I think I had a brain fart moment. The mumps in the k-510 are the big fill ins on the horn corners. And work in the opposite end of the frequency range. When I wrote that reply I was thinking about a horn I saw somewhere that had small little bumps on the horn wall just outside of the first opening to the driver

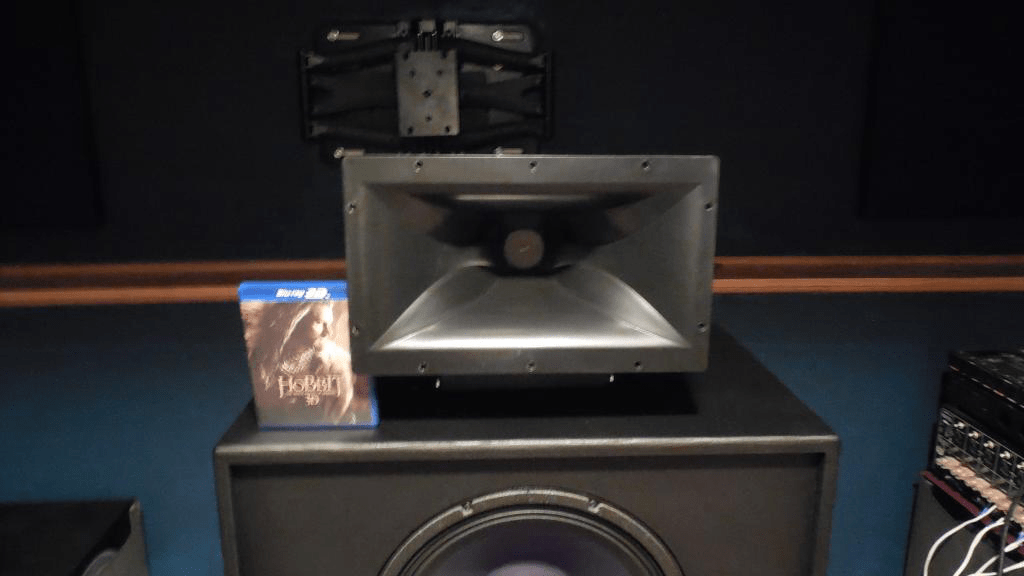

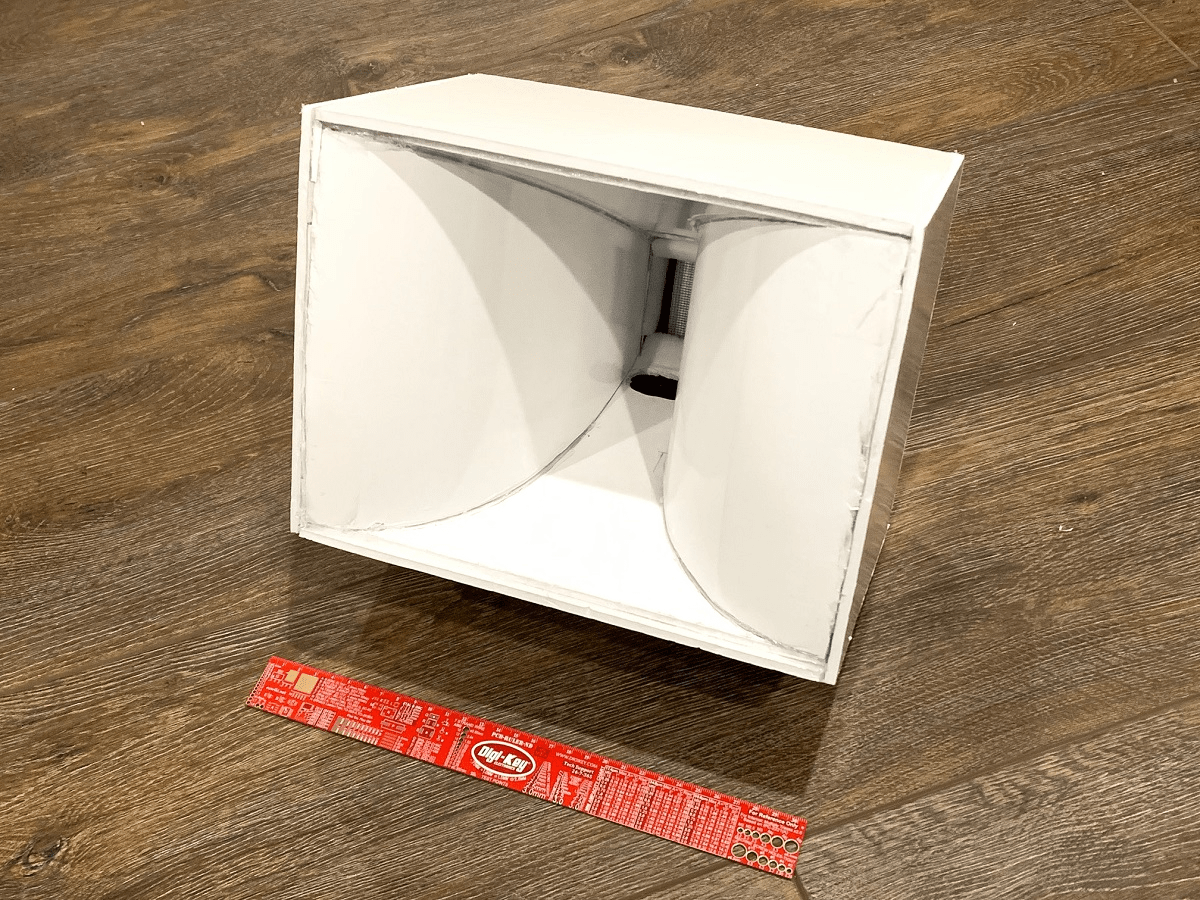

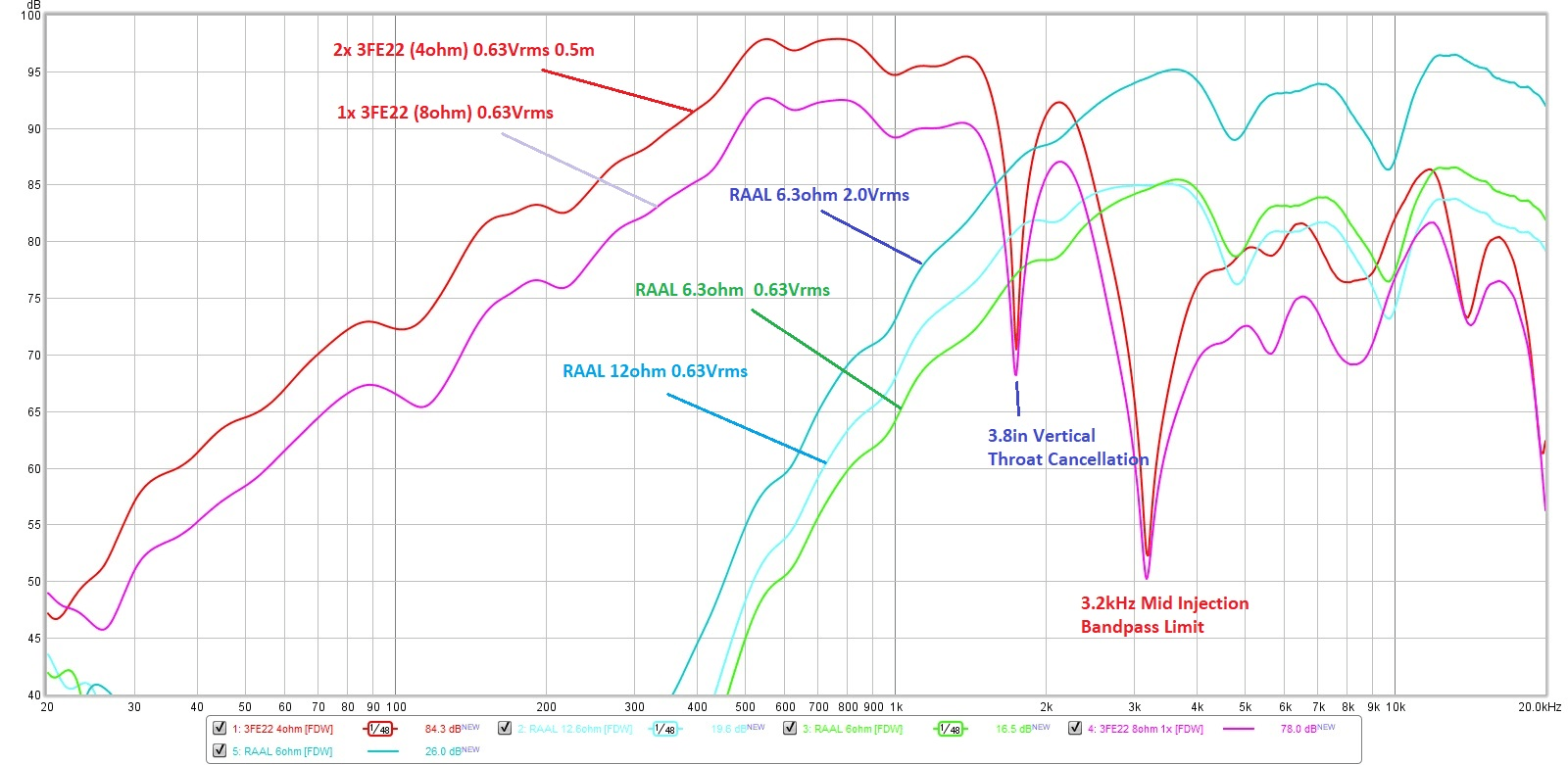

I was working on a tiny nano Trynergy with a RAAL and 3FE22's and could not get rid of a dip in response. I wonder if adding these bars across the mouth of the horn will help?

https://www.diyaudio.com/community/...ractrix-raal-ribbon-point-source-horn.352836/

