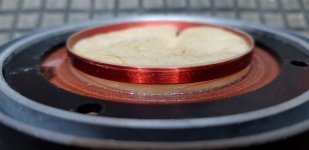

Hi, here I have a RCF compression driver that came out of a German Echolette Leslie wannabe. I think it is about 50 years old, and sadly it's voice coil is open. It's VC diameter is rather unusual at 53 mm. It has a threaded throat. Unfortunately it's voice coil is open, see the 2nd pic, and I don't know why, 'cause there's no visual sign of burn etc.

Is there any chance to get a replacement diaphragm, or what else could I do?

Best regards!

Is there any chance to get a replacement diaphragm, or what else could I do?

Best regards!

Attachments

Looks like it snapped from strain?

Since it's at the end of the coil, maybe it got loose somehow and either snagged on something in the gap, or ended up laying over itself, rubbed against the gap maybe?

The hardest part is probably removing the enamel coating without making a soar, then the second hardest part is making the bond tight, but maybe you do not have to.

When I wound coils for transformers a decade ago, we'd use riduculously thin silk wrap paper for the thinnest coil welds, locks itself after a round, sometimes paper tape is better, but it's also much thicker.

If you make the weld too long on purpose to make it easy for yourself, then just fold it tight and use the thinnest paper tape you can get both for isolation and holding it in place, maybe get it in one single even layer around the vc weld, and do not to have any tape covering the rest of the coil.

Edit:

Or just take off one round, fold it neatly down one side, solder real thin, thinnest possible paper tape evenly, done.

Alternatively use a tiny dab of heat resistant glue.

Since it's at the end of the coil, maybe it got loose somehow and either snagged on something in the gap, or ended up laying over itself, rubbed against the gap maybe?

The hardest part is probably removing the enamel coating without making a soar, then the second hardest part is making the bond tight, but maybe you do not have to.

When I wound coils for transformers a decade ago, we'd use riduculously thin silk wrap paper for the thinnest coil welds, locks itself after a round, sometimes paper tape is better, but it's also much thicker.

If you make the weld too long on purpose to make it easy for yourself, then just fold it tight and use the thinnest paper tape you can get both for isolation and holding it in place, maybe get it in one single even layer around the vc weld, and do not to have any tape covering the rest of the coil.

Edit:

Or just take off one round, fold it neatly down one side, solder real thin, thinnest possible paper tape evenly, done.

Alternatively use a tiny dab of heat resistant glue.

Last edited:

I've already contacted the German RCF subsidiary, just to get the info that replacements for this old driver (50 years?) aren't available any more. As it has a threaded interface with the horn, while modern CD's use to have mounting flanges, hence there's no modern option to replace the unit in toto, I'll follow your advice and unwind the lose turn, hoping it is the first or the last one, and do a new soldering junction to the respective terminal. Yes, impedance and sensitivity will be affected somewhat, but this would surely be better than no rotating horn at all.

Best regards!

Best regards!

I've had another very close look at the item just to find out that the open part belongs to the inner layer of this two layered VC. If I would unwind one turn and connect the new end to the relative terminal, I would have to pull the wire beneath the other end that comes from the outer layer. As the whole damn thing appears to be glued or sealed completely, a procedure of this kind seems impossible to me. New VC's of 53 mm dia appear to be unavailable from any manufacturer, so I'll toss this driver and get a suitable (1 3/8" 18 g threaded) replacement.

Best regards!

Best regards!

I have successfully rewound many voice coils on the original former, without separating it from cone/diphragm and suspension, so save irreplaceable stuff, BUT you need access to a lathe to make a cylindrical core out of aluminum/brass/nylon which tightly fits inside the former to hold it in place while rewinding.I've had another very close look at the item just to find out that the open part belongs to the inner layer of this two layered VC. If I would unwind one turn and connect the new end to the relative terminal, I would have to pull the wire beneath the other end that comes from the outer layer. As the whole damn thing appears to be glued or sealed completely, a procedure of this kind seems impossible to me. New VC's of 53 mm dia appear to be unavailable from any manufacturer, so I'll toss this driver and get a suitable (1 3/8" 18 g threaded) replacement.

Best regards!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- RCF Compression driver with open voice coil