Greetings to all!

I have been trying to understand the functional relationship between woofer Rms and Cms. Other T/S parameters don't seem confusing, but these two and their effect on Qms seem to be a bit counter-intuitive, and at times even inconsistent in observations made over data of a few drivers.

My questions as of now remain:

1. Do i understand this correctly that Rms and Cms are necessarily inversely related to each other?

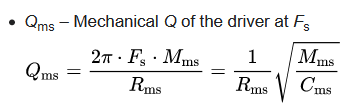

2. In the formula for Qms, i noticed both Rms and Cms being used as components in the denominator. Could it be reliable? My understanding of algebra is very poor, so I could have quite misunderstood it all!

So how do Rms and Cms each affect Qms?

3. What type of sonic behaviour can I expect from a driver with each of these variables I.e. Rms, Cms and Qms being lower or higher?

4. I have read conflicting statements. Some say EBP is important; whereas some say Qts is all that affects bass alignment, regardless of individual components (Qes and Qms). How can these two conflicting statements be reconciled?

5. Given that I have no means to measure parameters, and driver data doesn't mention Rms and Cms values, is it wise to rely solely on Qes, Qms, Qts & Vas?

I have been looking for clear insights in this regard, and have turned to this very useful forum as the last resort. Could any of you please help me by directing some light on this?

Thanks to all of you in advance!

Warmly,

sujat

I have been trying to understand the functional relationship between woofer Rms and Cms. Other T/S parameters don't seem confusing, but these two and their effect on Qms seem to be a bit counter-intuitive, and at times even inconsistent in observations made over data of a few drivers.

My questions as of now remain:

1. Do i understand this correctly that Rms and Cms are necessarily inversely related to each other?

2. In the formula for Qms, i noticed both Rms and Cms being used as components in the denominator. Could it be reliable? My understanding of algebra is very poor, so I could have quite misunderstood it all!

So how do Rms and Cms each affect Qms?

3. What type of sonic behaviour can I expect from a driver with each of these variables I.e. Rms, Cms and Qms being lower or higher?

4. I have read conflicting statements. Some say EBP is important; whereas some say Qts is all that affects bass alignment, regardless of individual components (Qes and Qms). How can these two conflicting statements be reconciled?

5. Given that I have no means to measure parameters, and driver data doesn't mention Rms and Cms values, is it wise to rely solely on Qes, Qms, Qts & Vas?

I have been looking for clear insights in this regard, and have turned to this very useful forum as the last resort. Could any of you please help me by directing some light on this?

Thanks to all of you in advance!

Warmly,

sujat

Last edited:

1. Do i understand this correctly that Rms and Cms are necessarily inversely related to each other?

More or less. Cms is the suspension compliance, Rms its mechanical resistance, so they are basically reciprocals. However, both can be affected to a point by external factors (environmental conditions).

2. In the formula for Qms, i noticed both Rms and Cms being used as components in the denominator. Could it be reliable? My understanding of algebra is very poor, so I could have quite misunderstood it all!

Yes, Small's formulas have been demonstated as reliable analogies at small-signal level for many years.

So how do Rms and Cms each affect Qms?

Qms is the unitless mathematical expression of mechanical damping at / near resonance, ergo the mechanical mass + airload (Mms), suspension compliance (Cms) and its mechanical resistance (Rms) define the extent of this. For a static Mms the higher the compliance (which could typically be expected to go hand in hand with a lower mechanical resistance) the higher the Qm figure & the less mechanical damping there is at Fs.

3. What type of sonic behaviour can I expect from a driver with each of these variables I.e. Rms, Cms and Qms being lower or higher?

'Sonic behaviour' has no technical meaning so you will potentially get a wide variety of responses which also have no technical meaning, some of which will be contradictory.

4. I have read conflicting statements. Some say EBP is important; whereas some say Qts is all that affects bass alignment, regardless of individual components (Qes and Qms). How can these two conflicting statements be reconciled?

Very easily. They are not conflicting. Bass alignment is dominated by Fs, Vas and total effective Qt (Qts + any series R in circuit). EBP by contrast is not a T/S parameter, just a very simple derivation from T/S parameters that attempts to provide a rough guideline about what type of box different drivers may (or may not) be suited to. By definition it is approximate only, with a large amount of grey area involved since it assumes a certain broad set of criteria apply to all situations, which is not the case. Most experienced designers don't even waste their time calculating it since it is of no value to them.

5. Given that I have no means to measure parameters, and driver data doesn't mention Rms and Cms values, is it wise to rely solely on Qes, Qms, Qts & Vas?

It depends on the reliability of the published (or other) data, but in terms of designing an enclosure, yes; you don't need Rms and Cms for that.

Last edited:

I am personally less than convinced by some of the broad assumptions made in that; since in some practical cases higher levels of mechanical damping are required for a given drive unit to function as intended. In my experience, it is also harder for manufacturers to consistently produce high compliance drive units, and as a result, they often (not always) tend to exhibit greater tolerance variability

.

I have seen from their data that most of the Fostex drivers are very high compliance designs. I wonder how they might adhere to tolerance levels then!

Besides, this came to mind - If high compliance.. low Rms and high Cms (higher Qms & greater Vas) drivers have appropriately low Qes (and therefore fairly low Qts), and if their system compliance is lowered sufficiently through being mated with a smallish closed box suspension design, then the driver might well see a benign environment towards performing as intended.. even at higher drive levels. For here there is no tune level below which it will ever unload. Do i understand this correctly?

In this context, is it wise to say that a low compliance driver would be required to exhibit intended performance primarily where it is likely to get unloaded below the tuned box resonance.. I.e. in any other design but a closed box?

It depends on the reliability of the published (or other) data, but in terms of designing an enclosure, yes; you don't need Rms and Cms for that.

I feel a bit relieved!

Now my dilemma has reduced to a narrower area. I have two 12" wide band drivers (with whizzers) available locally.

A. BL= 9.7, Re= 6.4, Xmax= 1.5 mm, Qes= 0.758,

Qms= 9.36, Qts= 0.7, Mms= 35.23 gms, Fs= 50 hz, Vas=104 l, SPL= 95 dB/2.83 V

B. BL= 11.2, Re= 6.8, Xmax= 2.5 mm, Qes= 0.92,

Qms= 3.26, Qts= 0.72, Mms= 36.7 gms, Fs= 50 hz, Vas= not mentioned(!), SPL= 95 dB/2.83 V

____

Now given these apparently similar drivers:

1. With nearly equal Mms and Fs being identical, is it safe to assume that their compliance too might be nearly identical? And therefore the Vas for driver B might be nearly identical to that of driver A? And yet the big difference in Qms values indicates something else.

2. Despite driver A having a lower Qes than driver B, the big difference in Qms results into a Qts value that is very close to each other's. In this case, although both drivers may perform quite similarly at and around resonance, as you explained, might driver A be a little more snappy and with better attack+decay at all frequencies above Fs.. owing to a lower Qes?

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Functional relationship between woofer Rms and Cms