Do you know how much the administrative work costs to deal with one such small order ?

Surely it must be expensive if they pack every single transistor in a huge antistatic bag...

This one was with a bunch of other small transistors (and no I didn't order a single BC337.. go figure why this one was orphaned...) that I cleared from their stock, shipped in a separate parcel than my IRFP order! The value of the Fedex shipment was more than the value of parts (again.. why they made 2 deliveries is a mystery..)

Attachments

Last edited:

OK Ladies and Gentlemen,

Spent the whole day tinkering with the parts!

I am able to conclude and give you some pricing

First on the matching Yield:

The yield is pretty good: very few singles and I even got several sextets.

Temperature matching

I did some tests with temperature, and it is clear: parts that are matched at room temp stay matched at 60°C. Within less than 0.2%.

Actually my conclusion is that room temperature garantees temp stability way better than I may achieve without a professional equipment and rocket science temperature control.

Matching at room temperature is clearly more than good enough. In my opinion, it is actually better than risking to introduce some temp measurement error.

Matching methodology:

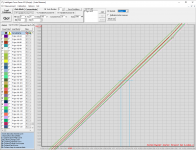

Firstly: I did a rough matching at 1.5A, with linear interpolation of Vgs between 2 measurement points to create groups within 0.02V (0.5%)

Secondly: I matched "by hand" (or rather by eye), part by part within consecutive groups to find the best matching between parts, with not only matching Vgs, but a nice overlapping curve => Quite often, the pure calculation of Vgs was not exactly perfectly "perfect": due to measurement dispersion at the Vgs spot, it can lead to ~0.2% error... by matching along the curve (up to 3A) I am confident that matching is done within 0.2% since I am using several points to "fit" so it cancels the error.

Due to the high number of parts, I did not run curve fitting algorithm to verify, but I think you may trust my objective subjectivity

The result:

I can guarantee accuracy within 0.5%. I am quite sure all parts are matched within 0.2%, but probably they are within 0.1% quite often

Spent the whole day tinkering with the parts!

I am able to conclude and give you some pricing

First on the matching Yield:

The yield is pretty good: very few singles and I even got several sextets.

Temperature matching

I did some tests with temperature, and it is clear: parts that are matched at room temp stay matched at 60°C. Within less than 0.2%.

Actually my conclusion is that room temperature garantees temp stability way better than I may achieve without a professional equipment and rocket science temperature control.

Matching at room temperature is clearly more than good enough. In my opinion, it is actually better than risking to introduce some temp measurement error.

Matching methodology:

Firstly: I did a rough matching at 1.5A, with linear interpolation of Vgs between 2 measurement points to create groups within 0.02V (0.5%)

Secondly: I matched "by hand" (or rather by eye), part by part within consecutive groups to find the best matching between parts, with not only matching Vgs, but a nice overlapping curve => Quite often, the pure calculation of Vgs was not exactly perfectly "perfect": due to measurement dispersion at the Vgs spot, it can lead to ~0.2% error... by matching along the curve (up to 3A) I am confident that matching is done within 0.2% since I am using several points to "fit" so it cancels the error.

Due to the high number of parts, I did not run curve fitting algorithm to verify, but I think you may trust my objective subjectivity

The result:

I can guarantee accuracy within 0.5%. I am quite sure all parts are matched within 0.2%, but probably they are within 0.1% quite often

Last edited:

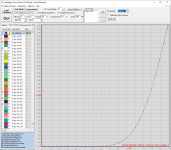

Here is what a sextet looks like (it's actually 7 parts, but they went so well together that I couldn't humanly separate them apart  ):

):

Look at the detail. There is 0.1% difference between min and max. So this one may well be within +/-0.05% from the average

For the record: I DO know the curve tracer is not lab equipment and there IS some measurement error, etc... But everything is very reproducible, so I do believe the statistical treatment more than compensate the equipment accuracy (those who have worked with measurement and statistics will know what I mean).

):

):Look at the detail. There is 0.1% difference between min and max. So this one may well be within +/-0.05% from the average

For the record: I DO know the curve tracer is not lab equipment and there IS some measurement error, etc... But everything is very reproducible, so I do believe the statistical treatment more than compensate the equipment accuracy (those who have worked with measurement and statistics will know what I mean).

Attachments

The Pricing

Here is the pricing:

Matched pairs: 11€

Matched Quads: 24€

Matched Sextets: 39€

and the matched Septet is available for 45.50€ if you feel like keeping a spare

+Packing and Shipping (within EU, it's your choice of tracked letter for 6.50€ or Express insured "Colissimo" for 13€, outside EU, ask by PM)

+Paypal Fee 5% (or 0€ if you "Send Money to Family or Friend" within the EU)

Please let me know what you want, with your real name and address by PM

Fred

Here is the pricing:

Matched pairs: 11€

Matched Quads: 24€

Matched Sextets: 39€

and the matched Septet is available for 45.50€ if you feel like keeping a spare

+Packing and Shipping (within EU, it's your choice of tracked letter for 6.50€ or Express insured "Colissimo" for 13€, outside EU, ask by PM)

+Paypal Fee 5% (or 0€ if you "Send Money to Family or Friend" within the EU)

Please let me know what you want, with your real name and address by PM

Fred

> Matching at room temperature is clearly more than good enough.