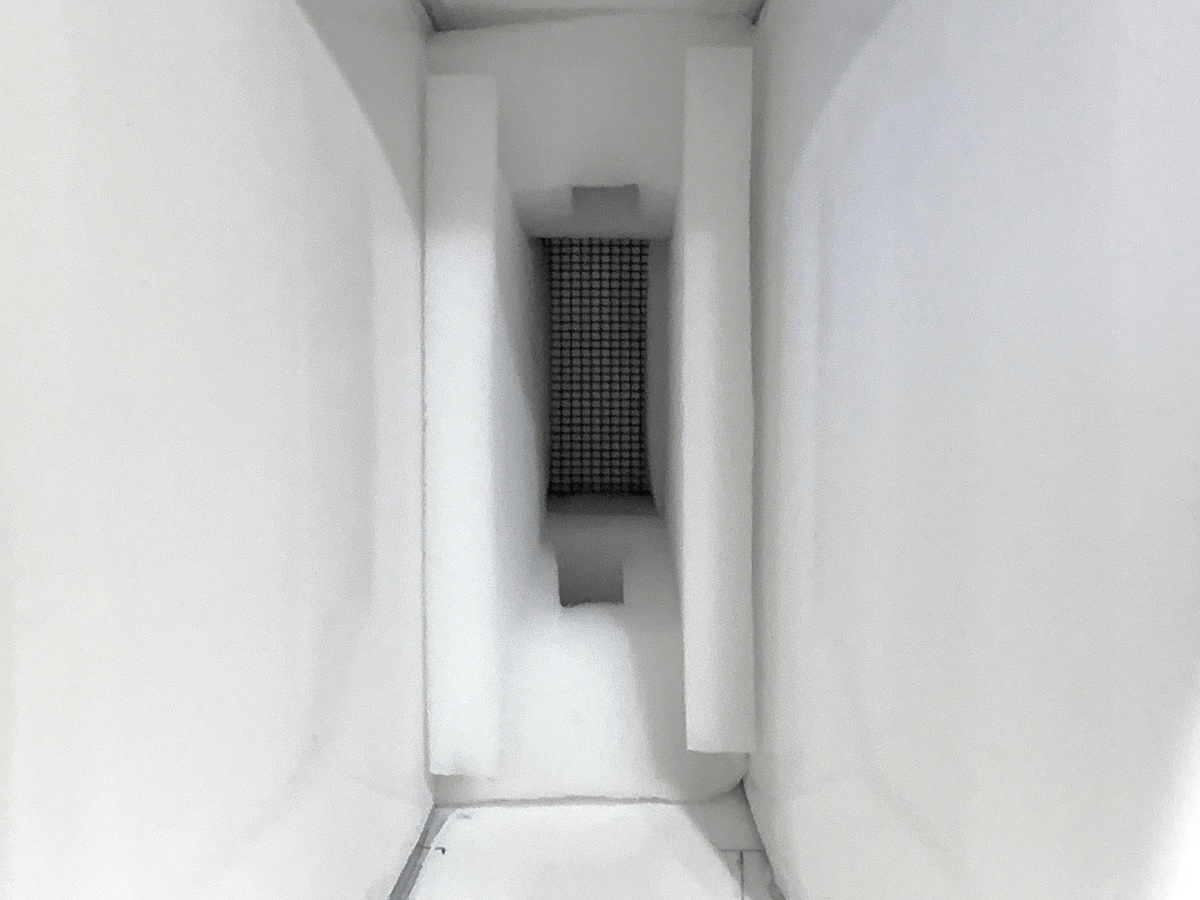

I kept thinking it was caused by the parallel throat walls and tried adding melamine foam in the throat with no improvement:

