Somewhere in this forum (Voodoo something) someone has build a isobarik or push pull sub with two 8" drivers and two of the larger bowls.

It is push-push.

http://www.diyaudio.com/forums/multi-way/80899-voodoo-vibration-loudspeakers-7.html#post989942

dave

An externally hosted image should be here but it was not working when we last tested it.

if I were to do this again, I would seriously consider attaching the drive unit and fittings to the "wagon wheel" spine.An externally hosted image should be here but it was not working when we last tested it.

Then attach the bowls flexibly (silicone?) to this spine and around the driver. This would minimise the effect of any slight mismatch in the Blanda wooden bowls and there will be some, I'll go bail on that.

Yes, I do know that my workmanship is firmly in the "what the eye don't see, the heart don't grieve about" school of fine cabinetwork. These guys are as much getting up to speed on basic speaker building before spending serious money and messing up the good stuff.

Steve

Hi all,

I took part in a furniture exhibition with 14 other people in Bristol, Uk.

Some photos are trickling in over flickr, with only my salad bowl speakers on there as of today

(missing their tweeters as they are still just floating on top and look a bit out of sorts):

Flickr: furnish furniture exhibition's Photostream

Some more info on my making can be found at:

Studio Au

I took part in a furniture exhibition with 14 other people in Bristol, Uk.

Some photos are trickling in over flickr, with only my salad bowl speakers on there as of today

(missing their tweeters as they are still just floating on top and look a bit out of sorts):

Flickr: furnish furniture exhibition's Photostream

Some more info on my making can be found at:

Studio Au

We used a template and centered by eye, so it was not perfectly true.

A friend got his done by CMM scanning & then CNC milling. It is perfect.

Cost N times more than the bowls themselves though.

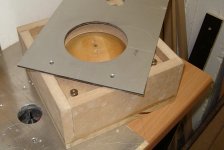

The "stand" was actually a sealed box for W6-1139 as sub to go with the sphere (for my study).

We borrowed them to make the pictures.

The spheres will get properly built stands eventually which are not as "fat".

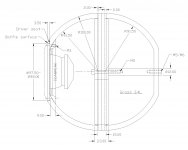

The ring in the middle is machine from solid aluminium.

Shown here is a different version with a different chassis.

But you get the idea.

I myself am not using the tie bar to the rear.

We should consider making the rings available if there would be sufficient interest.

Patrick

A friend got his done by CMM scanning & then CNC milling. It is perfect.

Cost N times more than the bowls themselves though.

The "stand" was actually a sealed box for W6-1139 as sub to go with the sphere (for my study).

We borrowed them to make the pictures.

The spheres will get properly built stands eventually which are not as "fat".

The ring in the middle is machine from solid aluminium.

Shown here is a different version with a different chassis.

But you get the idea.

I myself am not using the tie bar to the rear.

We should consider making the rings available if there would be sufficient interest.

Patrick

Attachments

Last edited:

Having checked through the photos in the forum, I realised that we are the only one with flush mounted chassis flanges for the IKEA bowls.

I am of course not counting those using custom-made solid-wood spheres.

A month or so ago, a German DIY magazine was offering solid wood spheres for a project.

I think there were 12~15cm diameter.

Guess how much? 240 Euro per piece.

Very well made.

But too much for a "kitchen radio" speaker, for me at least.

Patrick

I am of course not counting those using custom-made solid-wood spheres.

A month or so ago, a German DIY magazine was offering solid wood spheres for a project.

I think there were 12~15cm diameter.

Guess how much? 240 Euro per piece.

Very well made.

But too much for a "kitchen radio" speaker, for me at least.

Patrick

Hi Patrick

Do you have an estimate for the spacer rings? How do you fix the spheres to the alu spacer? Epoxy glue?

Did you grind the bowl end first to make it go flush to the spacer? My bowls are slightly oval and not of even height.

The idea with the aluminium plate that you lower onto the sphere to cut some off is very nice... I'm stealing that

Routing the edge for the driver to be flush mount (which is the point with this baffe) is more of a challenge. Still contemplating how to do this with normal router atm.

Do you have an estimate for the spacer rings? How do you fix the spheres to the alu spacer? Epoxy glue?

Did you grind the bowl end first to make it go flush to the spacer? My bowls are slightly oval and not of even height.

The idea with the aluminium plate that you lower onto the sphere to cut some off is very nice... I'm stealing that

Routing the edge for the driver to be flush mount (which is the point with this baffe) is more of a challenge. Still contemplating how to do this with normal router atm.

