chrisb said:Unfortunately, as was discussed in today's paper, at over $1million per mile to bury hydro lines, ( 10 times the cost of overhead lines) I'd not be counting on that on the mountain any time soon.

It would be cheaper to give everyone on the mountain a 10kw diesel generator.

Jeff

chrisb said:

Unfortunately, as was discussed in today's paper, at over $1million per mile to bury hydro lines, ( 10 times the cost of overhead lines) I'd not be counting on that on the mountain any time soon.

When I lived in Winnipeg, there was no such thing as overhead wires and power cost 1/3 less than in BC. I think their estimate is padded a wee bit

Geek said:

When I lived in Winnipeg, there was no such thing as overhead wires and power cost 1/3 less than in BC. I think their estimate is padded a wee bit

Victoria Times Colonist

Saturday Dec 2, 2006

B.C. Hydro financially powerless to bury lines

So, finally, after a week in which we discovered that few of us are more than three square meals and a downed electrical line away from the Stone Age, almost all the lights are back on/.

Late yesterday, B.B. Hydro was still working to restore power to 2,000 customers, primarily in Sooke, Colwood, Highlands and the Gulf Islands, but figured most of them would be back on the grid today.

Ooh, what weather. Not since the Paul Martin Liberals slipped on the political ice last January have so many people realized how casually they took power for granted, and how easy it is to lose. All it takes, as Martin found out, is one rotten branch.

It is branches, occasionally whole trees that have taken down power lines. "Vancouver Island has the highest tree count per kilometre of utility line in North America" says B.C. Hydro's Ted Olynyk.

Which leads to the obvious question: With so many trees teetering over the wires like ticking time bombs, why not just bury the lines?

Well, that's what has been happening with new subdivisions over the last generation (and in Uplands for almost a century). Don't hold your breath wating for Hydro to stick existing lines underground, though. It's too expensive, even after factorying in the cost of repeated repairs.

"It's basically about $1.2million a Kilometer to underground," says Olynyk. "And that's just our our cost. That's not telephone or cable"

Besides, burying lines doesn't always work. You can't do it in areas that have too much rock, or or floodprone. There is less flexibility to move lines around once buried. The roots of trees such as maples and willows play hell with underground systems. and while it's true that there are far fewer outages with underground lines, the blackouts last longer because the problems are harder to get at. Burying unsightly wires might make for a prettier place, but from Hydro's point of view, it's just not worth it.

Other power companies concur with Hydro. With climate change increasing the frequency of catastrophic storms (why do 100-year storms occur every three months these days?) the Edison Electric Institute, a U.S. based industry group commissioned a study to measure the benefits of undergrouding. Like B. C. Hydro, it found the costs prohibitive, about $1 million U.S per mile on average, "or about 10 times what it costs to install overhead power lines"

"The bottom line: Reliability benefits associated with burying existing overhead power lines are uncertain, and in most instances do not appear to be sufficient to justify the high price tag," the report concluded this year. Even in Florida, hit by four hurricanes in 2004, the cost of restoring downed power lines was dwarfed by the estimate for undergrounding.

So, instead of burying its lines, Hydro focuses on keeping them from being brought down by branches. Tree trimming is done on a four-year cycle. B.C. Hydro and the B.C Transmission Corp. budgeted $6.4 million for that purpose on the Island this year, up from $5 million five year ago.

It may sound like a lot of money, but it's cold comfort to those Islanders who spent this week uncomfortably cold, wondering if maybe a three year cycle might have have kept the goldfish from freezing in the bowl as though caught in amber.

Have to keep this in perspective, though "This is a major event," says Olynyk. "This is work than (damage of) '96. How often does Victoria get the pounding that it got?"

Once too often, say those shivering souls who feel like they'll be buried underground if the power lines aren't.

Now if you could install a back-up gen-set operating on self-grown biodiesel fuel (corn, or your favorite medicinal herbs), the electricity issue (and water, for those on wells like Dave) would be solved. The only remaining copper-line links to the world would be phone and cable/internet. Not all areas get 100% cel service, and true wireless internet access is still an economic pipedream.

Geek said:I didn't say I didn't believe you read the article

Since this was a local columnist, I just wanted to ensure that my comment wasn't taken out of the context of the article.