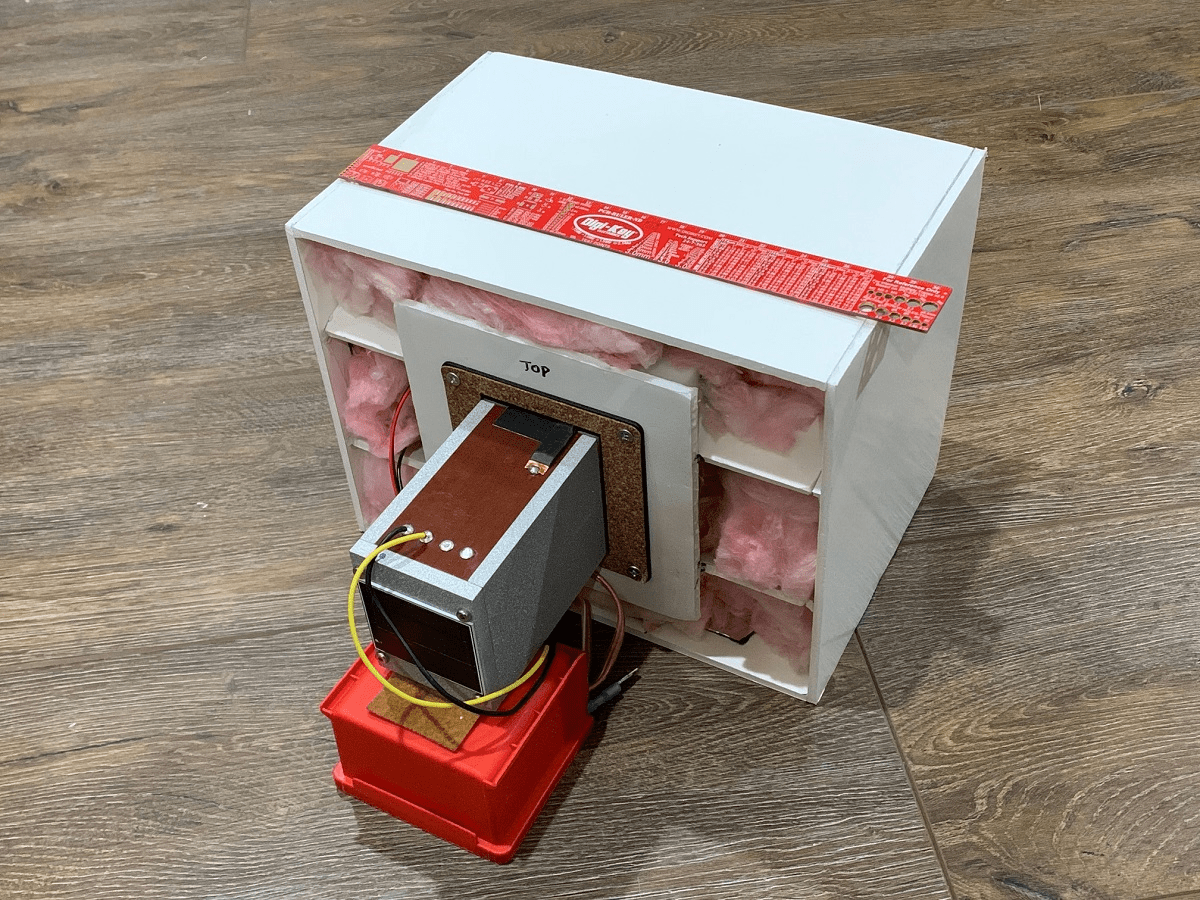

Backside:

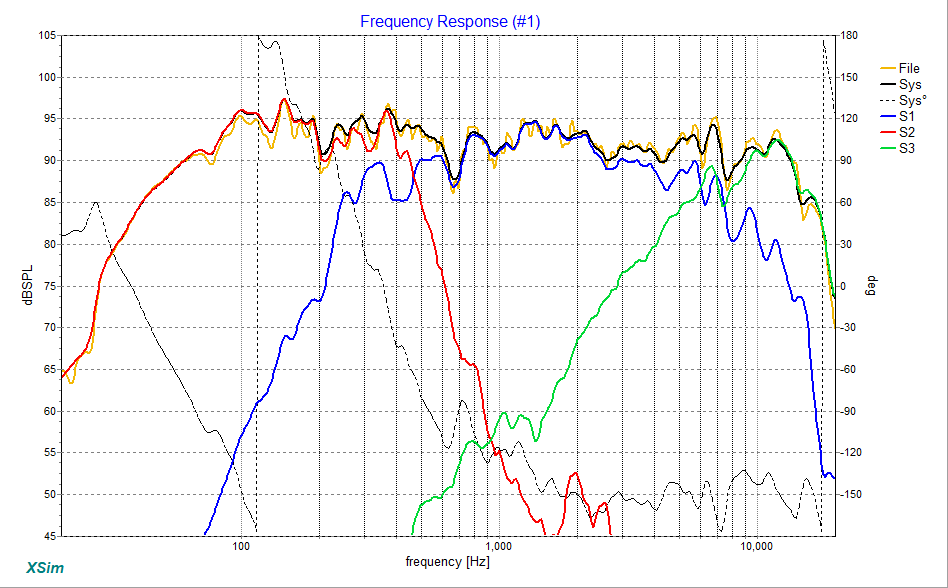

Would love to get this speaker working as the RAAL 70X20xr is very nice. If I could get this to work it could cross to woofer array from my XSD SLOB dipole speaker at 470Hz easily. That would be an interesting speaker. Here is the woofer array response from XSD (red) - XSD also has 12in wide front baffle width so a perfect fit:

https://www.diyaudio.com/community/...ractrix-raal-ribbon-point-source-horn.352836/

I kept thinking it was caused by the parallel throat walls and tried adding melamine foam in the throat with no improvement:

Backside:

