Hi,

I have a Dean Markley T120R head, which I've owned for several years, inherited from my late father.

I just switched it on tonight, and had a noodle for 15mins, and at this point the amplifier started popping or cracking very badly.

I have to admit at first I thought it was the Master volume pot, which crackles near the low end of its range. I figured the vibration was enough to make the pot crackle.

If I back off the gain, and move the Master pot to a higher level, it still occurs. It's a loud enough crackle for me to suspect the 4x10" speakers are clapping off the magnet pole piece.

The amplifier had odd pairing of tubes in the output stage when I got itz and has had all 4 6L6GC replaced with new (NOS). The preamp tubes are original GE electronic 12AX7.

Electrolytics have been on the to-do list for replacement, nt changed out due to lack of time at home, but I have replacements ready.

Has anyone got an idea what would cause this full volume popping sound?

I appreciate that schematics would be useful, but there is only fragmented schematics available.

Any help with 'likely suspects' for failure would be brilliant, and thanks in advance for any help.

I'm absolutely gutted and fearful to switch it back on, and blow the rather expensive quad of greenbacks

I have a Dean Markley T120R head, which I've owned for several years, inherited from my late father.

I just switched it on tonight, and had a noodle for 15mins, and at this point the amplifier started popping or cracking very badly.

I have to admit at first I thought it was the Master volume pot, which crackles near the low end of its range. I figured the vibration was enough to make the pot crackle.

If I back off the gain, and move the Master pot to a higher level, it still occurs. It's a loud enough crackle for me to suspect the 4x10" speakers are clapping off the magnet pole piece.

The amplifier had odd pairing of tubes in the output stage when I got itz and has had all 4 6L6GC replaced with new (NOS). The preamp tubes are original GE electronic 12AX7.

Electrolytics have been on the to-do list for replacement, nt changed out due to lack of time at home, but I have replacements ready.

Has anyone got an idea what would cause this full volume popping sound?

I appreciate that schematics would be useful, but there is only fragmented schematics available.

Any help with 'likely suspects' for failure would be brilliant, and thanks in advance for any help.

I'm absolutely gutted and fearful to switch it back on, and blow the rather expensive quad of greenbacks

Thanks peeps!

I was scouring you tube watching vids of popping tube amps last night.

I guess I came across similar conclusions:

Anode resistor in preamp section.

Cathode resistor in preamp section.

PSU caps

Coupling capacitor perhaps leaky

Corrosion

Cathode resistor in power section (have to check schematic)

Bad tube/s.

If the latter I will be truly hacked off.

The matched quad of 7581a cost in the region of £300 GBP from a so called reputable tube store.

They've seen less than 100 hours, the ones they replaced were unmatched and worked effortlessly for 10 years, and many hundreds of hours, and still functioned perfectly when I sold them.

Why did I sell them? Hindsight...I would say it was a wonderful thing, just the devil on the shoulder saying "told you so"

I was scouring you tube watching vids of popping tube amps last night.

I guess I came across similar conclusions:

Anode resistor in preamp section.

Cathode resistor in preamp section.

PSU caps

Coupling capacitor perhaps leaky

Corrosion

Cathode resistor in power section (have to check schematic)

Bad tube/s.

If the latter I will be truly hacked off.

The matched quad of 7581a cost in the region of £300 GBP from a so called reputable tube store.

They've seen less than 100 hours, the ones they replaced were unmatched and worked effortlessly for 10 years, and many hundreds of hours, and still functioned perfectly when I sold them.

Why did I sell them? Hindsight...I would say it was a wonderful thing, just the devil on the shoulder saying "told you so"

One important thing about tube audio, particularly "vintage" audio.

It's an expensive adventure, because of the insane costs of tubes (mostly NOS brands) and having mandatory restoration done.

The other thing about vintage tube audio, just because the tubes are easily replaceable, doesn't mean replacement of weak or bad tubes will cure the problem(s).

Tubes rely on the circuits themselves in order to operate properly, and within their design specifications.

Merely replacing a bad or weak tube might "help" things, bring back operation, but if the circuitry isn't in proper shape, that tube will not last long if it's being abused by its circuitry.

