There is no 'additional horn' to the FH series. It was designed from the outset as a tapped hypex horn with an internal low pass choke; the configuration was designed to conveniently provide both without resorting to additional panels, and to keep the overall package size down.

I was working at the voigt pipes today for a bit. i welded on mounting brackets for a speaker adapter plate and ground the welds smooth. i also made the existing speaker adapter plate wider to mate with the new brackets but the plates have warped with the heat and don't look able to provide a seal.

it's not the end of the world, i can make a wooden speaker adapter plate instead. I have some plywood left over from a household repair. wouldn't want to be buying much timber with the current market conditions.

it's not the end of the world, i can make a wooden speaker adapter plate instead. I have some plywood left over from a household repair. wouldn't want to be buying much timber with the current market conditions.

If Frugel is hypex horn thats very broad approximation...

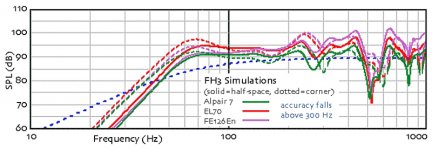

I found these simulations for Frugel-Horn mk3 and it looks like it has some similar response issues as Voigt pipes. They are less prominent beacuse of more elaborated design but some similar bass distortion is inevitable.

That simple Voigt is fairly good approximation what you may expect with Frugals.

I found these simulations for Frugel-Horn mk3 and it looks like it has some similar response issues as Voigt pipes. They are less prominent beacuse of more elaborated design but some similar bass distortion is inevitable.

That simple Voigt is fairly good approximation what you may expect with Frugals.

Attachments

You don't seem to have analysed it with other than the basic, undamped, single placement plane-wave simulations that I provided, considered a variety of microphone / modelling placements &c.

For the sake of interest, those simulations were very simple, rather than the complete model, and they did not incorporate the full effect of the acoustic low-pass, which is typically somewhat lower and steeper than what was shown in those system-response graphs (there being some variability with room placement). That was deliberate on my part -I rarely post simulations &c. on the forum using the full-blown / fully detailed model, hence the reason it is stated on the plot you found that 'accuracy falls above 300Hz'. FH3 also incorporates some curved-wavefront math first used by Ron in his Austin designs. You will note that in the various practical measurements taken over the years, a rather cleaner response in the lower midband is typical vis-a-vis the basic posted model when properly boundary-loaded. The FH series are not the most advanced horn designs available, and are not supposed to be -they were conceived for other purposes, physical simplicity being one of them, hence the fact that they are tapped (aka 'Voigt', since Voigt conceived the chamberless horn) horns rather than chambered designs. Some of the goals can be found elsewhere on this forum & on the FH site. However, there is a little more going on in it than is necessarily obvious at first glance, and significantly more than the Lowther Club of Norway Voigt Pipe.

For the sake of interest, those simulations were very simple, rather than the complete model, and they did not incorporate the full effect of the acoustic low-pass, which is typically somewhat lower and steeper than what was shown in those system-response graphs (there being some variability with room placement). That was deliberate on my part -I rarely post simulations &c. on the forum using the full-blown / fully detailed model, hence the reason it is stated on the plot you found that 'accuracy falls above 300Hz'. FH3 also incorporates some curved-wavefront math first used by Ron in his Austin designs. You will note that in the various practical measurements taken over the years, a rather cleaner response in the lower midband is typical vis-a-vis the basic posted model when properly boundary-loaded. The FH series are not the most advanced horn designs available, and are not supposed to be -they were conceived for other purposes, physical simplicity being one of them, hence the fact that they are tapped (aka 'Voigt', since Voigt conceived the chamberless horn) horns rather than chambered designs. Some of the goals can be found elsewhere on this forum & on the FH site. However, there is a little more going on in it than is necessarily obvious at first glance, and significantly more than the Lowther Club of Norway Voigt Pipe.

Last edited:

It is the lower quarterwave modes above the fundemental that is the biggest worry.

Right, what do you think is driving the eigenmodes? Yes, stuff them enough and we can quell them all, but better to damp panels and only use stuffing for the low amplitude reflections.

