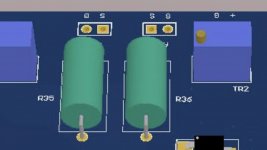

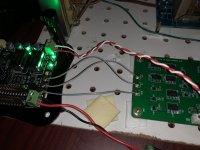

The D3, i2s2sim, ps boards were all tested and assembled by Ryan.

Pics attached

Pics attached

Attachments

-

C2DE09B1-80C2-4854-953B-6E668CBD729D.jpg763.7 KB · Views: 322

C2DE09B1-80C2-4854-953B-6E668CBD729D.jpg763.7 KB · Views: 322 -

66ECAC03-E4CA-4C0D-92C4-77CD316A491C.jpg812.7 KB · Views: 305

66ECAC03-E4CA-4C0D-92C4-77CD316A491C.jpg812.7 KB · Views: 305 -

AEF97D4E-8F6D-43EA-B269-D7669D7FE09D.jpg979.6 KB · Views: 298

AEF97D4E-8F6D-43EA-B269-D7669D7FE09D.jpg979.6 KB · Views: 298 -

9D15CAD3-D4CB-4EAC-ABFA-6F0E0CA4074B.jpg978.7 KB · Views: 296

9D15CAD3-D4CB-4EAC-ABFA-6F0E0CA4074B.jpg978.7 KB · Views: 296 -

B6B2C58C-DB19-4DEF-A3B9-38039B5AA3C7.jpg1,001.3 KB · Views: 280

B6B2C58C-DB19-4DEF-A3B9-38039B5AA3C7.jpg1,001.3 KB · Views: 280 -

4F57933A-201D-46BF-959D-20E0C177BE14.jpg992.6 KB · Views: 191

4F57933A-201D-46BF-959D-20E0C177BE14.jpg992.6 KB · Views: 191

Is it possible for you to test for sound directly out of the D3. Maybe try some 100ohm I/V resistors and then connect the D3 directly to a preamp and bypass your I/V stage. This will tell you if the output stage is the problem but be careful you will have to turn the volume way up to hear sound.

Mark K.

Mark K.

Hi Mark,

Thanks for the help.. the iv output stage works.. i swapped outputs from the d3 into the iv stage and the sound switched to the right channel.

I don’t know if its ians fifopi thats the problem or the i2s2sim and D3.. i ordered from ian his transportpi to output spdif to try with my other dac so i can eliminate if its the fifopi thats causing the problem.

Anyone pls recommend an spdif to i2s board that i can use for the i2s2sim and d3.

Anyone pls help on how i can diagnose the problem..

Thanks

Thanks for the help.. the iv output stage works.. i swapped outputs from the d3 into the iv stage and the sound switched to the right channel.

I don’t know if its ians fifopi thats the problem or the i2s2sim and D3.. i ordered from ian his transportpi to output spdif to try with my other dac so i can eliminate if its the fifopi thats causing the problem.

Anyone pls recommend an spdif to i2s board that i can use for the i2s2sim and d3.

Anyone pls help on how i can diagnose the problem..

Thanks

Hi tubo,

Is the appropriate jumper soldered on the underside of the D3? Are all the TDA pins making contact? Maybe the ufl coax cables? Are the supply voltages to the TDA correct? Beyond these I am not much help and I have no experience yet with Ians products. I'm sure you are close though.

Mark K.

Is the appropriate jumper soldered on the underside of the D3? Are all the TDA pins making contact? Maybe the ufl coax cables? Are the supply voltages to the TDA correct? Beyond these I am not much help and I have no experience yet with Ians products. I'm sure you are close though.

Mark K.

Hi tubo,

I noticed in your photos that the D3 AOL and AOR output wires are so the Red wire on the AOR is in the G spot and the Black wire is in the S spot and this is opposite for AOL. As long as the S outs are going to your I/V stage signal ins then this is ok but you may need to check this.

Mark K.

I noticed in your photos that the D3 AOL and AOR output wires are so the Red wire on the AOR is in the G spot and the Black wire is in the S spot and this is opposite for AOL. As long as the S outs are going to your I/V stage signal ins then this is ok but you may need to check this.

Mark K.

Hi tubo,

I noticed in your photos that the D3 AOL and AOR output wires are so the Red wire on the AOR is in the G spot and the Black wire is in the S spot and this is opposite for AOL. As long as the S outs are going to your I/V stage signal ins then this is ok but you may need to check this.

Mark K.

Mark you are very sharp,nice

Attachments

Hi Mark,

Thank you for spotting my mistake.. it wouldn’t make sound without your help..greatly appreciated everyones help.. my stack is now running and sounding prettying good..

thanks to Ryan for assembling and testing my pcb... thanks to sthcoaster for gifting me a tda1541a chip..

Now need to figure out why my rpi3 is not working with fifopi..

