Finally I found someone using©AdamFelix.. I've used the 18 sound HD1480T HF Compression driver.

What can you say about this driver?..

@ Flash, I haven't done any measurements of the 18 sounds in the syntripps yet. To my wooden ears they sound smooth in the syntripps. Maybe little EQ may be necessary in the upper frequencies. Distortions were low even at very high levels (crossed at 920Hz). I used only -6dB for them in the DSP setting and calibrated thier volume on the Volume knob of the amp. I didn't want to rip the people heads of. Very high spl. I think more than -12 dB are necessary to level them to the mids. Beware! They are heavy. Propper mounting is requried.

Christian

Christian

Thanks Christian. Have you compared hd1480t with others, may be subjectively?@ Flash, I haven't done any measurements of the 18 sounds in the syntripps yet.

Measurement below 1k and above 10k are interesting also. If and when

If you want your Fb loudspeaker to go lower than 82 Hz, the tuning(Fb) would also need to be lowered. Fb should be equal to or above Fs for maximum sensitivity.Thanks Art!

If I want the loudspeaker to go lower than 82 hz, would that be possible with different 10 inch drivers? If yes, what parameters should I be looking for?

Horn loading generally requires high Bl (motor strength) and high output requires high Xmax. Easy lifting requires light weight, neodymium magnets provide light weight and high Bl.

No idea what you mean by "TAP".How thick is the TAP if I use 1" exit driver?

Post #41 contains plans, Post #61 has the completed parts lists and assembly instructions, Post #100 has photos of the bass reflex port details, Post #115 has the throat port detail. Posts #128,138, & 568 have injection port and cone filler details.

@welterys thanks so much for sharing what looks like an amazing project. I'm another SoCal Burning Man enthusiast, and am planning to use this as the basis for a system to bring to playa this year, and our local San Diego Youtopia festival in October.

We're rather lazy woodworkers and don't have a CNC router, so we're going to do this on our big laser, using only right angles for most construction and making joiners on 3D printers.

We'll probably do the drawings in Solidworks, and will share the files with anyone interested in personal projects if it all works out.

One question; did you finish assessing the DE90TN?

Cheers!

Dan

We're rather lazy woodworkers and don't have a CNC router, so we're going to do this on our big laser, using only right angles for most construction and making joiners on 3D printers.

We'll probably do the drawings in Solidworks, and will share the files with anyone interested in personal projects if it all works out.

One question; did you finish assessing the DE90TN?

Cheers!

Dan

Dan,One question; did you finish assessing the DE90TN?

I never did an assessment of the B&C DE90TN, as the additional weight compared to the neodymium drivers already used made me decide against considering a swap.

Art

Dan,

I never did an assessment of the B&C DE90TN, as the additional weight compared to the neodymium drivers already used made me decide against considering a swap.

Art

Got it, thanks!

Hello Art.

I build my SynTripP using the JBL 2384 horn with the 2435HPL driver and I think that I made some mistakes in port location and LF ducts.

Can you please verify the distance between the port centers and also what is the length for 4pc 3 inch PVC pipe for the ducts?

Thanks again,

I build my SynTripP using the JBL 2384 horn with the 2435HPL driver and I think that I made some mistakes in port location and LF ducts.

Can you please verify the distance between the port centers and also what is the length for 4pc 3 inch PVC pipe for the ducts?

Thanks again,

Attachments

In this pic, you can see that the midranges are about 12.5cm ahead of the tweeter. The crossover point is about 1350hz.

1,350hz is 25cm long. So that 12.5cm gap is one half wavelength at the xover frequency.

I hope all of that makes sense.

If it does, then you'll realize that no DSP is required if you can use a filter on those midranges that will delay them by about one half wavelength at the xover frequency.

If you want to learn more about how this works, read this:

http://www.melaudia.net/zdoc/jml_crossovers_etf04.pdf

It is not about Synergy horns, but the idea is the same.

This gets particularly fun when you realize that this is 'fractal' in nature, and there's nothing stopping you from using this approach in a three-way (like the SH50) or even a four way.

I received an email where someone asked me to elaborate on this comment.

Basically what my comment above refers to, is that your midrange and tweeter don't have to be the same distance from the listener to be in-phase.

For instance, take a look at this Dunlavy speaker. Dunlavy used first order slopes on every driver in his speaker. That's the reason that the woofers, midranges and tweeters are arranged in an arc. By using the same filter slop on every woofer, the 'arc' shape keeps everything in phase.

The important thing to note, when it comes to Dunlavy, is that every driver is equidistant to the listener, and all of the filters slopes are the same. Electrically and geometrically, the delay is identical from top to bottom.

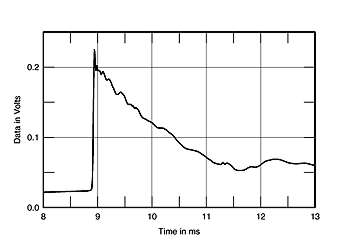

Here's the step response of a Dunlavy SC-VI? See how perfect it is? Now hold that thought...

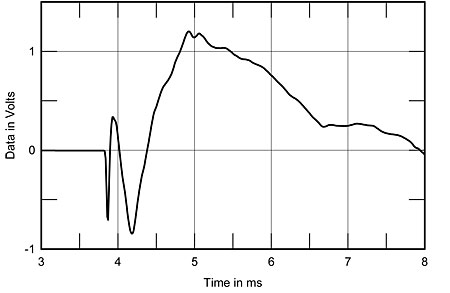

Here's a pic of a Focal Utopia III, and it's step response. See how the step response is a mess?