I like the self adhesive closed cell foam weatherstripping tape

Right, neoprene, it's used on all manner of weatherproof industrial equipment boxes when it has a Nema xx rating, so great for speakers where an access/whatever cover is required for [frequent] removal/install, just design so the hardware doesn't go through it, only clamps it.

I drilled the flanges yesterday on both cabinets with a mag drill, took a while cos i had to grind the surfaces smooth to get the magnet to stick. put 4 holes in the flanges, one on each corner of the square and a hole opposite in the back of the cabinet to route the cable.

I can lift the cabinet on my own but i got my dad to assist lifting one up the stairs. I have some stockholm tar maybe that would do to seal the surface. I could try a rubber inner tube as a gasket also.

Initially i wanted to have the wooden speaker adapter flush with the inside of the voigt pipe but that proved too difficult, so there will be a 6mm step between the steel cabinet and the plywood. I guess that will be sufficient to test.

I can lift the cabinet on my own but i got my dad to assist lifting one up the stairs. I have some stockholm tar maybe that would do to seal the surface. I could try a rubber inner tube as a gasket also.

Initially i wanted to have the wooden speaker adapter flush with the inside of the voigt pipe but that proved too difficult, so there will be a 6mm step between the steel cabinet and the plywood. I guess that will be sufficient to test.

I think same laws of physics applies for both.

Of course, but the geometry, mass, stiffness, damping and boundary conditions are very different.

I tried it out with one of the water damaged car drivers. only one of the voigt pipes, i set the balance to that channel. I was expecting it to be very tinny due to the metal resonating but it's hard to hear. it actually works quite well, though there seems to be a lot of treble. i understand that is why stuffing is commonly used with these builds. i was shaking the room with bass until my speaker changed, seems to have blown up. all it makes is rattling fuzzy noises now. better disconnect it before i do damage to my amp.

I lapped the speaker cable with insulating tape where it exits through a hole in order to plug the air leak. didn't use a gasket on the front as i just wanted to try it out.

I think i might buy 2 decent drivers and get a steel sheet machined to match it in an engineering firm, if i am unable to do so myself, then weld it in to avoid the plywood.

I'm surprised i damaged the speaker tbh, as it was rated for +4x the wattage of what the amp is. i guess it was old age. can't really use the plastic coned ones as they lack the foam seal so won't be able to plug the air leaks.

I lapped the speaker cable with insulating tape where it exits through a hole in order to plug the air leak. didn't use a gasket on the front as i just wanted to try it out.

I think i might buy 2 decent drivers and get a steel sheet machined to match it in an engineering firm, if i am unable to do so myself, then weld it in to avoid the plywood.

I'm surprised i damaged the speaker tbh, as it was rated for +4x the wattage of what the amp is. i guess it was old age. can't really use the plastic coned ones as they lack the foam seal so won't be able to plug the air leaks.

Attachments

Will do. I've been keeping an eye out for cabinets with second hand 8 inch 8ohm speakers i can harvest. found the occasional pair but haven't pulled the trigger yet.

I swapped in the plastic coned speaker into the voigt pipe a few hours ago, hasn't blown up yet. i listened to gary jules mad world and the piano sounded like a real one. it felt so strange being used to listening to a small mdf speaker cabinet.

I could swap in the other damaged speaker but it feel it would be a waste of time. better to get a proper speaker like what is recommended for the Frugel-Horn XL, then i can mount it from the outside.

I wonder would i recoup my costs if i listed the voigt pipes for sale as is and made another set without the errors in construction. I'd like to keep the front in one piece without the bolt on plate.

I know some of you are waiting to see what it sounds like so here's a recording from my boom mike. you can hear some tones in the song make the cabinet resonate with a metallic hum.

I actually didn't notice it much until now. it was especially bad when i recorded the voigt pipe and played it back through the same pipe. it was like a feedback loop for it.

Maybe i should try a wooden version instead, though this cabinet is fun to experiment on. I'd say the hum could be deadened by lagging it with layers of a brushed on wood glue and cloth, sort of like a plaster cast for a broken leg.

