Hi all,

This is my first attempt to upload some pics of my Seas 2-ways so please bare with me and I apologise in advance if my efforts are not very good and for poor picture quality.

Please correct me if images are not shown, thanks.

This is my first attempt to upload some pics of my Seas 2-ways so please bare with me and I apologise in advance if my efforts are not very good and for poor picture quality.

Please correct me if images are not shown, thanks.

Attachments

Thanks for your questions Dave,

The baffle is not yet complete its also having a 3.6mm plywood skin like the rest of the cabinet and then a 3mm MDF skin to flush mount the drivers using a gasket for the tweeters. I have limited tools and will invest in a router. I've chamfered the woofer holes which make the baffle appear thin atm its 18mm MDF. I have thought of adding more bracing especially for top and bottom, I have thought of 'V' braces, is this what you mean by bracing at uneven points.

I should of added more info on them so here goes...

Drivers:

Seas U18RNX/P, Seas 27TBFC/G

Cabinet:

20 litre, 18mm MDF with 3.6mm plywood skin glued with Titebond 2,

4mm Bitumen pads with 8mm felt material on internal walls except baffle,

Solid slot vent (not completely shown full vent length in pics) made from 9mm birch ply,

12mm birch ply 'picture frame braces above and below woofer drivers,

they will also have copper binding posts and black baffle soon.

Crossovers:

External crossovers using ClarityCaps and air-core inductors (will be re-designed).

The other speaker will be dyed this week and then AC lacquer from Fiddes 10% matt for finish.

http://www.fiddes.co.uk/product.php?name=acidcatalystlacquerssealersprimers

The baffle is not yet complete its also having a 3.6mm plywood skin like the rest of the cabinet and then a 3mm MDF skin to flush mount the drivers using a gasket for the tweeters. I have limited tools and will invest in a router. I've chamfered the woofer holes which make the baffle appear thin atm its 18mm MDF. I have thought of adding more bracing especially for top and bottom, I have thought of 'V' braces, is this what you mean by bracing at uneven points.

I should of added more info on them so here goes...

Drivers:

Seas U18RNX/P, Seas 27TBFC/G

Cabinet:

20 litre, 18mm MDF with 3.6mm plywood skin glued with Titebond 2,

4mm Bitumen pads with 8mm felt material on internal walls except baffle,

Solid slot vent (not completely shown full vent length in pics) made from 9mm birch ply,

12mm birch ply 'picture frame braces above and below woofer drivers,

they will also have copper binding posts and black baffle soon.

Crossovers:

External crossovers using ClarityCaps and air-core inductors (will be re-designed).

The other speaker will be dyed this week and then AC lacquer from Fiddes 10% matt for finish.

http://www.fiddes.co.uk/product.php?name=acidcatalystlacquerssealersprimers

Last edited:

Found a possible subwoofer driver for you it is slightly more than £120 but may be worth looking atPeerless XLS 830452

Any thoughts on me adding more bracing? Also thinking of a pair of subwoofers with 'fat bottom' cabinets for them to sit on, any thoughts on subwoofer drivers preferably 10" with black cones around £120 each?

You're building a lossy cabinet here, so more bracing will be a mistake. I like what you've done.

http://www.diyaudio.com/forums/multi-way/223174-interesting-read-i-found-lossy-cabinet-designs-harbeth.html

Found a possible subwoofer driver for you it is slightly more than £120 but may be worth looking atPeerless XLS 830452

Thanks, looks perfect! Good specs too

You're building a lossy cabinet here, so more bracing will be a mistake. I like what you've done.

http://www.diyaudio.com/forums/multi-way/223174-interesting-read-i-found-lossy-cabinet-designs-harbeth.html

Thanks Steve as I've just replied on a different thread I've tried and tested these drivers before braces then bitumen then felt material and it got better and better the bitumen had the biggest difference, seemed to speed the air flow too much without felt far too much reflection compared to before bitumen. The pics don't show poly wadding 20g (very little) is needed, differences in 2g of wadding is noticeable. Felt material get rid of standing waves well I think, controlled the bass a lot. Port length is around 100mm around 60mm shorter than Seas Idunn with different vent same size internal volume.

I must say also the bass and midrange improved with the plywood skin layer too, much more than I thought. Strange (but good) how the lower mids sounder clearer.

Last edited:

The bitumen and (especially if glued) felt will panel damp. Mostly affecting bass quality.

The loose fluff behind the woofer absorbs standing waves and some midrange backwave energy. But you can't overdo it with reflex or you wreck the bass.

It's all a bit rough and ready, but panel damping only absorbs midrange energy if the 1/4 wavelength is close to their thickness. In practise that means around 3kHz. I think the BBC doubled its thickness on the top and bottom panels for that reason.

