So I made some guitar cab inspired speakers with 12” coaxial from Eminence. The cabinets are 60x40x30cm and build in pine. I made rounded edges and painted it black but now I want to do something else. Maybe some fake leather of sorts. Any good ideas where to look and tips for how to go on with edges etc?

I found this pic online and found it pretty cool:

I found this pic online and found it pretty cool:

Would be good to say where you are. Tolex rolls tend to be large so you want to watch shipping costs.

tolex for guitar amps and speaker cabinets

Python snakeskin pattern tolex in Electric Blue

Tolex/Grill Cloth – tagged "tweed-and-tolex" – Allparts UK

Tolex & Tweed - Canada

Grill Cloth, Tolex & Piping - Tolex, Type | Amplified Parts

I used search "guitar cabinet snakeskin yard" because this stuff is common on g-cabs. You said snakeskin but other flavors will be in the same sites. "yard" filters-out complete cabinets giving more of the raw fabric. (That even worked in the UK, but if you are in a truly Metric market you can try meter. Complete amps mostly don't have yards or meters.)

You find similar stuff under "upholstery". There are some pretty eye-popping "20th century kitchen" chair patterns, and you may have an upholstery shop and its catalogs in your town. Fabric stores too.

tolex for guitar amps and speaker cabinets

Python snakeskin pattern tolex in Electric Blue

Tolex/Grill Cloth – tagged "tweed-and-tolex" – Allparts UK

Tolex & Tweed - Canada

Grill Cloth, Tolex & Piping - Tolex, Type | Amplified Parts

I used search "guitar cabinet snakeskin yard" because this stuff is common on g-cabs. You said snakeskin but other flavors will be in the same sites. "yard" filters-out complete cabinets giving more of the raw fabric. (That even worked in the UK, but if you are in a truly Metric market you can try meter. Complete amps mostly don't have yards or meters.)

You find similar stuff under "upholstery". There are some pretty eye-popping "20th century kitchen" chair patterns, and you may have an upholstery shop and its catalogs in your town. Fabric stores too.

Last edited:

I found this to be a good guide for doing speaker cab coverings:

https://metrodcmusic.com/blogs/guitar-kit-builder-amplifiers/how-apply-tolex-guitar-amplifier-cabinet

https://metrodcmusic.com/blogs/guitar-kit-builder-amplifiers/how-apply-tolex-guitar-amplifier-cabinet

Most people use weldwood contact adhesive.

You can also cover both surfaces with weldwood as normal

and use 3M contact spray on the material side for a super bond.

There is various methods of cutting the seam, usually put on the bottom of the cab

Also various ways used to cut angles for the corners.

Do a search on youtube for " How to tolex a guitar cabinet "

How to Cover a Cabinet with Tolex or Leatherette.....Part 1 - YouTube

You can also cover both surfaces with weldwood as normal

and use 3M contact spray on the material side for a super bond.

There is various methods of cutting the seam, usually put on the bottom of the cab

Also various ways used to cut angles for the corners.

Do a search on youtube for " How to tolex a guitar cabinet "

How to Cover a Cabinet with Tolex or Leatherette.....Part 1 - YouTube

...Do you know any such forums? I have been googling quite a bit but struggle to find anything sensible. ....

There are many.

The Gear Page

Amp Maker: Guitar amp kits

AMPAGE - Tube Amps / Music Electronics

The AX84 Project

Forums - Music Electronics Forum

https://www.tdpri.com

https://ampgarage.com

https://el34world.com/Forum/index.php

https://www.ssguitar.com

https://www.buildyourownguitar.com.au -- amplifier section

https://www.wattkins.com

https://www.guitargearforum.com

https://www.rig-talk.com

https://www.strat-talk.com › Forums › DIY Channel

https://bb.steelguitarforum.com

https://www.18watt.com

https://www.ax84.com

https://www.talkbass.com

https://ozvalveamps.org

vendors

https://www.tedweber.com

https://www.parts-express.com

https://www.mojotone.com

I would be cautious mixing brands of glue, they can have differences in their solvents that can lead to bad results.

This was a mock-up built for the purpose of gaining a contract that has so far realized $195 billion in revenue.

I was chosen to design and build this in a very short time, and that adhesive #*~+ up was the only hitch.

After my experience, I contacted 3M, who’s chemists told me to basically never to mix anything else with their specific adhesive that I was using. So unless you know for certain…

This was a mock-up built for the purpose of gaining a contract that has so far realized $195 billion in revenue.

I was chosen to design and build this in a very short time, and that adhesive #*~+ up was the only hitch.

After my experience, I contacted 3M, who’s chemists told me to basically never to mix anything else with their specific adhesive that I was using. So unless you know for certain…

Yes glue is a topic of its own I guess. Do you know any such forums? I have been googling quite a bit but struggle to find anything sensible. Talk-bass had some.

1) state your Country

Suggestions vary A LOT depending on where you are.

2) use solvent based contact cement, the kind you buy in a 4 liter can and apply with a fine toothed spatula/notched trowel.

You can use a medium sized short hard bristle brush to apply it to inside corners , along internal mounting cleats, etc. where trowel is impractical, but immediately after use wet it with solvent.

I keep my brushes inside cylindrical cookie tins with 1 cm or two of solvent at the bottom, metal is best barrier against evaporation, plastic is porous to Toluene/Xylene.

Forget water/"green"/"ecological" type adhesives.

Follow manufacturer´s instructions,including timing, ambient temperature and humidity, ventilated space but avoid drafts and sunlight, etc.

3) it´s a good idea to also buy a small can (250-500 cc) of factory recommended cement solvent to clean tools, spills, etc.

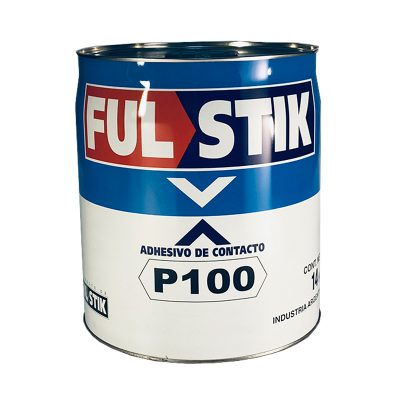

4) I suggest this brand, unless unavailable in your Country,Mother Company is British (EVO STIK):

Small World, I am NOW tolexing 2 Keyboard amplifier cabinets, go figure.

Over 14000 so far.

Last edited:

Small World, I am NOW tolexing 2 Keyboard amplifier cabinets, go figure.

Over 14000 so far.

That's not bad out of one tin

You should have seen the size of the BRUSH!That's not bad out of one tin

- Home

- Live Sound

- Instruments and Amps

- Advice on cab finish?