Hey Mr. Speakers, thanks for sharing these pics? How did they sound?

As a long time lurker and passionate dreamer to someday build a pair of SynTripP's. Huge shout out and thanks to Art, FinBot, JennyGirl, and others for all their passion and dedication sharing their builds with the community. Thank you!

Mr. Speakers, I'm intrigued by your approach to 3D print these. I can't imagine the performance would be the same using 3D printed plastic as it would be with wood though, right?

Durability issues aside (cracking, etc.), wouldn't the resonant and damping properties be different?

Art? Any thoughts?

Thanks again and let us know how they sound!

Sure, every material has different pros/cons for rigidity, internal damping, durability.

We are using a carbon loaded PLA for the horn, it's super light and very rigid. Right now in a sub-optimal MDF cabinet the printed parts are no noisier than the enclosure. The whole assembly has a primary resonance, which you expect, it's pretty high up there indicating decent rigidity, but it's not as damped as we'd like.

We don't have good distortion measurements as we've so far measured in our office (we're in an industrial park so getting real outdoor measurements requires a late-night weekend venture and we'll do that when we have the final bamboo box. Frequency response doesn't show any serious anomolies beyond results others have shown, and that was done in a small office with a mountain of reflections. And yeah, it sounds great!

When we switch to the bamboo shell we are going to treat a few of the larger, flatter surfaces on the box and the printed horn with acoustamat to deaden the enclosure.

We don't have good distortion measurements as we've so far measured in our office (we're in an industrial park so getting real outdoor measurements requires a late-night weekend venture and we'll do that when we have the final bamboo box. Frequency response doesn't show any serious anomolies beyond results others have shown, and that was done in a small office with a mountain of reflections. And yeah, it sounds great!

Thanks, can't wait to hear final results!

there are no plans, 'we' only have what is here in the topic and there is a synergy design tool called SynergyCalc designed by Bill Waslo. Also you can design using Hornresp with the multiple entry horn option.

I'm considering buying

2x Celestion CDX1-1445 tweeter (HF) drivers

8x

FaitalPRO 6FE100 6" Professional Midrange Midbass Woofer 8 Ohm

and

8x

FaitalPRO 3FE25 3" Professional Full-Range Woofer 8 Ohm

these will be going into two Synergy horns roughly 600mm wide x 400mm high x 240mm deep. Pretty much the same as the SynergyCalc plans.

Whats a smart approach to calculating, buying and building a project like this? Would I do it in that order? I feel like just buying the drivers so I can just get strait into the calculation side and not change my mind onto something else and have to wait for shipping.

Advice, guidance, criticism, anything would be much appreciated

Thanks

2x Celestion CDX1-1445 tweeter (HF) drivers

8x

FaitalPRO 6FE100 6" Professional Midrange Midbass Woofer 8 Ohm

and

8x

FaitalPRO 3FE25 3" Professional Full-Range Woofer 8 Ohm

these will be going into two Synergy horns roughly 600mm wide x 400mm high x 240mm deep. Pretty much the same as the SynergyCalc plans.

Whats a smart approach to calculating, buying and building a project like this? Would I do it in that order? I feel like just buying the drivers so I can just get strait into the calculation side and not change my mind onto something else and have to wait for shipping.

Advice, guidance, criticism, anything would be much appreciated

Thanks

Before starting a speaker project, it is best to determine what goals are important to it's success, such as budget, frequency response, dispersion pattern, and desired SPL. I described a 10 point goal criteria in the OP- your goals may have little in common with them.Whats a smart approach to calculating, buying and building a project like this?

Would I do it in that order? I feel like just buying the drivers so I can just get strait into the calculation side and not change my mind onto something else and have to wait for shipping.

Some basic calculations are important- for instance, your choice of 4x 6" drivers would have about 20% less displacement than the 2x10" used in the SynTripP design, more expense, complexity and less output. The mids would more than keep up though ;^).