What it boils down to, is you can't absorb standing waves and backwave so easily with reflex as you can with closed box. Hopefully the polycone will help too. It always mistifies me, but I'd swear midrange sounds better with reflex.

The loose fluff behind the woofer absorbs standing waves and some midrange backwave energy. But you can't overdo it with reflex or you wreck the bass.

It's all a bit rough and ready, but panel damping only absorbs midrange energy if the 1/4 wavelength is close to their thickness. In practise that means around 3kHz. I think the BBC doubled its thickness on the top and bottom panels for that reason.

What it boils down to, is you can't absorb standing waves and backwave so easily with reflex as you can with closed box. Hopefully the polycone will help too. It always mistifies me, but I'd swear midrange sounds better with reflex.

Last edited:

You're building a lossy cabinet here, so more bracing will be a mistake. I like what you've done.

http://www.diyaudio.com/forums/multi-way/223174-interesting-read-i-found-lossy-cabinet-designs-harbeth.html

By stating mistake are you implying a negative effect on the sound?

It's very hard to describe this briefly, but the lossy cabinet idea is a bit like aircraft construction or a cello or violin. It's light and rigid, so doesn't store much energy. What energy there is will be absorbed by the rubbery panel damping.By stating mistake are you implying a negative effect on the sound?

You let it resonate below 100Hz, so it does have a wooden sort of sound, but control and damp it higher.

If you built it out of chipboard or MDF, you could run into severe problems with braces or battens made of a different heavy material. Bracing should be light and rigid if not to interfere with the flexibility, if you follow. It merely serves to distribute the energy from the bass chassis, not stop it. You want to avoid abrupt changes of density and stiffness. The idea is that vibration can flow freely round the cabinet with no particular hotspots. The cabinet is all of a piece.

Does that make sense? I don't know!

This size (small) box made of 18mm (3/4") MDF plus 6mm skin layers plus some braces does not represent a lossy cabinet to me. Discussion of filling and bitumen sounds right to me.

You're right of course. But not answering the question about braces and battening.

This cabinet is a hybrid, actually closer to Troels Gravesen's MDF and ply SEAS CURV:

An externally hosted image should be here but it was not working when we last tested it.

Alan Shaw of Harbeth is still interesting on lossy thin wall cabinets though:

BBC-style thin-wall cabinets. Why so special?

Bracing, and what it's made of, depends on circumstances. It's a tricky subject. For the bitumen to work effectively, the walls have to flex IMO.

This cabinet wall resonance and dampening issue has own threads. I checked that Harbeth link and "lossy" comes from having a bit loosely attached front panel - it i s(paritally) de-coupled from the box.

Basically a box has ballooning by pressure and delayd enegy "ringing" due to panel vibrations. Each needs difrent measures to dampen. Thick board (and crossbraces) typically resists ballooning effectively but shift ringing to higher frequencies. Bitumen helps (if at all) only the ringing by added mass and constrained layers, it's benefit can be questioned.

The measurable/audible effect of these should appear at polar measurements, but I have not seen such a test done/published.

Basically a box has ballooning by pressure and delayd enegy "ringing" due to panel vibrations. Each needs difrent measures to dampen. Thick board (and crossbraces) typically resists ballooning effectively but shift ringing to higher frequencies. Bitumen helps (if at all) only the ringing by added mass and constrained layers, it's benefit can be questioned.

The measurable/audible effect of these should appear at polar measurements, but I have not seen such a test done/published.

Thanks again for all your posts,

The bitumen and felt is glued with Evostik solvent contact adhesive after braces were glued.

The braces and bitumen did a great role in panel resonance, the MDF cabs were vibrating loads before hand. Energy seemed to be soaked up a bit but seems to come from drivers more directly, fills the room more and almost silent when I put my ear against rear or side panels. Iv'e found the bitumen/felt soak up energy yet the added stiffness from the braces/plywood skin helps more energy come from the front, I don't think you can win either way in terms of energy but these things go really loud without noticeable distortion so am happy for now, I would much rather lose a bit of energy from the bitumen/felt to get their benefits.

As you can see Steve, my designed inspiration was from Troels Gravesen internally. The actually cabs I designed 15 years ago when I was 15 so I thought it should be a good starting project I could learn from. I will design one of Troels fantastic floorstanders when I get educated enough.

I thought Harbeth use 12mm plywood walls in a lot of there loudspeaker designs? The Harbeths do vibrate a lot but still sound lively with curtain music. Harbeth also use bitumen or rubber walls though and some have Seas drivers with similar size cabs and baffles to mine. My intention was to sound proof the cabs as much as possible, and being 18mm MDF plus 3.6mm plywood skin I don't think the cabs will sound like Harbeths.

The bitumen and felt is glued with Evostik solvent contact adhesive after braces were glued.

