Hi guys,

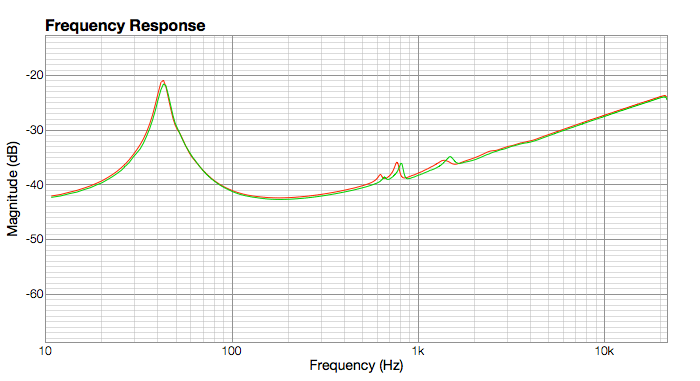

Just measured two KEF B139 SP1044 I had found in the basement:

Looks like fs is 43Hz. That's pretty far from the specified 25Hz. Is it time to let them go?

Just measured two KEF B139 SP1044 I had found in the basement:

Looks like fs is 43Hz. That's pretty far from the specified 25Hz. Is it time to let them go?

Attachments

New Life for wintage Audio Gear

Hello markus76,

A friend of mine have LINN ISOBARIC PMS speakers and he noticed after a long time of no use his main speakers due to some higher reasons (he move to a new finished house) - the speakers were playing a very thin sound overall and the worst of it, the bass was without any kind of extension - thin and boring.

He think to sell all the old stuff and go for something new. He invite me to come to his new place and while we listening the music (Linn LP12 as a source) I was really disappointing of his systems weak sound.

Than I remember my old friends words that rubber in a phono cartridge which keep the cantilever in its place become to loose its elastic properties. So I use the very thin wooden toothpick slightly round its nib put some thin film of a glycerine's oil on it and do some light, very precise rubber massage all around cantilever - The repeat listening test was a shock for bot of us Sound was become very enjoyable & listeneable.

Sound was become very enjoyable & listeneable.

From this experience learned I suggest him to use a Glycerin oil (a solution for external treatment of a car tires) to apply it on all speakers rubber surrounds (outer & inner) and at the theirs spiders too. He did it and then run all mid ranges and woofers for a a week with running a slow sweep from 10Hz to 250Hz 5 mm PP in a basement - (PC generated and ser + parallel connected driven with one NAP135) (Speakers were removed from encl. and were run in a free air). After the speakers were treated this way he put all of the speakers back to the encl. After the first play of some music he was so unbelievable surprised of the nice & pleasant sound that he come to pick me up after my job and insist I have to hear the beauty of the sound he have now.

Yes we spend all the afternoon and almost all night absorbing LP after LP and we were really enjoy that happening . . .

He is happy now and he will keep the old fashioned audio gear at his new home until last.

He is happy now and he will keep the old fashioned audio gear at his new home until last.

Now I wonder to suggest to You to try the same with Yours KEFs and I'm sure You won't be disappointed

They will return You the joy they were designed to.

With my best regards,

Andreas

Hi guys,

Just measured two KEF B139 SP1044 I had found in the basement: Looks like fs is 43Hz. That's pretty far from the specified 25Hz. Is it time to let them go?

Hello markus76,

A friend of mine have LINN ISOBARIC PMS speakers and he noticed after a long time of no use his main speakers due to some higher reasons (he move to a new finished house) - the speakers were playing a very thin sound overall and the worst of it, the bass was without any kind of extension - thin and boring.

He think to sell all the old stuff and go for something new. He invite me to come to his new place and while we listening the music (Linn LP12 as a source) I was really disappointing of his systems weak sound.

