Third, I am unable to put things together correctly.

This part might be a problem

Well, I think I will at least make a start. The three boxes full of drivers are staring at me constantly, reminding me of how I am a failure to myself and everyone I love.

I have a few drivers to play with so I will start there. The option of using the local CNC is still available, but I am starting to be interested in seeing how far I would be able to go without it. I will probably begin by making a test box.

I made my way into the garage tonight in order to fetch tools for holiday decorations. It was a journey of about 10 meters, which can best be described with that seen from the Lord of the Rings, where they are going through the pass of caradhras, but more dramatic. Luckily the new space heater does a fine job of keeping the garage warm. But at what cost?

I made a few orders from Germany (funny how things tend to get less expensive the longer the shipping route). I ordered some 60 meters of speaker wire. In a very smart move, I ordered four different colours. My thinking was that it would probably drive me mad looking at parallel and series wires of the same two colours. I also ordered binding posts, crimp tools and all of that nonsense. I have a roll of mass loaded vinyl, and sourcing sheep wool is easy.

The only things which are obviously missing are the DAC and actual cabinet materials. I think that DACs in general are starting to become very mature, thanks to how easily anyone can make measurements and the willingness of, mostly Chinese, manufacturers to adhere to scientific results, instead of just using marketing bull as comb-over.

There are a few I am interested in, and a couple that are not yet on the market. Whatever will happen, I know that for around 2-500 Euros I will get a unit that will be more than sufficient with more than 20 bits of dynamic range, balanced outputs and all of that good stuff.

I have a few drivers to play with so I will start there. The option of using the local CNC is still available, but I am starting to be interested in seeing how far I would be able to go without it. I will probably begin by making a test box.

I made my way into the garage tonight in order to fetch tools for holiday decorations. It was a journey of about 10 meters, which can best be described with that seen from the Lord of the Rings, where they are going through the pass of caradhras, but more dramatic. Luckily the new space heater does a fine job of keeping the garage warm. But at what cost?

I made a few orders from Germany (funny how things tend to get less expensive the longer the shipping route). I ordered some 60 meters of speaker wire. In a very smart move, I ordered four different colours. My thinking was that it would probably drive me mad looking at parallel and series wires of the same two colours. I also ordered binding posts, crimp tools and all of that nonsense. I have a roll of mass loaded vinyl, and sourcing sheep wool is easy.

The only things which are obviously missing are the DAC and actual cabinet materials. I think that DACs in general are starting to become very mature, thanks to how easily anyone can make measurements and the willingness of, mostly Chinese, manufacturers to adhere to scientific results, instead of just using marketing bull as comb-over.

There are a few I am interested in, and a couple that are not yet on the market. Whatever will happen, I know that for around 2-500 Euros I will get a unit that will be more than sufficient with more than 20 bits of dynamic range, balanced outputs and all of that good stuff.

Attachments

I made my way into the garage tonight in order to fetch tools for holiday decorations. It was a journey of about 10 meters, which can best be described with that seen from the Lord of the Rings, where they are going through the pass of caradhras, but more dramatic. Luckily the new space heater does a fine job of keeping the garage warm. But at what cost?

This certainly made me laugh out loud

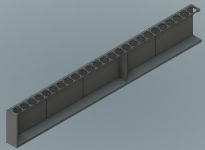

As restrictions have been eased a bit I am quite optimistic about the date I have with the CNC machine early next month. I have decided upon my simplest design yet. All suggestions would be very velcome!

1. I will do my own roundover, the largest roundover bit I have found is something like 12,8mm. I hope that will do.

2. I will chamfer the back of the baffle, as well as doing a roundover on the bracing (and probably some extra holes there.

3. I made a logo, as all respectable designers must have one. It combines a magical stave with an eighth note. As with all good art, the logo has deep hidden meaning and probably exposes the artist's vulnerabilities and sorrow.

1. I will do my own roundover, the largest roundover bit I have found is something like 12,8mm. I hope that will do.

2. I will chamfer the back of the baffle, as well as doing a roundover on the bracing (and probably some extra holes there.

3. I made a logo, as all respectable designers must have one. It combines a magical stave with an eighth note. As with all good art, the logo has deep hidden meaning and probably exposes the artist's vulnerabilities and sorrow.

Attachments

That looks to be about a half inch roundover. It should be better than no roundover. Another option would be to chamfer the baffle.

Well - I bought a router for this purpose mostly. The question is... what is the largest roundover bit available for my unit? I bought a Einhell TC-RO 1155.

- Performance: 1100 W

- Lifting height: 55 mm

- Milling cutter max. : 30 mm

- Collet Chucks: 6 + 8 mm

- Power connection: 230-240 V | 50 Hz

- Idle speed : 11000 - 30000 min-1

- Product weight: 3.7 kg

Perhaps I could do more than an half inch?

Ouch, most 19mm router bits are in need of a 1/2" collar, at least when I looked for them.

The mighty cheap Banggood might work though: 1/4 inch shank 3/4 inch radius carbide round over edging router bit wood working cutter Sale - Banggood.com-arrival notice-arrival notice

1/4 Inch isn't 6mm, but 6,35mm, so measure the collar if it will fit!

Not cheap, but for my subwoofer build I was looking for the biggest roundover I could get and found this one:

Festool 491017 Rounding Bit HW Shaft 15 mm Diameter 42.7 mm / 8 mm Bearing: Amazon.de: Baumarkt

I'll have to look which one I ended up buying, as I do recall it being 15mm radius (as I just confirmed in my drawings).