Would love to get this speaker working as the RAAL 70X20xr is very nice. If I could get this to work it could cross to woofer array from my XSD SLOB dipole speaker at 470Hz easily. That would be an interesting speaker. Here is the woofer array response from XSD (red) - XSD also has 12in wide front baffle width so a perfect fit:

Last edited:

Hi

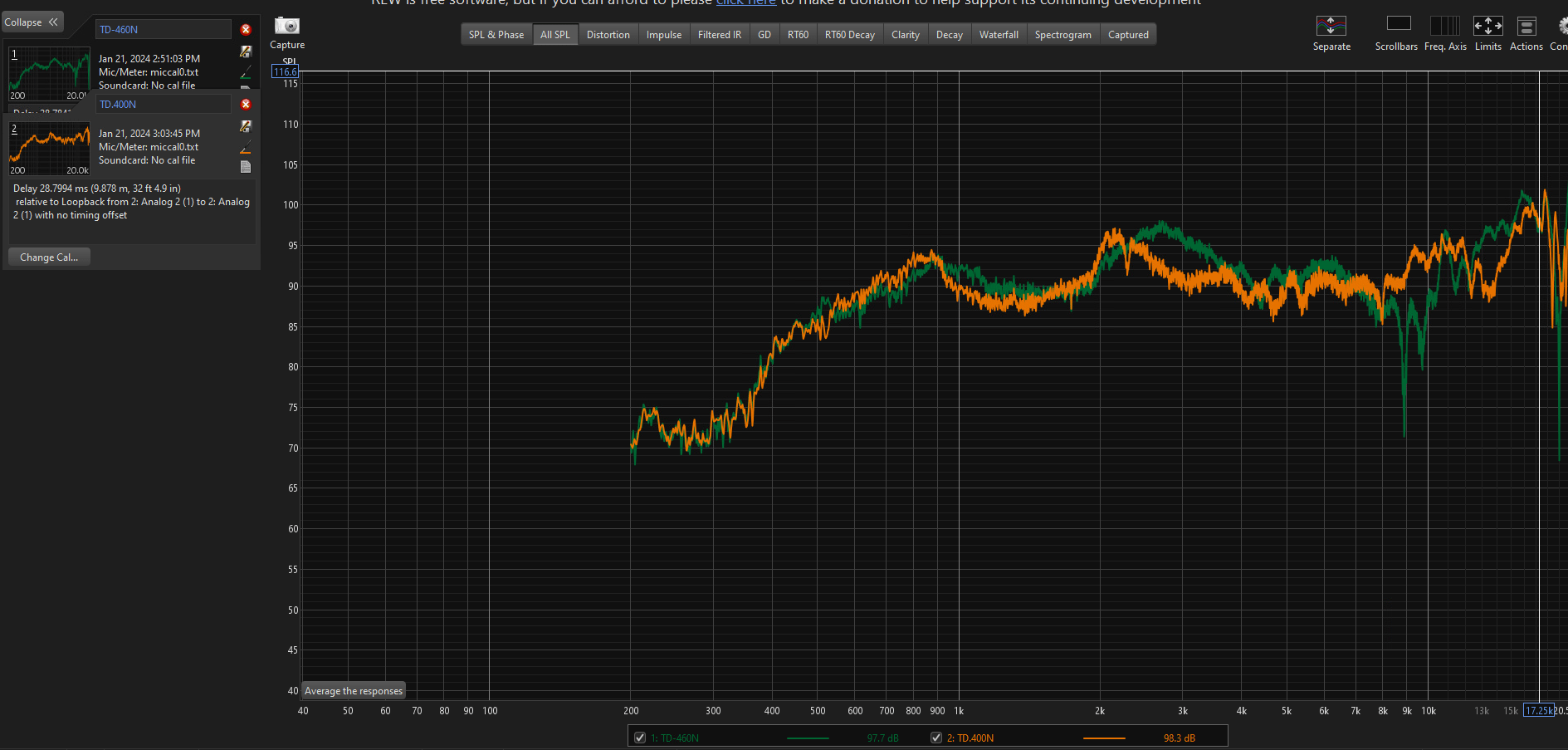

I also have to of the dicontinued TD-400

https://www.beyma.com/speakers/Fichas_Tecnicas/TD400.pdf

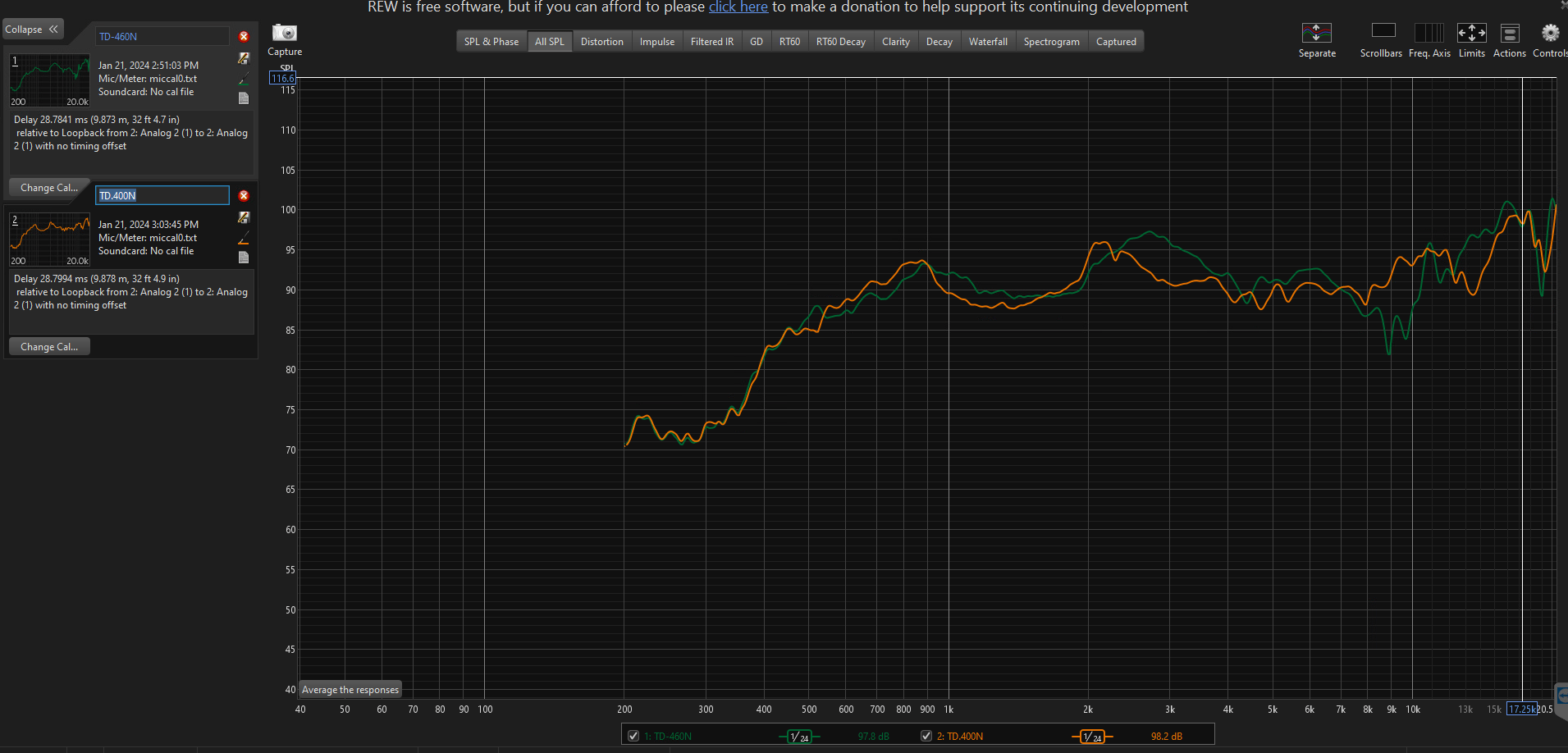

They have 2 "guids" in the horn and they don't show this Problem:

I also have to of the dicontinued TD-400

https://www.beyma.com/speakers/Fichas_Tecnicas/TD400.pdf

They have 2 "guids" in the horn and they don't show this Problem:

It's embarassing that B&C and SB Acoustics selling these antiquated designs. Either:

1) the people making these don't know any better

2) or these antiquated designs are still popular among buyers

But if you spend any time trying to get diffraction slots to work the way they're promised to work, you'll find that it's basically impossible. Believe me, I've tried for 10+ years

1) the people making these don't know any better

2) or these antiquated designs are still popular among buyers

But if you spend any time trying to get diffraction slots to work the way they're promised to work, you'll find that it's basically impossible. Believe me, I've tried for 10+ years

I haven’t tried these so it’s conjecture. They don’t look bad - but they are diffraction style horns meaning there is a vertical channel slot that opens up to the main horn body. But if you don’t mind a little DIY experiment to test out that’s fine. Don’t look at it as a recipe for a final version that will work guaranteed. I used the middle adapter but who know with this horn.Would the SB65 with the 3d printed adapter go well with the SB H280 Horn ?

Looks like it's got nice outsides to mount woofers to, good coverage, good extension, cheap, attainable.

Which depth of 3d printed adapter would be best, as there is 3 in the files XRK provided?

View attachment 1284714 View attachment 1284712

From an uneducated glance, this has the same thing going on?But if you spend any time trying to get diffraction slots to work the way they're promised to work, you'll find that it's basically impossible. Believe me, I've tried for 10+ years

https://www.rcf.it/en/products/product-detail/hf950

It doesn't seem anyone is making a "large" horn for a reasonable sum of money that doesn't have a fundamental flaw.

What is the deciding factor between the adapters?I used the middle adapter but who know with this horn.

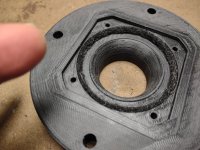

I have been experimenting with using the XT1464/SB65 combination . I was inspired by the work done by Bushmeister and xrk971. I used xrk971’s back cover which worked quite well. I merged xrk971’s thickest adaptor (25mm) and the SB65 adaptor plate by chriss0212.

Thanks guys for uploading your work.

I had to use 2 layers of 10mm felt inside the back cover to get a clean response.

The stl files are attached.

Note: There was a null at 6K. This can be resolved by a 2mm thick felt ring glued to the adaptor. (outside the SB65 roll surround. refer pictures.)

Thanks guys for uploading your work.

I had to use 2 layers of 10mm felt inside the back cover to get a clean response.

The stl files are attached.

Note: There was a null at 6K. This can be resolved by a 2mm thick felt ring glued to the adaptor. (outside the SB65 roll surround. refer pictures.)

Attachments

Last edited:

Nice work! I don’t recall uploading a ready chamber for the SB65?I have been experimenting with using the XT1464/SB65 combination . I was inspired by the work done by Bushmeister and xrk971. I used xrk971’s back cover which worked quite well. I merged xrk971’s thickest adaptor (25mm) and the SB65 adaptor plate by chriss0212.

Thanks guys for uploading your work.

I had to use 2 layers of 10mm felt inside the back cover to get a clean response.

The stl files are attached.

Note: There was a null at 6K. This can be resolved by a 2mm thick felt ring glued to the adaptor. (outside the SB65 roll surround. refer pictures.)

Nice that you were able to get rid of the 6kHz dip with the felt.

I got the back chamber from a zip file you posted in #1689.Nice work! I don’t recall uploading a ready chamber for the SB65?

Nice that you were able to get rid of the 6kHz dip with the felt.

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn