Hi all

I read several thread but I have no clear idea.

I design my box (2 way with sb17nrxc35-8) with internal volume of about 15,4L (30,2x25,2x20,2 cm).

Initially I think to build it without dumping material. But now I'm not sure.

First question: dumping material is needed or not?

If I have to use damping material, I suppose that internal volume decrease. For example if I use polyurethane with piramid shape with depth of 50mm, I reduce the volume at 20,2x15,2x10,2 =3,1L.

Second question: this calculation is right?

In this case I have to use a dumping material with low depth.

Third question: have you suggestion?

Thanks

I read several thread but I have no clear idea.

I design my box (2 way with sb17nrxc35-8) with internal volume of about 15,4L (30,2x25,2x20,2 cm).

Initially I think to build it without dumping material. But now I'm not sure.

First question: dumping material is needed or not?

If I have to use damping material, I suppose that internal volume decrease. For example if I use polyurethane with piramid shape with depth of 50mm, I reduce the volume at 20,2x15,2x10,2 =3,1L.

Second question: this calculation is right?

In this case I have to use a dumping material with low depth.

Third question: have you suggestion?

Thanks

a fine fibre allows good damping if it's located where the air amplitude is high, i.e. in the middle of the cabinet. At the walls/panels the air amplitude is zero.

Long fibre wool used to be the "in thing", but technology has moved on and there are others that are suitable.

The fibres help hold the air at a nearly constant temperature instead of compression and rerefaction changing the air temperature.. This gives adiabatic behaviour and makes the cabinet seem bigger than it actually is.

Long fibre wool used to be the "in thing", but technology has moved on and there are others that are suitable.

The fibres help hold the air at a nearly constant temperature instead of compression and rerefaction changing the air temperature.. This gives adiabatic behaviour and makes the cabinet seem bigger than it actually is.

the change in resonant frequency (it should move downwards in frequency with a good damping material) can be measured and it is not insignificant.usually not enough to matter in design calcs

Hi Ggerla!

It kind of depends what you are trying to do. Thick liners are best for reducing cabinet resonances. Selah audio has positively reviewed and I like the Sonic Barrier for cabinet resonance. Selah is much more experienced than I am, but I especially like the multi-layer stuff. This is also good to cover crossovers with. Gravesen's designs often spec 8mm felt for the cabinet lining.

It is quite common if not almost universal to use both. A cabinet liner as well as loose, synthetic or natural fibers like Acousta Stuff, fiberglass or wool equivalents.

D'Appolitto's book on speaker measurements includes a pretty helpful discussion about this. Someday I'll actually read it.

Best,

Erik

It kind of depends what you are trying to do. Thick liners are best for reducing cabinet resonances. Selah audio has positively reviewed and I like the Sonic Barrier for cabinet resonance. Selah is much more experienced than I am, but I especially like the multi-layer stuff. This is also good to cover crossovers with. Gravesen's designs often spec 8mm felt for the cabinet lining.

It is quite common if not almost universal to use both. A cabinet liner as well as loose, synthetic or natural fibers like Acousta Stuff, fiberglass or wool equivalents.

D'Appolitto's book on speaker measurements includes a pretty helpful discussion about this. Someday I'll actually read it.

Best,

Erik

Thanks all for clarification...

Probably better solution for me is to paste damping to each cabinet wall.

Following your suggestion I found

https://loudspeakerfreaks.com/Product.asp?Product_ID=6823

and

https://loudspeakerfreaks.com/Product.asp?Product_ID=12495

For me one or the other it's the same. What do I have to prefer?

Unfortunately I have already placed the order this morning on loudspeaker. I try to add damping on monday.

The alternative would be to buy at the store near the house something like

https://www.leroymerlin.it/catalogo/pannello-fonoassorbente-bugnato-1000-x-1000-sp.-20-mm-35887481-p

or

https://www.leroymerlin.it/catalogo/pannello-in-lana-di-roccia-dp10-1000-x-600-sp.-20-mm-34070995-p

Wdyt?

regards

Giuseppe

Probably better solution for me is to paste damping to each cabinet wall.

