Looking to build enclosures for my Super 8s from Audio Nirvana using the mini-monitor plans (bass reflex). The plans call for the box to be lined with fiberglass but I have concerns about working with it.

Is there a good alternative? It specifically says not to use foam damping.

Is there a good alternative? It specifically says not to use foam damping.

In the UK we now use Rockwool for insulation and damping.

ROCKWOOL insulation is a rock-based mineral fibre insulation comprised of Basalt rock and Recycled Slag. Basalt is a volcanic rock (abundant in the earth), and slag is a by-product of the steel and copper industry. The minerals are melted and spun into fibres.

ROCKWOOL insulation is a rock-based mineral fibre insulation comprised of Basalt rock and Recycled Slag. Basalt is a volcanic rock (abundant in the earth), and slag is a by-product of the steel and copper industry. The minerals are melted and spun into fibres.

In the UK we now use Rockwool for insulation and damping.

ROCKWOOL insulation is a rock-based mineral fibre insulation comprised of Basalt rock and Recycled Slag. Basalt is a volcanic rock (abundant in the earth), and slag is a by-product of the steel and copper industry. The minerals are melted and spun into fibres.

Thanks, I had looked at that. Can it be stapled to the walls like fiberglass? Unfortunately it’s expensive locally, but I may give it a shot.

As far as I'm aware there are few confirmed issues to working with fibreglass other than the fact that you're better off wearing gloves & should take the usual precautions. OC-703 bonded fibreglass board is one of the most effective damping materials easily available and since it isn't loose, it cuts down irritation when working with it and you have very little in the way of escaped fibres to concern yourself over. Alternatively there is equivalent rockwool, or if you prefer natural fibre, SAE-F10 rated wool felt or jute carpet underlay. Ultratouch recycled denim can be effective depending on source.

Last edited:

Thanks, I had looked at that. Can it be stapled to the walls like fiberglass? Unfortunately it’s expensive locally, but I may give it a shot.

It is plentiful and should not be very expensive in the USA. It goes by the name Rouxul and can be found at Lowes and Home Depot. It will be thicker than you might need, but a thinner layer can be "peeled" off.

Although I have not personally used it before, there is an insulation made from re-cycled denim called Ultra Touch. The density is similar to pressed fiberglass (3 lb/cuft) and has similar absorption coefficients. It is also widely available. Note, my knowledge of the denim is second hand.

Good luck

xrk971 mentioned melamine sponges in this post. They are available on Amazon in bulk.

What can I do against 'box sound' ?

And you can use the extras to clean your house.

What can I do against 'box sound' ?

And you can use the extras to clean your house.

Last edited:

one of the oddest things I've heard for damping = steel wool, for small sealed chambers and of course, contained with cloth. Its probably been used in "suppressors" (?)

A long time ago, Kimberly-Clark's paper insulation material "Kim-sul" was popular for speaker cabinet damping and used by Bozak, Karlson, and many others. A shame its gone.

A long time ago, Kimberly-Clark's paper insulation material "Kim-sul" was popular for speaker cabinet damping and used by Bozak, Karlson, and many others. A shame its gone.

Last edited:

sheeps wool works great, performs at least as good as fiberglass. It's really nice to handle too. Easier to use when you can buy it in sheets rather than free wool like this: Dampmaterial Farull

That specific sheet of wool measured slightly better attenuation than fiberglass for low frequencies than fiberglass in a comparison I can't find the link for.

That specific sheet of wool measured slightly better attenuation than fiberglass for low frequencies than fiberglass in a comparison I can't find the link for.

xrk971 mentioned melamine sponges in this post. They are available on Amazon in bulk.

What can I do against 'box sound' ?

And you can use the extras to clean your house.

This might be a great solution. Cheap and safe if it’s effective as the insulation its probably a winner.

Are there measurements comparing it to fibreglass or rockwool against none?if it’s effective

It shouldn't be doing much placed against the walls, so I'm wondering if it is loading the panels instead?

This might be a great solution. Cheap and safe if it’s effective as the insulation its probably a winner.

If looking for cheep and effective to line the walls try this -

https://www.homedepot.com/p/UltraTo...tion-Roll-16-in-x-48-in-60301-16482/202709974

If the budget allows for a little more $$ try this -

https://www.mscdirect.com/product/details/48544829?rItem=48544829

For stuffing, I go with Acousta-Stuf -

Acousta-Stuf Polyfill 5 lb. Bag Speaker Cabinet Damping Material

Last edited:

Rockwhool RockSono Solid is also working well, it has a density of 45kg/m³ and is easy to get here in Europe as it's used a lot to soundproof buildings by damping and absorption. it's as good as OC703, but not fiberglass (silicium) but made from basalt fibers. And those are not dangerous to work with.

I would use melamine or 100% wool batting for quilts: https://www.diyaudio.com/forums/mul...n-methods-shootout-thread-18.html#post6351877

sheeps wool works great, performs at least as good as fiberglass. It's really nice to handle too

Works well but tends to sag. Mix 50-50 with Acoustastuff. But not suitable for a reflex.

dave

Super 8s from Audio Nirvana using the mini-monitor plans (bass reflex).

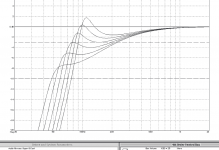

No good alignment with that large a box. In actuallity the Super 8 is best suited to be used as a midTweeter above 200 Hz (you can use the natural sealed box rolloff as 2 orders of an XO).

dave

Attachments

I've heard of similar - absorbent which incorporates fine strands of copper.one of the oddest things I've heard for damping = steel wool, for small sealed chambers and of course, contained with cloth.

The idea of incorporating copper, which is a good conductor of heat, is to improve the isothermal (equal temperature) loading of the enclosure.

The inclusion of copper increases the ability of the absorbent to absorb and release heat, helping to maintain a constant enclosure temperature. This results in a larger apparent increase in enclosure volume than the norm.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Alternative to fiberglass for damping