Regarding SynTripP plans, as stated in the OP, Post #41 contains plans and a preliminary parts lists, Post #61 has the completed parts lists and assembly instructions, Post #100 has photos of the bass reflex port details, Post #115 has the throat port detail. Posts #128, 138, & 568 have injection port and cone filler details.

Cheers,

Art

Before starting a speaker project, it is best to determine what goals are important to it's success, such as budget, frequency response, dispersion pattern, and desired SPL. I described a 10 point goal criteria in the OP- your goals may have little in common with them.

Some basic calculations are important- for instance, your choice of 4x 6" drivers would have about 20% less displacement than the 2x10" used in the SynTripP design, more expense, complexity and less output. The mids would more than keep up though ;^).

Regarding SynTripP plans, as stated in the OP, Post #41 contains plans and a preliminary parts lists, Post #61 has the completed parts lists and assembly instructions, Post #100 has photos of the bass reflex port details, Post #115 has the throat port detail. Posts #128, 138, & 568 have injection port and cone filler details.

Cheers,

Art

Thanks Art, good advice on goal setting considering my hastiness to buy a bunch of drivers!

Calculations isn't my strong point, I'm self taught in audio and but have good electrical knowledge (electrician) and woodwork skills. I understand what you mean by basic calculations, but I would like to just try and mimic the different builds here, and if I fail, thats probably inevitable but not necessarily a bad thing.

I'll look at all your post recommendations thank you

I also reached out to fellow Australian FinBot, and will be attending the next Rainbow Serpent Festival to hear his SyntripP's in action!

Cheers,

riji

Updated SolidWorks file

Hi SynTripP fans,

Just checking back a few weeks later if there is any possibility of sharing the SolidWorks files for this with the community?

I was hoping to do an A/B test with a standard plywood build and a 3D printed build to get some science around the performance of 3D printed enclosures and would love to kick it off with the SynTripP.

Art, would this be OK with you? A lot of us would be tremendously grateful if you would let Mr.Speakers share their model, assuming of course that was OK with them as well!

Thanks again for all your hard work on this. You're doing the next gen DIY Audio community a massive service.

All my best,

Noah

Sure, every material has different pros/cons for rigidity, internal damping, durability.

Hi SynTripP fans,

Just checking back a few weeks later if there is any possibility of sharing the SolidWorks files for this with the community?

I was hoping to do an A/B test with a standard plywood build and a 3D printed build to get some science around the performance of 3D printed enclosures and would love to kick it off with the SynTripP.

Art, would this be OK with you? A lot of us would be tremendously grateful if you would let Mr.Speakers share their model, assuming of course that was OK with them as well!

Thanks again for all your hard work on this. You're doing the next gen DIY Audio community a massive service.

All my best,

Noah

Noah,Just checking back a few weeks later if there is any possibility of sharing the SolidWorks files for this with the community?

I was hoping to do an A/B test with a standard plywood build and a 3D printed build to get some science around the performance of 3D printed enclosures and would love to kick it off with the SynTripP.

Art, would this be OK with you? A lot of us would be tremendously grateful if you would let Mr.Speakers share their model, assuming of course that was OK with them as well!

If Mr. Speakers wants to share his files, I'm OK with that.

If you would like to compare a standard plywood build and a 3D printed version, go ahead!

Cheers,

Art

Noah,

If Mr. Speakers wants to share his files, I'm OK with that.

If you would like to compare a standard plywood build and a 3D printed version, go ahead!

Cheers,

Art

That's great, thanks for your blessing. Will check in with Mr. Speakers and see how they feel about sharing, then come back with some comparison results once I get both built.

Much obliged!

Best,

Noah

We're just about done, and sure, when we're finished we'll be happy to share STL files for print, cut sheets, and laser patterns. The project got slowed down due to a combination of parent-care and worked getting BUSY, but that's life for ya.