The braces and bitumen did a great role in panel resonance, the MDF cabs were vibrating loads before hand. Energy seemed to be soaked up a bit but seems to come from drivers more directly, fills the room more and almost silent when I put my ear against rear or side panels. Iv'e found the bitumen/felt soak up energy yet the added stiffness from the braces/plywood skin helps more energy come from the front, I don't think you can win either way in terms of energy but these things go really loud without noticeable distortion so am happy for now, I would much rather lose a bit of energy from the bitumen/felt to get their benefits.

As you can see Steve, my designed inspiration was from Troels Gravesen internally. The actually cabs I designed 15 years ago when I was 15 so I thought it should be a good starting project I could learn from. I will design one of Troels fantastic floorstanders when I get educated enough.

I thought Harbeth use 12mm plywood walls in a lot of there loudspeaker designs? The Harbeths do vibrate a lot but still sound lively with curtain music. Harbeth also use bitumen or rubber walls though and some have Seas drivers with similar size cabs and baffles to mine. My intention was to sound proof the cabs as much as possible, and being 18mm MDF plus 3.6mm plywood skin I don't think the cabs will sound like Harbeths.

It's a very nice cabinet from the look of it.

Are we going to see a crossover schematic soon? That always interests me. I did a 6" two way recently, and it's not as easy as you might think. My next version of the crossover will get a bigger 2.2mH bass coil and a higher impedance at the top based on experience. The 5kHz LCR notch seems OK.

But I rubber damped the side and top and bottom panels. It's a good idea.

Are we going to see a crossover schematic soon? That always interests me. I did a 6" two way recently, and it's not as easy as you might think. My next version of the crossover will get a bigger 2.2mH bass coil and a higher impedance at the top based on experience. The 5kHz LCR notch seems OK.

But I rubber damped the side and top and bottom panels. It's a good idea.

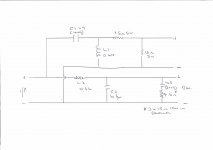

Get ready to laugh at the crossover I got from the suppliers (never again)...

As you can see the 0.86mH inductor is too small to start with therefore a new design is needed. I was thinking of a 2.2uF to start with myself. I don't really want resistors on the woofers though if possible. I've had several reads on the great thread... http://www.diyaudio.com/forums/mult...designing-crossovers-without-measurement.html

Am going to focus on completing the baffles first, the crossovers are external anyway so makes it easy enough.

BTW, each cab weighs 11.2kg with drivers and a x-over sat on top, pretty heavy, will use 18mm birch ply instead of MDF next time, will also post my friends Seas 2-ways with 5" woofers, curved cabs, gorin's x-over soon as its complete, must say their stronger than mine and much more good time taken.

As you can see the 0.86mH inductor is too small to start with therefore a new design is needed. I was thinking of a 2.2uF to start with myself. I don't really want resistors on the woofers though if possible. I've had several reads on the great thread... http://www.diyaudio.com/forums/mult...designing-crossovers-without-measurement.html

Am going to focus on completing the baffles first, the crossovers are external anyway so makes it easy enough.

BTW, each cab weighs 11.2kg with drivers and a x-over sat on top, pretty heavy, will use 18mm birch ply instead of MDF next time, will also post my friends Seas 2-ways with 5" woofers, curved cabs, gorin's x-over soon as its complete, must say their stronger than mine and much more good time taken.

Attachments

Last edited:

Hmm, a bit bass light and shouty in the midrange vocals I think. Very flat impedance so maybe a valve design....

Of course SEAS give you the Idunn design. 2.2mH plus 10uF shunt at 2.2kHz. You'd need to tweak that to allow for a regular tweeter rather than the DXT.

I expect you'll have fixed the broken link in your post. Nothing wrong with resistors in a bass shunt. You need them badly sometimes with small coils or for gentler rolloff or good phase. But the bass unit is very low Le inductance, so maybe not this time.

Of course SEAS give you the Idunn design. 2.2mH plus 10uF shunt at 2.2kHz. You'd need to tweak that to allow for a regular tweeter rather than the DXT.

I expect you'll have fixed the broken link in your post. Nothing wrong with resistors in a bass shunt. You need them badly sometimes with small coils or for gentler rolloff or good phase. But the bass unit is very low Le inductance, so maybe not this time.

Thanks again Steve, I have corrected the link.

Yes bass light and a bit of sibilance around 4k.

I'll get my measurement equipment and software sorted then get them sounding much better, my baffle will have rounded edges and flush mounted drivers which will improve them again at HF and ready for new x-over.

Yes bass light and a bit of sibilance around 4k.

I'll get my measurement equipment and software sorted then get them sounding much better, my baffle will have rounded edges and flush mounted drivers which will improve them again at HF and ready for new x-over.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- First pics of first build Seas 2-ways. Seas U18RNX/P, Seas 27TBFC/G.