The step response of the Focal is a mess because of it's high order filters. A second order low pass delays the signal by 180 degrees at the xover frequency, a third order delays things by 270 degrees, etc...

Here's a LeCleach horn. See how the midbass is *significantly * closer than the tweeter?

The trick - as described in the LeCleach paper - is that you can use the delay introduced by the lowpass filter on the midbass to compensate for the fact that the midbass is much closer to the listener than the tweeter. The filter on the midbass introduces a delay; so moving it *closer* to the listener compensates for that delay.

It's a way to achieve excellent phase response even though the drivers aren't equidistant.

Of course, you could also do this via DSP if you want, but it's kinda elegant to do it passively!

I hope that makes sense. I know it made my head hurt the first time I read the LeCleach paper.

Fun fact:

If memory serves, I head this LeCleach setup in Silverdale Washington in September of 2001. IIRC, this was built by a student who went on to work for Apple, and designed their Homepod speaker... which is also a horn. Kinda neat to see DIY projects influence commercial audio:

vsacdr1

Last edited:

Sergey,Hello Art.

I build my SynTripP using the JBL 2384 horn with the 2435HPL driver and I think that I made some mistakes in port location and LF ducts.

Can you please verify the distance between the port centers and also what is the length for 4pc 3 inch PVC pipe for the ducts?

The SynTripP cabinet design does not use a JBL 2384 horn or PVC pipe, so it's port locations have little bearing on what you built.

For what it's worth, the throat ports were located as close to the HF driver as was physically possible considering the geometry of both.

Art

Sergey,

The SynTripP cabinet design does not use a JBL 2384 horn or PVC pipe, so it's port locations have little bearing on what you built.

For what it's worth, the throat ports were located as close to the HF driver as was physically possible considering the geometry of both.

Art

Got it!

Thank you.

@De45dd:

You asked me a technical question via PM. Please post question here or in my thread on bookshelf point source horn. This way, others can learn and can help me answer your questions. I tried to PM you but your PM storage space is full so not accepting any inbound messages.

You asked me a technical question via PM. Please post question here or in my thread on bookshelf point source horn. This way, others can learn and can help me answer your questions. I tried to PM you but your PM storage space is full so not accepting any inbound messages.

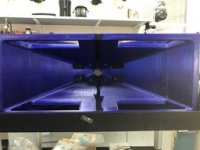

3D printed and Laser-Cut SyntripP

We are building a set of SyntripP speakers for Burning Man. Being fundamentally lazy woodworkers, we decided to try building the project using 3D printing for the interior baffling to get rid of the complex woodwork. The printer we use is large format, but it still takes 4 days to print one half of one insert.

Here are a few photos of the unit in process. The first prototype used a conventional filament, but for the final two units we're swtiching to a carbon loaded filament that has less shrinkage, and much greater rigidity.

The exterior is currently MDF, but we plan to laser cut bamboo for the final unit. We oversized all the panels the precision cut them to size and used the laser to drill the holes. FAST. Assembly time was under an hour.

We are building a set of SyntripP speakers for Burning Man. Being fundamentally lazy woodworkers, we decided to try building the project using 3D printing for the interior baffling to get rid of the complex woodwork. The printer we use is large format, but it still takes 4 days to print one half of one insert.

Here are a few photos of the unit in process. The first prototype used a conventional filament, but for the final two units we're swtiching to a carbon loaded filament that has less shrinkage, and much greater rigidity.

The exterior is currently MDF, but we plan to laser cut bamboo for the final unit. We oversized all the panels the precision cut them to size and used the laser to drill the holes. FAST. Assembly time was under an hour.

Attachments

3D Printed SynTripP's?

Hey Mr. Speakers, thanks for sharing these pics? How did they sound?

As a long time lurker and passionate dreamer to someday build a pair of SynTripP's. Huge shout out and thanks to Art, FinBot, JennyGirl, and others for all their passion and dedication sharing their builds with the community. Thank you!

Mr. Speakers, I'm intrigued by your approach to 3D print these. I can't imagine the performance would be the same using 3D printed plastic as it would be with wood though, right?

Durability issues aside (cracking, etc.), wouldn't the resonant and damping properties be different?

Art? Any thoughts?

Thanks again and let us know how they sound!

We are building a set of SyntripP speakers for Burning Man. Being fundamentally lazy woodworkers, we decided to try building the project using 3D printing for the interior baffling to get rid of the complex woodwork. The printer we use is large format, but it still takes 4 days to print one half of one insert.

Hey Mr. Speakers, thanks for sharing these pics? How did they sound?

As a long time lurker and passionate dreamer to someday build a pair of SynTripP's. Huge shout out and thanks to Art, FinBot, JennyGirl, and others for all their passion and dedication sharing their builds with the community. Thank you!

Mr. Speakers, I'm intrigued by your approach to 3D print these. I can't imagine the performance would be the same using 3D printed plastic as it would be with wood though, right?

Durability issues aside (cracking, etc.), wouldn't the resonant and damping properties be different?

Art? Any thoughts?

Thanks again and let us know how they sound!

- Home

- Loudspeakers

- Multi-Way

- SynTripP: 2-way 2-part Virtual Single Point Source Horn