@ EddieT - got a reply from John Lapaire - his favorite speaker for X15 was the cheap and cheerful stamped frame Eminence Delta15A - and I can see "why"

Look at the shelved HF rise on the response curve

https://www.eminence.com/pdf/Delta_15A.pdf

Look at the shelved HF rise on the response curve

https://www.eminence.com/pdf/Delta_15A.pdf

I found this comment over on talkbass.com;

I usually rub glue and clean paint brushes on raw plywood edges to seal them then sand them smooth.There were resonances due to the flimsy removable back. I had to beef it up with aluminum channels to get the back to settle down. Once that was accomplished, the Karlson was a great bass speaker. I used a JBL D130F in mine, and drove it with a McIntosh 30 watt tube amp! It was LOUD.

I ran curves on the unit and it was pretty flat to about 1 khz, then began to show phase problems. Once I replaced the raw wood edge of the opening curve with Formica the high end went up to 2.5 khz without any problem.

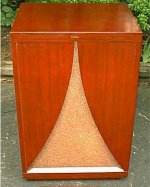

I found a fully Formica finished Karlson used as an organ speaker in a Phoenix church. It had a triaxial 15" speaker. Wonderful sound.

I built my first Karlson around 1962. It was the original K15 but I did the speaker cut-out for a 12" driver as I had a Phillips 12" full range speaker on hand. I didn't have a shop and cut my pattern out of a single sheet of fir plywood with a jig saw attachment on a 1/4" drill. I used a powder/water mix resorcinol glue and #8 wood screws for joinery. Since my joints were not perfect I dipped fabric strips in glue and covered all interior joints to seal them. I used Bondo as necessary on the exterior and covered it with walnut veneer. I found gold grill cloth that was a close match to the original. I used it until around 1972 when I went to stereo building a pair of original K12s driven with Layfayette branded University 312 coaxes.

I put a 12" guitar speaker in the K15 powered by a MMM Amplifier that I built from a kit from SW Technical Products Co. started by Popular Electronics author Daniel Meyers. It lived on until my son traded it and a Harmony H19 Silhouette electric guitar for an Ovation 12 string acoustic guitar around 1975 while in college.

I put a 12" guitar speaker in the K15 powered by a MMM Amplifier that I built from a kit from SW Technical Products Co. started by Popular Electronics author Daniel Meyers. It lived on until my son traded it and a Harmony H19 Silhouette electric guitar for an Ovation 12 string acoustic guitar around 1975 while in college.

Last edited:

Hey EddieT - that is cool.

Have you seen any grill cloth, especially something "sparkly" for sale recently ? - its seems almost impossible to find silver or gold of that type. My blonde K15 have the silver - that's the Fisher Doctor's K15 with gold cloth and mahogany "Karlsonite" (Formica) - and my vote for the most beautiful speaker in the world . and don't understand why its not in a museum as example of the best of the atomic age.

. and don't understand why its not in a museum as example of the best of the atomic age.

I'm most interested these days in finding the perfect "K10" - meaning somewhat smaller than K12 yet the punch of X15. An "X10" could be nice. Eminence's Delta10A has the kind of motor needed - there's one in that K10 next to my K15. XRK971's "XKi" might be the ticket if there's not too much peaking in the 200-300Hz region. A smoothing stub can be used in such cases.

My blond K15's Formica is faded - is there a safe way to get it looking better ? - It looks just like the one at the 1952 show.

BTW, speaking of Formica type laminates, just having the laminate on one side of so-so grade 3/4" plywood, really stiffens panels - it would be good to use on K wings.

Have you seen any grill cloth, especially something "sparkly" for sale recently ? - its seems almost impossible to find silver or gold of that type. My blonde K15 have the silver - that's the Fisher Doctor's K15 with gold cloth and mahogany "Karlsonite" (Formica) - and my vote for the most beautiful speaker in the world

I'm most interested these days in finding the perfect "K10" - meaning somewhat smaller than K12 yet the punch of X15. An "X10" could be nice. Eminence's Delta10A has the kind of motor needed - there's one in that K10 next to my K15. XRK971's "XKi" might be the ticket if there's not too much peaking in the 200-300Hz region. A smoothing stub can be used in such cases.

My blond K15's Formica is faded - is there a safe way to get it looking better ? - It looks just like the one at the 1952 show.

BTW, speaking of Formica type laminates, just having the laminate on one side of so-so grade 3/4" plywood, really stiffens panels - it would be good to use on K wings.

Attachments

Last edited:

I haven't seen grill cloth for sale in years. I just figured it left when the hi-fi era came to an end. I wonder how it affects performance?

I am with you on the X10 idea that would be a neat size. What makes K enclosures interesting is that the door is still open for experimentation. I may try a K slot on the ducts in my semi K5s to broaden the tuning. Of course with no test equipment it would be subjective.

Off-subject but I wonder how a ping-pong ball section might work for replacing damaged domes or dust covers?

I am with you on the X10 idea that would be a neat size. What makes K enclosures interesting is that the door is still open for experimentation. I may try a K slot on the ducts in my semi K5s to broaden the tuning. Of course with no test equipment it would be subjective.

Off-subject but I wonder how a ping-pong ball section might work for replacing damaged domes or dust covers?

did someone say grill cloth...Mellotone Acoustic Fabrics Canada - Largest inventory and selection in Canada.

Thanks Turk 182

would this "spandex boucle" stuff be acoustically transparent enough ? would it look good as a speaker cloth ?

GOLD METALLIC STRETCH SPANDEX BOUCLE FABRIC (45 in.) Sold By The Yard | eBay

would this "spandex boucle" stuff be acoustically transparent enough ? would it look good as a speaker cloth ?