I swapped in the plastic coned speaker into the voigt pipe a few hours ago, hasn't blown up yet. i listened to gary jules mad world and the piano sounded like a real one. it felt so strange being used to listening to a small mdf speaker cabinet.

I could swap in the other damaged speaker but it feel it would be a waste of time. better to get a proper speaker like what is recommended for the Frugel-Horn XL, then i can mount it from the outside.

I wonder would i recoup my costs if i listed the voigt pipes for sale as is and made another set without the errors in construction. I'd like to keep the front in one piece without the bolt on plate.

I know some of you are waiting to see what it sounds like so here's a recording from my boom mike. you can hear some tones in the song make the cabinet resonate with a metallic hum.

I actually didn't notice it much until now. it was especially bad when i recorded the voigt pipe and played it back through the same pipe. it was like a feedback loop for it.

Maybe i should try a wooden version instead, though this cabinet is fun to experiment on. I'd say the hum could be deadened by lagging it with layers of a brushed on wood glue and cloth, sort of like a plaster cast for a broken leg.

Attachments

You probably won't need to go to that sort of extreme. That's the thing about high frequency, high Q modes. A strip or pad of self-adhesive bitumen, stratetically placed, should do the job; you're very unlikely to need to line the whole thing, which would in part defeat the object anyway. Just listen while playing the problematic material for where the main mode is and position accordingly.

Re solids, as I recall, Derek Walton made a varition using laminated pine furniture board e.g.

Clear pine Furniture boards | Timber & sheet materials | B&Q

Wickes General Purpose Pine Timberboard - 18mm x 200mm x 2350mm | Wickes.co.uk

Re solids, as I recall, Derek Walton made a varition using laminated pine furniture board e.g.

Clear pine Furniture boards | Timber & sheet materials | B&Q

Wickes General Purpose Pine Timberboard - 18mm x 200mm x 2350mm | Wickes.co.uk

it was especially bad when i recorded the voigt pipe and played it back through the same pipe. it was like a feedback loop for it.

When I was in college I attended a demo where the person on stage spoke about it, while recording the sound of his voice in the hall on a R-R deck.

Playing that back, he recorded his speech again using a 2nd R-R deck. He went back 'n forth between the two tape machines until all you could hear was the hall resonances that were excited by his voice.

Now I bet if you did that repeatedly...but it only took once for you to notice the sound. Put the end result through a spectrum analyzer, id the frequencies and use a frequency generator to go through a tuning them out process using bracing and sticky back pad mass loading.

Eh don't worry about cluttering up the thread on my account. I've used a lot of forums over the years and with the exception of reddit, 4chan, hackaday and here they're all ghost towns now. As regards mounting the speakers, i guess i could weld them on to eliminate movement, not that i care all that much.

I was reading about a spacecraft that was shielded from cosmic rays by using water tanks around the exterior some years ago and i think the same technique could work to silence my speaker. i wouldnt try it with a wooden type though, but mine is quite waterproof.

I have noticed that hitting barrels of oil or drums of water makes a low thud that does not vibrate.

all i would have to do is weld a second wall around every surface, leaving an aperture around the speaker and the bottom port, then fill the enclosure up with buckets of water. I'm not sure how that would influence how the acoustics spread around the room. I could have water beneath the bottom port but i think it is intended to couple bass into the floor.

I was reading about a spacecraft that was shielded from cosmic rays by using water tanks around the exterior some years ago and i think the same technique could work to silence my speaker. i wouldnt try it with a wooden type though, but mine is quite waterproof.

I have noticed that hitting barrels of oil or drums of water makes a low thud that does not vibrate.

all i would have to do is weld a second wall around every surface, leaving an aperture around the speaker and the bottom port, then fill the enclosure up with buckets of water. I'm not sure how that would influence how the acoustics spread around the room. I could have water beneath the bottom port but i think it is intended to couple bass into the floor.

- Home

- Loudspeakers

- Full Range

- About to dive into a steel voigt pipe build