Hello all,

I am am a noob here. So please don't judge too harshly... yet...

I looked around in the older posts and have not found any previous details other than references to my issue so if its OK ill give it a shot here.

I have a pair of B&W CDM1's that seem to have had the ferrofluid dry out and the tweeters are down. Does anyone have any experience/advise for taking them apart/cleaning/re-assembling? or if that is a no-go does anyone know of a suitable replacement tweeter that would fit in the odd-pod it sits in? Perhaps even a car tweeter due to the size? Looking to do a reasonably priced repair and do not mind getting my hands dirty.

Thank You

Brian

I am am a noob here. So please don't judge too harshly... yet...

I looked around in the older posts and have not found any previous details other than references to my issue so if its OK ill give it a shot here.

I have a pair of B&W CDM1's that seem to have had the ferrofluid dry out and the tweeters are down. Does anyone have any experience/advise for taking them apart/cleaning/re-assembling? or if that is a no-go does anyone know of a suitable replacement tweeter that would fit in the odd-pod it sits in? Perhaps even a car tweeter due to the size? Looking to do a reasonably priced repair and do not mind getting my hands dirty.

Thank You

Brian

Bummer Brian,

Looks like some others have had some luck with the following methods:

Option 1: Drain & replace ferrofluid

Option 2: Replace with Vifa OC25SC65-04...

Links to guides, and the Vifa similar tweeter are available on the attached thread:

http://www.diyaudio.com/forums/multi-way/201868-b-w-p6-tweeter-replacement.html#post2843599

Looks like some others have had some luck with the following methods:

Option 1: Drain & replace ferrofluid

Option 2: Replace with Vifa OC25SC65-04...

Links to guides, and the Vifa similar tweeter are available on the attached thread:

http://www.diyaudio.com/forums/multi-way/201868-b-w-p6-tweeter-replacement.html#post2843599

Crap. I guess those tweeters are discontinued from Parts Express.

Here is a link to another forum with some useful disassembly pics. You will have to create an account to look at the full resolution version of the pics. Looks like you will need to remove the woofer in order to get at the tweeter.

B & W CDM1 blunder. Any replacement tweeter? B&W is out . | Audiokarma Home Audio Stereo Discussion Forums

Here is a link to another forum with some useful disassembly pics. You will have to create an account to look at the full resolution version of the pics. Looks like you will need to remove the woofer in order to get at the tweeter.

B & W CDM1 blunder. Any replacement tweeter? B&W is out . | Audiokarma Home Audio Stereo Discussion Forums

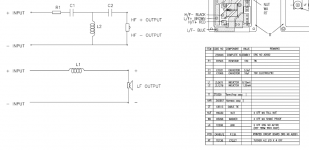

I do love B&W's "no mystery" approach. Their documentation is superb:

B&W Group North America Service & Support - Service Manuals

The ferrofluid is made by ferrotec, aka APG1021.

I suspect you'll find something similar on eBay. I've never done this, but it looks like you can buy a little phial of the stuff easily enough. It's just oil and ferrite grains with a binding agent.

Troels Gravesen describes removing fresh ferrofluid from the magnet gap:

Vifa C17WH-

You use tissue and a solvent, IME. I used WD40 for some dried up cloggy stuff. You apparently add just enough to fill the magnet gap completely, it sticks to magnetism, then reassemble.

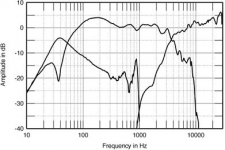

B&W LOVE this 3kHz 4 ohms tweeter filter. I've seen it so many times. Kevlar 6" bass. B&W Compact Domestic Monitor 1 loudspeaker | Stereophile.com

B&W Group North America Service & Support - Service Manuals

The ferrofluid is made by ferrotec, aka APG1021.

I suspect you'll find something similar on eBay. I've never done this, but it looks like you can buy a little phial of the stuff easily enough. It's just oil and ferrite grains with a binding agent.

Troels Gravesen describes removing fresh ferrofluid from the magnet gap:

Vifa C17WH-

You use tissue and a solvent, IME. I used WD40 for some dried up cloggy stuff. You apparently add just enough to fill the magnet gap completely, it sticks to magnetism, then reassemble.

B&W LOVE this 3kHz 4 ohms tweeter filter. I've seen it so many times. Kevlar 6" bass. B&W Compact Domestic Monitor 1 loudspeaker | Stereophile.com

Attachments

Last edited:

Bobakrep, Face and Steve.

Thanks for replying to my noob question. I understand there are lots of posts with "fix my problem" out there where folks took no effort to solve their own problem. I did a bit of digging on this forum and interwebs and found myself deep into some "q" values and crossover compatibility stuff that was way over my head. I guess I did not look deep enough to find the right stuff.

Thank you again for responding and pointing me in the right direction. I will post back some pics and reports on my progress when I get started next week.

Cheers

brian

Thanks for replying to my noob question. I understand there are lots of posts with "fix my problem" out there where folks took no effort to solve their own problem. I did a bit of digging on this forum and interwebs and found myself deep into some "q" values and crossover compatibility stuff that was way over my head. I guess I did not look deep enough to find the right stuff.

Thank you again for responding and pointing me in the right direction. I will post back some pics and reports on my progress when I get started next week.