And since in a lot of cases this equipment was designed around a specific AC line voltage that was "the normal" at the time, an increase, such as common today, will also run tubes into "hard use" - 115/117 volts equipment when used on 120/125 volts is an increase around 6 percent, and a DC power supply of 350 volts can rise to 400 volts easily, stressing resistors, capacitors, and tubes - obviously shortening the life of tubes.

So in that case, certain "modifications" must be done to bring back normal operation.

People wonder why a given tube "redplates" and cooks to failure.

It's an expensive adventure, because of the insane costs of tubes (mostly NOS brands) and having mandatory restoration done.

The other thing about vintage tube audio, just because the tubes are easily replaceable, doesn't mean replacement of weak or bad tubes will cure the problem(s).

Tubes rely on the circuits themselves in order to operate properly, and within their design specifications.

Merely replacing a bad or weak tube might "help" things, bring back operation, but if the circuitry isn't in proper shape, that tube will not last long if it's being abused by its circuitry.

And since in a lot of cases this equipment was designed around a specific AC line voltage that was "the normal" at the time, an increase, such as common today, will also run tubes into "hard use" - 115/117 volts equipment when used on 120/125 volts is an increase around 6 percent, and a DC power supply of 350 volts can rise to 400 volts easily, stressing resistors, capacitors, and tubes - obviously shortening the life of tubes.

So in that case, certain "modifications" must be done to bring back normal operation.

People wonder why a given tube "redplates" and cooks to failure.

First suspect is a bad connection, dry solder joint, coroded socket, though other components can also produce this.

Prodding with a (long insulated) stick can help identify which part of the circuit is popping, since its usually a mechanical failure that is sensitive to movement (and thus temperature changes).

Prodding with a (long insulated) stick can help identify which part of the circuit is popping, since its usually a mechanical failure that is sensitive to movement (and thus temperature changes).

That's precisely the thing.

Looking harder at what schematics I have (without cracking the case open just yet) the output stage is fixed bias, and appears no adjustment.

Previously the tubes were a pair of early ish Chinese 6L6GC and a pair of Phillip's ECG 6L6GC (actually identical to 7581a but not JAN, and consumer grade white printing)

The phillips ran cool, the Chinese junk red plated badly, still the amplifier worked, and seemed to work well.

They tubes got swapped out for a matched quad of 7581a. Now I have no red plating at all, much cooler overall, just as much punch and glorious tone.

I really need to just get the lid off, find a speaker load I dont mind destroying, and check for red plating in one or more tubes. Check rail volts, sockets, cold solder or bad joints.

I just hope I have the nouse to sort it, it's got to be the most complex tube circuit I have had to fix, to date. I started a thread on it a few years back when I inherited it. A few almost unobtainium parts, some parts completely irreplaceable.

Looking harder at what schematics I have (without cracking the case open just yet) the output stage is fixed bias, and appears no adjustment.

Previously the tubes were a pair of early ish Chinese 6L6GC and a pair of Phillip's ECG 6L6GC (actually identical to 7581a but not JAN, and consumer grade white printing)

The phillips ran cool, the Chinese junk red plated badly, still the amplifier worked, and seemed to work well.

They tubes got swapped out for a matched quad of 7581a. Now I have no red plating at all, much cooler overall, just as much punch and glorious tone.

I really need to just get the lid off, find a speaker load I dont mind destroying, and check for red plating in one or more tubes. Check rail volts, sockets, cold solder or bad joints.

I just hope I have the nouse to sort it, it's got to be the most complex tube circuit I have had to fix, to date. I started a thread on it a few years back when I inherited it. A few almost unobtainium parts, some parts completely irreplaceable.

I really need to just get the lid off, find a speaker load I dont mind destroying,

and check for red plating in one or more tubes.

Use a dummy 8R load. In parallel with that, add a 5k 1W resistor in series with a test speaker,

and the noise will be more tolerable until you fix it. The dummy load is in case the amplifier

requires a load for proper operation.

Last edited:

I second rayma's recommendation. In the past when I've had this same problem, it's been bad plate resistors (yes, as noted before, carbon comp can be the worst) and loose tube socket receptacles on power tubes, or less often, bad preamp tubes. I've not had any bad preamp tube plate resistors, and I would suggest focusing on the power tube section first.

