Hi,

I was just looking out the window one day and I thought to myself, can you make a BLH with a traffic cones. I checked it out on the internet and you could buy one locally fairly cheaply if you don't have to ship over long distances and they are available for up to 3 feet. My thoughts are it will most likely build/buy a small box, drill a hole at the bottom of the box, cut off the top of the cones and stick the box to the cones.

I see some are available in rubber, and some in PVC, I wonder which is better. I could imagine lining up the inside with butyl rubber dampeners etc.

What are your thoughts on these....

A typical example of a traffic cones

https://www.amazon.com/36-Traffic-C...ffic+cones+36+inch&qid=1633949155&sr=8-9&th=1

Oon

I was just looking out the window one day and I thought to myself, can you make a BLH with a traffic cones. I checked it out on the internet and you could buy one locally fairly cheaply if you don't have to ship over long distances and they are available for up to 3 feet. My thoughts are it will most likely build/buy a small box, drill a hole at the bottom of the box, cut off the top of the cones and stick the box to the cones.

I see some are available in rubber, and some in PVC, I wonder which is better. I could imagine lining up the inside with butyl rubber dampeners etc.

What are your thoughts on these....

A typical example of a traffic cones

https://www.amazon.com/36-Traffic-C...ffic+cones+36+inch&qid=1633949155&sr=8-9&th=1

Oon

I use 9in sport cones (for soccer practice) as tapered rear chambers for a full range driver. I use them sealed but I suppose the small end could be open as an aperiodic tapered TL. It works well to absorb the back wave.

For a BLH you have 18in and cost is rather high at $70 for 2. I didn’t realize traffic grade ones were that expensive given we see thousands set up on a section of freeway under construction.

What kind of frequencies will you enhance with an 18in long horn?

Speed of sound is 342m/Sec. Assume 1/4 wave so 18in is good for 187Hz corner frequency. That’s still considered mid bass and not bass yet. You need about 1.5m for that.

By then, you might try foam core in a folded BIB, Cornu, etc.

For a BLH you have 18in and cost is rather high at $70 for 2. I didn’t realize traffic grade ones were that expensive given we see thousands set up on a section of freeway under construction.

What kind of frequencies will you enhance with an 18in long horn?

Speed of sound is 342m/Sec. Assume 1/4 wave so 18in is good for 187Hz corner frequency. That’s still considered mid bass and not bass yet. You need about 1.5m for that.

By then, you might try foam core in a folded BIB, Cornu, etc.

Hi X,I use 9in sport cones (for soccer practice) as tapered rear chambers for a full range driver. I use them sealed but I suppose the small end could be open as an aperiodic tapered TL. It works well to absorb the back wave.

For a BLH you have 18in and cost is rather high at $70 for 2. I didn’t realize traffic grade ones were that expensive given we see thousands set up on a section of freeway under construction.

What kind of frequencies will you enhance with an 18in long horn?

Speed of sound is 342m/Sec. Assume 1/4 wave so 18in is good for 187Hz corner frequency. That’s still considered mid bass and not bass yet. You need about 1.5m for that.

By then, you might try foam core in a folded BIB, Cornu, etc.

If you read carefully those are 36" cones. Admittedly I haven't seen one this tall yet in real life. But it does exist. Price each seems to be closer to USD$20+ locally from the friendly hardware store over here in Singapore. I think it should be similarly priced in the US[emoji6].

I was thinking of adding a PVC pipe approximately 1.5× the diameter of the top part of the cone as an outer sheath. That would be sort of a folded horn and increase the length a bit more....

So frequency should be about 100Hz and the box on top will be made out of foam core.

Total height is about 1m including the box...

Oon

Hi X,Ok, sorry I missed the 36in length - the link showed an 18in cone. 100Hz is good if you have some roll off and room gain. A 90deg elbow would allow the horn to aim towards the floor.

Funny, when I clicked on the link it shows me the 36" version.

That's an interesting idea, an PVC elbow to mount the driver.

My original plan was to raise the cones with some rubber footer. That will make it a down firing BLH. Then I build a box out of foam core with a hole at the bottom and this will be attached to the cone, after I saw off the top of course.

Drivers will be front facing of course. I thought about adding in internal partitions in the box to form a labyrinth of sorts to make it an extension of the traffic cone horn. Just to make it longer.

Any thoughts?

