit like the attached pic of a Klipsch horn (Volti).

Angle horizontal horn sections will be made in thin cardboard/MDF to create tricky shape first.

Driver is the famous Altec "Giant Voice" 290 phenolic model, which is designed for low freq...hence the 200Hz horn cut off. I'll test with 300Hz using active xover initially, then quality passive later. Goal is 300Hz to 3,000Hz...which is comfortable range for domestic setting.

http://www.greatplainsaudio.com/vintage_altec/GiantVoice_saleslit_outdoor_Part_3.pdf

Bass is re-coned 420A Altec in large 250 liter cab....which is sounding excellent so far.

Future bass will be 817 or similar, maybe Klipsch Jubilee...or Fastlane Audio dual 12 front loaded horn (JWC Mini Punch).

JWC Mini Punch

Tweeter horn to be decided.

A fun project.

Andrew

Attachments

OK, I've ditched my kirfing MDF horn project...and today I collected 68 individual pieces of CNC'd 25mm MDF horn flares....with mouth 600mm wide....and axial length 600mm.

I'll laminate these using 12mm dowel.

Then decide to finish by applying thin bendy ply or MDF for painting or staining.

I'll decide if I "angle" cut the horn side sections to create a traditional horn shape...or keep as is, then add a flat top/bottom piece....a bit like the attached pic of a Klipsch horn (Volti).

Angle horizontal horn sections will be made in thin cardboard/MDF to create tricky shape first.

Driver is the famous Altec "Giant Voice" 290 phenolic model, which is designed for low freq...hence the 200Hz horn cut off. I'll test with 300Hz using active xover initially, then quality passive later. Goal is 300Hz to 3,000Hz...which is comfortable range for domestic setting.

http://www.greatplainsaudio.com/vintage_altec/GiantVoice_saleslit_outdoor_Part_3.pdf

Bass is re-coned 420A Altec in large 250 liter cab....which is sounding excellent so far.

Future bass will be 817 or similar, maybe Klipsch Jubilee...or Fastlane Audio dual 12 front loaded horn (JWC Mini Punch).

JWC Mini Punch

Tweeter horn to be decided.

A fun project.

Andrew

Hey there Andrew,

All sounds like a great plan, except, if it were me, I would try to reach a bit higher than 3K. Where do you get Altec 290's these days ?

http://www.greatplainsaudio.com/vintage_altec/290 Series_hfdriver_spec_sheet.pdf

In Oz, we have two of the largest suppliers of Altec gear in the world, both NOS and vintage.

For future reference, who are they?

ray

Lew, Yes, pretty close to finish the Beyma 3 way...just finished xover boxes will bi-wire/bi-amp inputs. Spray tweeter horn to be done.

Looking good!

I don't understand the mid-in/mid-out and treble-in/out, though. Could you please explain? I was expecting one pair of input posts and 3 pairs of posts for treble/mid/bass.

Future bass will be 817 or similar....

A 'word to the wise', no parallel walls in large horns; been there, done that with 210s and assuming you're not completely tone deaf and listen to a wide range of music other than just loud, then sooner or later this odd coloration gets on your last nerve in a typical HIFI app and at least in my case never could eradicate it without compromising horn response.

Great work as usual!

GM

Lew, the bass is active, so it is bypassed from the passive Xover box.Looking good!

I don't understand the mid-in/mid-out and treble-in/out, though. Could you please explain? I was expecting one pair of input posts and 3 pairs of posts for treble/mid/bass.

Dual inputs for mid/tweeter to cater for bi wiring/amping if required.

Thanks GM, your input always appreciated.A 'word to the wise', no parallel walls in large horns; been there, done that with 210s and assuming you're not completely tone deaf and listen to a wide range of music other than just loud, then sooner or later this odd coloration gets on your last nerve in a typical HIFI app and at least in my case never could eradicate it without compromising horn response.

Great work as usual!

GM

Yes, I've debated that issue over parallel walls for years.

Recently spotted a 'room friendly' sized front liaded bass horn inlike, from Fastlane Audio, JwC Mini Kick.

JWC Mini Punch

200Hz Tractrix horn getting glued up, adding horizontal angled piece, sound deadening. Driver is famous Altec "Giant Voice" 290, crossed at 300Hz. Ignore 'crack' in the side walls...two sections not yet glued together...to be painted inside first.

Attachments

You'll also need to convert from the square opening to a round entrance for the 1.4" driver exit to meet... don't forget about that too!

Are you sure you have enough mouth area to reach 300Hz?

Guessing to my eye, looks like ur on the edge... of course testing will tell for sure...

I'd make the flat expansions as solid as is possible. I have used a gypsum based compound acquired from pottery supply houses to fill spaces like that... actually expands slightly as it cures, ends up ROCK hard (harder than concrete) and could be molded in place and painted if one wanted to (the stuff I used has a color that is close to maple or pine, maybe a bit more yellow/brown shade). Of course you can use it between two surfaces also, and/or mold it and then use an epoxy or other adhesive to hold it. Also this adds mass...

Sand would work too... better than fibrous materials. That would work nicely, you'd need a good fill on the bottom...

Very nice construction!

Hope it sounds terrific...

Are you sure you have enough mouth area to reach 300Hz?

Guessing to my eye, looks like ur on the edge... of course testing will tell for sure...

I'd make the flat expansions as solid as is possible. I have used a gypsum based compound acquired from pottery supply houses to fill spaces like that... actually expands slightly as it cures, ends up ROCK hard (harder than concrete) and could be molded in place and painted if one wanted to (the stuff I used has a color that is close to maple or pine, maybe a bit more yellow/brown shade). Of course you can use it between two surfaces also, and/or mold it and then use an epoxy or other adhesive to hold it. Also this adds mass...

Sand would work too... better than fibrous materials. That would work nicely, you'd need a good fill on the bottom...

Very nice construction!

Hope it sounds terrific...

You'll also need to convert from the square opening to a round entrance for the 1.4" driver exit to meet... don't forget about that too!

Are you sure you have enough mouth area to reach 300Hz?

Guessing to my eye, looks like ur on the edge... of course testing will tell for sure...

I'd make the flat expansions as solid as is possible. I have used a gypsum based compound acquired from pottery supply houses to fill spaces like that... actually expands slightly as it cures, ends up ROCK hard (harder than concrete) and could be molded in place and painted if one wanted to (the stuff I used has a color that is close to maple or pine, maybe a bit more yellow/brown shade). Of course you can use it between two surfaces also, and/or mold it and then use an epoxy or other adhesive to hold it. Also this adds mass...

Sand would work too... better than fibrous materials. That would work nicely, you'd need a good fill on the bottom...

Very nice construction!

Hope it sounds terrific...

Thank you for your thoughtful feedback.

I'm using the attached spreadsheet for the tractrix profile....taken from Volvotreter web site.

Tools – Volvotreter Homepage

The mouth size is an accurate conversion from circular to rectangular (identical cm squared).

Re the sound deadening...yes, I concur. I'm not happy with the current "knock test" on the angled horizontal board...too empty sounding. I will pull out the wool felt and add expanding foam or sand.

Yes, I am aware of the need for throat adapter...I will use standard Altec 1.4 inch to 2.0 inch....not unlike what I used for my Walnut conical horns (one inch to two inch)...see pic.

Regards.

Andrew

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- 200Hz CNC'd Tractrix horn starts with Altec "Giant Voice" drivers