Following your suggestion I found

https://loudspeakerfreaks.com/Product.asp?Product_ID=6823

and

https://loudspeakerfreaks.com/Product.asp?Product_ID=12495

For me one or the other it's the same. What do I have to prefer?

Unfortunately I have already placed the order this morning on loudspeaker. I try to add damping on monday.

The alternative would be to buy at the store near the house something like

https://www.leroymerlin.it/catalogo/pannello-fonoassorbente-bugnato-1000-x-1000-sp.-20-mm-35887481-p

or

https://www.leroymerlin.it/catalogo/pannello-in-lana-di-roccia-dp10-1000-x-600-sp.-20-mm-34070995-p

Wdyt?

regards

Giuseppe

For the liners, mass and high density is king. Good placement of liners will make bass and midrange less muddy and give better clarity to speech. In addition, you can run your hand around the speaker to feel the effects. If it's not improved by liner a brace may be needed instead.

For the stuffing, don't overstuff the speaker! The stuffing will change the alignment/Q, so if the speaker sounds boomy it's been too much. Often kits will specify 20% - 30 % fill.

Often kits will specify 20% - 30 % fill.

For the stuffing, don't overstuff the speaker! The stuffing will change the alignment/Q, so if the speaker sounds boomy it's been too much.

For the liners, mass and high density is king. Good placement of liners will make bass and midrange less muddy and give better clarity to speech. In addition, you can run your hand around the speaker to feel the effects. If it's not improved by liner a brace may be needed instead.

Sorry, I didn't understand. What do you mean with "liners"?

For the stuffing, don't overstuff the speaker! The stuffing will change the alignment/Q, so if the speaker sounds boomy it's been too much.Often kits will specify 20% - 30 % fill.

If I well understand, damping volume should be 3L-4,5L. Right?

Because internal surfaces is about 0,8m^2 I can use this dumping material

https://www.leroymerlin.it/catalogo/...-mm-35887481-p

Ggerla,

There are two types of materials. One is used to line the surfaces only. This includes Sonic Barrier, bitumen, and thick felt sheets. This material is often glued to the cabinet sides.

The other is used as stuffing, like a turkey. You insert it to take up the volume of air inside the cabinet. This can be natural wool fibers, or loose fiberglass like you would use in a wall in your house.

You insert it to take up the volume of air inside the cabinet. This can be natural wool fibers, or loose fiberglass like you would use in a wall in your house.

Does it make more sense now?

There are two types of materials. One is used to line the surfaces only. This includes Sonic Barrier, bitumen, and thick felt sheets. This material is often glued to the cabinet sides.

The other is used as stuffing, like a turkey.

Does it make more sense now?

Ggerla,

There are two types of materials. One is used to line the surfaces only. This includes Sonic Barrier, bitumen, and thick felt sheets. This material is often glued to the cabinet sides.

The other is used as stuffing, like a turkey.You insert it to take up the volume of air inside the cabinet. This can be natural wool fibers, or loose fiberglass like you would use in a wall in your house.

Does it make more sense now?

Ahhh ok. Now it's clear.

Thanks Erik, now I have parameters to select and buy right material.

Damping will have a negligible impact on the virtual volume "seen" by the driver but will help deal with back waves that would otherwise find their way through the cone and reduces box resonances by a serious margin.

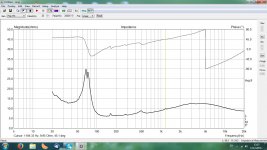

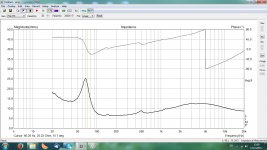

Below is a 10" paper cone woofer with a stamped steel chassis - same enclosure, same driver, only the first one is with no fill and the second is with polyester wool. The blip at 490Hz is a mechanical resonance of the driver.

Below is a 10" paper cone woofer with a stamped steel chassis - same enclosure, same driver, only the first one is with no fill and the second is with polyester wool. The blip at 490Hz is a mechanical resonance of the driver.