Cheers

brian

Hello All,

I spend some time taking it all apart and cleaning it out. I got most all of it out but there is still some metallic particles in there but the dried up "fluid" residue is gone. The copper wound "ring" that sits in the slot is all cleaned up and looking good. I reassembled and the tweeter seems to move in/out without hanging up but I will give it another go to get it as clean as I can. I ordered some ferrofluid and expect it to arrive this week. I was planning on using some rubber cement to hold the tweeter cap on the magnet assembly unless you all think I should use something else.

Picture of tweeter attached.

Thanks again for all the great advise. I will post more as I get it back together.

Brian

I spend some time taking it all apart and cleaning it out. I got most all of it out but there is still some metallic particles in there but the dried up "fluid" residue is gone. The copper wound "ring" that sits in the slot is all cleaned up and looking good. I reassembled and the tweeter seems to move in/out without hanging up but I will give it another go to get it as clean as I can. I ordered some ferrofluid and expect it to arrive this week. I was planning on using some rubber cement to hold the tweeter cap on the magnet assembly unless you all think I should use something else.

Picture of tweeter attached.

Thanks again for all the great advise. I will post more as I get it back together.

Brian

Attachments

Hello Brian,

You must remove all metallic particles left in the gap.

The best way to remove them is to bend a little piece of adhesive tape (sticky side out ) and graft it into the gap so that the metal particles stick to tape (a strip of cardboard can help to insert tape)

Then clean the remaining adhesive from tape with some solvent.

Have a nice day.

You must remove all metallic particles left in the gap.

The best way to remove them is to bend a little piece of adhesive tape (sticky side out ) and graft it into the gap so that the metal particles stick to tape (a strip of cardboard can help to insert tape)

Then clean the remaining adhesive from tape with some solvent.

Have a nice day.

Last edited:

Hey everyone.

Thank you for the great advise. I cleaned out the tweeters and ordered some ferrofluid. I carefully refilled it and reassembled. Fired them up and the tweeters are working great. I tested on a small NAD amp to start and will move them to the bigger amp later to give them a full workout.

Thanks again for the help.

Thank you for the great advise. I cleaned out the tweeters and ordered some ferrofluid. I carefully refilled it and reassembled. Fired them up and the tweeters are working great. I tested on a small NAD amp to start and will move them to the bigger amp later to give them a full workout.

Thanks again for the help.

Hello Brian - many thanks for this thread. I just bought a pair of CDM 1's with this exact issue (previous owner claims that he never realized the tweeters are 99 % out)

I'm now aiming to fix the tweeters the same way you have - but regrettably I am a complete newbie to repairs.

Was it difficult? How did you actually remove the dried up fluid? the Are you completely satisfied with the result even without replacing the ferrofluid?

I would be most thankful for you reply! Kind regards, Erik, Stockholm

I'm now aiming to fix the tweeters the same way you have - but regrettably I am a complete newbie to repairs.

Was it difficult? How did you actually remove the dried up fluid? the Are you completely satisfied with the result even without replacing the ferrofluid?

I would be most thankful for you reply! Kind regards, Erik, Stockholm

Hello,

Recently I did a repair of my CDM1 as well. I had bigger issue because my both coils were burnt. I ordered new diaphragms (not complete tweeter) for model CC6 because CDM1 parts are not available. According to service manuals, they looked the same.

I did disassemble of both tweeters and disassembled metal part of tweeter, removing pole piece, exposing a magnet. Then I realized that there is plenty of space around magnet, because there is a groove in tweeter cap around magnet (it's visible on drawings in service manual) and magnet diameter is slightly lower than pole piece. Then I took my karcher pressure washer and holding tweeter in one hand I removed all metal pieces from chamber with water.

Then dried everything, mounted (instant glue) and centered pole piece, applied ferrofluid and assembled new diaphragms. It took less than one hour and now my speakers are working great again.

Regards

Bartosz

Recently I did a repair of my CDM1 as well. I had bigger issue because my both coils were burnt. I ordered new diaphragms (not complete tweeter) for model CC6 because CDM1 parts are not available. According to service manuals, they looked the same.

I did disassemble of both tweeters and disassembled metal part of tweeter, removing pole piece, exposing a magnet. Then I realized that there is plenty of space around magnet, because there is a groove in tweeter cap around magnet (it's visible on drawings in service manual) and magnet diameter is slightly lower than pole piece. Then I took my karcher pressure washer and holding tweeter in one hand I removed all metal pieces from chamber with water.

Then dried everything, mounted (instant glue) and centered pole piece, applied ferrofluid and assembled new diaphragms. It took less than one hour and now my speakers are working great again.

Regards

Bartosz

Hey guys,

I need to work on my tweeters too and I am planning to follow this guide:

B&W CDM1 Hochtoner Reparatur (ZZ09989 / ZZ9989)

I have one question though, do I need to repleace the diaphragm? I really see no point, if I just want to change the fluid, unless I am missing something.

Thank you,

Nándi

I need to work on my tweeters too and I am planning to follow this guide:

B&W CDM1 Hochtoner Reparatur (ZZ09989 / ZZ9989)

I have one question though, do I need to repleace the diaphragm? I really see no point, if I just want to change the fluid, unless I am missing something.

Thank you,

Nándi

Is it easy to swap the original (damaged) tweeter with a Vifa-Peerless OC25SC65-04?

https://www.infinity-electronic.hk/datasheet/a5-OC25SC65-04.pdf

https://www.infinity-electronic.hk/datasheet/a5-OC25SC65-04.pdf

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- B&W CDM1 Tweeter Repair/Swap