Than I remember my old friends words that rubber in a phono cartridge which keep the cantilever in its place become to loose its elastic properties. So I use the very thin wooden toothpick slightly round its nib put some thin film of a glycerine's oil on it and do some light, very precise rubber massage all around cantilever - The repeat listening test was a shock for bot of us

From this experience learned I suggest him to use a Glycerin oil (a solution for external treatment of a car tires) to apply it on all speakers rubber surrounds (outer & inner) and at the theirs spiders too. He did it and then run all mid ranges and woofers for a a week with running a slow sweep from 10Hz to 250Hz 5 mm PP in a basement - (PC generated and ser + parallel connected driven with one NAP135) (Speakers were removed from encl. and were run in a free air). After the speakers were treated this way he put all of the speakers back to the encl. After the first play of some music he was so unbelievable surprised of the nice & pleasant sound that he come to pick me up after my job and insist I have to hear the beauty of the sound he have now.

Yes we spend all the afternoon and almost all night absorbing LP after LP and we were really enjoy that happening . . .

Now I wonder to suggest to You to try the same with Yours KEFs and I'm sure You won't be disappointed

They will return You the joy they were designed to.

With my best regards,

Andreas

After applying glycerine to the upper part of one of the rubber surrounds, fs dropped already by 3Hz. Only 15Hz to go

Dear Markus,

Please do as follow:

Put very small amount of the Gl. solution on Yours 1.st an 2.nd finger then go with both of them over ext. Alu spkr frame one finger at the outer top half of rubber surround and the 2.nd. finger to inner lover half part of the surround now touch with both fingers the rubber surround and lightly tightly circle fingers together to apply the ''Massage'' to the both sides of the rubber surround at once - With left hand secure the membrane to not move excessively - and please be careful to not apply the solution to the Styrofoam couse it might evaporate latter .... Go this way all around to come to the start position. This is necessary to assure the solution to go as deeply as possible in to the rubber surround

With my best regards,

Andreas

Hi Markus,

This what I wrote in a B 139 thread some years ago. Your experience seems to match mine.

Welcome to the wonderful world of KEF in de late seventies/early eighties. QC either absent or on sick leave.

I owned a number of B 139 's with Fs around 36 and 40 Hz (!) and rubbing VC's at any level over 2-3 Volts driving voltage. Cones were not flatly glued in place..

They worked reasonably well in my Chris Rogers' Practical Hifi ' PRO 9 TL, but in terms of build quality, power handling plus specs they were definitely not something to write home about.

Hope you have more luck with your samples.

Regards,

Eelco

This what I wrote in a B 139 thread some years ago. Your experience seems to match mine.

Welcome to the wonderful world of KEF in de late seventies/early eighties. QC either absent or on sick leave.

I owned a number of B 139 's with Fs around 36 and 40 Hz (!) and rubbing VC's at any level over 2-3 Volts driving voltage. Cones were not flatly glued in place..

They worked reasonably well in my Chris Rogers' Practical Hifi ' PRO 9 TL, but in terms of build quality, power handling plus specs they were definitely not something to write home about.

Hope you have more luck with your samples.

Regards,

Eelco

QC either absent or on sick leave.

Eelco

Hi,

The KEF Constructor series of drivers were simply the rejects.

rgds, sreten.

Just cleaned the rubber surround of the other driver with a damp cloth. Just water, no glycerine. The effect on fs is nearly the same. So I guess it's not the glycerine causing the lower fs.

Hello Markus,

The full and long term effect would be achieved only if the steps in #5 would be as closely followed, otherwise this would be only partial result and for a very short time period.

With my best regards,

Andreas

Hello Markus,

The full and long term effect would be achieved only if the steps in #5 would be as closely followed, otherwise this would be only partial result and for a very short time period.

With my best regards,

Andreas

Not sure about the spider - where would you apply the glycerine?

Any thoughts as to how glycerine affects rubber and spider?