> Do you have an estimate for the spacer rings?

Yes, but with the 4 spokes they are currently too expensive (> 10x the cost of one bowl). So we are still changing the design to cut cost. It will be much less if it were an "empty" ring, though it is still cut from a solid plate. And you can calculate the raw material cost alone yourself.

Unfortunately no easy way out.

The real function of the rring is to make the two halves into a complete sphere (the bowls ate 20cm dia but < 9.5cm high which varies from bowl to bowl). Also it provide extra contact surfaces for gluing (lap joint rather than butt joint).

> How do you fix the spheres to the alu spacer? Epoxy glue?

Yes, but silicone will also do.

> Did you grind the bowl end first to make it go flush to the spacer?

Yes, but not grind; rather mill.

> My bowls are slightly oval and not of even height.

We brought alone a template to IKEA and picked 4 from 20+ on the shelf that day, also matching the colour in the process.

> The idea with the aluminium plate that you lower onto the sphere to cut some off is very nice... I'm stealing that

I expected that when I posted.

> Routing the edge for the driver to be flush mount (which is the point with this baffe) is more of a challenge.

Not if you have the router built into a milling table (tool pointing up), and then holding the bowl with the 20cm diameter down with a wooden fixture (as shown in post 208 but with the bowl the other way round). You only need to drill 2 holes on the bowl bottom for that. We use them later on as feed-throughs for the speaker terminals.

QED.

Patrick

Yes, but with the 4 spokes they are currently too expensive (> 10x the cost of one bowl). So we are still changing the design to cut cost. It will be much less if it were an "empty" ring, though it is still cut from a solid plate. And you can calculate the raw material cost alone yourself.

Unfortunately no easy way out.

The real function of the rring is to make the two halves into a complete sphere (the bowls ate 20cm dia but < 9.5cm high which varies from bowl to bowl). Also it provide extra contact surfaces for gluing (lap joint rather than butt joint).

> How do you fix the spheres to the alu spacer? Epoxy glue?

Yes, but silicone will also do.

> Did you grind the bowl end first to make it go flush to the spacer?

Yes, but not grind; rather mill.

> My bowls are slightly oval and not of even height.

We brought alone a template to IKEA and picked 4 from 20+ on the shelf that day, also matching the colour in the process.

> The idea with the aluminium plate that you lower onto the sphere to cut some off is very nice... I'm stealing that

I expected that when I posted.

> Routing the edge for the driver to be flush mount (which is the point with this baffe) is more of a challenge.

Not if you have the router built into a milling table (tool pointing up), and then holding the bowl with the 20cm diameter down with a wooden fixture (as shown in post 208 but with the bowl the other way round). You only need to drill 2 holes on the bowl bottom for that. We use them later on as feed-throughs for the speaker terminals.

QED.

Patrick

Attachments

Last edited:

Great idea to level the pieces that is going to be glued together, but I meant how you routed for flush mounting the driver as the router has nothing to guide it due to the side walls being a sphere.

Regarding the alu spacer I suspected as much. I have been contemplating using a piece of thin steel sheet, cut to dimensions and welded together as a cheapo solution

Regarding the alu spacer I suspected as much. I have been contemplating using a piece of thin steel sheet, cut to dimensions and welded together as a cheapo solution

The hole on the aluminium plate in post #208 is the guide. Every hand mill have one of those flanged cylindrical guides that can be latched on and sits above the cutter outside the shaft.

Pls google to see how you mill holes.

If you can mill holes you can also mill the recess for the flange.

Or I did not understand your question at all.

Alu ring looks great, so for me no substitute.

Before you use steel, I would say you should consider using a dark wood like akazius for the ring. Would probably be the lowest cost solution that still looks good.

If you just want Alu ring without the spikes, the price could be almost halved (shipment on top).

Patrick

Pls google to see how you mill holes.

If you can mill holes you can also mill the recess for the flange.

Or I did not understand your question at all.

Alu ring looks great, so for me no substitute.

Before you use steel, I would say you should consider using a dark wood like akazius for the ring. Would probably be the lowest cost solution that still looks good.

If you just want Alu ring without the spikes, the price could be almost halved (shipment on top).

Patrick

My little project is finally completed with a small amplifier based on LM3886 in a strainer case:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

You went from:

to these cool yellow speakers and amp. Very nice work. Bravo!humm... I think I'm gonna visit Ikea soon...

- Home

- Loudspeakers

- Multi-Way

- Ikea spherical speakers, first build done.