Question for scottmoose

Hi

While we're waiting for the drawings from Dave, perhaps you could answer a question for me. Way back in Post # 150 of this thread, vangogh_hk proposed a smoothly radiused version of the horn. I'm thinking of trying to do something like that with the new version.

The question is how to convert the design to that shape. The best approach seems to me to be to draw the ellipse that defines the centre of the horn shape (the red line in the attached drawing) and then draw perpendicular lines (green) whose length is determined by the distance from the origin - the ends of the perpendicular lines would then define the inner and outer curves. If this is correct, the problem then becomes (i) how to derive the central ellipse from the angular drawing, and (ii) how to determine the appropriate lengths for the perpendiculars.

Thank you for any help you can give me.

Aengus

Hi

While we're waiting for the drawings from Dave, perhaps you could answer a question for me. Way back in Post # 150 of this thread, vangogh_hk proposed a smoothly radiused version of the horn. I'm thinking of trying to do something like that with the new version.

The question is how to convert the design to that shape. The best approach seems to me to be to draw the ellipse that defines the centre of the horn shape (the red line in the attached drawing) and then draw perpendicular lines (green) whose length is determined by the distance from the origin - the ends of the perpendicular lines would then define the inner and outer curves. If this is correct, the problem then becomes (i) how to derive the central ellipse from the angular drawing, and (ii) how to determine the appropriate lengths for the perpendiculars.

Thank you for any help you can give me.

Aengus

Attachments

Good question. I for one, have no idea I'm afraid. Art is not my subject. There will be a tapered version using the same expansion as the stepped cabinet too BTW, when we get round to it. But this is a long-path design, and one of the reasons I used the stepped type, aside from wanting to design one in MathCad, is that it's easier to pack it all into a restricted cabinet size. You might find it harder with a smooth transition.

Smoothing edges

Well I may not be the one with the most numbers but I have an idea to offer in this regard. Would it not make sense to use the angular intersecting points as reference anchors and a nice thin bendy stick to draw the coresponding curve shapes. I suspect the math has a high enough degree of "slop" to not be impacted.

I have always wondered why these designs use the stepped approach when curves are so much more graceful.

Well I may not be the one with the most numbers but I have an idea to offer in this regard. Would it not make sense to use the angular intersecting points as reference anchors and a nice thin bendy stick to draw the coresponding curve shapes. I suspect the math has a high enough degree of "slop" to not be impacted.

I have always wondered why these designs use the stepped approach when curves are so much more graceful.

SCD said

Hi SCD

It's an approach that works with boats - when the offsets disagree with the faired curve drawn with a "bendy stick" (boat guys call it a "batten"), go with the faired curve. Seems as if for fluid flow at displacement hull speeds the eye understands what works.

My worry is that so much of acoustics is counter-intuitive for me that I don't want to coount on my eye without some confirmation from the more experienced posters on the forum. Thanks for the suggestion, though - it's what I'll probably do if I get no other feedback.

Regards.

Aengus

Would it not make sense to use the angular intersecting points as reference anchors and a nice thin bendy stick to draw the coresponding curve shapes

Hi SCD

It's an approach that works with boats - when the offsets disagree with the faired curve drawn with a "bendy stick" (boat guys call it a "batten"), go with the faired curve. Seems as if for fluid flow at displacement hull speeds the eye understands what works.

My worry is that so much of acoustics is counter-intuitive for me that I don't want to coount on my eye without some confirmation from the more experienced posters on the forum. Thanks for the suggestion, though - it's what I'll probably do if I get no other feedback.

Regards.

Aengus

Re: Smoothing edges

Technically stepped designs are not horns at all -more an expanding cascade of straight 1/2 wave resonators. They do have some points in their favour though, if correctly implemented. They're easy to build, and take up less space than curved types, allowing a longer horn to be packed into a given box-size, with less dead-space. The edges scatter any unwanted HF that's leaked through into the horn (rather than encouraging its forward motion, as a smooth curve would), while the bass frequencies, which aren't bothered about sharp edges or curves, are preserved. Not quite as graceful aesthetically, as you point out, but they can work pretty effectively.