I had two B139s which had more or less self destructed because the polystyrene foam had separated from the voice coil; furthermore the foam seemed to have developed internal cracks in the body of the foam resulting in wrinkles in the foam "cover" (which I think was a stressed, very thin, aluminum foil). So I also injected glu into the cracks and recovered the foil with a very thin, stressed, epoxy impregnated fiberglass cloth, and coated that cloth with a rubbery compound that I had on hand. These repairs worked out very well and all seemed fine until I measured the driver and found that the compliance had decreased significantly over rated spec. This was despite the increase in weight due to the fiberglass epoxy skin. At this point I was thinking it is time for this driver to go (and still think so) but I searched around and found a suggestion to use transmission fluid on the rubber surround (I repeated this over the course of a week and kept the speaker powered at roughly resonance on the theory that that might warm the surround up a bit and help to work the fluid in). That did, in fact, lower fs significantly. I used transmission fluid because, I read, it contains compounds used to keep seals in transmissions soft and compliant.

Somewhere I have the final parameters that the driver ended up with. As I recall, however, with all the changes Qts had increased a bit too much for the 62 liter box I had the speakers in, so I converted it from a vented to a closed box. The predicted 3 db response, if memory serves, was a bit below 40 hz-about 38 I think, with a system Q of a bit less than 1. As might be expected from a closed box design with these specs, low frequency extension is adequate if not subterranean.

The driver sounds pretty good now, but, the B139 never had a very high efficiency and my mods just made that worse. Nonetheless, it was an interesting experiment. If I hadn't made the changes I did I would have had to discard the driver. It stresses my much modded DH-200 a loud volumes a bit too much (sounds wonderful at medium volumes) but is serviceable until I get around to building a new system. If the glycerin doesn't work for you, give transmission fluid a try.

Somewhere I have the final parameters that the driver ended up with. As I recall, however, with all the changes Qts had increased a bit too much for the 62 liter box I had the speakers in, so I converted it from a vented to a closed box. The predicted 3 db response, if memory serves, was a bit below 40 hz-about 38 I think, with a system Q of a bit less than 1. As might be expected from a closed box design with these specs, low frequency extension is adequate if not subterranean.

The driver sounds pretty good now, but, the B139 never had a very high efficiency and my mods just made that worse. Nonetheless, it was an interesting experiment. If I hadn't made the changes I did I would have had to discard the driver. It stresses my much modded DH-200 a loud volumes a bit too much (sounds wonderful at medium volumes) but is serviceable until I get around to building a new system. If the glycerin doesn't work for you, give transmission fluid a try.

Not sure about the spider - where would you apply the glycerine?

Any thoughts as to how glycerine affects rubber and spider?

Hello Markus76,

Been off my place for a few days, now I'm back.

Only the glycerin has the most positive effect to a rubber surround as make it more flexible and prevent its wearing,

best side effect is improving prolonged term rubber elastic properties => for speaker it is alo a lover FS - also as a result - more subtle Bass details can be obtained, the same is valid for all speakers drives containing Rubber Surrounds - The same effect is valid for Mid-Bass and Mid-Range drivers

For Glycerin how to apply it to speakers Spiders - the Glycerin should be applied only to a waved piece of the spider or some 5 mm away from where the spider is glued to the voice coil former and apply all the way to the outer side,

some 5mm away from outer chassis where the spider is glued to chassis.

The key point is that spider become more flexible - less mech. noise and the membrane much easier follow the 1/16 - 1/32th of a musical note - More subtle details - more smaller movements of membrane = more subtle higher harmonics been reproduced - more life - like sound achieved - The Linn PMS Isobarics sound better than ever before at my friends place.

With my best regards,

Andreas

Looks like mine settled around 33Hz after the glycerine treatment. Not the advertised 25Hz but about 10Hz better than a week ago.

Hello Markus76,

The Linn Isobarics PMS (active) which was treated with Glycerin are now singing as newer before

I couldn't believe my ears . .

The treatment was a miracle for the KEF 139 and B110 drivers in those cabinets.

It was a no cost treatment and the results are way better than imaginable.

Perhaps those 139s used by LINN have for sure best specs KEF was able to make at that time, I'm not sure the for the difference comparing to speakers made by KEF for the Diy use

With my best regards,

Andreas

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- KEF B139 SP1044 fs 43Hz?