Oon

Hi X,

Maybe it is the same thing... Something like this.

https://www.amazon.com/Expanded-PVC...a8a16&pd_rd_wg=q5jKG&pd_rd_i=B08PC7HHZ1&psc=1

And a video showing me an application on it...

PVC Foam Board Furniture Making Process - YouTube

Oon

Maybe it is the same thing... Something like this.

https://www.amazon.com/Expanded-PVC...a8a16&pd_rd_wg=q5jKG&pd_rd_i=B08PC7HHZ1&psc=1

And a video showing me an application on it...

PVC Foam Board Furniture Making Process - YouTube

Oon

Last edited:

Hey Scott,'Have fun' is my answer. Why not, it probably (almost certainly) won't be optimal for any particular alignment, but this is the spirit of DIY.Should be an entertaining little project, and isn't that one of the points?

Definitely this is intended as a fun project. If I wanted something serious, I would have built one of the frugal horns.

However, I am incompetent in horn design. I should really learn how to simulate things using Hornresp.

I was hoping you can help me out potentially with some ballpark figures and design.

I was thinking as I mentioned earlier, of using some rubber footers to elevate the traffic cones, and attach a small box on to it at the top. The cones are 36" or 90cm. The diameter at the bottom I guess would be about 12" and the diameter at the top about 2 or 3".

I was thinking of using this as a down firing BLH with the drivers front facing. I am thinking either a 3" or 4" driver. Potentially the Fostex FF85K, Faitalpro 3Fe22 or the SB acoustics sp12pgc21.

I can also consider putting a larger PVC pipe 4 or 5" at the top. Sort of like a folded horn. I can also consider closing the bottom and adding in a tube to mass load it.

Would appreciate your thoughts and comments on it....

Oon

If you bifurcated (those words again, cant think of anything else) the horn with a piece of foam board, but not as wide as the cone, so when fastened, it bent the soft material and turned the mouth ovular (sorry...) - would it change the taper from linear to something else?

Or to get things out from inside the horn taper, you could put two long braces on the outside opposite to one another and pull them together with a couple threaded rods to bend the cone shape into an oval. The base of course would interfere, you have to modify it somehow to accept the bend.

Of course I have no idea if having two different rates of expansion - narrow and wider - would be advantageous in a BLH? If you're going to put a port at the end, maybe it's now a small Metronome.

Or to get things out from inside the horn taper, you could put two long braces on the outside opposite to one another and pull them together with a couple threaded rods to bend the cone shape into an oval. The base of course would interfere, you have to modify it somehow to accept the bend.

Of course I have no idea if having two different rates of expansion - narrow and wider - would be advantageous in a BLH? If you're going to put a port at the end, maybe it's now a small Metronome.

Last edited:

Maybe try this? Calculate the mouth opening (around the periphery) to give expansion ratio that is similar to cone area expansion from throat to mouth of cone. This is set by height of slot or even make slot only front facing or sides and front etc. make the rear chamber maybe no larger than 2 liters or so. Ideally all this should be simulated. But where’s the fun in that?

You will double the horn length and hit a nice 50Hz bass now.

You will double the horn length and hit a nice 50Hz bass now.

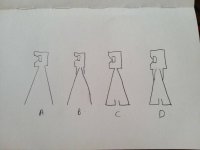

Attachments

Last edited:

To keep the cross section constant at transition from cone to box, diameter of outer shell needs to be 1.4-1.5 diameter of cone, which is 18". Any idea what is a 18" cylinder and 36" high... thrash can. Have to figure out how to suspend the cone too...Maybe try this? Calculate the mouth opening (around the periphery) to give expansion ratio that is similar to cone area expansion from throat to mouth of cone. This is set by height of slot or even make slot only front facing or sides and front etc. make the rear chamber maybe no larger than 2 liters or so. Ideally all this should be simulated. But where’s the fun in that?

You will double the horn length and hit a nice 50Hz bass now.

Makes no sense to build the box, cause the idea was so I don't have to build any box... If I wanted to build a box, might as well build the foamcore frugal horn lite and copy your design [emoji2].

And ideally just keep it as a one afternoon kinda project. But thanks for the suggestion...

Oon

Well, here we have it, a trash can with traffic cone that expands to a horn 18" in diameter....Trash can is a good idea. Have you tried the Cornu BLH? It’s got an amazing expansion ratio.

I haven't tried the cornu BLH yet. Was wondering the amount of work it involves in making those curvy separators inside the horn. Would love to try that one day...

Oon

- Home

- Loudspeakers

- Full Range

- BLH with traffic cones