If you have the right equipment (temperature controlled heater block AND curve tracer in continuous mode, as in a Class A amp),

you will come to a different conclusion.

If you don't have those (Locky Z is NOT capable of continuous mode), then it does not really matter whether room temperature or not.

But your matching is then not identical to operating conditions.

Still better than none at all.

I really do not want to interfere.

But you make a statement which is NOT in line with our (considerable) matching experience.

So I need to set the record straight.

Cheers,

Patrick

If you have the right equipment (temperature controlled heater block AND curve tracer in continuous mode, as in a Class A amp),

you will come to a different conclusion.

If you don't have those (Locky Z is NOT capable of continuous mode), then it does not really matter whether room temperature or not.

But your matching is then not identical to operating conditions.

Still better than none at all.

I really do not want to interfere.

But you make a statement which is NOT in line with our (considerable) matching experience.

So I need to set the record straight.

Cheers,

Patrick

I really do not want to interfere.

But you make a statement which is NOT in line with our (considerable) matching experience.

So I need to set the record straight.

I don’t want to start an endless debate, but unless you are able to control the temperature at the same extreme accuracy in real life application as during your matching procedure, with the exact same measurement conditions, you end up with the same inaccuracy as with the Lockyz curve tracer.

Hence the “more than good enough” statement.

As I said before, I’m the engineer type, so I know where to stop when it comes to accuracy. To each their own approach/faith, sorry if I offended you.

As a side note, I’d sincerely be VERY interested to see how matched parts at room temperature behave so differently with 30 degrees temp elevation.

This is not my experience (at my modest level) on these parts (maybe other types behave differently)

I did several tests, measurements, etc and it was very repeatable: matched parts stay matched at all temperatures in the 0~60degC range. (I say that not to claim anything, but just to say that The increased representativity/accuracy I would get from matching at higher temp is not worth the effort. I did it Very carefully on a couple of parts for understanding purposes, but I won’t do it for 100!)

Having some experience with statistical treatment, I know for a fact that repetition compensates for inaccuracy.

In addition, Whatever absolute error the measurement equipment has is cancelled since we are doing a relative matching. For sure, absolute value may be off by 5%, but in most application we don’t care... it may be 20%, I would still be happy as long as the parts are matched.

Since you have equipment that I don’t, It would be great if you could share some of your considerable experience.

I can send a pair to you (for free

It would also illustrate how ”off” my matching is versus real lab equipment.

Last edited:

> unless you are able to control the temperature at the same extreme accuracy in real life application

0.1°C accurate enough?

The scientific explanation is simple.

You have demonstrated yourself that the device is sensitive to (substrate) temperature.

The substrate temperature for each device can be deduced from the case temperature (on the metal tag), the device dissipation, and the Rthjc.

The variable is Rthjc, which is NOT identical for each device, due to variation of silver epoxy thickness (+/-10%).

So two devices having the same case temperature does not mean they have the same substrate temperature.

It is perfectly fine to say that you match at room temperature to 0.xx%.

To say that it is even better than matching at operating conditions is simply not true.

We don't go into such trouble without reasons, especially when we are matching thousands of devices.

Of course you are entitled to your own opinion.

Signing off,

Patrick

0.1°C accurate enough?

The scientific explanation is simple.

You have demonstrated yourself that the device is sensitive to (substrate) temperature.

The substrate temperature for each device can be deduced from the case temperature (on the metal tag), the device dissipation, and the Rthjc.

The variable is Rthjc, which is NOT identical for each device, due to variation of silver epoxy thickness (+/-10%).

So two devices having the same case temperature does not mean they have the same substrate temperature.

It is perfectly fine to say that you match at room temperature to 0.xx%.

To say that it is even better than matching at operating conditions is simply not true.

We don't go into such trouble without reasons, especially when we are matching thousands of devices.

Of course you are entitled to your own opinion.

Signing off,

Patrick

To say that it is even better than matching at operating conditions is simply not true.

Did I say that ?

-NO

I said “my conclusion is that room temperature garantees temp stability way better than I may achieve without a professional equipment and rocket science temperature control.”

In other words I risk introducing more error by attempting to match at higher temp, so I prefer to not take the risk. (I NEVER said matching is not improved by controlling the variables ! Of course they are!)

Please accept my offer to draw curves on one of my matched pairs and we can discuss facts, not opinions.

> unless you are able to control the temperature at the same extreme accuracy in real life application

0.1°C accurate enough?

Most people won’t have that kind of temperature control in their amplifiers (=real life application).... I know I won’t

0.1°C accurate enough?

The scientific explanation is simple.

You have demonstrated yourself that the device is sensitive to (substrate) temperature.

The substrate temperature for each device can be deduced from the case temperature (on the metal tag), the device dissipation, and the Rthjc.

The variable is Rthjc, which is NOT identical for each device, due to variation of silver epoxy thickness (+/-10%).

So two devices having the same case temperature does not mean they have the same substrate temperature.

I think you’re missing the (other) elephant in the room...

I suppose you’re not drilling through the case to measure substrate Temperature ? (I didn’t see the holes in the Semisouth from the other GB...

So you are left with case temperature measurement which is as you said an approximation of substrate temperature... your 0.1 deg accuracy is meaningless in such conditions since there is so much variation (as you said) in epoxy thickness and Rthjc.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Group Buys

- NOS Harris IRFP9240s, Vgs matched quads and pairs [The Europe Group Buy]