In the past when I've had this same problem, it's been bad plate resistors

(yes, as noted before, carbon comp can be the worst)

A bad plate resistor ime usually makes more of a rustling sound, not loud pops.

To me, the noise sounds more like a dirty/bad pot or switch, or other contact.

Perhaps the circuit allows removing the small tubes, one at a time, starting at the

input and going toward the output. When/if the noise stops, look at that stage

more closely.

Last edited:

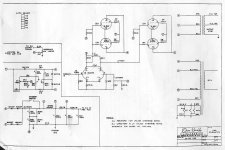

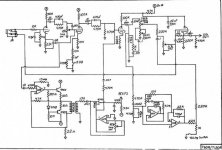

Hang on, I've found most of the schematics

Multiple fails, HDDs and mobile devices has meant I has lost all the schematics and info I'd picked up.

I know these aren't quite complete, but at least I have some more idea what I'm looking at.

To state the symptoms as clearly as I can, these were loud pops, way louder than the volume level of the guitar.

Not crackley, or rushing, just spurious pops say from maybe 1 a second to 3 a second.

I've worked in high voltage engineering for over a decade now, and I think that the sockets are the first stop.

I suspect tracking or arcing. Possibly a bad solder joint that arcs to the pin, or has a tracking path and high resistance connection.

Once a tracking path has been established, it only escalates from the resulting carbonisation so I should be able to see it.

Thanks all, sometimes having a little direction makes all the difference!

Now I just have to find my Allen keys

Multiple fails, HDDs and mobile devices has meant I has lost all the schematics and info I'd picked up.

I know these aren't quite complete, but at least I have some more idea what I'm looking at.

To state the symptoms as clearly as I can, these were loud pops, way louder than the volume level of the guitar.

Not crackley, or rushing, just spurious pops say from maybe 1 a second to 3 a second.

I've worked in high voltage engineering for over a decade now, and I think that the sockets are the first stop.

I suspect tracking or arcing. Possibly a bad solder joint that arcs to the pin, or has a tracking path and high resistance connection.

Once a tracking path has been established, it only escalates from the resulting carbonisation so I should be able to see it.

Thanks all, sometimes having a little direction makes all the difference!

Now I just have to find my Allen keys

Attachments

Last edited:

these were loud pops, way louder than the volume level of the guitar.

With the power off, you can pull the 12AX7 driver for the output tubes,

and see if the noise is gone. That will be a big help in localizing the problem.

The schematic cannot be completely correct, since there are no connections

to the cathodes of the output tubes. Perhaps they are all grounded.

Last edited:

I have a big enough dummy load (3 parallel 22R 100W), and it's simple

to a a series resistor upstream so I can still hear the fault....

Connect the dummy load directly to the output.

Also connect directly to the output, (i.e. in parallel with the load),

the series connected resistor and speaker.

Don't connect the 5k resistor between the output and the dummy load.

A bad plate resistor ime usually makes more of a rustling sound, not loud pops.

Perhaps the circuit allows removing the small tubes, one at a time, starting at the

input and going toward the output. When/if the noise stops, look at that stage

more closely.

Hmm. Now that I give this more thought, I've definitely had crackling with bad output tube plate resistors (first time 10 years ago with my old Acoustic 160, and once or twice with other amps since), but loud pops only with arcing of OP tube pins. Definitely though, a whooshing or rustling sound is the more common symptom I've had with power tubes.

Definitely agree with the sequential tube pulling...

Haha I had no intent on trying to drive watts through 5k!

And Yes!

It puzzled me why the cathode are just joined, but appear not to be referenced to ground.

I've pulled the tubes from the output, and all pins are shiny bright metal, sockets dont look too bad either, brown bakelite/tufnol? Not a trace of arcing topside.

When I check the underside, I'll have to see if the cathode really are just joined to each other!

And Yes!

It puzzled me why the cathode are just joined, but appear not to be referenced to ground.

I've pulled the tubes from the output, and all pins are shiny bright metal, sockets dont look too bad either, brown bakelite/tufnol? Not a trace of arcing topside.

When I check the underside, I'll have to see if the cathode really are just joined to each other!

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Live Sound

- Instruments and Amps

- Tube head crackle and pop after warm up