GOLD METALLIC STRETCH SPANDEX BOUCLE FABRIC (45 in.) Sold By The Yard | eBay

Last edited:

hey pelanj - maybe you could make a curved cardboard "reflector" to put behind the mini-klam to get some.rough idea of how that worked. IF not too tall, it might sit on the front shelf of your K15 clone. Be careful - I've kicked a 5lb driver and K-tube forwards on percussion. (did not hit the cone -ha)

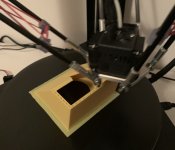

4 mm walls printed with three perimeters and 30 % infill or so, the back chamber is to be printed, maybe tomorrow. It is just a quick and dirty model, so it will be held by double sided tape only and some tape outside to make it air tight. Inside the slot there are some cosmetic issues, but the structure is very dead and rigid.

Hi pelanj, that's great work, Post #33, and so fast!

What would y'all think about using a KR5 Rocket, Post #17 in the link, inside the front chamber?

NASA consultant John Karlson, his little KR5 "Rocket" and Rise of the Klam projectors

What would y'all think about using a KR5 Rocket, Post #17 in the link, inside the front chamber?

NASA consultant John Karlson, his little KR5 "Rocket" and Rise of the Klam projectors

Hi TB46

maybe use KR5"s general shape in a smaller packate with 6 degree slope walls viewed from the front and 12 degree slant walls viewed from the side ?

an alternative which I know has been explored by Carl Neuser, would be to use a K-tube whose cross section moves towards oval at its end.

See K's open end waveguide patent and also 3540544 below

https://patentimages.storage.googleapis.com/0b/3f/f3/ba462c85c48ff9/US3445852.pdf

https://patentimages.storage.googleapis.com/a2/33/52/7e84065907a786/US3540544.pdf

maybe use KR5"s general shape in a smaller packate with 6 degree slope walls viewed from the front and 12 degree slant walls viewed from the side ?

an alternative which I know has been explored by Carl Neuser, would be to use a K-tube whose cross section moves towards oval at its end.

See K's open end waveguide patent and also 3540544 below

https://patentimages.storage.googleapis.com/0b/3f/f3/ba462c85c48ff9/US3445852.pdf

https://patentimages.storage.googleapis.com/a2/33/52/7e84065907a786/US3540544.pdf

Two different K-tube seen in X15

my X15 were loaded with a 2"OD slotted pipe while those of Klipsch forum member "Johny Holiday" had what appeared to be about a 1.25" diameter slotted pipe whose slot had been adjusted (shortened with a small piece)

I'd imagine the smaller diameter tube would measure much smoother due to less of a transitional jump from a 1 inch compression driver's exit.

This does show Karlson was experimenting with the tweeter design as time went on.

That's Carl Neuser's early attempt at X15 size in two pictures. The one with one wing removed has a 9 inch long version of the 7.125" long by 2"OD K-tube. The picture with the greenish looking tube is an original 7.125" long X15 tube.

I bought the X15 cabinets sans tubes - Carl got the K-tubes and drivers. The seller took a jigsaw and removed the tubes rather than disassembling them properly - so I put the pieces back in the cabinets with epoxy putty.

Carl said a re-make of this X15 size with a fully curved laminated wood reflector was an improvement

BTW, a K-with 5.3" length slot plus enough extra length to go through a port panel, will fit a K8 or K12

and make an "X8" as shown here with one of Carl's K8 or an "X12" with the 2nd or 3rd K12 (not done to my knowledge

but could be very good for those who don't have a first rate coax or FR). That gray tube is one I made to give to Carl,

and based on Transylvania's "THE TUBE". "THE TUBE" had a somewhat smaller exit as its sidewalls were sloped 2 degrees IIRC ?

Eminence's Beta 8A has a smooth rise and should make a nice "X8". I can see that's the early

Eminence APT50 phenolic diaphragm driver on the K-tube - that was a very nice driver.

my X15 were loaded with a 2"OD slotted pipe while those of Klipsch forum member "Johny Holiday" had what appeared to be about a 1.25" diameter slotted pipe whose slot had been adjusted (shortened with a small piece)

I'd imagine the smaller diameter tube would measure much smoother due to less of a transitional jump from a 1 inch compression driver's exit.

This does show Karlson was experimenting with the tweeter design as time went on.

That's Carl Neuser's early attempt at X15 size in two pictures. The one with one wing removed has a 9 inch long version of the 7.125" long by 2"OD K-tube. The picture with the greenish looking tube is an original 7.125" long X15 tube.

I bought the X15 cabinets sans tubes - Carl got the K-tubes and drivers. The seller took a jigsaw and removed the tubes rather than disassembling them properly - so I put the pieces back in the cabinets with epoxy putty.

Carl said a re-make of this X15 size with a fully curved laminated wood reflector was an improvement

BTW, a K-with 5.3" length slot plus enough extra length to go through a port panel, will fit a K8 or K12

and make an "X8" as shown here with one of Carl's K8 or an "X12" with the 2nd or 3rd K12 (not done to my knowledge

but could be very good for those who don't have a first rate coax or FR). That gray tube is one I made to give to Carl,

and based on Transylvania's "THE TUBE". "THE TUBE" had a somewhat smaller exit as its sidewalls were sloped 2 degrees IIRC ?

Eminence's Beta 8A has a smooth rise and should make a nice "X8". I can see that's the early

Eminence APT50 phenolic diaphragm driver on the K-tube - that was a very nice driver.

Attachments

Last edited:

- Home

- Loudspeakers

- Full Range

- Karlson's "X15" A New Frontier in the Perfect Size