We designed the box to screw together so assembly is super fast, and the rear panel is easily removed to service drivers, etc.

Printing the parts takes a while, and a good large format printer. We ended up using a carbon fiber filament that was dimensionally stable when cooling to keep the part on the platform, it's not a print job for newbies.

Cutting the wood with the laser was done on a 100W CO2 with a 5" lens, anything shorter was char-o-rama. We're debating whether to sand and seal the exterior to let the wood show, or just basic sound-system-black.

We designed the box to screw together so assembly is super fast, and the rear panel is easily removed to service drivers, etc.

Printing the parts takes a while, and a good large format printer. We ended up using a carbon fiber filament that was dimensionally stable when cooling to keep the part on the platform, it's not a print job for newbies.

Cutting the wood with the laser was done on a 100W CO2 with a 5" lens, anything shorter was char-o-rama. We're debating whether to sand and seal the exterior to let the wood show, or just basic sound-system-black.

Attachments

Done!

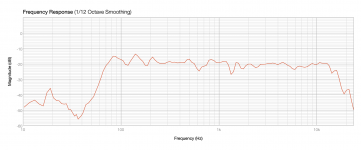

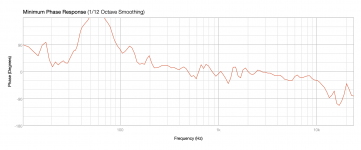

We're super happy with how these came out. The sound is very clean and coherent, the phase results show that really clearly, they're totally linear through the low mids through the middle of the highs.

EQ was not terribly complex, we're currently using a MiniDSP and it took a few hours to work it and feel it was pretty well optimized. We used a simple combination of shelves and one or two EQ points on the mids and highs and came up with the results shown below.

For curiosity we'll be testing the DIRAC impulse response optimization soon.

We loved the way the bamboo came out, and the black cuts from the laser gave it a slick looking trim, so we left the screws exposed, and ran with an oil-based wood clear coat. Bamboo is super hard, we'll see how that works out over time.

We're super happy with how these came out. The sound is very clean and coherent, the phase results show that really clearly, they're totally linear through the low mids through the middle of the highs.

EQ was not terribly complex, we're currently using a MiniDSP and it took a few hours to work it and feel it was pretty well optimized. We used a simple combination of shelves and one or two EQ points on the mids and highs and came up with the results shown below.

For curiosity we'll be testing the DIRAC impulse response optimization soon.

We loved the way the bamboo came out, and the black cuts from the laser gave it a slick looking trim, so we left the screws exposed, and ran with an oil-based wood clear coat. Bamboo is super hard, we'll see how that works out over time.

Attachments

I like. Looking forward to the plans and the STLs

They are actually in this thread a little way back there Mr. Waslo Bill Sir.

Very nice work, MrSpeakers!

Can you please share with us the name and model do 3D printer you used and the material? Is it continuous carbon fiber filled nylon filament or chopped carbon? Or did you use a 3D print shop?

Thanks,

X

We used a heavily modified 3D printer with a 300 x 300 mm plate, modified firmware, and highly customized print head. There's no way most people would reproduce this readily, better to spend $700-1000 for a proper large format printer that doesn't need the customizations.

The filament was chopped carbon fiber PETG. A good printer would have a 400mm x 400mm base, smaller bases will have trouble holding the temp uniform to the edges, increasing the risk of lift. We used a little cyanocrylic to tack the corners down to the plate.

Congrats!

Congrats, these look awesome! Looking forward to seeing those STL files. You're going to make a lot of people happy.

Thanks again,

JSS

We're super happy with how these came out. The sound is very clean and coherent, the phase results show that really clearly, they're totally linear through the low mids through the middle of the highs.

Congrats, these look awesome! Looking forward to seeing those STL files. You're going to make a lot of people happy.

Thanks again,

JSS

- Home

- Loudspeakers

- Multi-Way

- SynTripP: 2-way 2-part Virtual Single Point Source Horn