The mighty cheap Banggood might work though: 1/4 inch shank 3/4 inch radius carbide round over edging router bit wood working cutter Sale - Banggood.com-arrival notice-arrival notice

1/4 Inch isn't 6mm, but 6,35mm, so measure the collar if it will fit!

Not cheap, but for my subwoofer build I was looking for the biggest roundover I could get and found this one:

Festool 491017 Rounding Bit HW Shaft 15 mm Diameter 42.7 mm / 8 mm Bearing: Amazon.de: Baumarkt

I'll have to look which one I ended up buying, as I do recall it being 15mm radius (as I just confirmed in my drawings).

Last edited:

Hi Drengur,

The Festo 15mm radius Wesayso mentioned was the largest one I could find for an 8mm router, when I faced similar considerations long ago.

When I needed a larger roundover diameter of 25,4mm for another project I was forced to buy another router with a 12mm collar, to meet the 25,4mm bits available. I bought a cheap router, the bit itself was more expensive than the router. Both together were around 200€, and the chinese machine is working nicely since a few years. But then a 25,4mm roundover bit on a 1,5kW router is, at least for me, a bit scary handheld and about the biggest what I would personally feel safe to work with.

Are you in Akureyri? Have been there many times for work, and a few times for vacations...

Best regards to Iceland, Bless

Mattes

The Festo 15mm radius Wesayso mentioned was the largest one I could find for an 8mm router, when I faced similar considerations long ago.

When I needed a larger roundover diameter of 25,4mm for another project I was forced to buy another router with a 12mm collar, to meet the 25,4mm bits available. I bought a cheap router, the bit itself was more expensive than the router. Both together were around 200€, and the chinese machine is working nicely since a few years. But then a 25,4mm roundover bit on a 1,5kW router is, at least for me, a bit scary handheld and about the biggest what I would personally feel safe to work with.

Are you in Akureyri? Have been there many times for work, and a few times for vacations...

Best regards to Iceland, Bless

Mattes

Hello Mattes.

Thank you for this information. If I will be doing all of the roundover myself, I will simply use the 12,7mm.

I used to own a HiFi-store in Akureyri. But I don't currently live there, I am an hours drive away from there. Take the china-router with you next time, we could pre-roundover some MDF for future projects

Thank you for this information. If I will be doing all of the roundover myself, I will simply use the 12,7mm.

I used to own a HiFi-store in Akureyri. But I don't currently live there, I am an hours drive away from there. Take the china-router with you next time, we could pre-roundover some MDF for future projects

This went quite well. All the pieces are now according to my 20th revision of the design. I made the baffle as narrow as possible, and it is a bit flimsy. However, with bracing and glue, it should become quite steady. So I was happy for about twenty minutes.

Then I saw wesayso and Fluid being huge nerds with their simulation of the 6mm "wave guide". I can't say I was disappointed, rather inspired. This means I have the opportunity to "fix" my design by adding a second baffle, effectively sandwiching the elements in between. This helps with two problems; addressing directivity and the baffle edge, as I could make a baffle which serves no other function than to "massage" the front wave... and look cool.

Thoughts?

Then I saw wesayso and Fluid being huge nerds with their simulation of the 6mm "wave guide". I can't say I was disappointed, rather inspired. This means I have the opportunity to "fix" my design by adding a second baffle, effectively sandwiching the elements in between. This helps with two problems; addressing directivity and the baffle edge, as I could make a baffle which serves no other function than to "massage" the front wave... and look cool.

Thoughts?

...and it seems I may have found the "perfect" DAC.

Measurements of Topping D10□□(NDA) DAC | L7Audiolab

Measurements of Topping D10□□(NDA) DAC | L7Audiolab

I'd say yes to a double baffle. It is what I have...

I used this opportunity to make that double baffle a CLD construction by using butyl in-between.

Front baffle is 6mm in thickness while the round-over I used is 8mm, flush at the front.

I used this opportunity to make that double baffle a CLD construction by using butyl in-between.

Front baffle is 6mm in thickness while the round-over I used is 8mm, flush at the front.

Attachments

One persons huge nerd is another's inspired open source researcherThen I saw wesayso and Fluid being huge nerds with their simulation of the 6mm "wave guide".

Thoughts?

I think it is a good idea in general, I can't see a downside at this point.

It is hard to go past Topping if measured performance and price are considerations...and it seems I may have found the "perfect" DAC.

Thank you for your input. I have been thinking hard about the newest turn of events. Don't get me wrong; first of all, I am impressed by your "open source" mentality. As a rather avid proponent of that thought of school myself, it makes me quite happy. I like to think that I would contribute... if I ever had a non-mediocre thought.

I have been rather preoccupied by thoughts of how to mount an additional baffle. I would like the speakers to be somewhat serviceable, although it has come to my attention that there is no way I can fit my hands through the baffle holes. The only way I can see this working is using a similar method of what Ronald uses, using threaded rods from the back.

I got to play around with a laser cutter a couple of days back. If you all are starting to worry about what to get me for Christmas, a laser cutter could be a good plan-b. I was seriously amazed by this machine - how easy it is to work with and how quickly it goes through HDF.

I have been rather preoccupied by thoughts of how to mount an additional baffle. I would like the speakers to be somewhat serviceable, although it has come to my attention that there is no way I can fit my hands through the baffle holes. The only way I can see this working is using a similar method of what Ronald uses, using threaded rods from the back.

I got to play around with a laser cutter a couple of days back. If you all are starting to worry about what to get me for Christmas, a laser cutter could be a good plan-b. I was seriously amazed by this machine - how easy it is to work with and how quickly it goes through HDF.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Drengur's build: Langanes 25 - Line arrays

Totally agree on the necessity of having a logo!

Totally agree on the necessity of having a logo!