SCD said:I have always wondered why these designs use the stepped approach when curves are so much more graceful.

Technically stepped designs are not horns at all -more an expanding cascade of straight 1/2 wave resonators. They do have some points in their favour though, if correctly implemented. They're easy to build, and take up less space than curved types, allowing a longer horn to be packed into a given box-size, with less dead-space. The edges scatter any unwanted HF that's leaked through into the horn (rather than encouraging its forward motion, as a smooth curve would), while the bass frequencies, which aren't bothered about sharp edges or curves, are preserved. Not quite as graceful aesthetically, as you point out, but they can work pretty effectively.

Scottmoose said:

So what I'd be hoping for is that the sharp edges in the compression chamber, and at the opening to the horn, would discourage the high frequencies; while the smooth horn shape would provide the aesthetics

Scottmoose, while I have your attention - there was discussion a while back about how tipping back the speaker made a difference. Have you considered building some tilt into the basic design, or is the degree of tilt dependent on too many factors?

Regards.

Aengus

The edges scatter any unwanted HF that's leaked through into the horn

So what I'd be hoping for is that the sharp edges in the compression chamber, and at the opening to the horn, would discourage the high frequencies; while the smooth horn shape would provide the aesthetics

Scottmoose, while I have your attention - there was discussion a while back about how tipping back the speaker made a difference. Have you considered building some tilt into the basic design, or is the degree of tilt dependent on too many factors?

Regards.

Aengus

Chrisby has shown me some wonderful bending ply that would fit this application perfectly. A vey graceful presentation could be developed if desired. I can see a very cool artsy enclosure that would be a lot of fun to create.

As long as the steps do not play an integral part of the design. Lots of fun to be creative

As long as the steps do not play an integral part of the design. Lots of fun to be creative

SCD said:

SCD, what was the source for this? I was thinking that BB 1/8" would work fine for the outer curve, but the inner curve is likely to be pretty sharp. Lee Valley sells some very flexible stuff, but it's expensive and comes (from them) only in 2' x 2' sheets IIRC.

How flexible was the stuff you saw?

Regards.

Aengus

Chrisby has shown me some wonderful bending ply...

SCD, what was the source for this? I was thinking that BB 1/8" would work fine for the outer curve, but the inner curve is likely to be pretty sharp. Lee Valley sells some very flexible stuff, but it's expensive and comes (from them) only in 2' x 2' sheets IIRC.

How flexible was the stuff you saw?

Regards.

Aengus

The sample he showed me was about 4 inches wide and a foot or so long. It has soft core and the skin was luan I think. He bent it in to a 4 inch curve no problem. It is used in cabinet constuction.

I think if you made a simple form of he shape you wanted then bent two pieces with a wet glue line between them, clamp anchor and let dry you would be very happy.

I was thinking of steam bending and glue laminating 6 plys of 1/8" fir with the outside and inside plys being best presentation. Then rabbiting the edge of the outside curve to accept the side pannels or something like that?

I think if you made a simple form of he shape you wanted then bent two pieces with a wet glue line between them, clamp anchor and let dry you would be very happy.

I was thinking of steam bending and glue laminating 6 plys of 1/8" fir with the outside and inside plys being best presentation. Then rabbiting the edge of the outside curve to accept the side pannels or something like that?

SCD said:

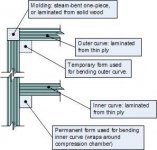

I haven't thought it all the way through. I'm considering using 3/4" BB for the sides. The inner curve would bend around a permanent set of blocks built on the outside of the compression chamber and fastened to the side; the outer curve around either a rabbet in the sides, or - since I'm considering using solid wood edging - would be moulded around a temporary form.

Regards.

Aengus

I was thinking of steam bending and glue laminating 6 plys of 1/8" fir

I haven't thought it all the way through. I'm considering using 3/4" BB for the sides. The inner curve would bend around a permanent set of blocks built on the outside of the compression chamber and fastened to the side; the outer curve around either a rabbet in the sides, or - since I'm considering using solid wood edging - would be moulded around a temporary form.

Regards.

Aengus

Attachments

- Home

- Loudspeakers

- Full Range

- Spawn of Frugel-Horn