Attachments

ggeria, what thou call damping can be two different things, or even three. At first, damping the vibrations running thru the cabinet walls. At second and third, damping the sound running thru the air enclosed by the cabinet. It all shall damp resonances. For the former, one uses heavy tough stuff fixed to the cabinet walls, could be even on the outside. For the latter, one mostly uses light wooly stuff which is permable for air, filling the entire volume (except maybe close to woofer and port) and damps sound velocity. One can also use heavier air-impermeable stuff, fixed to walls, stuff like the foam on carpet backs and bathroom mats, damping the sound pressure.

The increase in apparent volume has a maximum of 40% given by a full change from an adiabatic to an isothermal compression/expansion process. The change won't be full, the damping material steals volume, damping materials differ in their effectiveness, etc... but increases of 25-30% are reported. Not large but probably worth having if the design is struggling with volume.Damping will have a negligible impact on the virtual volume "seen" by the driver but will help deal with back waves that would otherwise find their way through the cone and reduces box resonances by a serious margin.

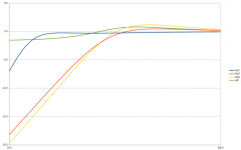

It is quite hard to measure or simulate these effects properly. Let's say you get a 25% increase Here is a picture showing the effects of a 12" woofer (Adire Shiva) put in:

1: a vented box 120liter tuned to mid 20's.

2: a 25liter heavily damped closed box

3: a 20 liter lined closed box.

This difference between 2 and 3 is less than a dB above 40 Hz, and the F3 is around 65Hz. It is likely the difference in response shape between (say) 0.2V in and 5 volts in (due to nonlinearity) would be much more than this. Also likely, the difference in moving your listening position 6" is more than this. The room will swamp this entirely.

1: a vented box 120liter tuned to mid 20's.

2: a 25liter heavily damped closed box

3: a 20 liter lined closed box.

This difference between 2 and 3 is less than a dB above 40 Hz, and the F3 is around 65Hz. It is likely the difference in response shape between (say) 0.2V in and 5 volts in (due to nonlinearity) would be much more than this. Also likely, the difference in moving your listening position 6" is more than this. The room will swamp this entirely.

Attachments

Last edited:

Those look like simulations and most box simulation programs do not implement a change to the polytropic index with stuffing. They simply change the dissipation (a resistor in the equivalent circuit). To check, change the amount of stuffing in a fixed volume and see if the resonant frequency changes. If it doesn't then the effect you looking for is not included in the simulation program.It is quite hard to measure or simulate these effects properly...

Those look like simulations

Whatever. I wrote the sim and to "model" the effects I changed volume by 25% and changed the damping resistor by a factor of 2. Less than 3/4 dB difference above 40 Hz. I have also used more complex sims and the responses were quite similar. More complex sims are hardly worth the complexity.

The problem with simulating or measuring is that these effects are complicated (MANY variables, location density, fiber properties, box shape, etc...) and either sims or measurements (or both) can lead you to a wrong conclusion. Depending on where you put the damping material you can mass load the driver (also shows up as lowered resonance) and/or change the mechanical Q (synergy) in addition to the effects of stuffing. You could have a perfect sim and if your stuffing settles or your stuffing has slightly different parameters than you simulated, you get a different (potentially misleading) result. The whole point of doing the sim is to get a feeling for what the effects are, and they are much smaller than room effects and much less than most frequency response aberrations elsewhere.

IMO, all but insignificant. THe effect of the damping on the midrange is more important.

Gravesen, of course, has a pretty thorough treatment (meaning article) on the matter. I encourage you to read it and his conclusions here.

Cabinet-damping

Cabinet-damping

The increase in apparent volume has a maximum of 40% given by a full change from an adiabatic to an isothermal compression/expansion process. The change won't be full, the damping material steals volume, damping materials differ in their effectiveness, etc... but increases of 25-30% are reported. Not large but probably worth having if the design is struggling with volume.

While in theory this is absolutely correct, I have never measured this happening in real.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Closed volume and damping material