Thanks everyone

Thank you for spotting my mistake.. it wouldn’t make sound without your help..greatly appreciated everyones help.. my stack is now running and sounding prettying good..

thanks to Ryan for assembling and testing my pcb... thanks to sthcoaster for gifting me a tda1541a chip..

Now need to figure out why my rpi3 is not working with fifopi..

Thanks everyone

Ben,

Thanks for asking. It did not. I had to order a new board from Ryan and I've been just too busy. But, I did do a test with air for the U.Fl male connectors,and had perfect success. So, when I get some some time after family stuff over the holidays I will populate the new board with air.

I bought both low temp paste and flux paste. Are you using flux or just paste?

Cheers, and thanks again for asking!

Merry Christmas,

Greg

Hi Greg,

Sorry to hear that you couldn't get your D3 running.

I just used regular temperature paste when I assembled mine. I did not apply extra flux.

I don't have much experience with smd and hot air. I have a low cost hot air station (about 60 CAN$). I had previous assembled perhaps three or four boards but they were smaller than the D3, with mainly small smd components. They were fairly easy to solder with hot air because the traces and components were small and therefore easy to preheat and then ramp up the temperature to solder.

However, I did have issues with hot air on the D3 because of the mix of small and large components, and also because some components were soldered to areas where the copper was heavy for heatsinking. I specifically had trouble soldering the larger electrolytic capacitors and I think also the LM317s. They needed a lot of heat and I was worried that I would damage them and even more worried that I would damage any surrounding smaller components. In the end I finished soldering the electrolytics and LM317s with my iron.

I also had to go back and touch up some solder joints and I use my iron for that.

Looking back I think that I would definitely consider using lower temperature paste. Because I had problems hot air soldering the large components, I would consider hot air soldering only the small components and use my iron to solder the smd components that are large enough to be soldered by hand.

I think that perhaps an oven might be the most appropriate apparatus for assembling the D3 if you want to avoid soldering with an iron. It can preheat and heat the board and components, big and small, evenly. However most diyers don't have one although some have rigged toaster ovens for that purpose.

Ryan has assembled many boards. I wonder how he does it and what advice he can provide.

Happy Holidays,

Ben

Hi Greg,

Sorry to hear that you couldn't get your D3 running.

I just used regular temperature paste when I assembled mine. I did not apply extra flux.

I don't have much experience with smd and hot air. I have a low cost hot air station (about 60 CAN$). I had previous assembled perhaps three or four boards but they were smaller than the D3, with mainly small smd components. They were fairly easy to solder with hot air because the traces and components were small and therefore easy to preheat and then ramp up the temperature to solder.

However, I did have issues with hot air on the D3 because of the mix of small and large components, and also because some components were soldered to areas where the copper was heavy for heatsinking. I specifically had trouble soldering the larger electrolytic capacitors and I think also the LM317s. They needed a lot of heat and I was worried that I would damage them and even more worried that I would damage any surrounding smaller components. In the end I finished soldering the electrolytics and LM317s with my iron.

I also had to go back and touch up some solder joints and I use my iron for that.

Looking back I think that I would definitely consider using lower temperature paste. Because I had problems hot air soldering the large components, I would consider hot air soldering only the small components and use my iron to solder the smd components that are large enough to be soldered by hand.

I think that perhaps an oven might be the most appropriate apparatus for assembling the D3 if you want to avoid soldering with an iron. It can preheat and heat the board and components, big and small, evenly. However most diyers don't have one although some have rigged toaster ovens for that purpose.

Ryan has assembled many boards. I wonder how he does it and what advice he can provide.

Happy Holidays,

Ben

Ben,

That's what I did, I bought low temp paste. It worked great on my test with a U.Fl. Amazingly, with an iron I almost, I say almost, did the D3 board without air. So, 2nd time will be the charm with my $60 air gun and the low temp paste that is touted for SMD chip rework. Therefore, the Vregs and passive components should be no problem.

Yeah, those caps are hard, and I will first try the low temp and air and then switch back to the iron if necessary. I will keep everybody posted. Too much going on lately with the holidays and multiple birthdays in just a few weeks plus a big trip overseas.

I will have the board populated in January and go from there! I'm expecting full success this time.

If not, Ryan will get some work.....

I've never failed at a DIY audio project, and I don't plan on it now!

Happy Holidays,

Greg

Hi Ben,

Lately, when soldering pads with a high thermal mass ive been preheating the board with hot air before soldering with an iron - makes it so much easier, the solder flows and wets into all areas with ease.

Lately, when soldering pads with a high thermal mass ive been preheating the board with hot air before soldering with an iron - makes it so much easier, the solder flows and wets into all areas with ease.

Hi Greg,

Ryan has assembled many boards. I wonder how he does it and what advice he can provide.

Happy Holidays,

Ben

- Home

- Group Buys

- DIY TDA1541A PCB "D3"